You must be logged in to rate content!

368 minute(s) of a 758 minute read

1-8-2021

1967 Pro-Touring 122 Amazon (Project Volvo X) 540 Horsepower LS6/Tremec TKO600 5-Speed

Compliments of Iamtheonlyreal1 @ www.stanceworks.com

I am starting a thread on my 1967 Amazon build, because it will be coming together very quickly. I have not stopped on Project Changling, because I am duplicating key parts for both projects.. Project Changling will be marketing the Flush Mount Glass Kits along with the Newly Designed Crossmember/Suspension kit I am releasing shortly.

The goal of the Volvo X build, is to build a Daily Driver/Track Friendly car, that has all the comforts of a newer car.. I have been asked why I have gone with the Volvo Builds at this time. All I can say is, they need alot of support, and it is much easier to stand out in the Volvo Community with an awsome build.. LOL

I am still debating on the actual Powertrain at this point, but there are three choices I am working with..

1st Choice- A 5cyl Turbo Volvo Powerplant, that is capable of a very dependable 450 horsepower, but can be a bit tempermental during daily driving. Performance parts and Knowledge isnt as widely available as it is with the other 2 choices, so that has to be considered.

2nd Choice- A 2002 LS1 V8 that I have sitting around, and had already planned on using a LS1 in my Project Changling Build.. I am planning on offer several Motor Mount Options for different engine upgrades with my suspension kits, so I didnt really want to build two cars with the same powerplant.

3rd Choice- A Nissan Sr20Det Turbo 4cylinder.. These motors are also capable of a dependable 450 horsepower, and have a wider range of parts and knowledge supporting them. The engines are widely available, and seem to have plenty of testing behind them.

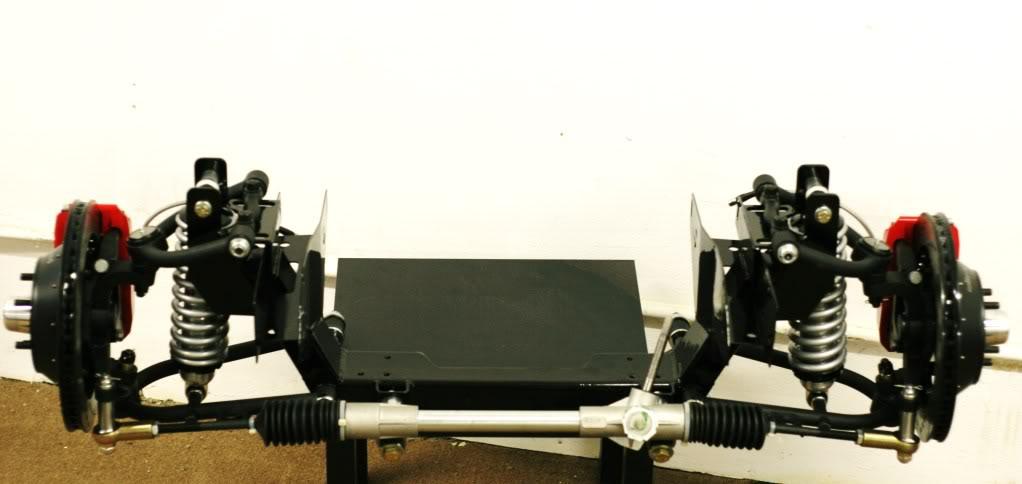

This Amazon will have the Crossmember/Suspension kit that my company is producing, so the car will now have.

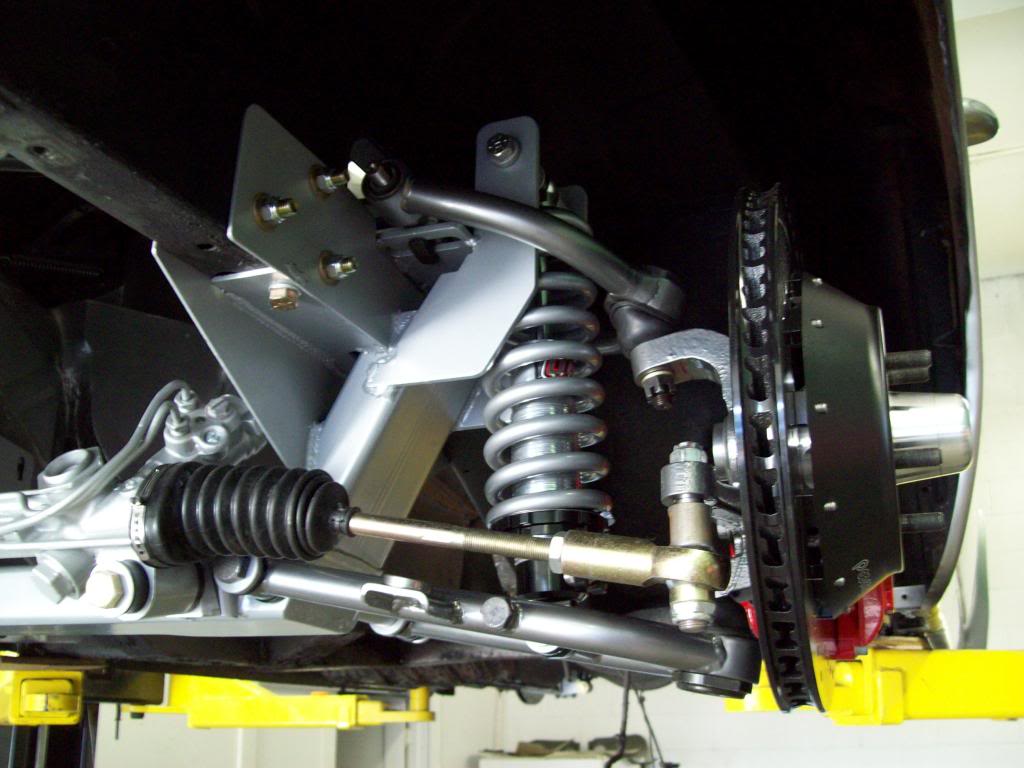

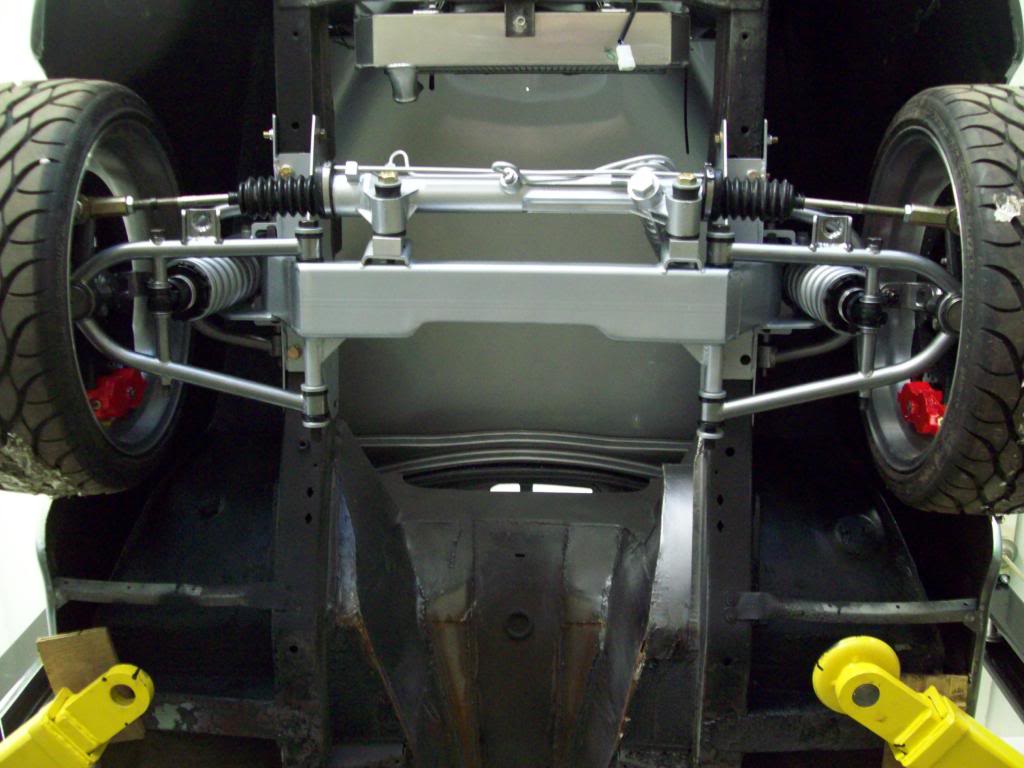

Rack and Pinion Steering

Tubular Control Arms

Adjustable Coil Over Suspension

Quick Adjust ride height Feature with the Front and Rear Suspension

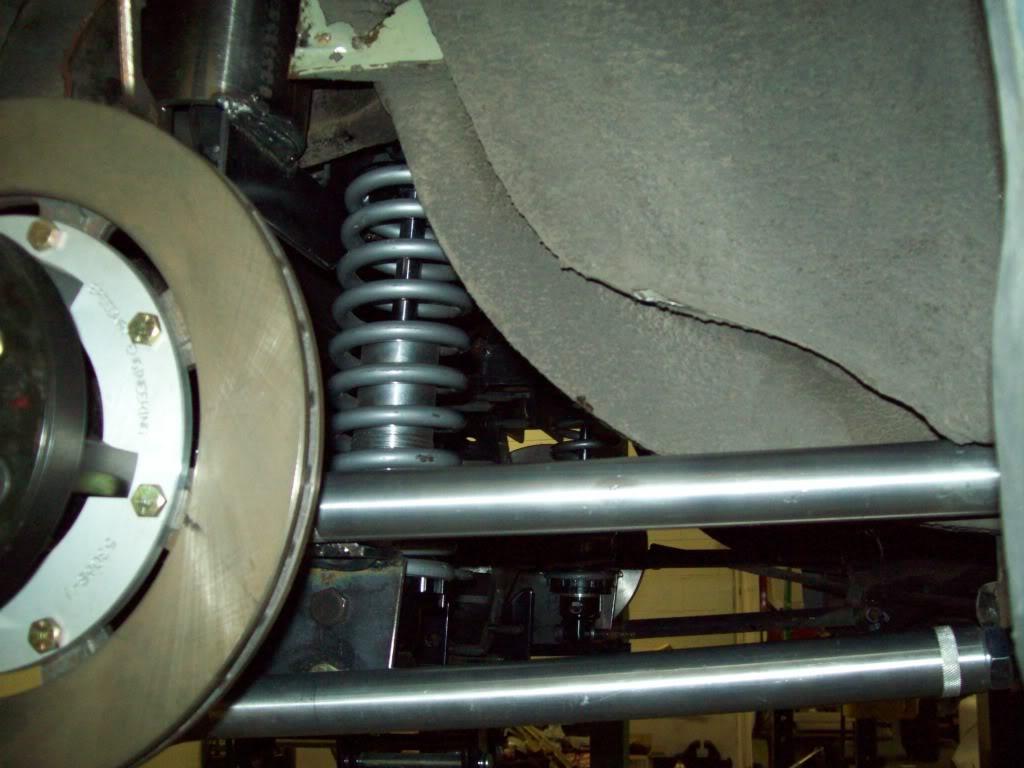

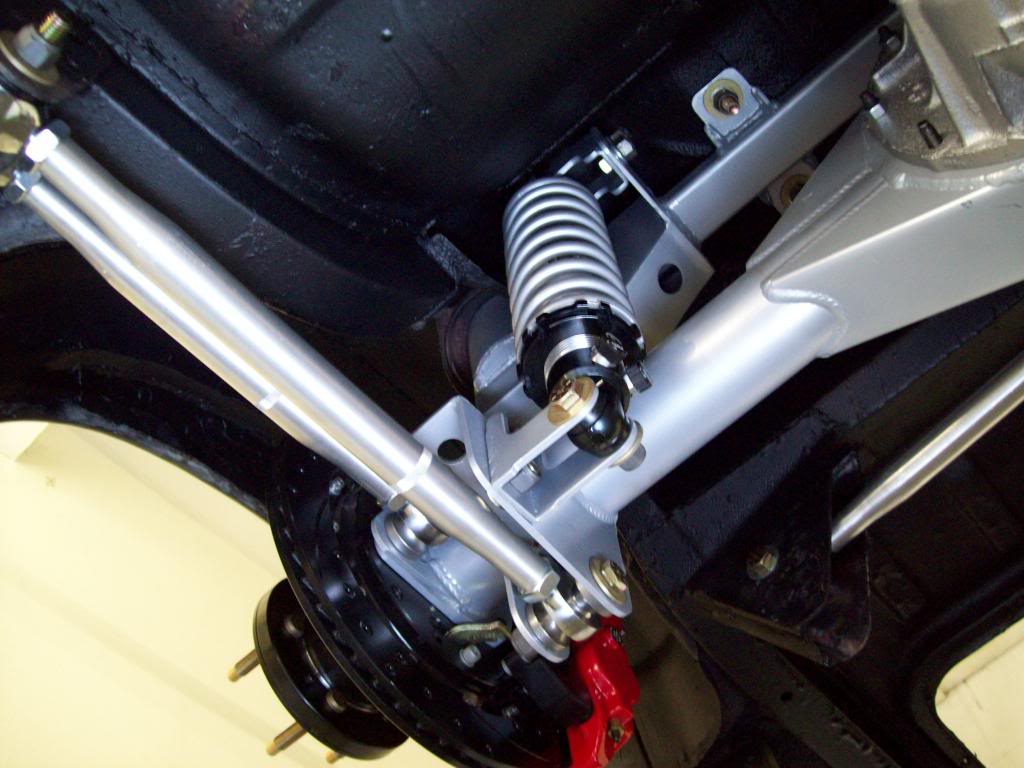

Rear Adjustable Coil Over Suspension with Adjustable 4-link arms.

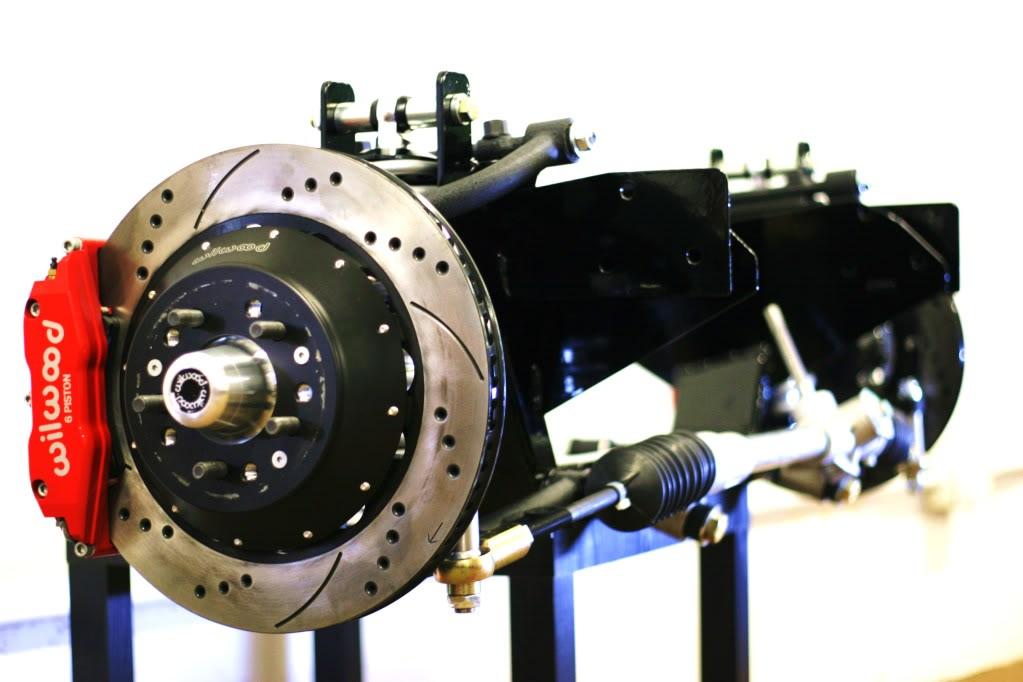

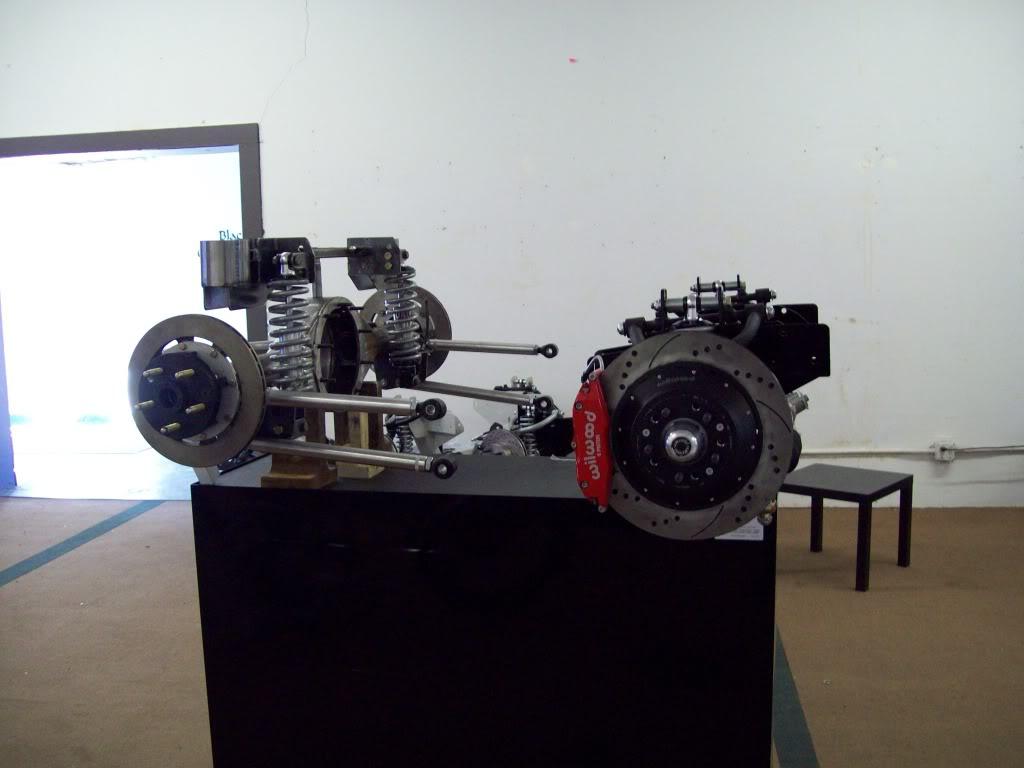

14 inch Wilwood Drilled/Slotted front rotor assemblies with 6 Piston Calipers

13 inch Rear Wilwood Drilled/Slotted brake kit.

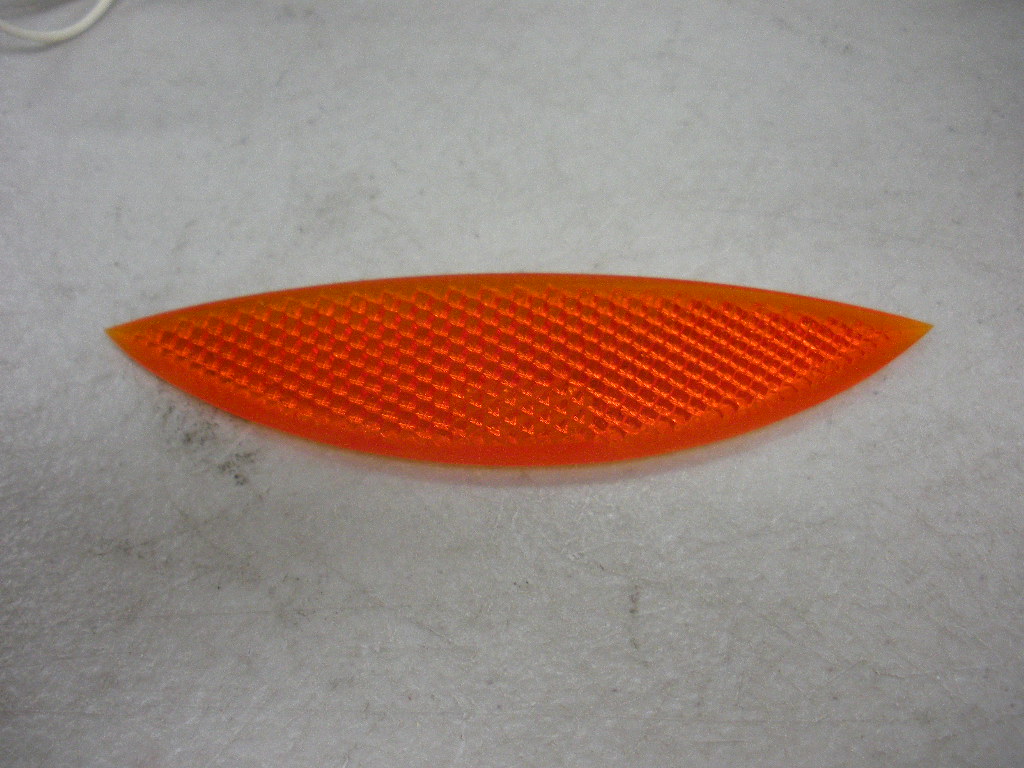

I am wanting to go with a Race theme.. So, I am thinking about a nice Satin Paint Job with some sort of striping.. I am also debating about a Swedish Flag on the roof with racing numbers on the doors. As far as body mods go, I may flare out the rear archs a bit, I will be removing the rear reflectors, and remove the large front park lamps. I am not real clear what I am going to do about the bumpers, I see alot of nice cars with the bumpers left on them, so I am very open about that so far.. I would like to consider some sort of Air Dam, that I dont have to kill myself trying to make or make fit, but the bumper would have to be eliminated if an air dam was installed.

Any suggestions as to direction with the car would be greatly appreciated.. I plan on the car going to the track and hopefully some of the Events the Pro-Touring and Lateral G guys are having so much fun at.. I am tired of hearing about all the fun, and would really like to join in.

I am also looking for a seasoned driver, that would be interested in helping me post a great time at one of these events.. I plan on giving the car hell myself, at these events, but I am really an amatuer, and I dont need that handicapping the cars capability. This will be a promotional car, so it does need to prove a point to the Volvo Builders out there when it comes to the capability of the suspension products. I am taking names and suggestions... LOL

Here are a few Pics of the build, along with some various pics and video's of other builds.

Here is some current pictures of the stance so far after the suspension install.. In the pictures, I have factory steel wheels and 16inch Factory Mustang Wheels installed. I am not using these wheels in the build.

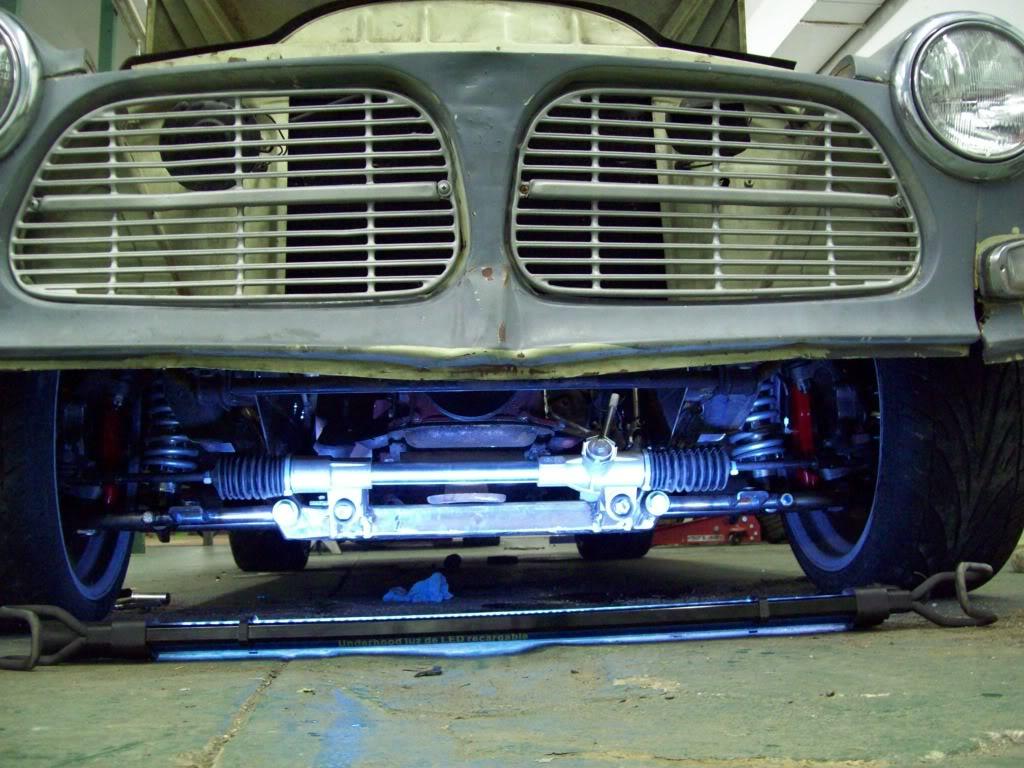

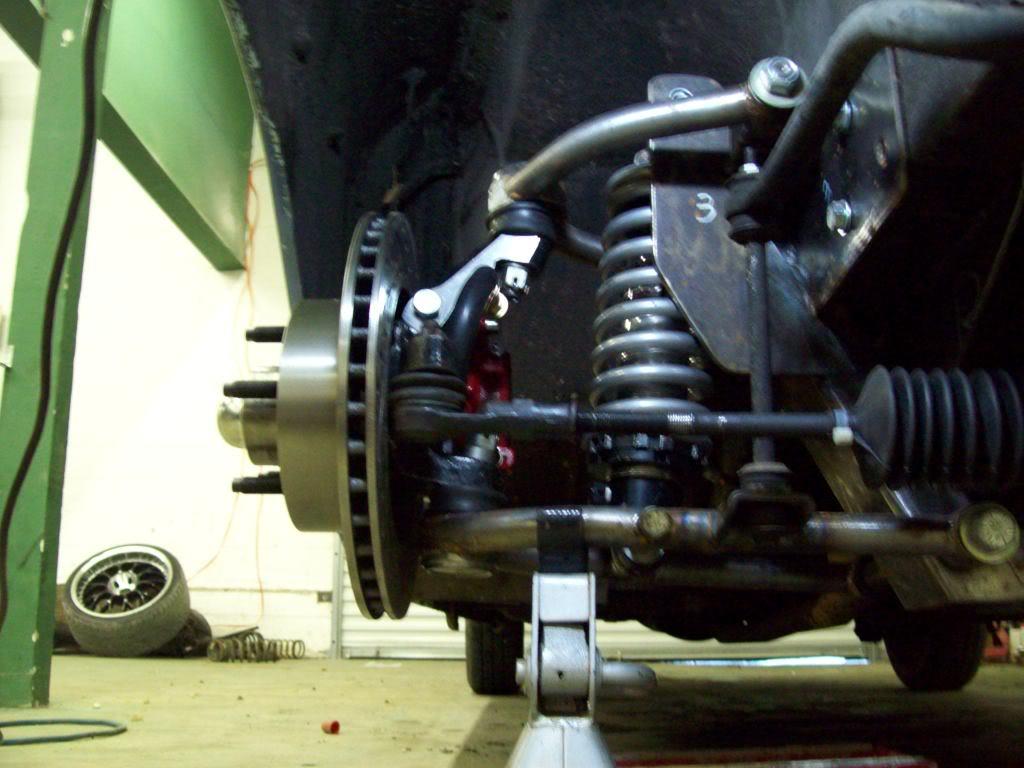

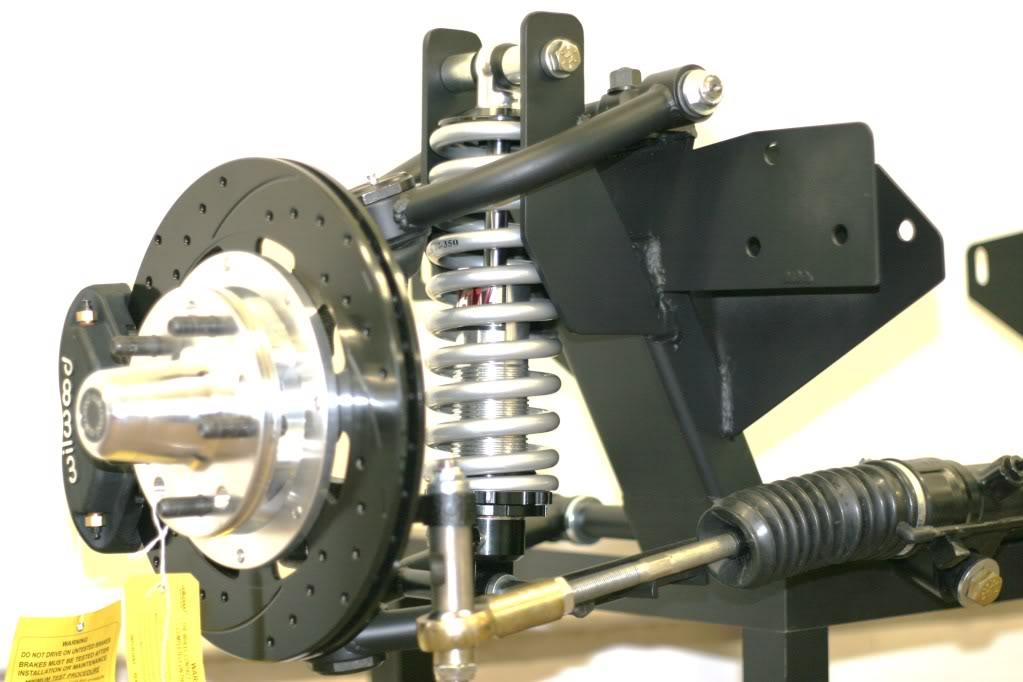

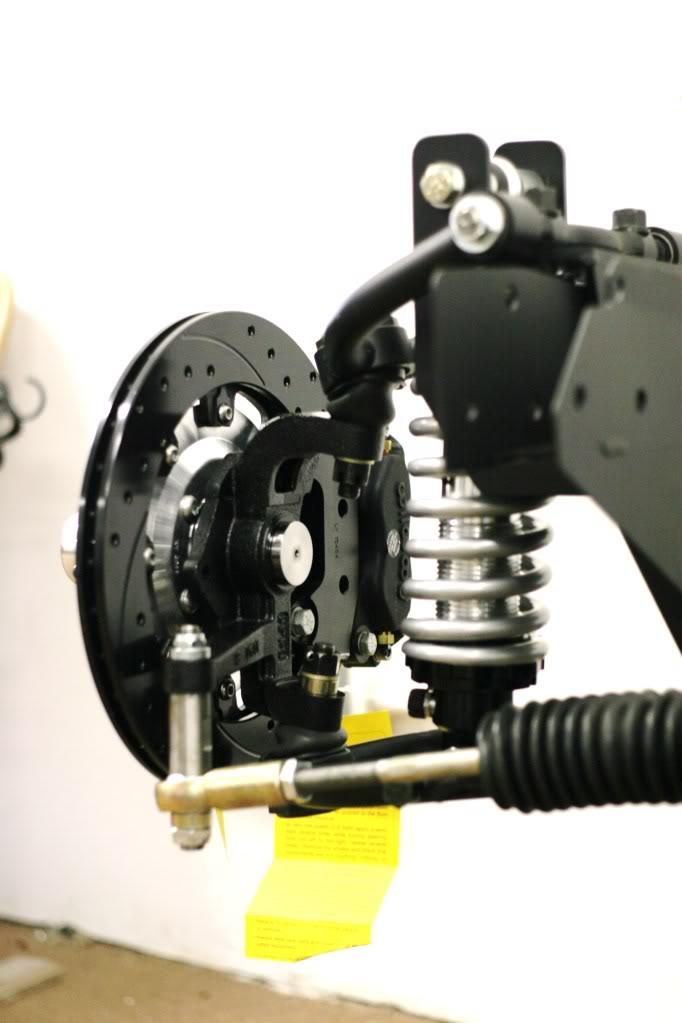

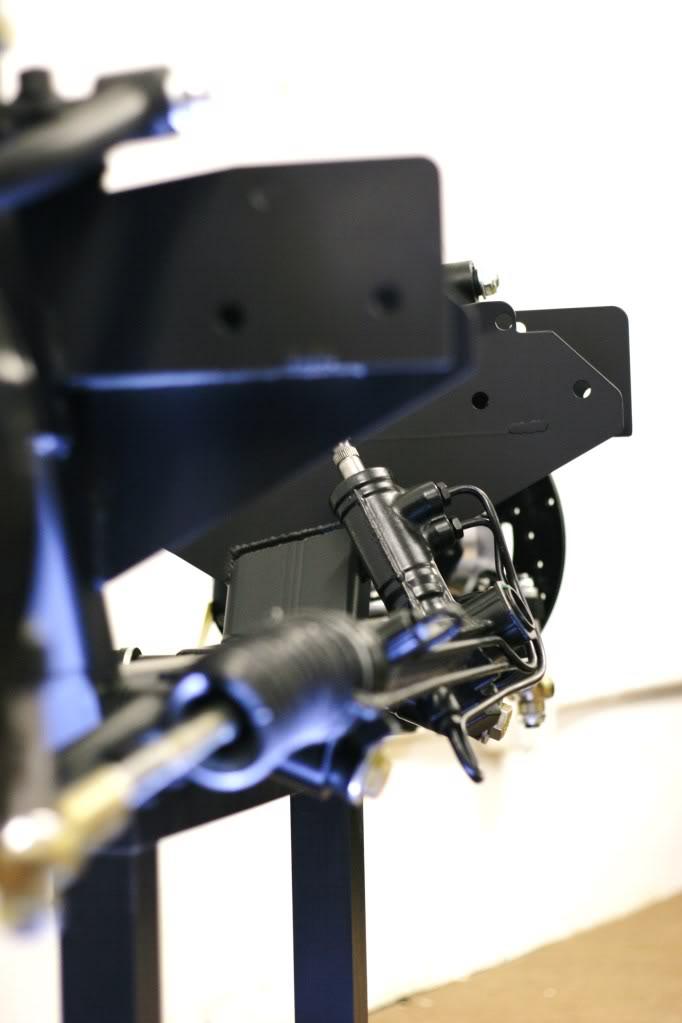

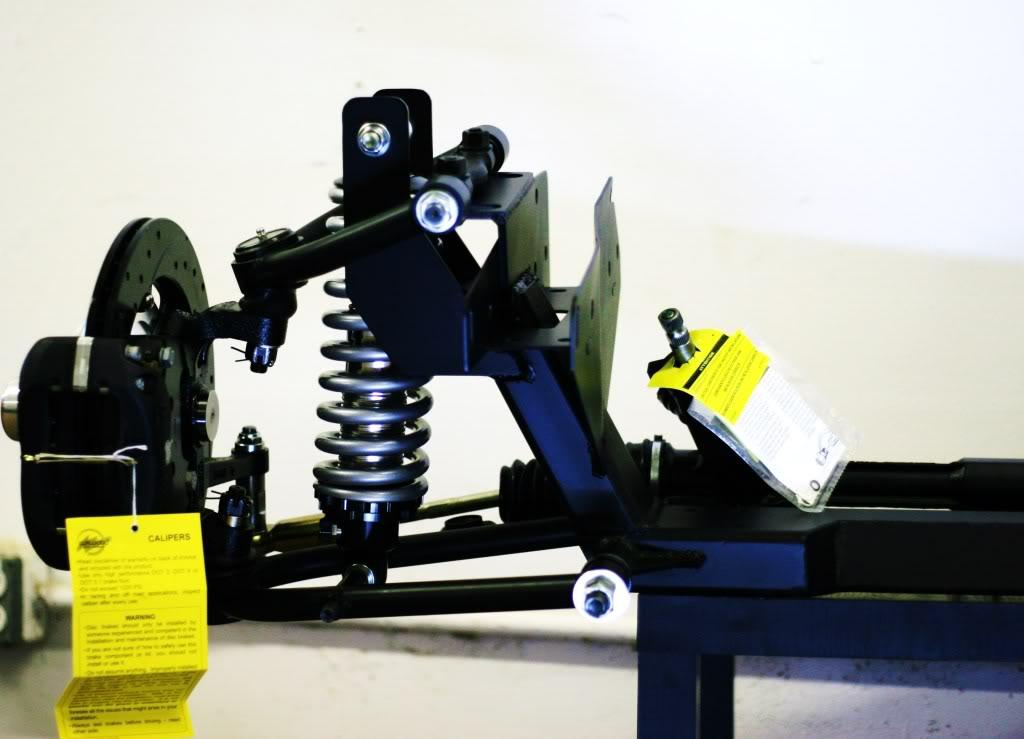

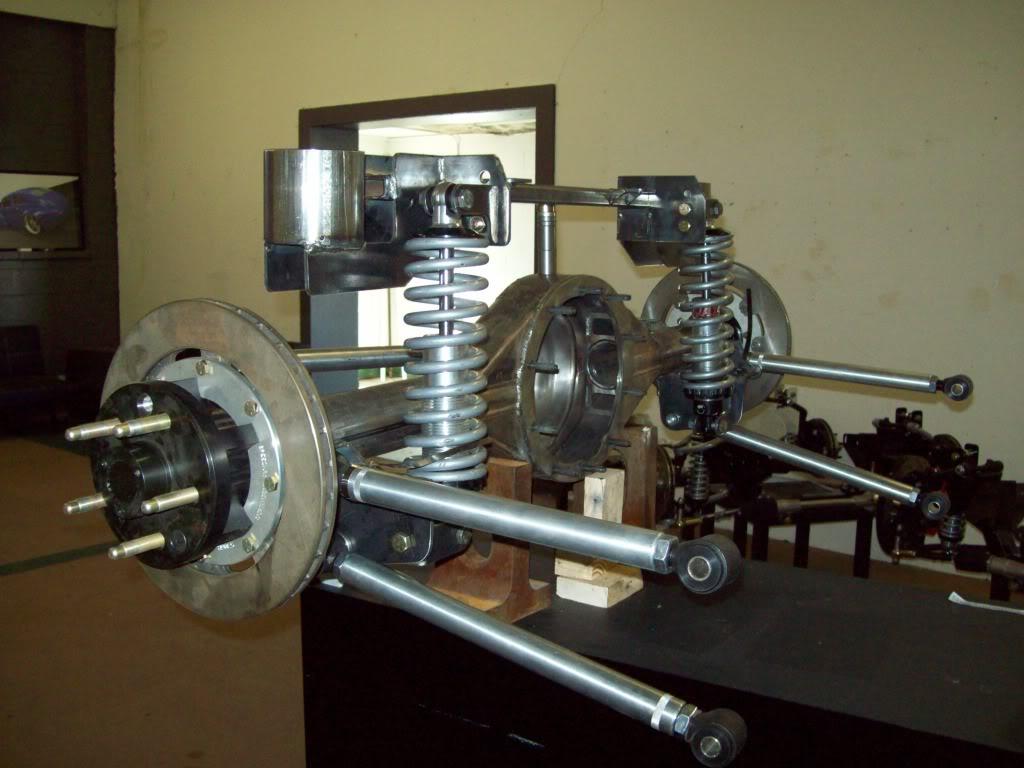

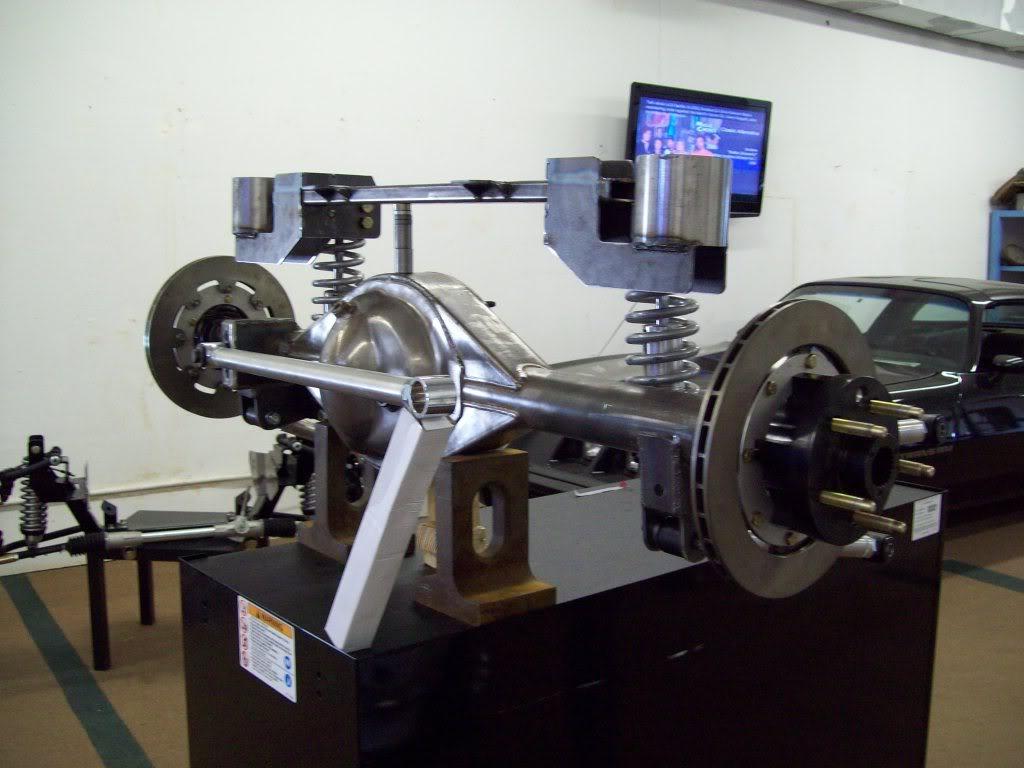

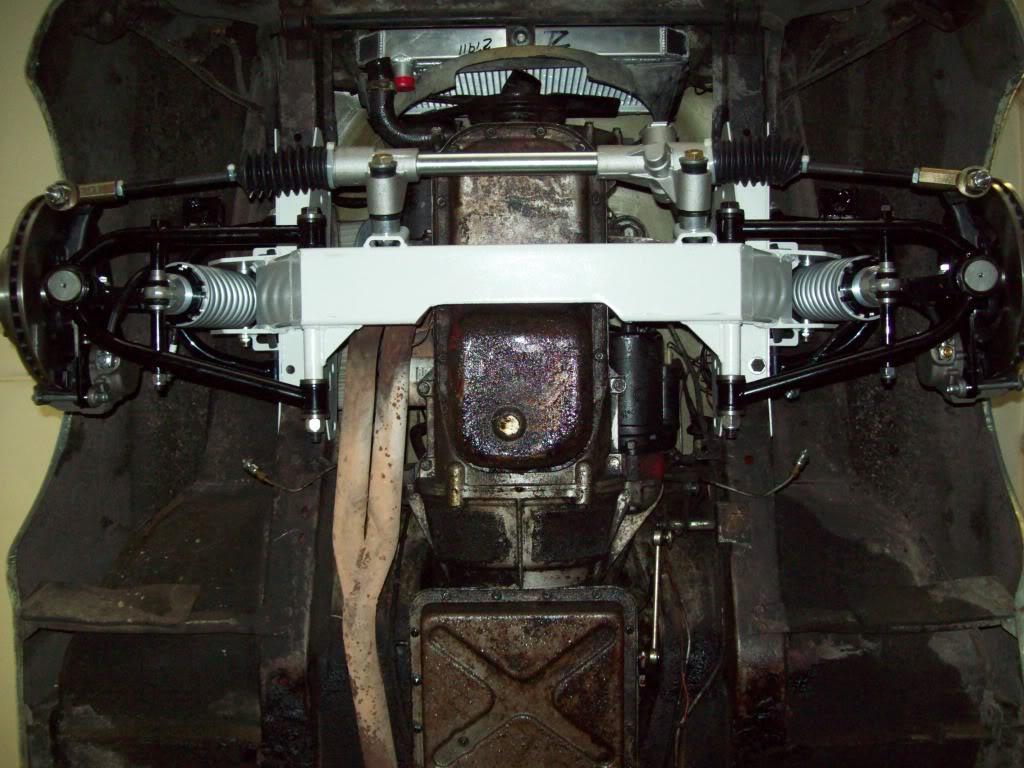

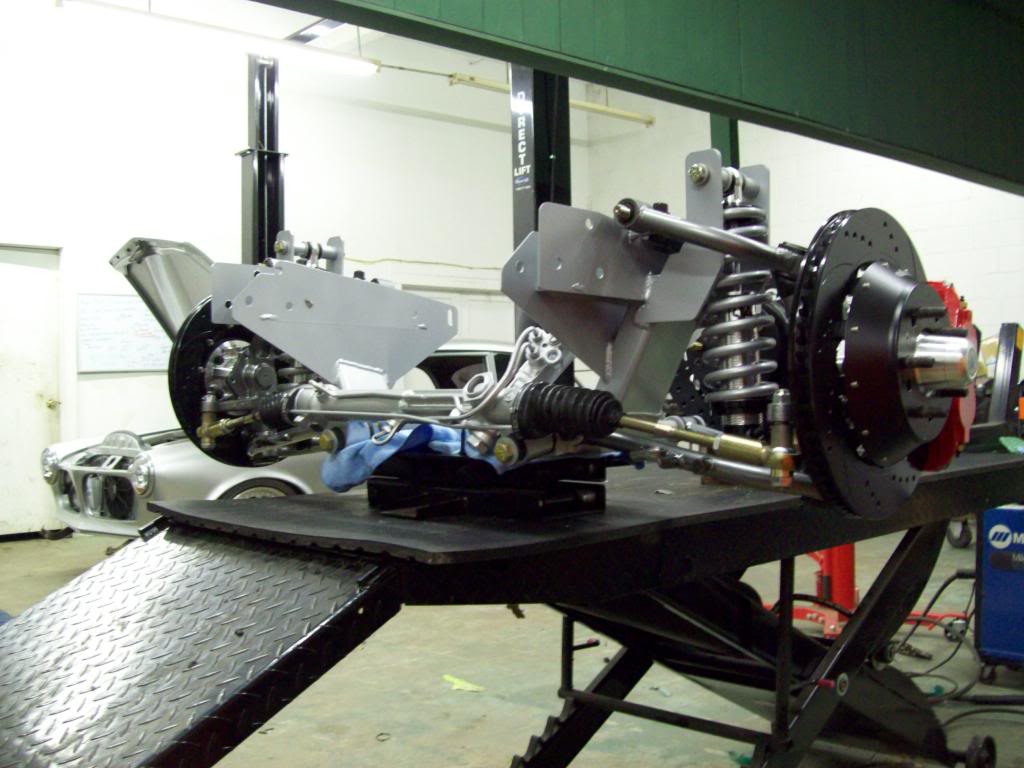

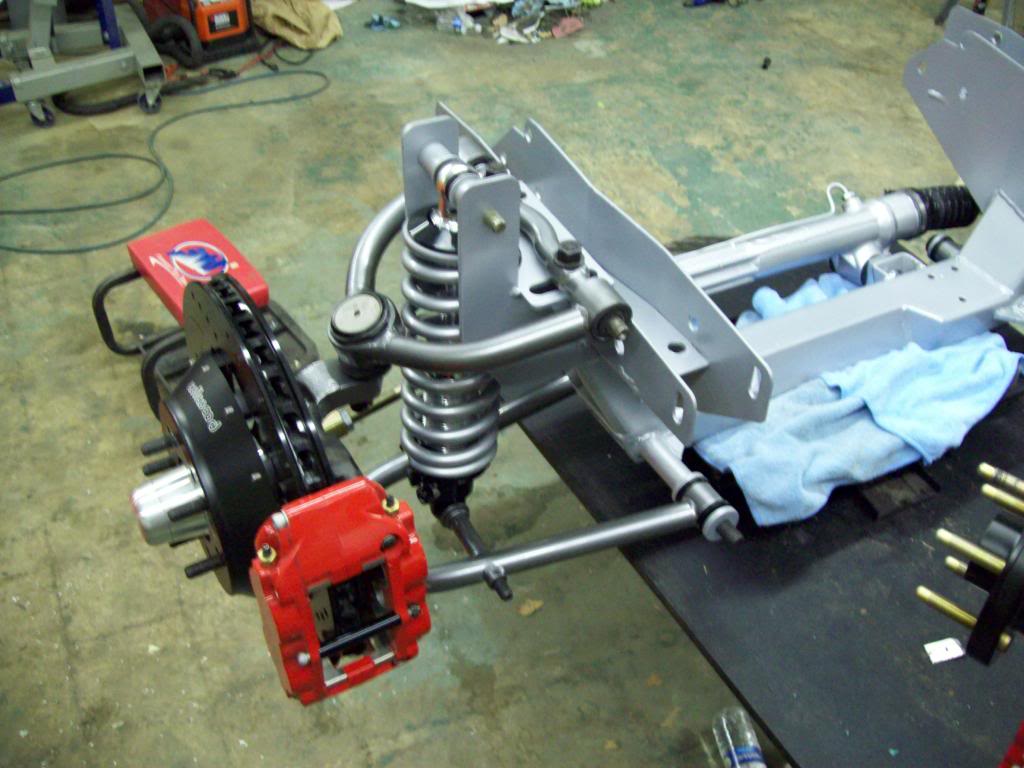

Here are some pictures of the Prototype Crossmember/Suspension Kit. Pictured are the Standard 11 inch brakes with the base kit. I will post pics of the 14 inch Brake kits, when the actual Production Crossmember/Suspension Kit comes in.

Here are some pics of the style wheels I plan on running.. These are 19x8.5 front and 19x10 rear.. I may end up stepping it down to an 18 inch wheel if I dont like the overall all stance and ride height. I think the 14 inch Wilwood front brakes, and 13 inch rear brakes, are going to look great with this style wheel.

Here are a few pictures of various Amazons with different stances and styling.. The first car is factory wheels and factory stance, the others are cars people tweeked..

Here are a few Youtube videos.. These are running the later Model Upgraded Volvo Turbo Powerplants. The first Video, is a really cool computer generated Police Concept car.

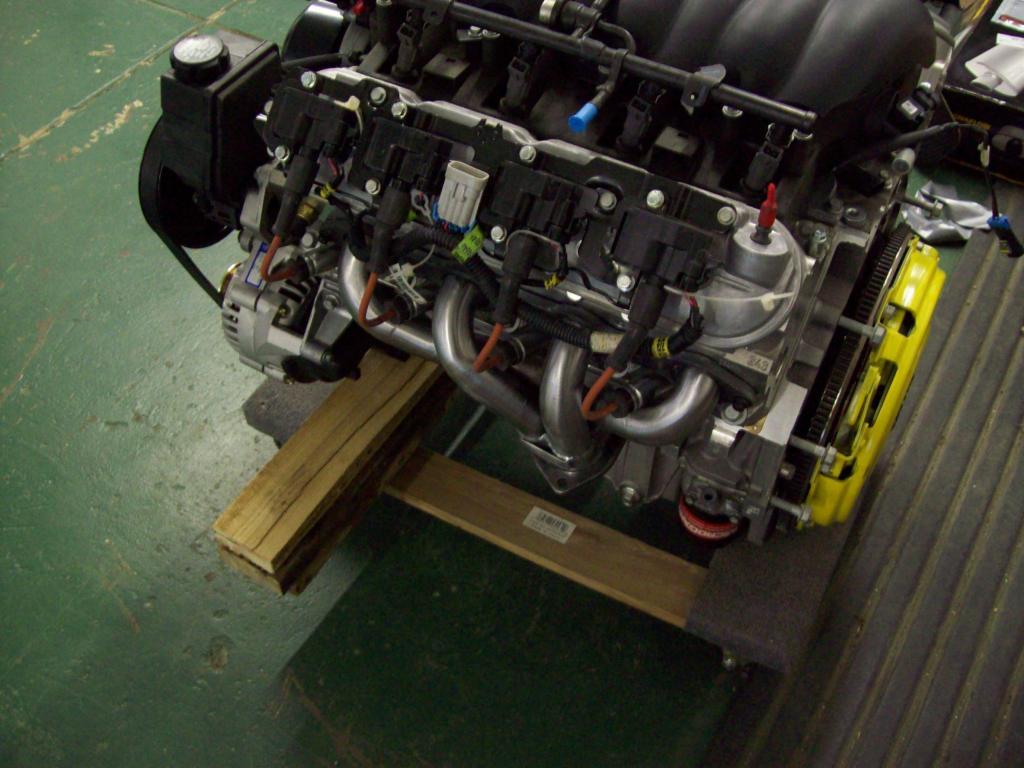

No carburation here... I can purchase brand new Cammed up and fully accessorized LS6's with 425 Rear Wheel Horsepower, with (Altenator, power steering, coils, throttle body, Programmed ECM, Painless harness kit, everything minus Headers and AC compressor for 7000 dollars all day long. I dont mind spending that kind of money on a package like that, because I know it will hold up, and you can get parts anywhere.

I actually have guys in Europe saying they would prefer the LS version, because they are widely available there also. I would like to have something different for sure, but I need it to appeal to the masses in this case. And I must say, a Ls Series motor in an Amazon it a bit different.. Just go to Youtube, and you will see plenty of the T5 Volvo Swaps along with the carubrated 350's and 302's...

6/3/2011

Well I have my rear end solution figured out.. I will be have some Custom Ford 9 inch floaters made, that will be direct bolt in to the Factory Volvo 4-link arms. These rear housing's will be made to the exact track width of the factory Volvo, and will allow all the variations in gear rations, traction options, brake options, etc, etc. They will literally slide under the car, and pin up to the factory arms.. Now I have to figure out the driveshaft hook up and possible length difference.

I have been trying to make all these kits direct bolt in, but does anybody think it is too much to ask, for the customer to work out their driveshaft hook up? I can give them the solution, and post it before purchace, but ultimately leave it to them to handle. It may be that the best solution is a hybrid driveshaft, that is best to be done per application by the customer.. If I can offer some sort of double U-joint, I would obviously do that, but I dont know if I can come up with a solution that caters to every application with the driveshaft hook up.

6/6/2011

Well I got our first production Crossmember and Control Arms in. It fits great, but I have changed the design of the Upper Coil Over mount.. Our kit is coming with a quick adjust ride height capability, I will post some picture of that set up when I have the complete unit togther this week.. I will have picture with the standard 11 inch brakes, and the optional Wilwood 14 inch drilled/slotted rotors and 6 piston calipers.

I have also added some punched holes to brake up a bit of the gusseting, and will be adding two gussets to the Upper control arm plate.. I have others point out the fact that the upper control arm bolts are in upside down, my guy put them in that way for transport, I dont know why.. LOL

The drawn squares and the marked hole locations in the square, is the location of the bolt in motor stands. I have opted to make various engine stands that bolt directly to the crossmember, that way you can have several options and can change engine configuration at any time. And with this type of mounting, you never affect the powder coating or painted surface if you ever decided to change engine configuation later. As of right now, we will be offering a standard Volvo B18 engine stand(Factory to the P1800/Amazon), the later model T5 Volvo Powerplant, and the General Motors LS Series engines. We will also offer a base plate that will allow you to build your motor appication stand on, so can always remove it as an option.

6/8/2011

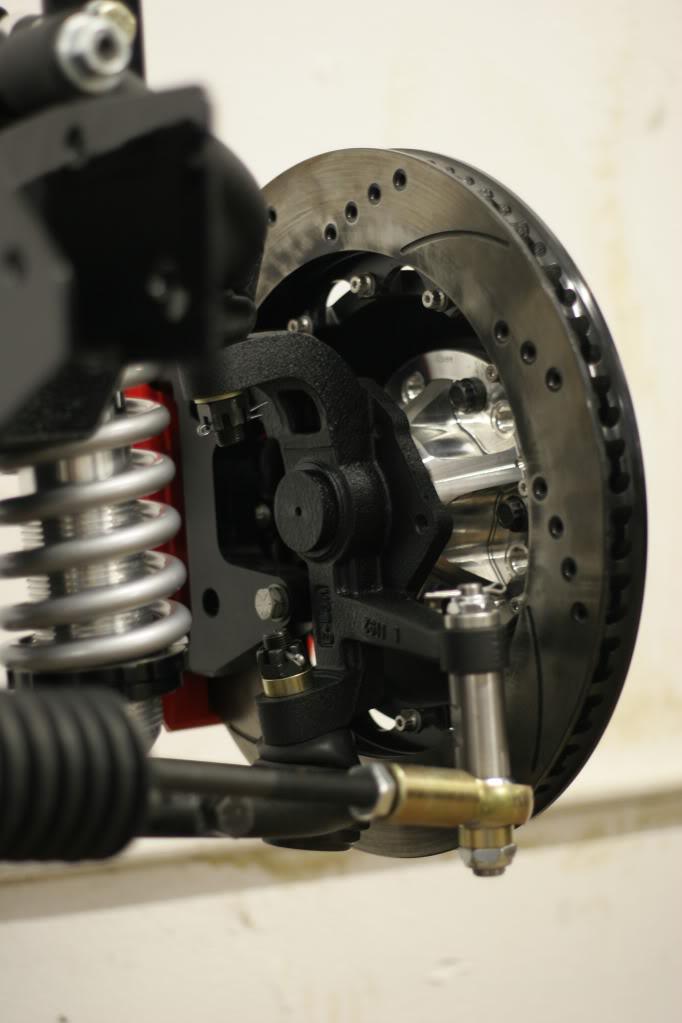

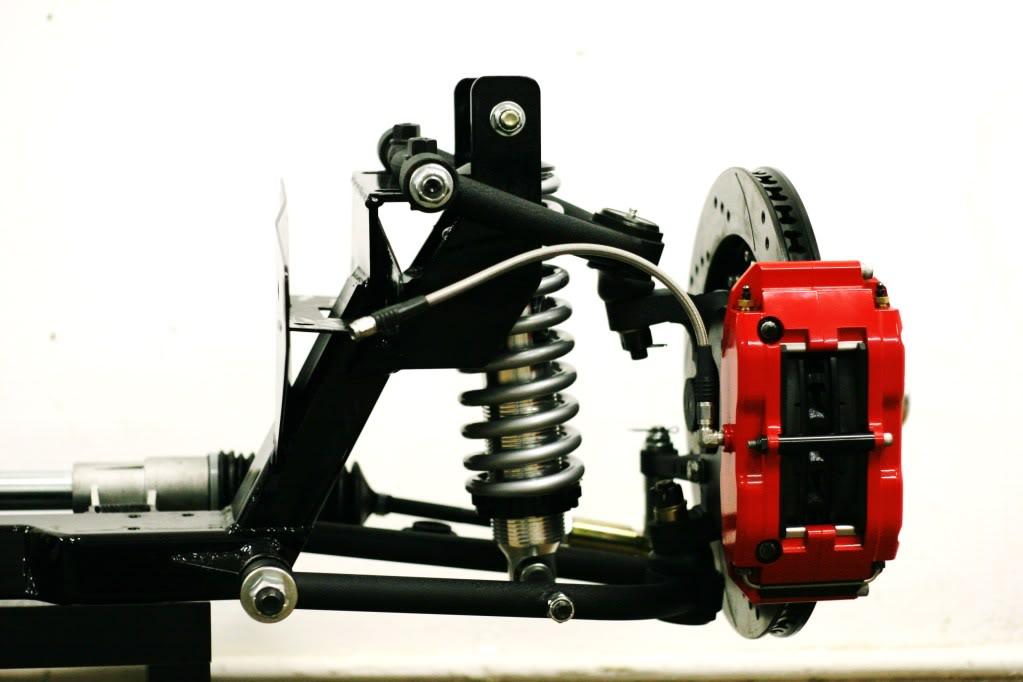

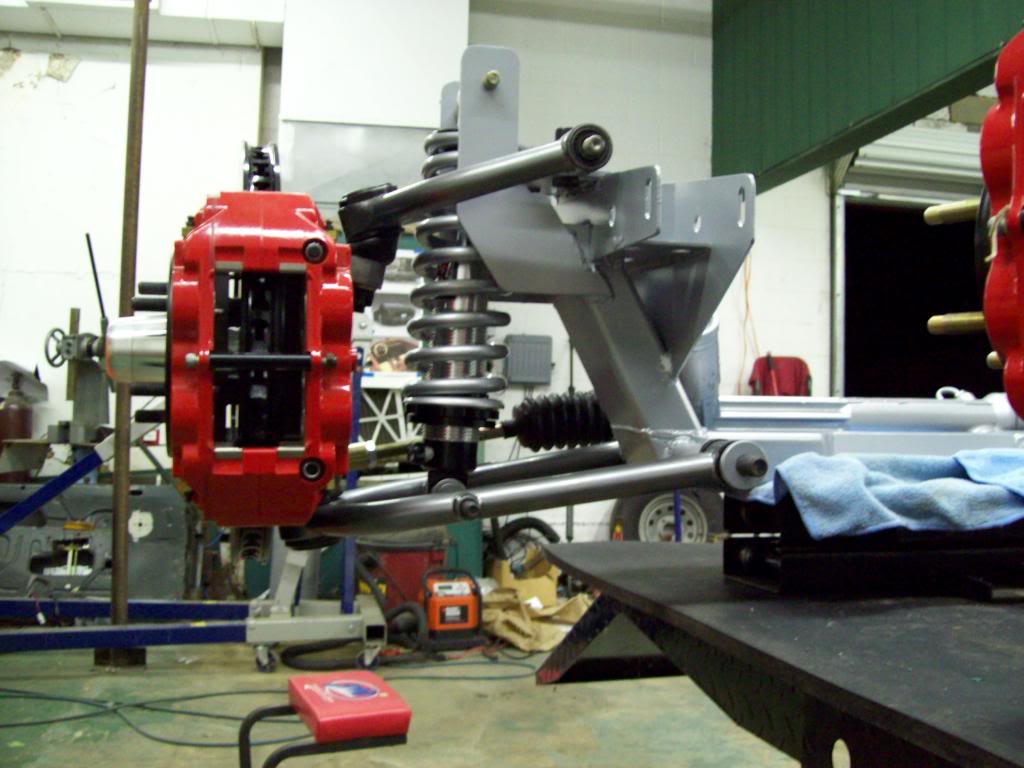

Here are some pictures of the 14 inch Wilwood Drilled/Slotted Rotor and 6 Piston Caliper kit.. The other 11 inch Drilled/Slotted Rotor is an upgrade also, which will be considerably less. The kit comes standard with the 11 Smooth Rotors.

I will have some updated pictures of the complete Front end kit later this weekd.

I have been getting emails about some more pics of the Crossmember, here are a few more.. I am waiting on the tie rod ends and another ball joint for the bottom, so I can complete the other side.

Before I get comments on ball joint and geometry questions, keep in mind there is no LOAD on the suspension.. Once the load is on, there geometry and ball joint position is just right..

6/9/2011

Here are a few pictures with both sides together and a wheel installed.. I am getting ready to put it in place today, and double check the motor mounts..

Here are some pictures of the crossmember installed.. I am taking for alignment tomorrow.... The used wheels I got a deal on, arent quite the correct offset.. Damn it.. I am thinking I am going to drop to 18's...

6/10/2011

Here are some pictures of the car outside.. I am going to see if I can work with the wheels a bit, I really like the way they look.. I am thinking I may just order some 18 inch front, and keep the 19 inch rear...

6/18/2011

Well here is another update on the P1800/Amazon Crossmember Suspension kit. These are available for order next week, starting the June 20th. In order to qualify for the discount, all orders must be in by July 1st.. At that time, I will know how many I need to order for the people that are wanting them.. Things look good for a second run at this time, but interest will surely play a factor.

All service parts are readily available at any chain Auto Parts Store, along with a considerable price savings over the OEM Volvo Components. I did this, so people can service their Front Ends and Rear Ends with ease, due to parts availability and savings.. Every kit, will have a parts number break down of all the servicable components.

The Custom Direct Bolt in Ford 9in Rear ends will be available in about the next 60 days, along with some other very cool parts.. I am working with Vintage Air, so we will have some efficient and working heat and air systems for these cars. My company Classic Auto Glass Innovations will be offering the Flush Mount Windshields and Back Glass's. We will have completely updated Electronic Guages (Direct Replacement) with a GPS speedometer, so there will be no Gear Ratio or Tire size issues for speedo Calibration. Custom Interior Panels, that will be retro, but updated in styling, etc, etc..

Diversified Auto Group is pursuing all of these bolt on items, becuase early next year, we plan on releasing a Re-Badged Amazon and P1800. These cars will have the best of in suspension and brakes, up to 500 Dependable and Economic Horsepower, 5-speeds or 4 speed overdrive Auto's, Power windows, modern AC/Heat, Retro but modern interiors and conveniences, etc, etc.. We will be releasing Artist Renditions of these Rebadged vehicles in the near future.. We will also be taking on Customer who wish to send us their cars for the Resto-Mod/Pro-Touring restorations. Everything is completely Bolt in, so the steady quality will be there in each build.

Here are some pictures of the Various Ride Positions the Front Suspension kit is capable of.. Please keep in mind, all the different ride heights, are capable of proper wheel alignment (toe, caster, camber) If you would like information, to order, or get on the contact list, dont hesitate to email or call...

Factory Ride Height with Standard Spindles (Factory Wheels)

Factory Ride Height with Standard Spindle (Mustang 16" Wheels)

Lowered Ride Height with 2 in Drop Spindles and spaced out wheels (Factory Wheels)

Lowered Ride Height with 2 inch Drop Spindles Spaced out Wheels (Mustang 16" Wheels)

Lowered Ride Height with 2 inch Drop Spindles (19" Aftermarket Wheels)

Here are some pictures of the suspension kit itself, along with some installed pictures.. This is a completely Bolt In Unit (No Cutting or Drilling)

Here are some pictures of how the unit comes to your door step, and it being installed into the Amazon.

Standard 11 Inch Brake Pictures (Drilled/Slotted is an upgrade), along with some pictures of the 14 Inch 6 Piston Caliper Option available also.. 11", 12", 13" Wilwood also available in the 4 or 6 Piston Caliper Options..

Here are some pictures of the 19" wheels on the car at factory ride height with standard spindles, with the 14 inch Wilwood Brake option..

6/25/2011

Ok here is an announcement.. I have had too many people asking me what is going on, and why I am working on these Early Model Volvo Components, so here it is.. This is the reason for the components I am working on...

As you all know I have moved forward with the front suspension kits, and they

are on the Market now.. The interest has been high, and the interested have

stepped up for purchase. We have a few Major Volvo Parts Dealer's (You may be

Surprised Who) that have picked up the suspension lines. The rear kits will be

available in about the next 30-60 days, I will post info and picks later.

There has been alot of interest in other products that we are working on, and if

the same interest is there, I will put them on the market also. I would also

like to know what else you guys may like to have available.. I am not looking to

do reproduction parts, I am looking for updated parts or features.

Here is what we are working on at this time.

UNIQUE SUSPENSION SOLUTIONS Will Offer...

Front Suspension kit: is done, and on the Market

Rear Suspension kit: will be on the market shortly, and will include 3

variations.

First: A rear Coil over conversion kit, that will bolt to the Volvo Body and

rear end, and it remove the original Coil Springs and shocks.. This kit will

give you more ride dampening control, along with ride height control. It will

also eliminate the typical rear suspension sag.

Second: A complete new Rear End Assembly.. This is a Mod Light Ford 9in rear

end that is a direct bolt in.. It can use the factory coil spring and shocks,

but will give Gear Ratio Options, Traction Options, Brake Options, and be alot

more durable with plenty of parts support.

Third: A bundle of both packages for the best of durability and Adjustability.

The coil over kit is made to work with both the Original Volvo Rear end and the

New Design rear end we will offer.

CLASSIC AUTO GLASS INNOVATIONS Will Offer....

This company will be offering Flush Mount Windshields and Back Glass's. These

kits will remove the need for the Rubber seal that leaks and causes rust out.

Plus it gives the car alot cleaner look, with less bulk from the rubber.

SWEDISH SKUNK WERKS Will Offer....

This is a new company that is working on new products on several fronts..

Swedish Skunk Werks will be offering Restorations and Restored Vehicles for

sale. These vehicles are not Original, they will only be built with the

products stated above and below. We will have two levels of car:

A Resto-Mod version.. This car will appear original in appearance parked or

going down the road. However, it will not be original in

drivetrain/Suspension/Comforts. They will be a General Motors LS Series Based 350 Fuel Injected Horsepower with a Performanced Based and Durable 5-Speed,

and higher fuel economy than the original Volvo Platform.

A Pro-Touring Version.. This car will appear to be a bit different, with some

slight body mod's and clean ups. Flush Mount Glass Kits, A General Motors LS6 Series Engine at 500+ Managable (Daily Driver and Economic)

Horsepower, A performance Based and Durable 5-Speed, the best of the Adjustable Suspension and Large 14 inch brakes all

the way around. They will only come in certain colors with certain badgework.

They will have some Unique Options in Performance and Comfort, that the

Resto-Mod version will not offer.

SWEDISH SKUNK WERKS is working on these items as we speak..

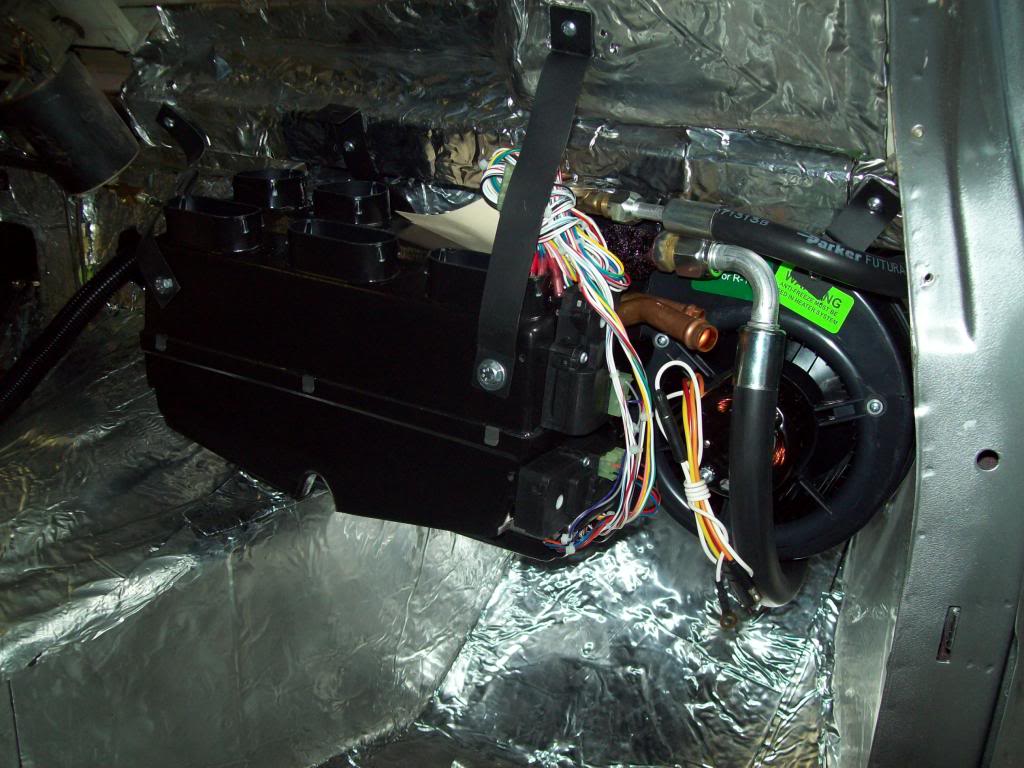

A working direct bolt in AC/Heat unit.. Swedish Skunk Werks has joined with

Vintage Air to offer a quality package. This unit will be compact and more

efficient than the original add on.. If you are running the original motor, it

will take less effort to operate it.

New Updated Gauges. These guages will now be electronic, but they will be a

direct replacement to the original. The speedo will use a GPS signal, so there

will be no need for calibrations for tires, gears, ect. They will be original

in appearance, but we will also offer some classic Resto-Mod look guages as an

alternative.

Direct Bolt Power Windows.. These kits will eliminate the cable regulators that

the cars currently have, and replace it with a quality power window regulator.

New Interior Panels... We will have direct replacement door panels and other

interior panels.. These will be retro, but they will be updated in materials and

appearance. They will also offer the Power Window option and the standard crank

option. Also working on direct replacment seats with Headrest.

So there is what is in the works, and just like the Suspension Kits and other

products I have done for other vehicles, these products will happen for my

builds.. Now the only thing is, is there enough interest in these products to

set them up for Mass Production? Let me know if you are interested, and do let

me know if there is something out there you would like me to see if we can get

it done..

Thanks

Robert Jackson

DIVERSIFIED AUTO GROUP

Unique Suspension Solutions

Swedish Skunk Werks

Classic Auto Glass Innovations

580-263-0454

Classicautoglassinnovations.com

7/5/2011

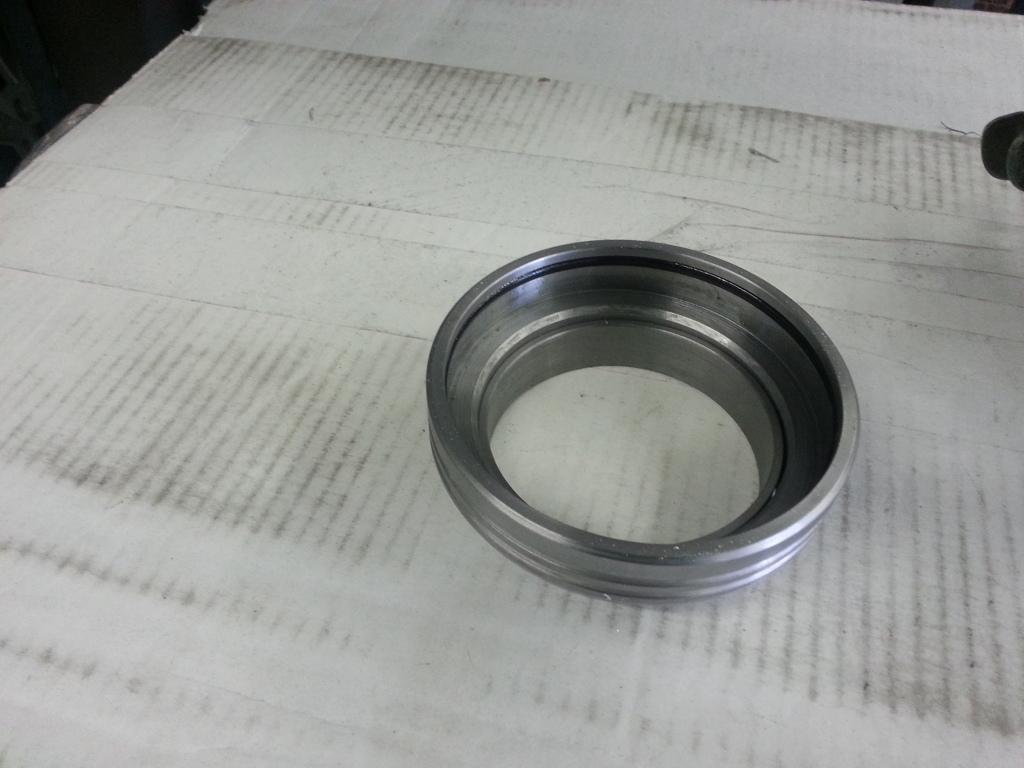

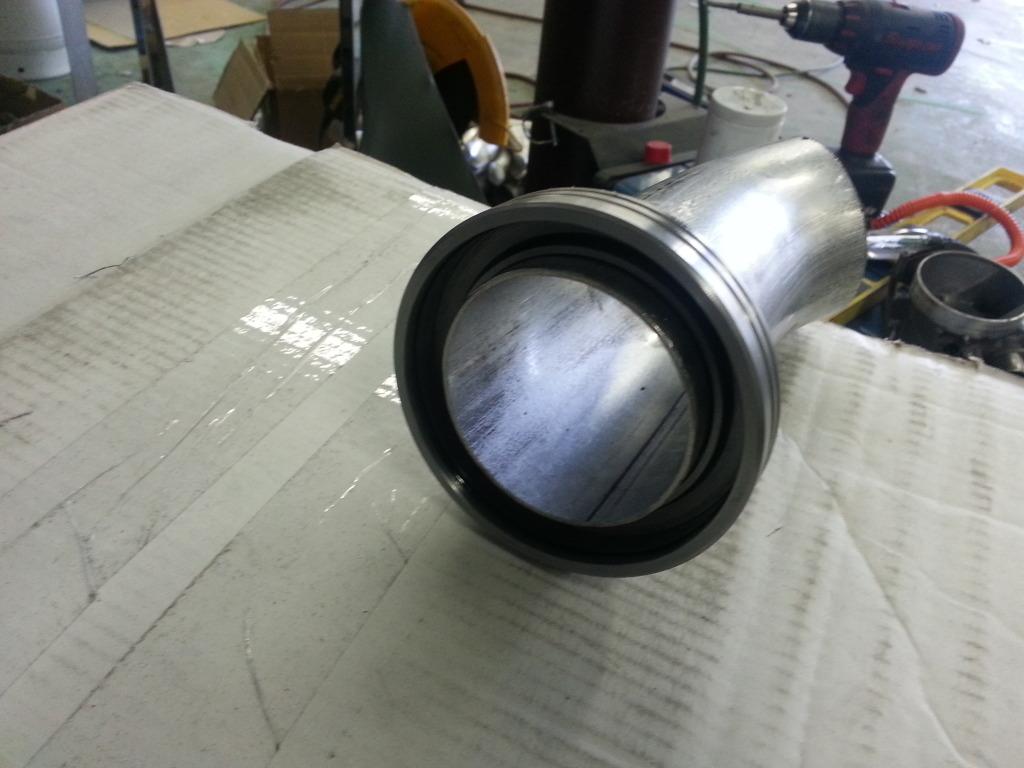

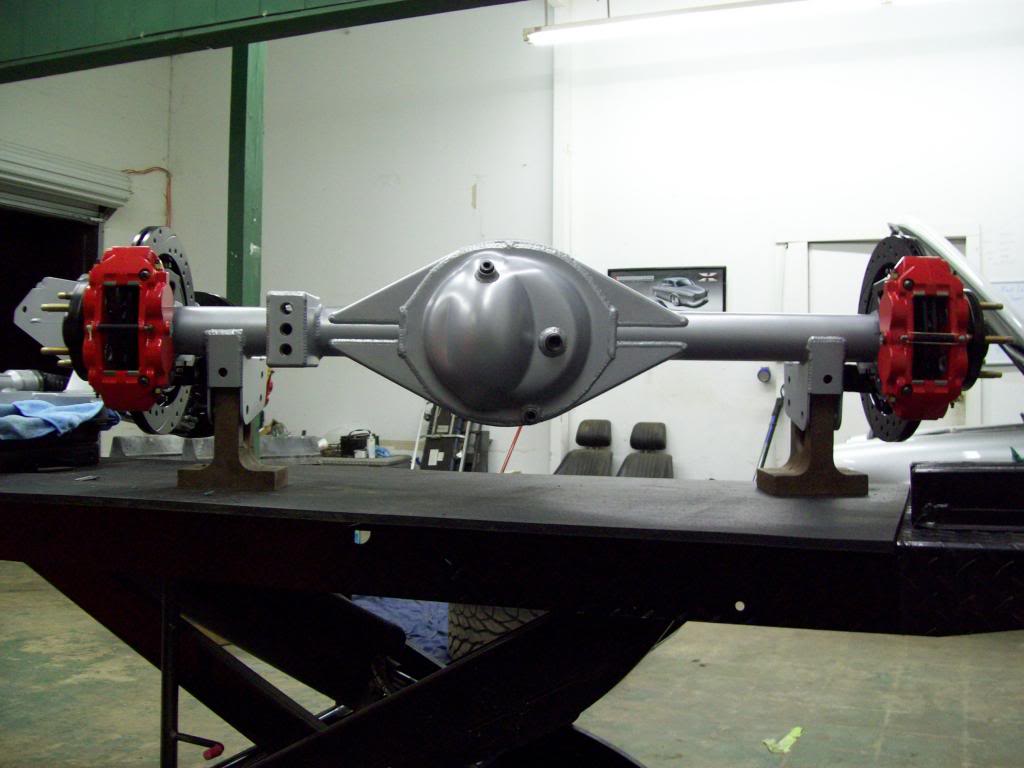

Here are some pictures of the first round of the Rear End works.. It is a very

solid and heavy duty housing, but weighs less than 80 pounds minus the gear

set.. It looks larger, but the actual pumpkin housing is about an inch bigger,

which translates to a 1/2 lower clearance position...

I am still working on the final mounting plates, but this will give you the idea

of the quality that is going into it... It will accept the General motors

Calipers with the Emergency Brake feature with a 11 inch brake rotor...

These rears are also the largeer 31 spline quick change axles, and the gear set

will offer any gear ratio and traction option you could need.

7/17/2011

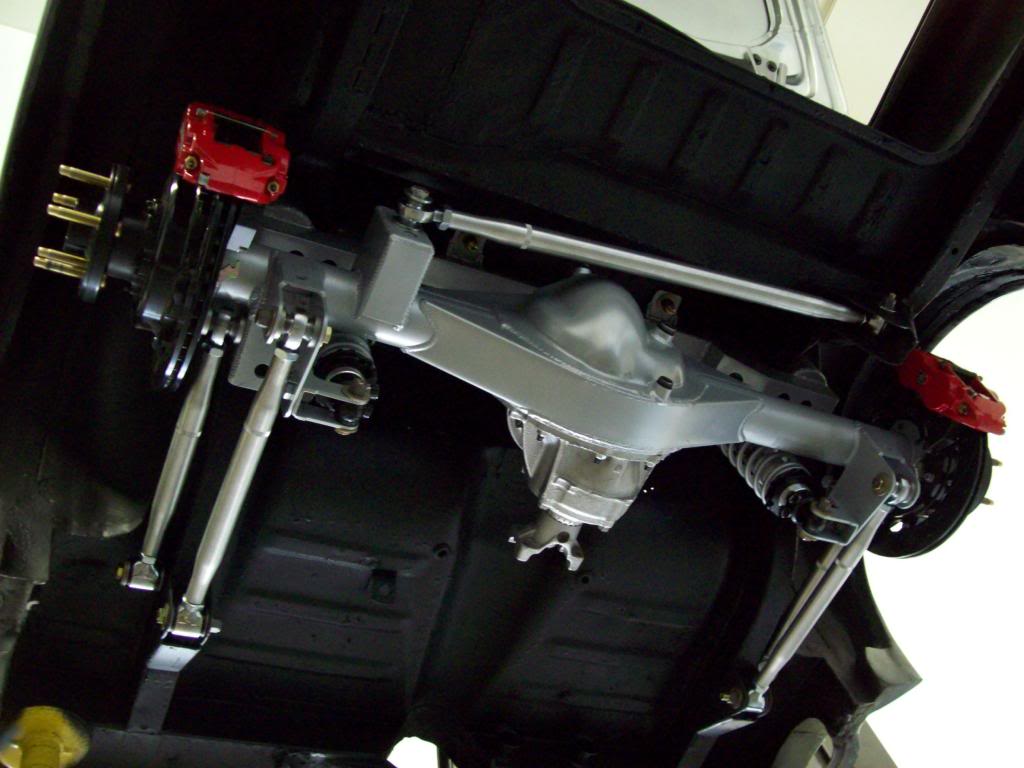

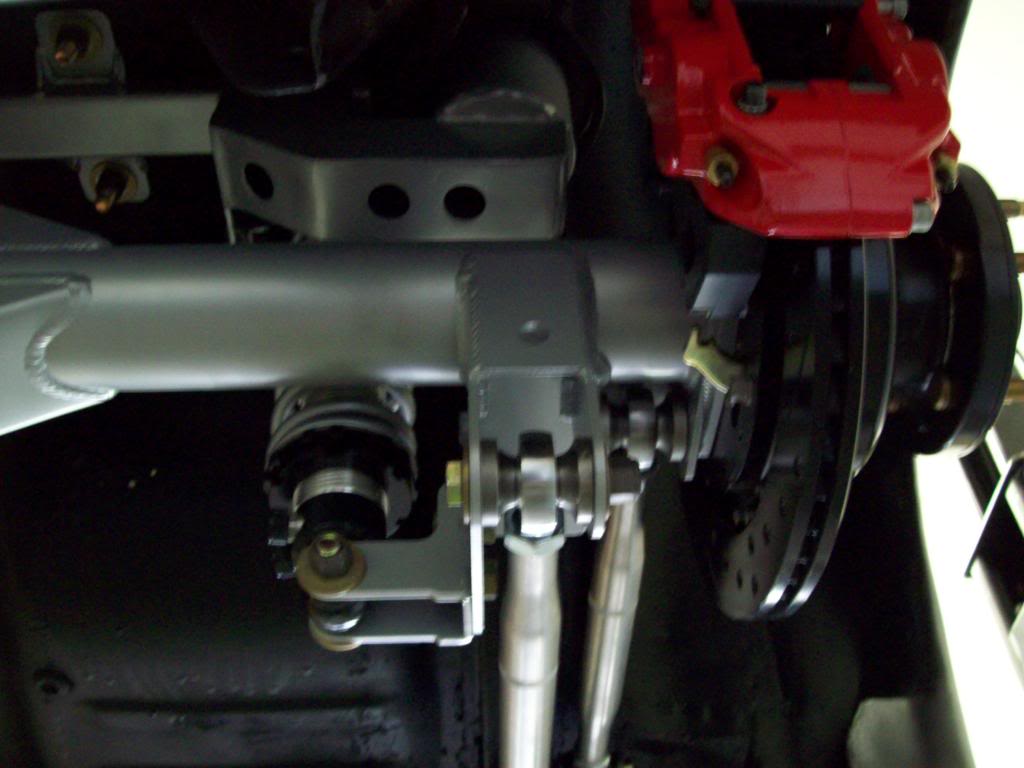

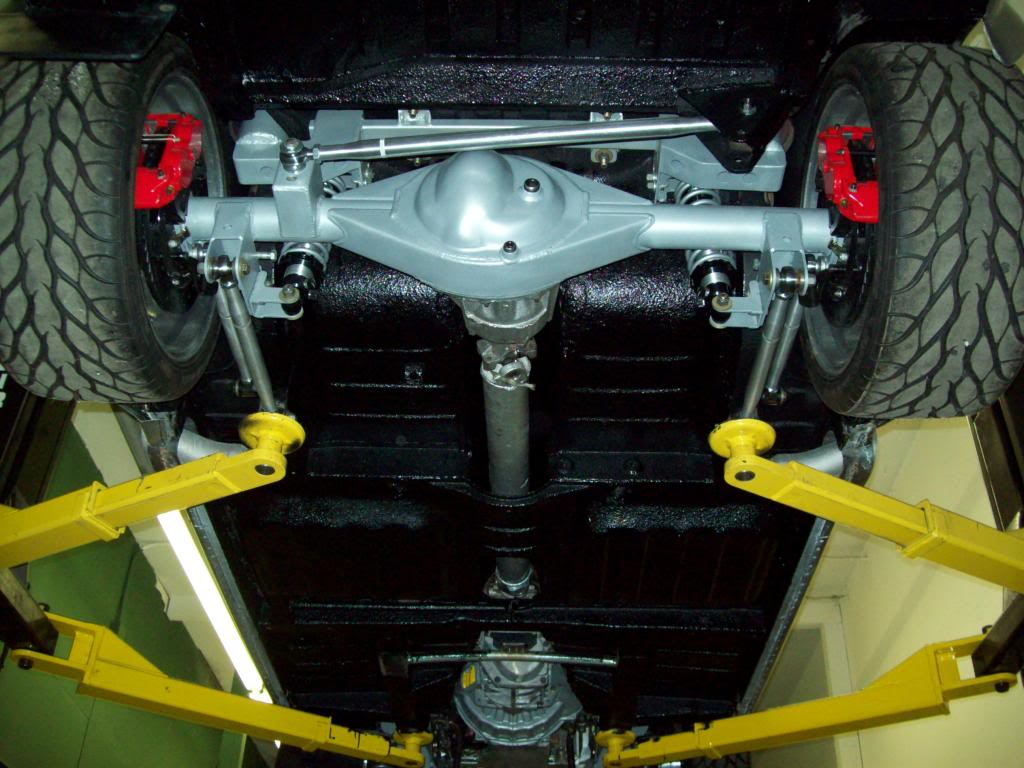

Here is an update of the rear end mocked up in the Amazon body.. I have some New Design Adjustable Aluminum Rear End Links and Panhard Bar being manufactured for this application, and for a stock arm replacement package. The custom link kit will directly bolt to the body and factory rear end assemblies also, which will help with replacement bushing issues for the factory links. This will also allow for all the possible adjustment I need, and allow this rear end assembly to go in all the models of Amazons and P1800's. This is mock up mountint is with the factory springs and shocks, to show that it is a direct replacement for the factory rear, but we also have a Coil Over Spring Conversion kit to eliminate the original coil springs and shocks. This will allow for better vehicle set up, and will also eliminate the pesky suspension sag these cars are plagued with.

These rear end assemblies will be offered in several packages.. Just the Floater rear end assembly that you can install any 9in ford carrier you may have.. A complete unit with carrier assembly already installed, and with your gear ratio and traction specs. With or with out the Coil over conversion. The links will be offered seperately for people that want to use them with the factory rear ends, but will have to be purchased with the New Design rear end assembly for ease of install.

Along with the gear ratio and traction options, these assemblie have numerous brake options up to 14 inch brakes. The pictures below, show the base level kit with general motor calipers. These calipers do have an emergency brake application, so nothing is lost there.

I am using either a 19x9.5 rear or an 18x9.5 rear.. Not real sure yet...

Here are some preliminary renditions.. Ben is still working on the rear views, and there will be a couple of tweeks to them...

8/19/2011

Here are some pictures of our New Direct Bolt on Aluminum Rear Trailing Arms. These work with the factory rear end, or our New Design Mod-Light 9in rear end..

1/1/2012

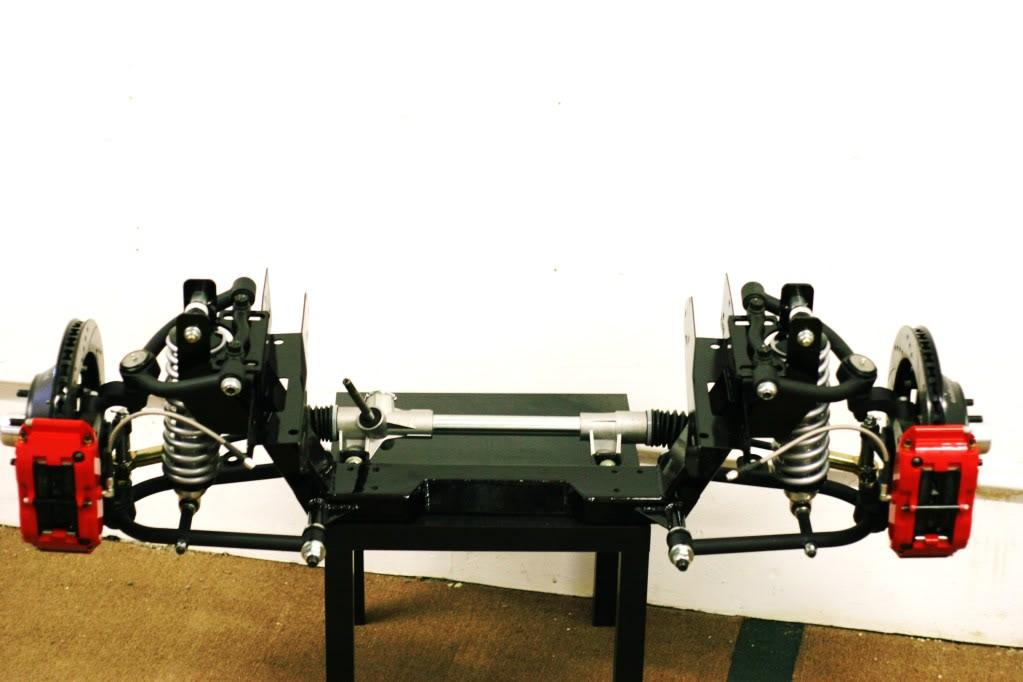

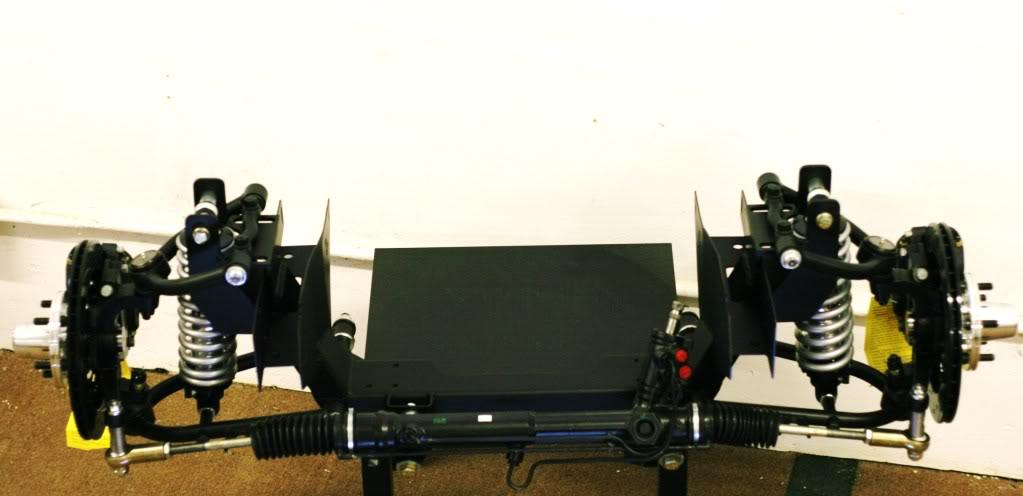

Here are a few updated pictures of the Swedish Ops Crossmember/Suspension Kits.. I had a photographer come in and takes some pics a week or so ago, and here is some of what I got.. As you can see there are alot of color and texture combinations, braking options, rack and pinion options, along with coil over options.. These are how the kits are shipped out, fully assembled and coated..

14 Wilwood Rotor with 6 Piston Calipers

Wilood 12.19 inch Rotors and 4 Piston Calipers with Power Rack and Pinion

1/5/2012

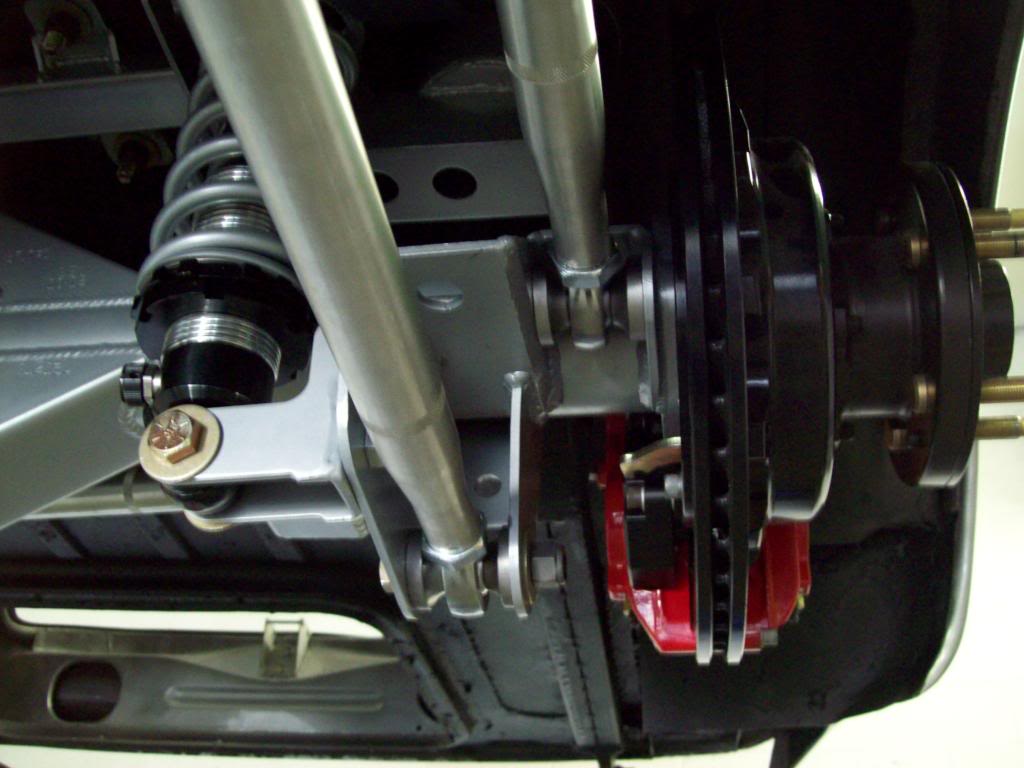

Here are some preliminary pics of the Swedish Ops rear coil over conversion kit we will be using on this build and others we have going on also.. We are adding a Punch Hole finish plate to the bottom opening near the spring pockets, and few other asthetic features, along with finish grinding and full powder coating. This is a bolt in bar that transfers ALL the LOAD back to the original spring pockets.. It is self centering, and will bolt in with out removing the rear axle. We have the Bolt On adapter brackets to convert your original Volvo rear end coil over to accept the coil over mounting..

This bar give your P1800/Amazon up to 5 inches of incremental ride height settings, from stock to an extreme lowered position. You also have quick adjust ride sensitivity and stiffness settings, with a twist of a knob. We have about unlimited spring load and rate options, so no more settling on what you are looking for in ride height or ride quality. You have the same ride potential at any ride height you choose.

The rear end pictured, is the Swedish Ops Universal Direct Bolt In rear end. It comes with all the gear ratio and traction options you can ever need, along with a disc brake range of 11in to 14 inch rotors and up to 6 piston Calipers. The aluminum adjustable trailing arms/panhard bar allows you to keep your proper rear end alignment and and pinion angles, no matter the ride height setting.. Another unique feature to this rear end is, it comes in a 54in, 55in, and 56in track width, which will allow you to use a wider variety of common wheels and offsets with out spacers.

1/6/2012

Here are a few pics with the unit out of the car, you should be able to see how it works.

1/8/2012

Here are some pics of different views of the P1800/Amazon front and rear kits together.. Keep in mind, this is our base kit with base brakes, but this what you see is the minimum of what you get... All the front end kits come fully assembled and ready to install, no welding, no cutting, so once you have your factory components removed, it literally slide right in and matches up with all the existing Volvo bolt holes.. You can also see the front end kit actually has longer braces forward of the OEM. And we do this, because after you remove the factor steering components, the extra reienforced holes are there to utilize for extra support and bracing of the new front crossmember.

9/24/2012

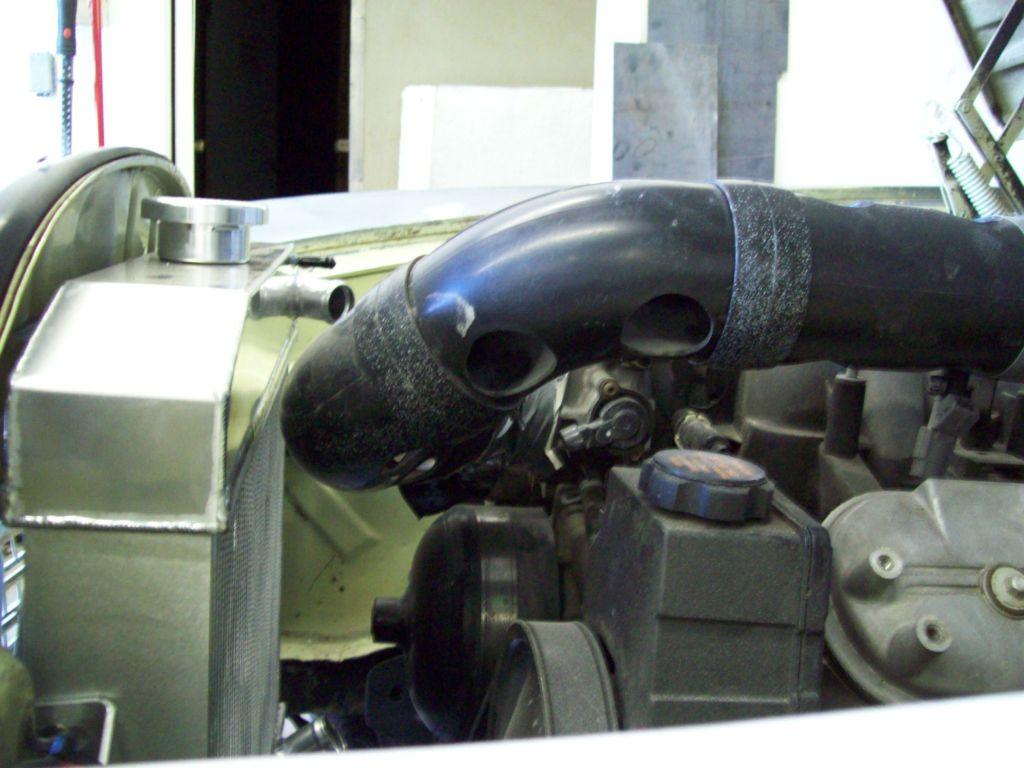

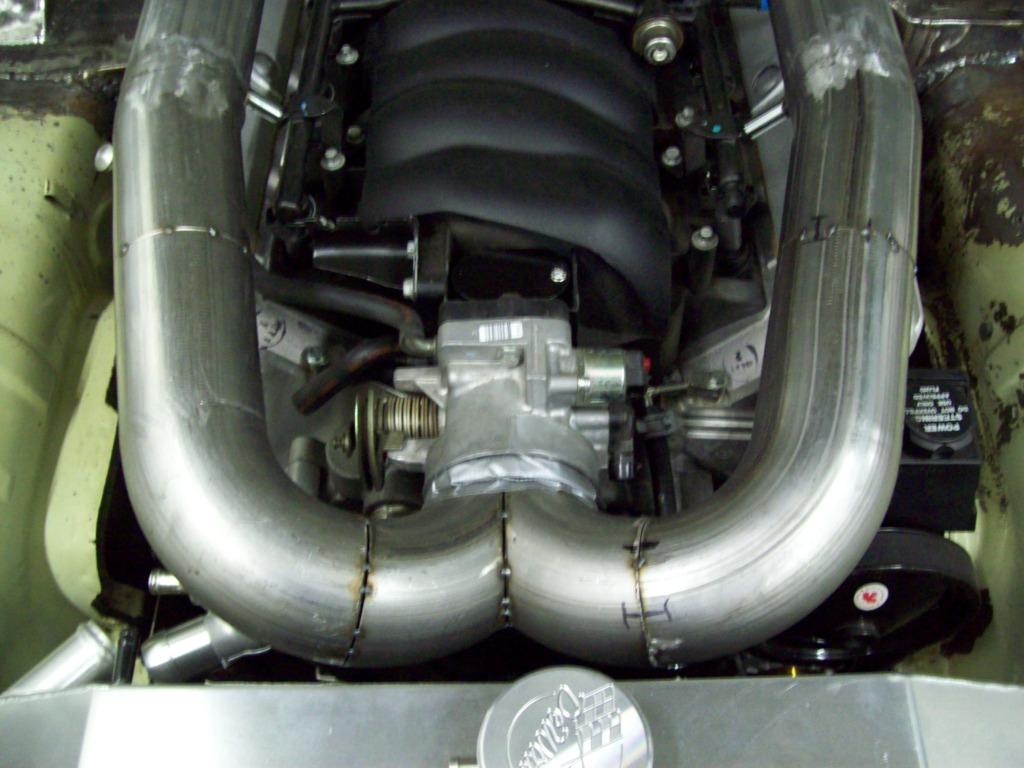

Well, it has been a bit since I have updated anything on this car, but there has been alot of development and behind the scenes going on.. I have been waiting for a few more key parts be finished up with the CAD work and cutting programs, so I can install actually production parts on this car.. I didnt want a car on the road, that wasnt actually running the production parts people are buying.. I think it would be a bad thing to take this car to events, and have people notice some key items are different from what Swedish Ops is offering to the public... I hope to have it on th road in the next couple of weeks, and I am waiting on the Production Driveshaft, LS Conversion Radiator, Conversion Headers, and the New LS engine to be delivered..

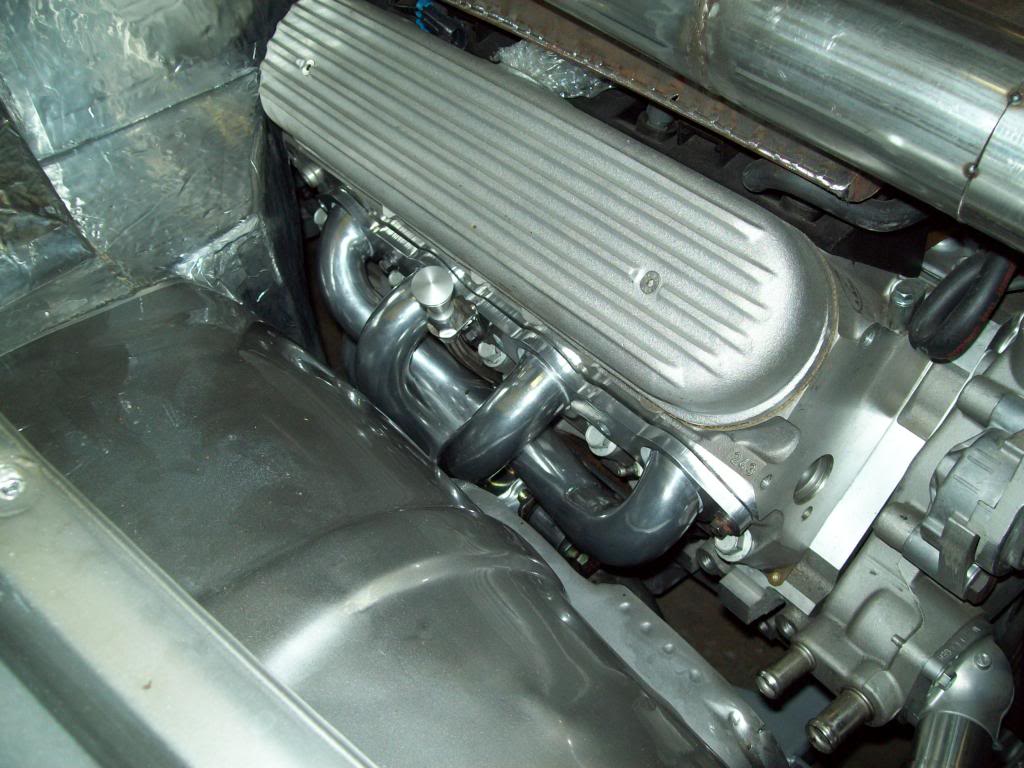

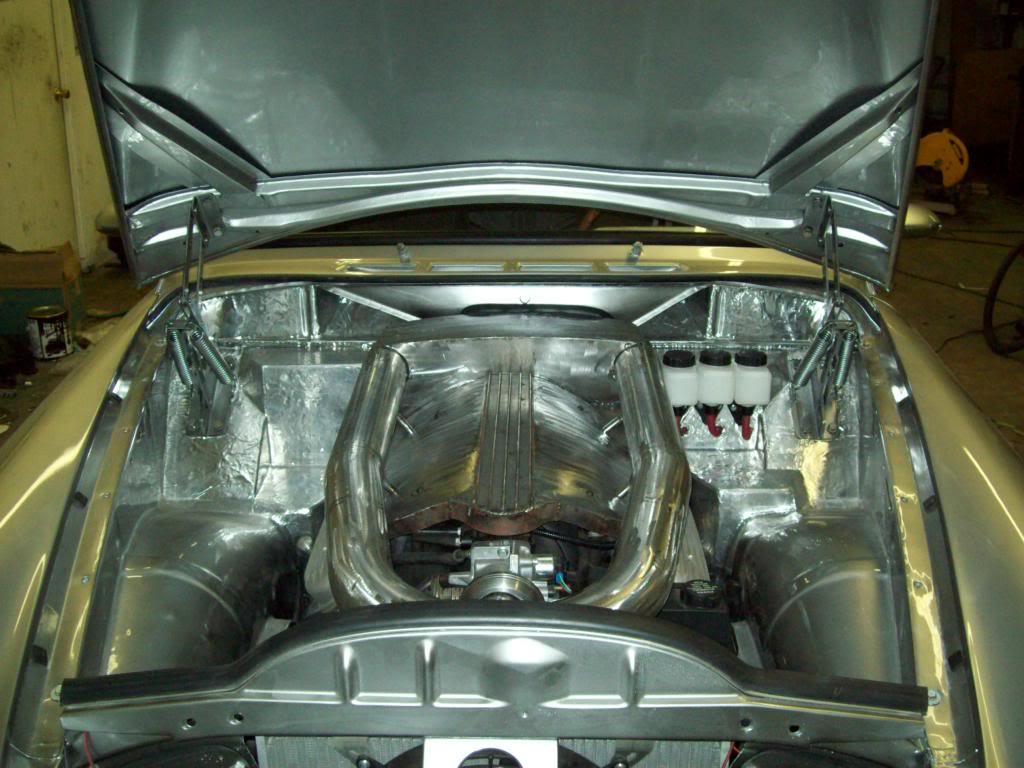

Here is the Mock Up Accessorized Ls Engine/Keisler RS600 5-speed in the hole, and as you can see, it fits great.. Here is the interesting thing about our Front Suspension/Crossmember kits. The motor sits lower and further back than the original 4cyl, but you can drop the oil pan, remove the headers, change spark plugs, change AC compressor/altenator/power steering pump, etc, without even jacking or moving the motor..

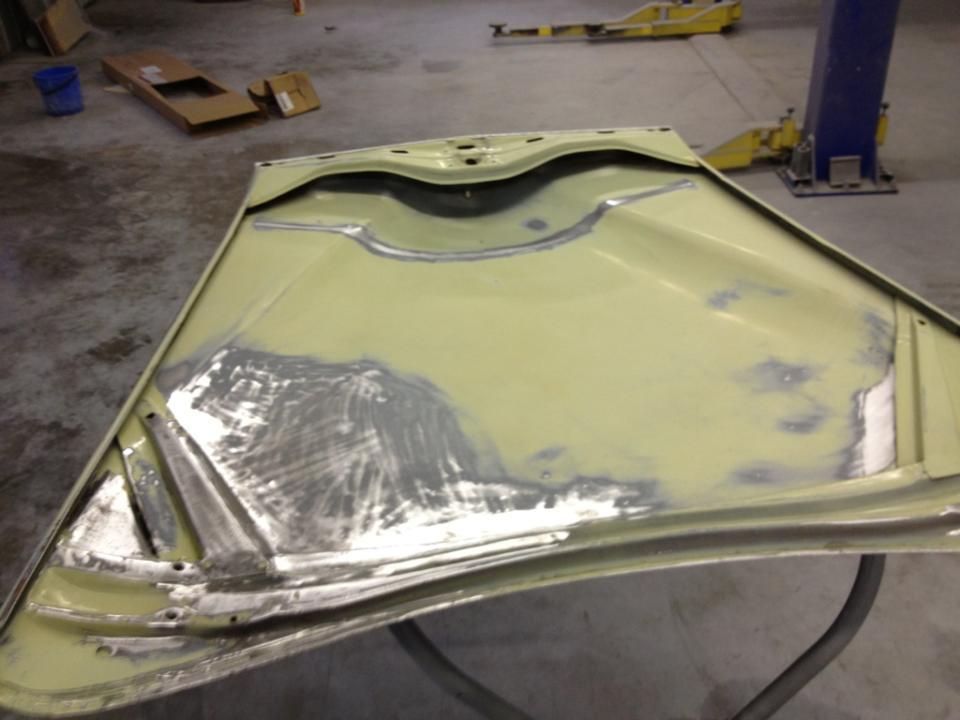

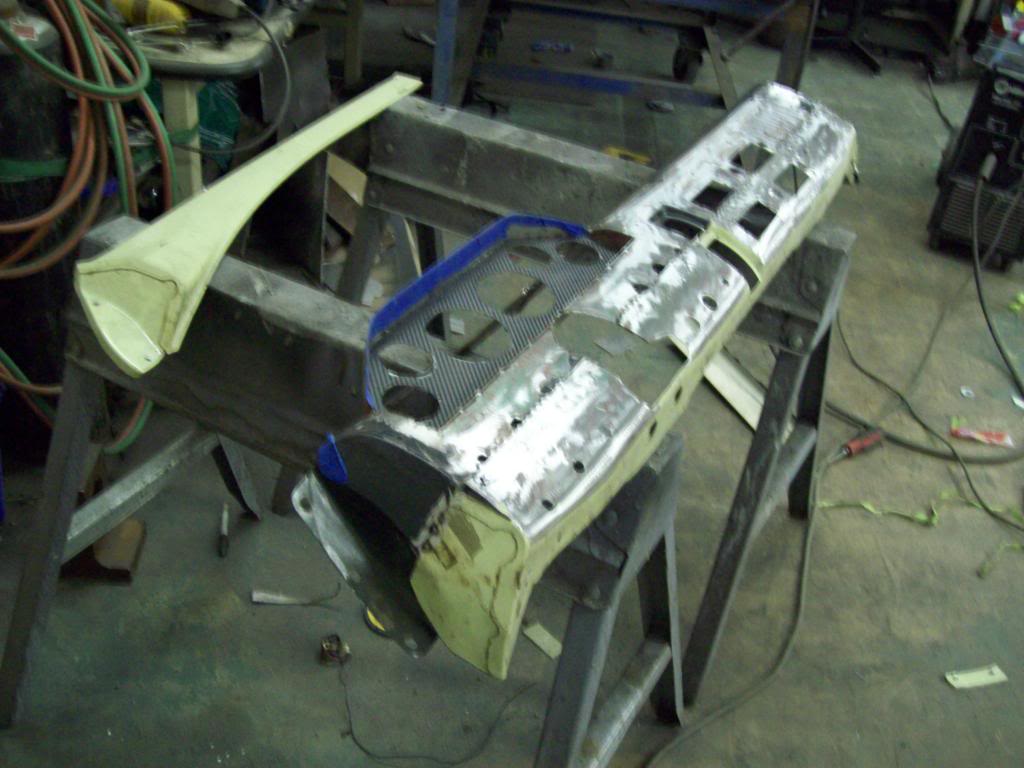

In these pictures, you will see the multi piece firewall conversion mock up, but it has all been CAD'd and in production, so I will be installing the new productionfirewall conversion kit during the new engine replacement. Most of the underhood is still the factory structure, with only the actual firewall changed.. The fender wells, core support, and unibody structure is still factory and un-modified, as you can tell by the factory paint.

You will also notice the cowl air intake for the heater box is still there, and I cant cut it off, because it has Car Numbers on it, so I am going to use it for a engine compartment heat escape.. I am going to make a nice dual funnel system, that will draw the heat out the cowl vent.. I hope I can make it look right, along with function correctly, because I cant really remove it without potential paperwork problems later..

I will also be running the Wilwood Pedal Assembly hidden under the dash, with the remote fluid resevoirs, so the brake booster option for the firewall will not be there also.. Once the production Firewall conversion kits is fully installed, things will look much cleaner, and I can prep and paint under the hood..

Before

After, before paint and new motor

9/25/2012

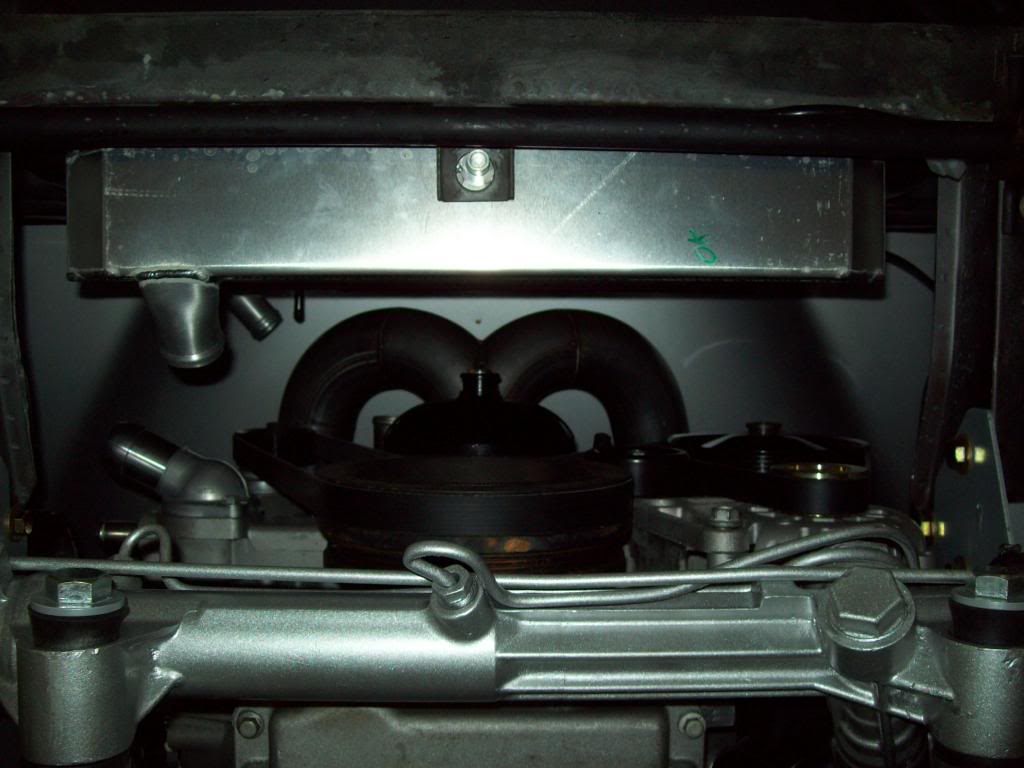

I think I came up with a better idea for the old heater vent. I am going to use the cowl vent as a fresh air vent for the motor, by building a fitler box that attaches where the factory heater box did, and then have two intake runners that will run along the top of the valve covers. I am really considering, having a Louvered Intake Cover that is bridges the gap between the two runners, and will hide the intake and injector wiring.. It should give it a LS Engine Cover look, but be functional?

The pictured radiator isnt the LS Conversion Radiator and is a single core I had on hand, so the upper water neck is in the wrong location. That is what makes the mock up fabbed intake look too close. I also ran out of the Mock Up intake pieces, sure seems like they would give you more pieces, but you can get the idea..

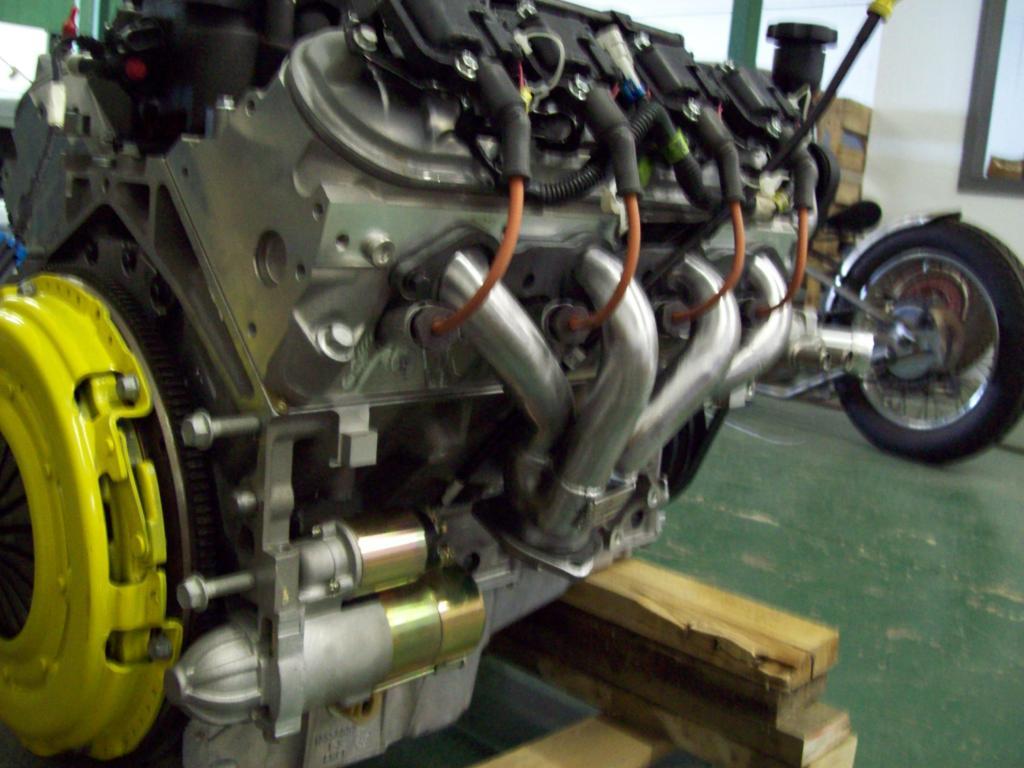

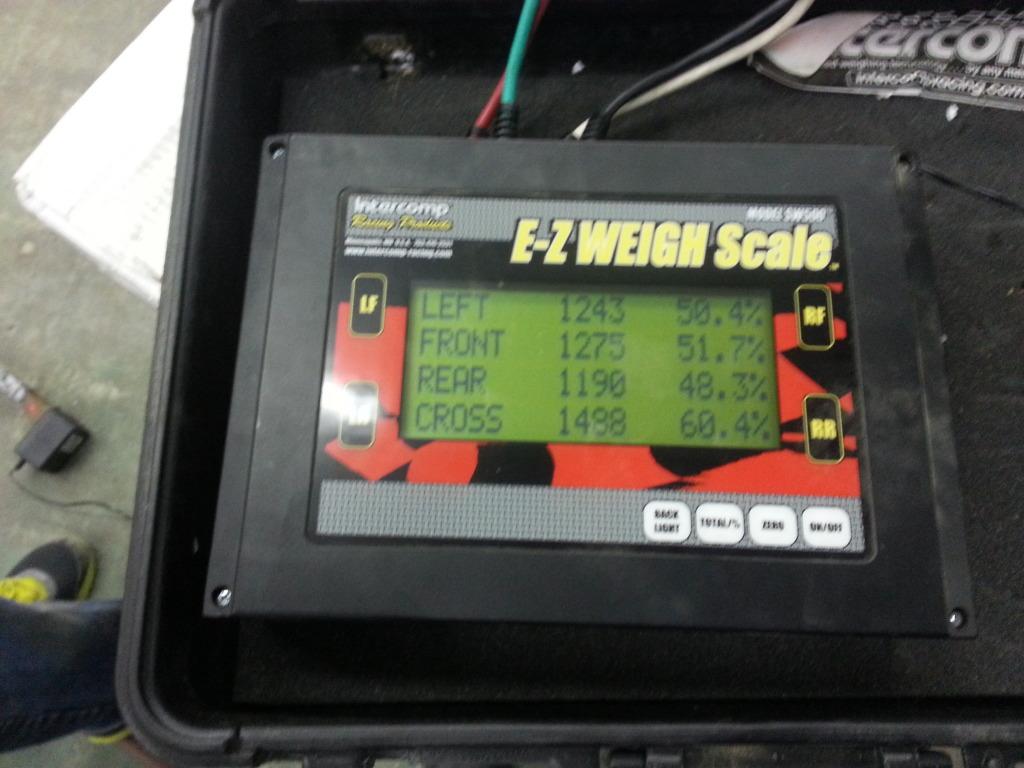

I should have the 540 horse LS6 here at the beginning of next week, and I am running the Tremec TKO600 with the .82 final drive in 5th, and now I am debating on what rear end gear ratio to start with first.. The car will weigh in at about 2700 pounds, so I was thinking it would be useless to go any lower than 3:42's, but I was thinking of starting with 3:08's. This would be also be a decent posi-trac with 18x9.5 rear wheels, and I think it will still perform very strong there, while get about a 2000 rpm at about 70mph.

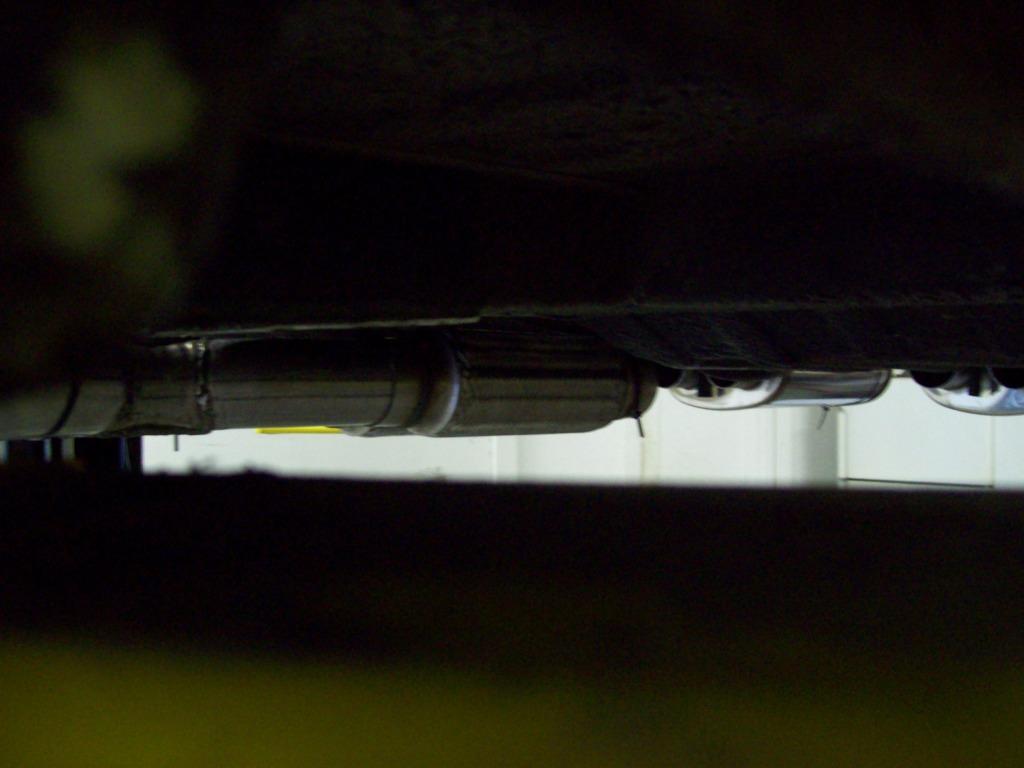

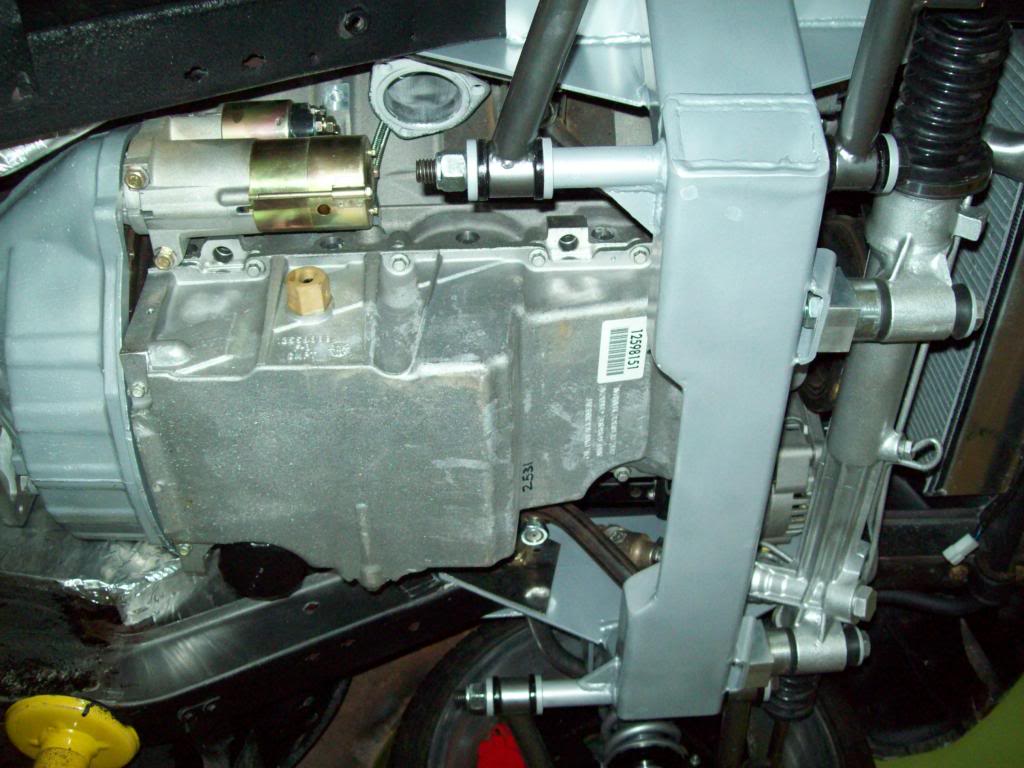

9/28/2012

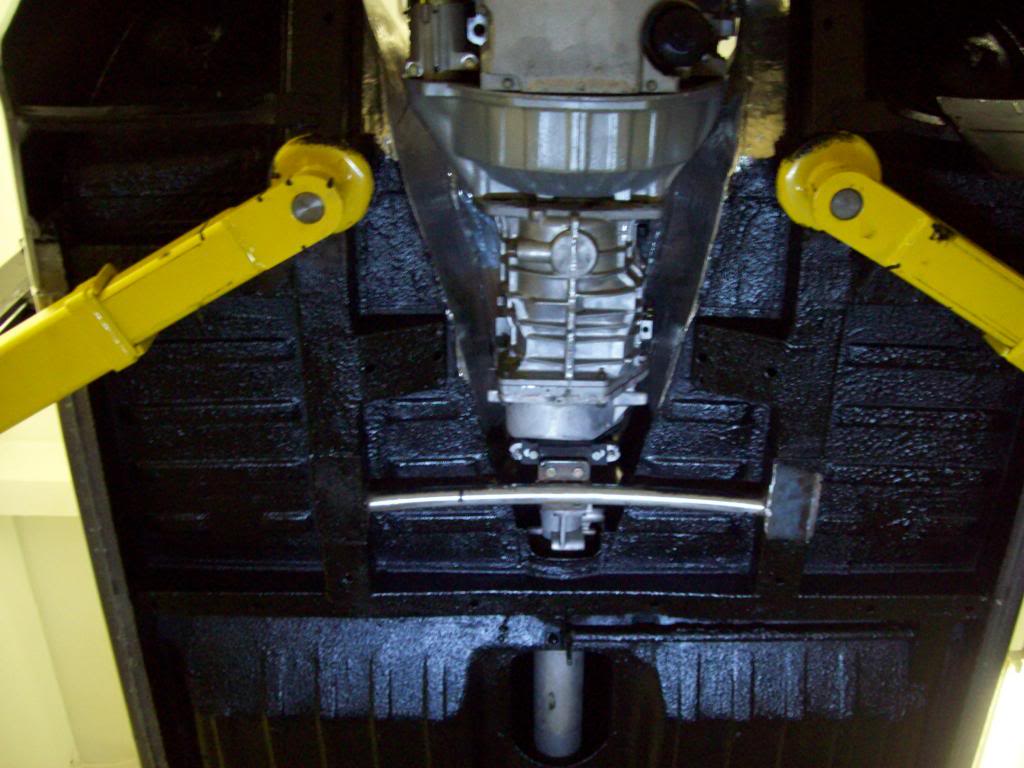

Here are some pics of how the underneath is set up, with the Front and Rear Suspension, LS Motor, Tremec TKO 600 5-speed, the Speedway Engineering Mod-Light 9in Rear End, ect.. None of the drivetrain is below the body structure or rockers, so I wont have any Oil Pan ground clearance issues, because it and the transmission are tucked up in the body structure pretty decently. It also appears that there will be plenty of room for a decent sized exhaust pipe, so I can get a decent sounding and free flowing exhaust.

The mock up trans crossmember is pretty minimal, and will allow the exhaust pipes to sit in a nice ground clearance position. All of these components are part of our LS Conversion kit, so it should make the job much easier.. The engine stand and transmission mount are totally shimable, so you can dial in what ever angles or drivetrain positions you want..

9/29/2012

Here are some pics of the finished Replacement Trailing Arm/Panhard Bar kit for the later cars, and I do have the brackets to make them work for the early cars too.. You will also see the new 8.8 Ford rear axle conversion bracket kit, for the guys that dont want to use the heavy duty 9in Mod Light Ford we are using for our V8 Builds.. These brackets are offered in the Do it Yourself fold and weld set up, or we can weld them up for you for a fee.

Also pictured is the Rear Coil Over Conversion bar that puts all the weight load back into the original coil spring pockets, instead of installing on the inner sided of the unibody frame rails like most kits do. There is 4 inches of ride height adjustment with this kit, and that is at one inch increments by fliping coil over mount brackets around..

Rear Trailing Arm/Panhard Bar kit.. It comes with the standard Rubber Bushing rod end, or the optional Heim Joint set up pictured. As you can see, there is a redesign in the production models versus the earlier pictured arms in the build threads. We had changed to a swedge end set up, because it offers a bit more space, along with making them stronger. This bar set works with the Original Volvo rear axle, so it a direct replacement for all the original arms and bushings.

Here is the 8.8 Ford Axle Conversion Bracket Kit... You can see the Do it Yourself version, which are the flat foldable plates, and the finish welded brackets above them. This will make the Ford Mustang/Explorer conversion much easier.

Here is the complete kit set up, with the Rear Coil Over Conversion Bar and Coil Overs.

10/4/2012

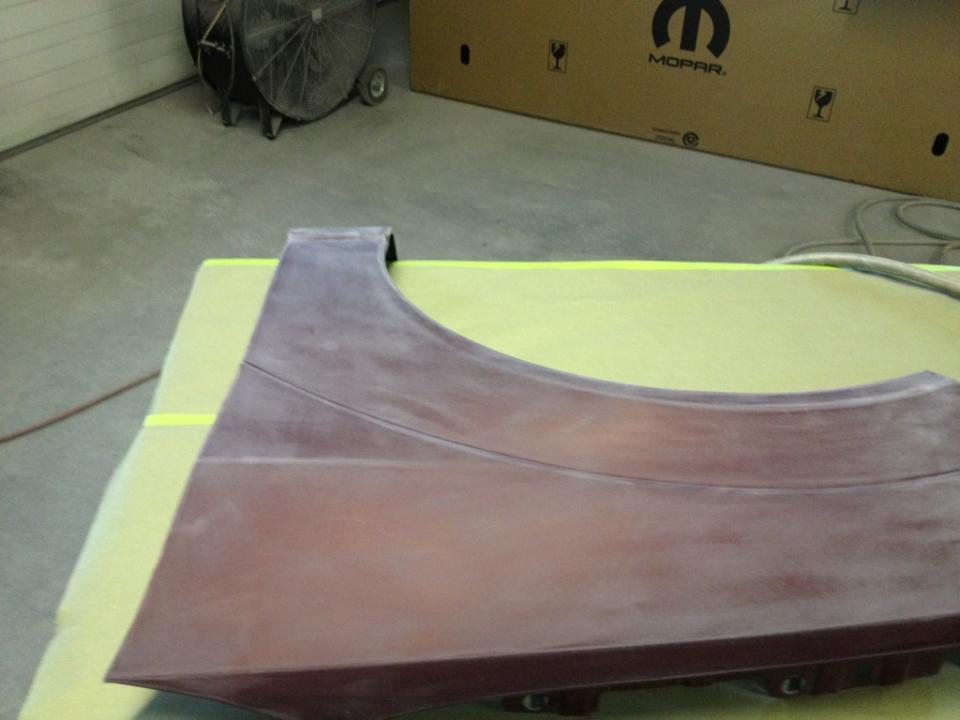

Well it turns out I will have to do a bit of flaring to allow the 265/35/18 to fit properly.. I cant belive the actual dimension difference between the 245's that will fit under there, versus the 265's.. I have a set of 225's, 235's, and 245's here, and you can barely tell the difference between all of them in the group, but you put that damn 265 next to the 245, and there is a huge visual size difference..

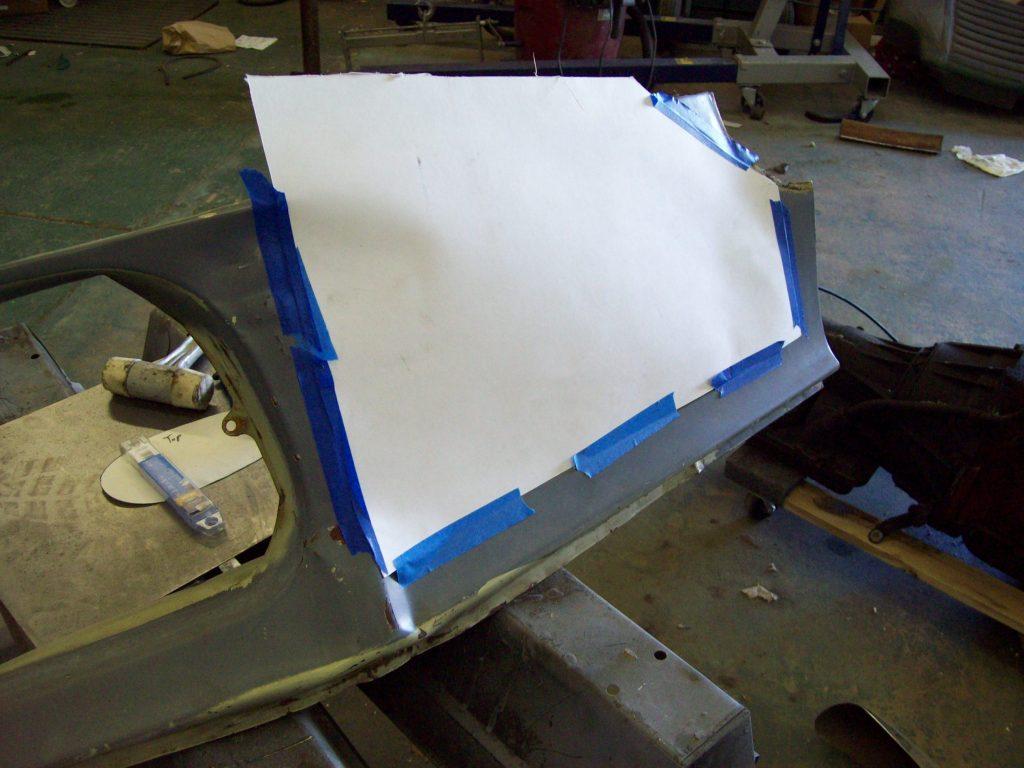

I didnt have to raise the actual arch, but it did have to come out 1.5 inches on the top.. It really seems like alot of extra work, just to gain that extra 1.5 inches, but the 265's look so much better under there.. I know by Pro-Touring standards, that isnt a very large tire. But in this body, and with this vehicle weight, I think it might do the trick.

These old Volvo bodies actually start narrowing right after the doors, so the exaggerated rear flares, still dont stick out past the fron fender flares, when you are standing right in front or back of the car.. I used the masking tape (Duct Tape) analaysis on this, because it helps see proportions, with out the overwhelming contrast of welded metat, ground paint, ect. It hasnt grown on me yet, so I will sit on it a day or two before I start the other side. I still have to blend the bottoms into the rockers, but that shouldnt be too bad..

10/5/2012

I have the Boze V12 Wheels in a 18x9.5 rear and 18x8 front started on, and I also have the 14inch Wilwood Front Disc in the Red 6-piston caliper option, along with the 13 inch Wilwood rear with the matching caliper option..

10/8/2012

I am getting some of the body work done on the car this week, and at the same time doing some of the necessary body clean up mods. I have found that the Volvo P1800 trunk button is very easy to use on the Amazon, and I think it will potentially make the car much cleaner looking in the rear.. All you have to do is drill a hole for the P1800 button body to fall into, and the mechanicals of the P1800 button will actually work the Amazon trunk release, with no Mods..

I am also working on installing the license plate into the bumper, but I have to do a bit of contouring and tweeking still.. I am not set on it yet, but I think it all could potentially work out. I will also be removing the bumper guards, and plan on welding the bumper up, to make it a one piece bumper.

Before, with the Amazon Trunk Latch, and original license plate position

The after, with the P1800 Button, and the relocated license plate. I am not sure about it yet, but I think it does have some potential

10/10/2012

The body guy has started on the body work rough in, and I finally have my flares tweeked where I think they will work out fine.. Here are some pictures of the flares ground down, but I still have to do a bit more finish welding..

Here are some follow up pictures to the removal of the license plat bracket/trunk latch, and in these pics, the holes are welded up.. I also removed the fuel filler from the back, because with the horsepower I am running, I dont think I will be able to keep gas from sloshing out.. LOL We have our new Swedish Ops fuel tanks in the works, so I hope I have something done in time, so I dont have to temporarily run a fuel cell.

I have also removed my front marker/turn signal lights, because I will be adding the turn signals to the custom projector headlamps..

I have seen alot of these cars get built with extremely bulky late model seats, and I wanted to steer away from that.. I have been saving this seats for awhile, and I think they will fit the styling of the car.. They actually mounted to the factory Amazon Floor Mount, so I didnt have to change the floor at all.. I will be doing some extra bracing and attachments to the floor mount, because you cant be too safe..

I am doing all this to work toward a body wrap, rather than doing the final paint.. I really like this color called Matte Pencil, and was planning on paying for the artwork time to have all the Swedish Ops logo's strategically placed about the car, along with all the logo's for the companies that are supplying parts for our products..

This color is awsome, and I think it will go awsome with the Brushed Aluminum Boze V12 wheels I ordered.

10/14/2012

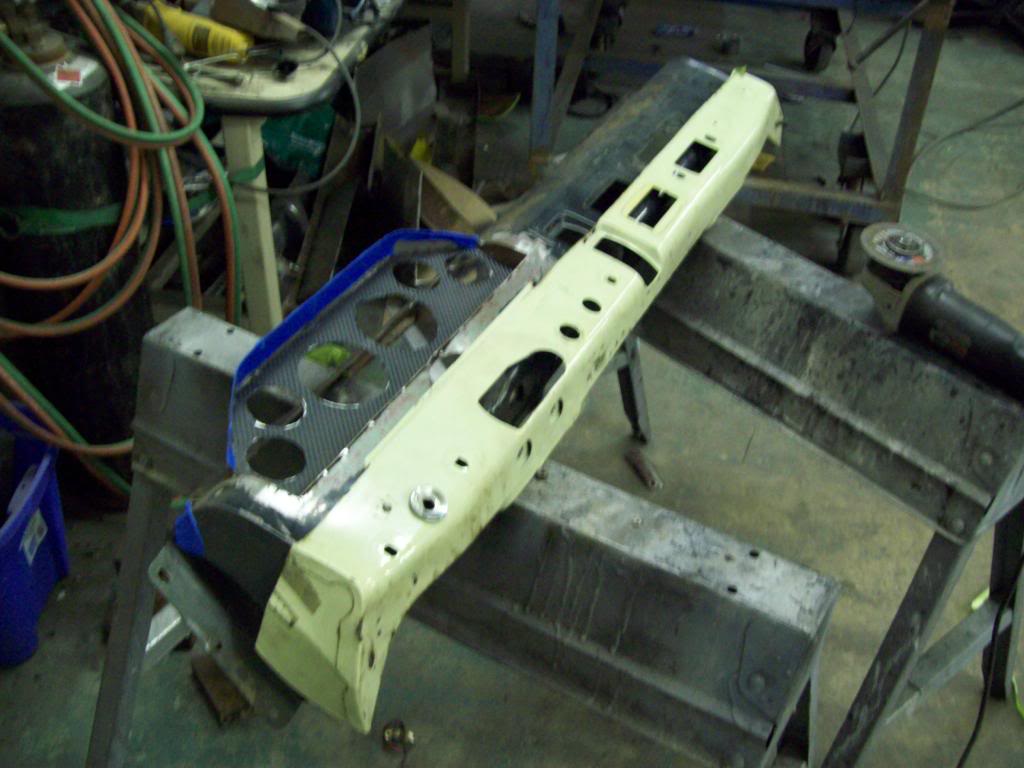

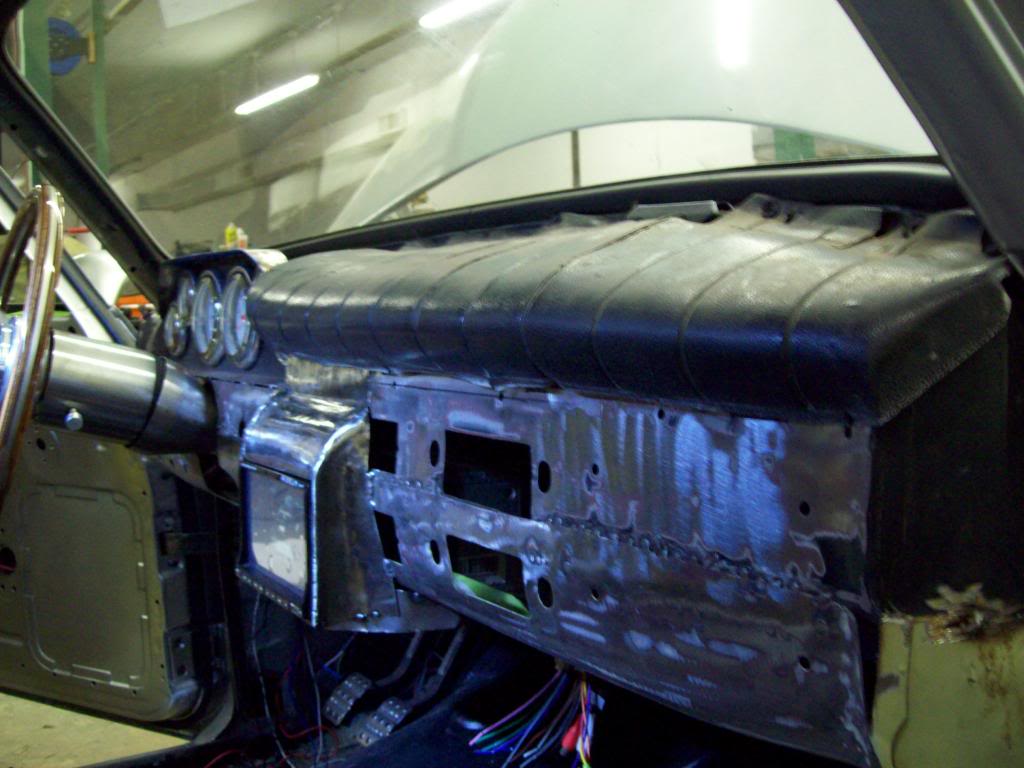

I am trying to sort out the dash modification that will allow some traditional guages, because the original Amazon cluster is really pretty small and the guage setup, doesnt allow much updating to the original cluster.. The P1800's I am working on, have a very easy update situation, so they arent any problems with an updated/factory set up..

Here is a pic of the original cluster set up.

Here are some pics of the roughed in cluster/dash set up, and as you can see, it will give me all the necessary gauge options. In its postion, it is only about 1/2 inch taller than the original set up, and about 1.5 inches wider. I plan on having the dash top done in the same fashion as the original, and I think that will keep it sort of era correct looking. And if you look at the pics of the original, you will see that I will have a bit of hole filling for the uneccessary items like the Choke, but I do plan on using the original style wiper, lights, and other knobs, because I like the look.

10/17/2012

I am sure this will cause more questions than answers, but here is the new fill position for your upcoming fuel tanks.. I should have some pics of the new test fuel tank later this week or early next, which will show you how it all comes together.. We should be in a 14-16 gallon capacity, and it will only take up the space forward of the trunk hinges, which will leave about all the existing trunk space. It will also be in a safer position, when it comes to rear end collisions. With the Amazon/P1800 rear panel acting as a natural firewall, it is like these cars were made for this position fuel tank.

In the case of spillage, the is a drain system to the outside of the car, as most cars with closed in fuel fills do. The same drain setup, should also act as a vent for any fumes from the residual fumes during fill up, and the trunk seal will block the rest. The original fuel tank setups that I have encountered, tend to have a bit of leakage from the fuel sender gaskets at times, and I am sure this set up will offer less actual smell than the factory..

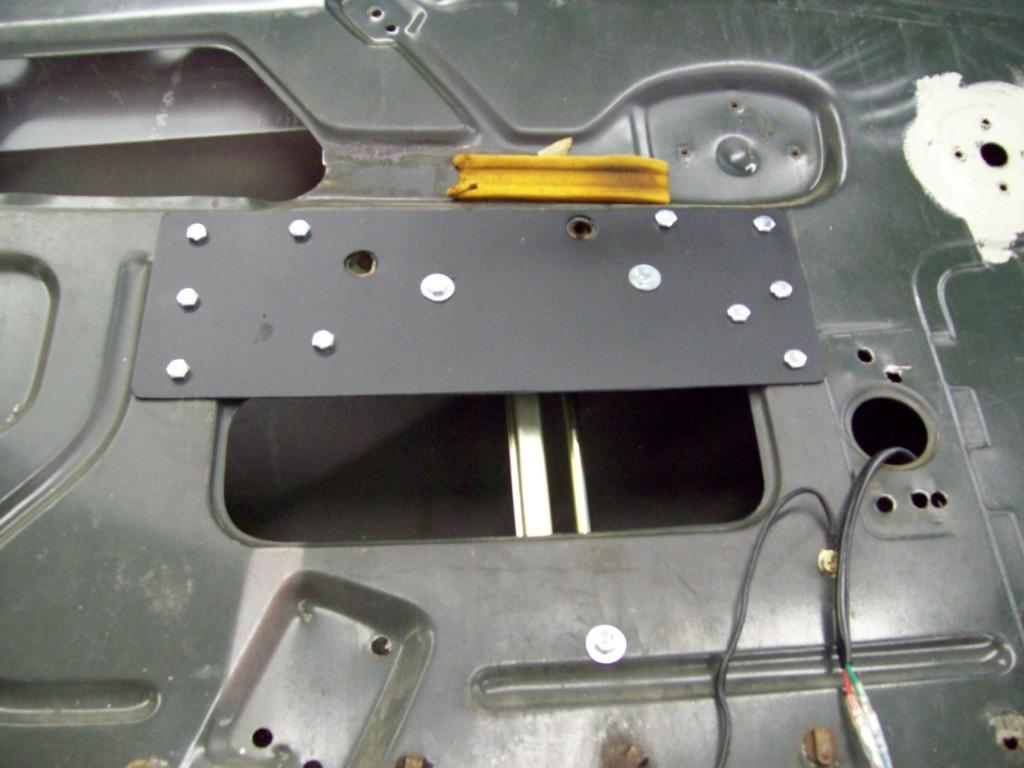

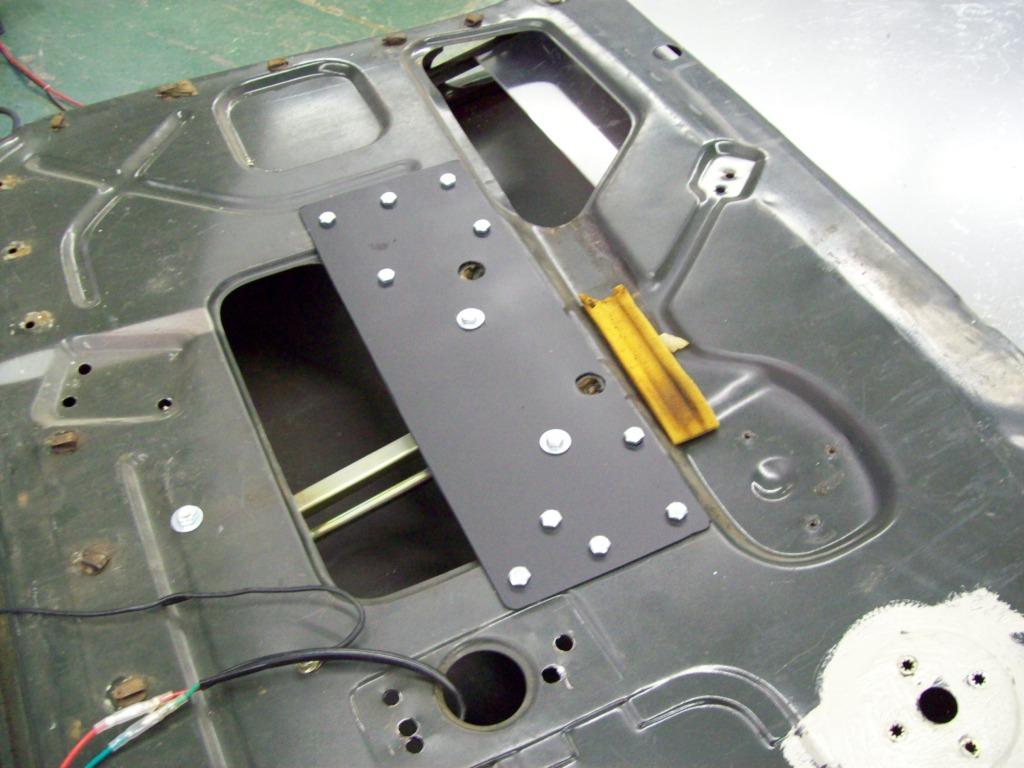

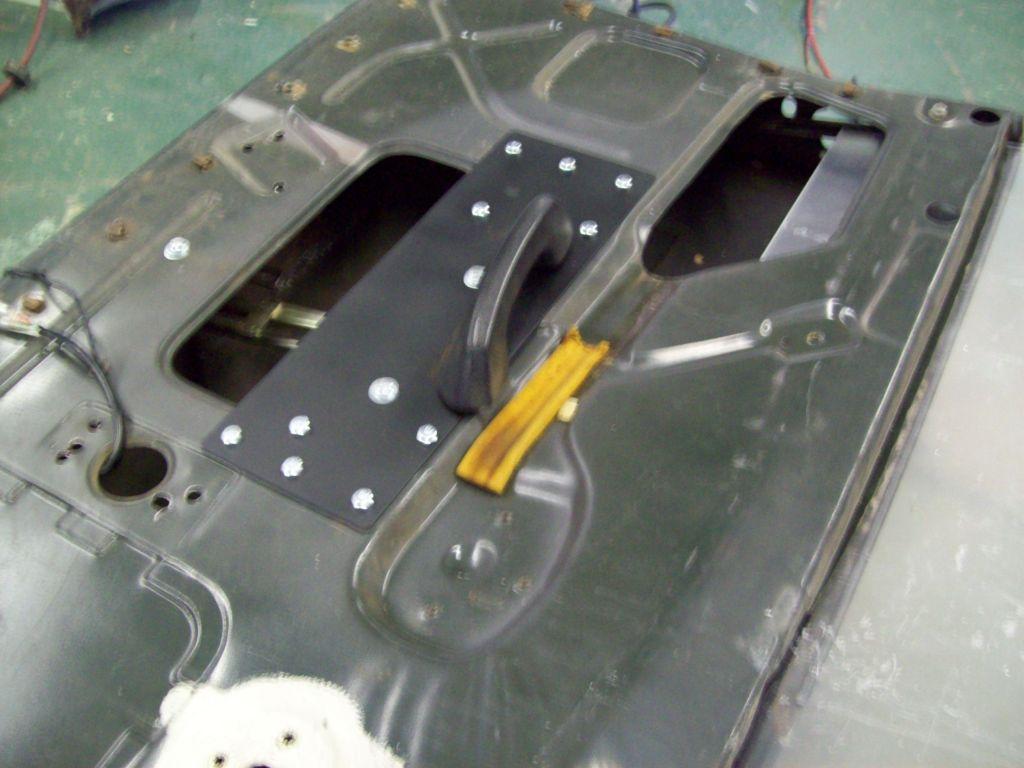

When these are done, they will bolt in, so there will be no need for welding.. As you can see, it mounts with the outer trunk hinge bolt, and the tab that is used for the spare tire strap. The only draw back to this tank for some, will be the elimination of the spare tire holder, but you can still haul a spare laying down if you wish. I will also have some pics of the OEM tank elimination plate, and for the performance guys, this plate will relocate your battery to a sub floor position that is centered at the back of the rear axle. If you didnt want to use it for a battery, it can be used as storage.

10/19/2012

Here are some pics of the guages that I ordered for the bezel I was working with, I think they very decent for the money, and come with everything to operate them.. I put a piece of vinyl film behind them to show some contrast, but I am not still sure what I am going to do for coloring back there. The bezel will not be polished, and will more than likely be powdercoated black or some contrasting color to the body interior color..

Well I got out steering column in today, and it looks pretty good, and fits pretty nicely.. I have always been partial to the sport wood steering wheels, so I thought I would give the old Cobra style a chance. It looks like the new cluster style, column, and steering wheel will come together nicely as a package, but I am still unsure on the actual background color for the back wall of the guages..

I am really want to stick with the classic styling, and I think this works.. In the pictures, you will see a construction paper dash top over the guages, and that represents to shape of the new dash top.. At this point, I am not sure if I am going to make that out of steel, or just make a full fiberglass backer for the upholstery shop to cover.

Here is the factory style cluster and steering column.

Here is my new layout..

10/20/2012

I am working out the final routing for the air intake, so I can order all the aluminum joints. As I said before, I cannot remove the old cal vent/heater duct, because the body vin number is actually stamped on it.. I removed the firewall attachment ring from the old heater box, becauses it is attached with a rubber/foam gasket between it and the firewall, so it should allow for motor torque/flex. I build the filter box on top of the factory attachement ring, because it has a water resevoir and drain made into it, The shape of the filter box provides a function with the water draining, while looking somewhat recognizable as a Volvo feature.

There will be identical aluminum runners on each side, so that should make everyting look even.. I have found a company that extrudes aluminum sheets with a fin pattern in it, and I was think about making a curved intake cover that will be welded into the insides of both runners, so it would have an appearance of a engine cover.

I am sure it isnt too easy to see what is going on here, but I really think will come together as a nice package, once all the components are put in place and finished out..

10/21/2012

I scored some pretty cool old exhaust tips, and will be running them through the rocker panel at the front of the rear wheel. I like the fact they are cast aluminum, because I think they will go with the color and trim them of the build. I have the MagnaFlow mufflers coming, and it appears they will work out great for this type of application, because the inlet and outlet are coming out the same end.

This will make the overall exhaust system way more compact, because I have a nice floor board pocket in front of the rear axle for the mufflers, and then it is a quick bend out to the correct outlet position at the rocker panel.

10/22/2012

Got the first mock up tank in, but we left the back all off, so I can position the filler, baffles, and outlets for the productiong fuel tanks.. They will be in stainless, rather than the steel example here, because this one is only being used for mapping out accessories.. On the production fuel tank, the front, bottom, top, and back will all be one bent piece, with just two end caps welded on.

I haveent figured out the fuel capacity of this tank yet, but I am thinking I might have to reduce some of the size.. I was targeting about 14-16 gallons, and I think I will be closer to 20 gallons on this one, which I am not sure I want to carry that much fuel. I am also debating on an internal fuel pump, because I would rather have the smallest gaskete openings possible, being this tank is actually in the trunk.

Pictured below is the tank without the back wall, so you can see the basic shape of the tank, and the actual space it is removing from the trunk... Most of the space being taken up, is the step up between the wheel wells, so there is still plenty of trunk room left. As you can see also, I made the gas filler tray seperate from the fuel tank, which will make service the tank much easier, because it just sets in place.

Dont you just hate it when someone comes around and makes you look like a dumbass? I have been debating on what to do about the stainless side moulding for a bit, because I do like the look of it. So I have cut, hammered, bent some old use trim I had, in order to figure out some way to use it.. The rear flare work got in the way of the trim, so tried to make it bend over the flare, along with cutting it before and after the flare, but none of looked worth a damn, so I told my body guy to start welding moulding holes..

Anyway, a friend of mine stopped by the shop today, and looked at it for about 20 seconds, and then said " Why dont you just raise its position?" At that moment I felt like a complete dumb ass, because I didnt come up that elementary solution.. The only thing that makes me feel a bit better is, I dont know how many other people looked at this situation, and no one else made that suggestion either.

Anyway, here is the pics with the trim in its new position, and I dont think it will be that noticable over the stock location. Now I need to find a good source for some perfect new side trim, or some exceptional used pieces.

10/26/2012

I am waiting on my exhaust tips, so I can build the rocker cut out/box, but I did mock up the Magna Flow mufflers, and it appears this exhaust configuration will work.. I am debating on solid mounting the mufflers and exhaust tips, and using a small flex joint to attach the header pipe to the inlet of the mufflers.. I am wanting to keep a fairly tight tolerance with the exhaust tips running through the body, and I think that might be the best way to solve any rattling issues.?

Here are some pictures of the Magna Flow muffer placement, and if I solid mount them, I will pick them up just a bit higher. The are up there pretty tightly now, but I would like to have them totally above the rocker pinch weld, and they are very close to being there now.. These mufflers are just tacked up in a mock up position, so they are not at the exact hieght and perfectly centered/level, but you should get the idea.

Here are a couple of pics of the Fuel Tank alterations.. As you can see, I brought the tank down in height a bit, because it worked out to be about 26 gallons, which is way too much fuel to carry. The tank is just under 18 gallons at this point, which should be about perfect.

I have positioned the fuel pump/pick up and fuel level sensor, but have not installed the fuel pump pick up baffle yet.. These tank will work with an internally mounted fuel pump, along with a external or manual fuel pump, so it should fit alot of applications.

10/27/2012

The exhaust tips were just a bit tricky, and I know I going to have a bit of specialize pipe bending to get them hooke up, but it is doable.. I am planning on solid mounting the actual mufflers and exhaust tips, and have a small flex joint betweeh the exhaust header pipe to the muffler. I dont want to take any chances of exhaust tip rattle in the body, and I would like the air gap to be a constant.

Here are some pics of the basic layout, and I think they work out great, eventhough I would have actually liked them just a bit further back, but that wasnt optimal for exhaust pipe plumbing. The perspective will change a bit, once the car is on the ground, and it is out in the open.

This is the box piece that I made to close off the cut hole.. There is access for proper finish welding to the body/rocker support, so I dont have any worry about any weaking of the body structure, and I dont see how it couldnt have actually strengthened it..

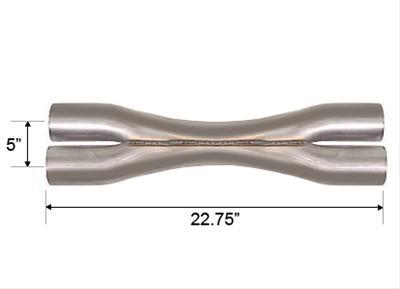

12/28/2012

I am thinking that I should get plenty of exhaust vibration insulation by running the pictured flex joints below.. The mufflers, tail pipes, and tips will be rigidly mounted to the body, but will still be mounted on a very dense rubber bushing, so they should be very solid..

The exhaust pipe coming off the headers will go into the x-pipe pictured below, which will let me keep the header pipes running tightly down the center of the car, between the floor pans for a tight ground clearance fit. The Flex joints will be mounted between the x-pipe and mufflers, and this should allow me to get an extreme body hugging exhaust, and not have to worry about tolerances and rattling..

10/31/2012

I couldnt take leaving the later grilles in this build, and I didnt have the best of luck sourcing a new facia, so this is what I came up for a solution.. I had some old style grilles that I bought off Ebay about a year ago, and it was bugging me that I couldnt use them, because they look so much better than the later grilles. Here is what I came up with, so I will show the relatively inexpensive and simple alternative, and hope this helps someone else in the same situation..

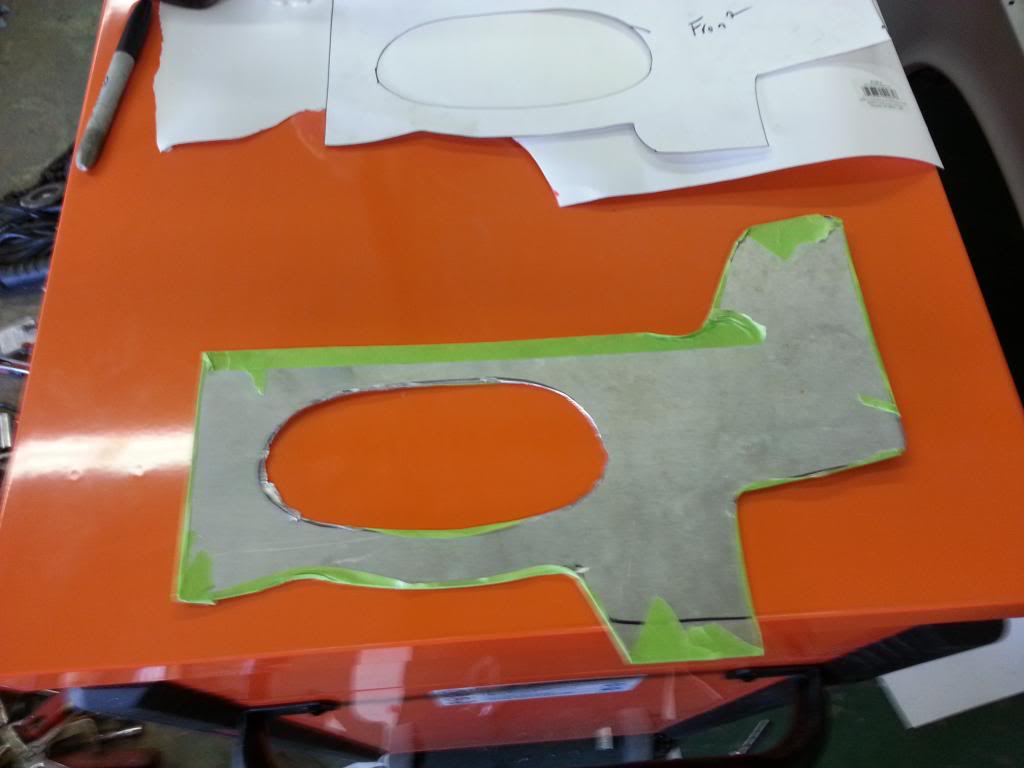

The first thing I did, was to make a poster board template of the later grille shell hole.. I had a donor grille shell, but it could be done on the car, so you dont have to take the facia off the car.

After you use a marker to outline the hole, you will cut out the template of the later grille shell hole, which you will then be able to use the early grille to mark the new hole position, which will leave the actual piece of metal that you need to weld in the later facia.

If you flip the grill upside down on the template, you can then find the grilles reference position on the the later hole template.. This is relatively simple, because most of the upper and bottom of the early and late hole is the same.

I used a 4.5in angle grinder with a cut off wheel to cut out the piece from the sheet steel.

After that, you can put the new filler piece in place, and then you will have a bit of grinding to fine tune the fit. Once that is done, you can tack weld it all in place, and then do some finish grinding to make sure your new grille opening is the right size and contour.

Once you are satisfied with that, you can then add the inside boxing sheet metal, by rolling it and tacking as your continue around the new opening.

After all that is tacked in, keep checking your new grill opening, so you can make sure nothing has change during the postioning and tacking procedure. After you are insure the fit is where you want it, you can then do the finish welding, which is where I need to continue from the pics seen.

It appears with just a bit of hammering and grinding, along with just a bit of filler, the early grilles will fit nicely. I still have to make the mount tabs at a later date, but I will wait until I get the new opening finished out nicely, because that could change something if I made the tabs now.

My grilles are not the straightest at this moment, so I will need to locate some better ones to work with for the final fitment.

For the guys that have asked for the side exit exhuast, here are a few pictures of what I had done.. I apologize for them being grainy, but I didnt realize it, until I had things buttoned up..

It is very important to make sure that you open the rocker panel skin up to a larger hole, so you have access to weld the new exhuast loop to the inner rocker structure, otherwise you will only be welding to the weaker outside rocker skin..

Not trying to pull over anything on anybody, but I did forget to point something out about this procedure, and I was reminded by another viewer that I need to disclose this information..

The grilles are actually on the opposite side, which isnt really that noticable, unless you have a trained eye. (Derek) LOL The early grilles fit better in the later facia, if they are on the opposite side, because you dont have to actually cut into the later facia panel. The early grilles dont level out correctly in the later facia, unless you drop them down too far, or you do some structural cutting to the later facia.

I had intented on mounting them in the OEM position, but in laying them out in their opposite positions, I noticed that the deeper ring side of the grille, actually complimented the center point/bulge of the hood and grille facia, because it added an additional appearance of depth to the center extension of the facia.. It may not be that noticable in the pictures, but it does make a difference in person.

11/1/2012

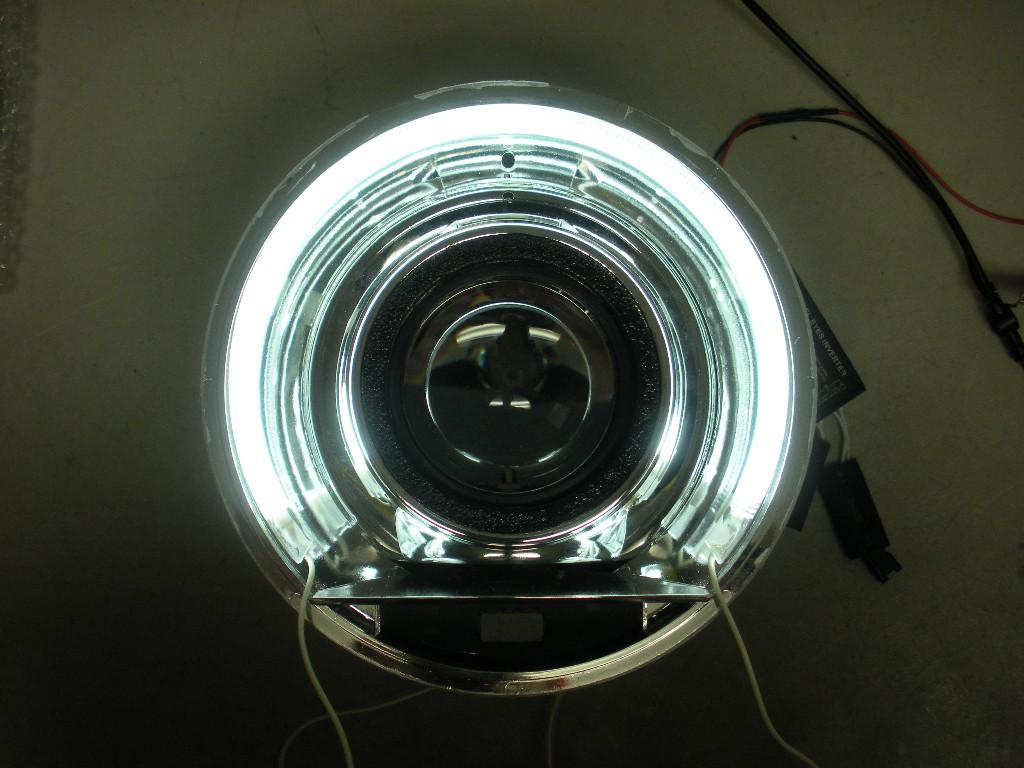

Sorting out the lighting at this time, and will be trying to clean it up a bit.. I have some custom made HID Projector Headlamps that I had made, with the LED Halo daytime running light. They are smooth lenses, and smooth reflectors, which really make the headlamps very crystal and clean.

In the renditions the headlight ring in painted body color, and I think I am going to try it both ways, before I made a decsion on which one stays.. I am removing the chrome tail light housing, so it I leave the headlamp ring chrome that might look out of place. The renditions for the Amazon builds, have the headlight rings and tail light bezels painted body color, and I think that looks best.

For the rear tail lights, I wanted to clean up them up a bit, really only by getting rid of the gasket system. I found that if you do just a bit of trimming to the tail light lense, you can install it from inside the body, so I will be welding the bezel to the end of the quarter panel.. This will eliminate the need for the rubber gasket, and will allow me to paint and blend the bezel into the body, to give the quarter panel a completed look..

11/2/2012

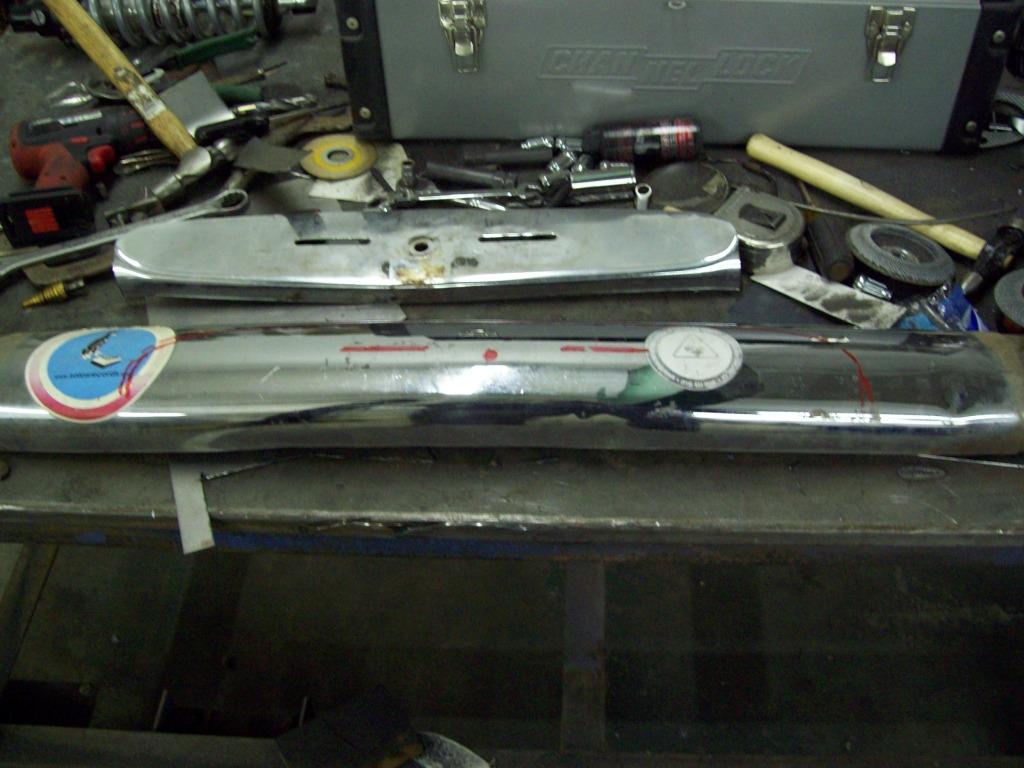

Started working on the One Piece Bumper, and wanted it to mount with no exposed bolts, and also have a better fit.. I was told by a chromer to make sure and butt weld the bumper, rather than weld the overlap, because welding the overlap will cause potential problems later due to trapped chemicals.. So that is what I did.

Being that this car is going a satin silver/grey color, and I have brushed aluminum wheels, I am looking into a Brush/Satin Chrome for the bumpers and all the trim. I have found a company that says they can do it, and they are sending me a sample. The more common place to see this type of chroming is normally household accessories, and will have more of a stainless steel affect, but with just a bit more sheen.

Here are a few steps of how I did the bumper, but keep in mind I am working with old parts, so there will be just a bit more straightening of the bottom and top edges.. It was more important to get the front curvature of the bumper and centers to be clocked correctly, than making the top and bottom edges perfectly level.

After I got the center bumpers overlap sections cut off, and also got the bumper to the desired width, I tacked welded it.. I didnt like the curve/shape of the bumper wrap around on the ends, so I reshaped that by making a slice at the top, and a couple of verticle slits at the bottom, so I can pull and twist the end with our changing the overall shape.

Here are the before and after the cut.. You can see that it allows you to fine tune the bumper end to follow the wheel opening much better.

Rather than just weld stud or bolts in the exist hole, I made these bolt pieces to weld inside the bumper.. It is important to get as much off a welding/support footprint as possible, because this will help against future cracking later.. If you just weld a bolt in the bumper hole, the footprint is too small, and it will allow the bumper to flex the welded joint.

Now that I have some solid mounts, and the bumper is tacked well enough to hammer and jack on, I can install it to the car for fine tuning.. I have also sloted the bumper brackets where the mount to the car and bumper, and that will give me all the adjustment I really need. Also, if you look at the pics of the bumper, you will see the welded footprint of the new mounting stud, and you will see that you fill in the old holes, and weld the the stud plate at the same time.

11/4/2012

I have been doing alot of thinking about what to do with the front of the car for an air dam/splitter, and havent really come up with a solution as of yet.. I know that IPD has had an air dam out there for quite awhile, and personally I dont think it is very attractive at all, because it removes the front bumper totally..

The question I have is this, Has anyone tried to use the IPD air dam, with the bumper? I know you would have to do some trimming, and even find a new mounting position, but I do think it is doable. I dont want to actually add it to the bulk of the bumper itself, because that would put things back to the stubby appearance, so I want it mounted rearward of the bumper, which should be a much better appearance..

I really think this air dam could look great, if it was mounted correctly and still used the factory bumper, and have this only to compliment and fill out the bottom of the front end. Most of your modern cars all have some sort of small plastic air dam/splitters now, and they are mounted underneath the bumper, but reward of it.. From all the examples of this air dam mounted I have seen, it seems that you have to trade on incompleteness with the front end, so I would think someone has to have made the attempt to have both the factory bumper and the IPD air dam.

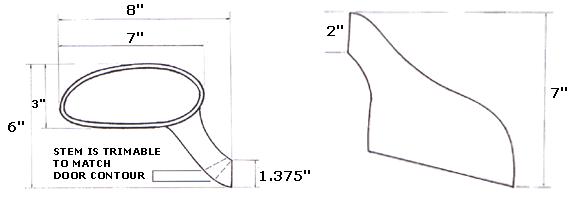

I went ahead and ordered an air dam like you see pictured below, so I will have to wait for it to come in so I can see if it will work like I think it could, but I wonder if anyone has any pictures of how they may have run the factory bumper with it?

11/9/2012

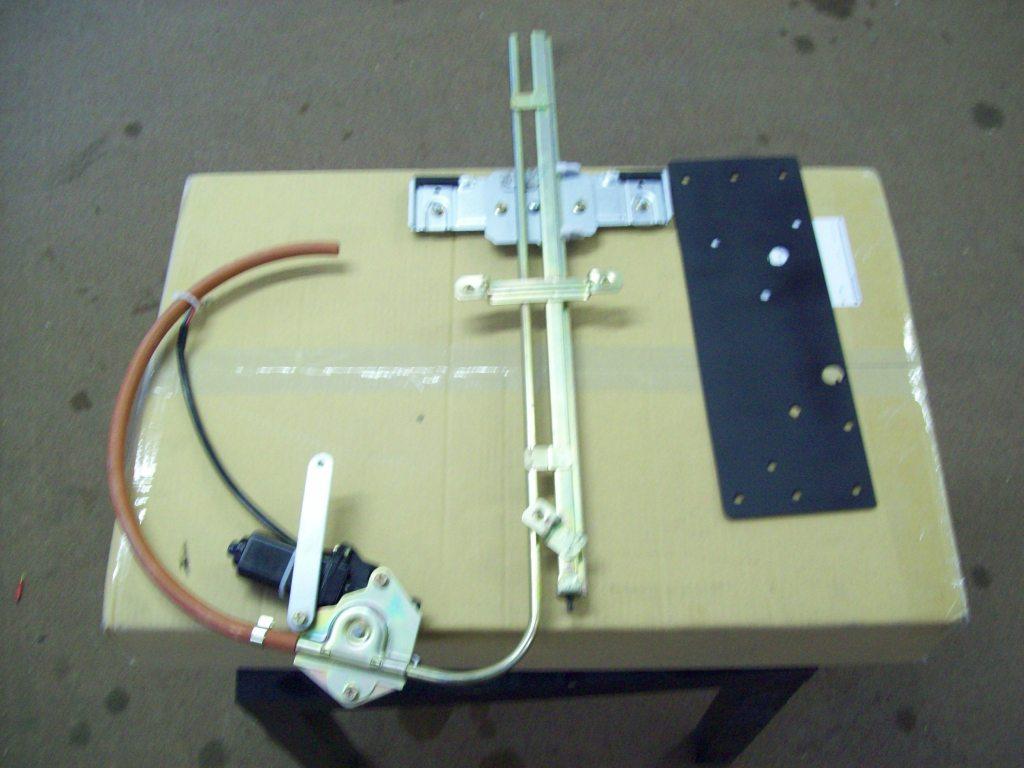

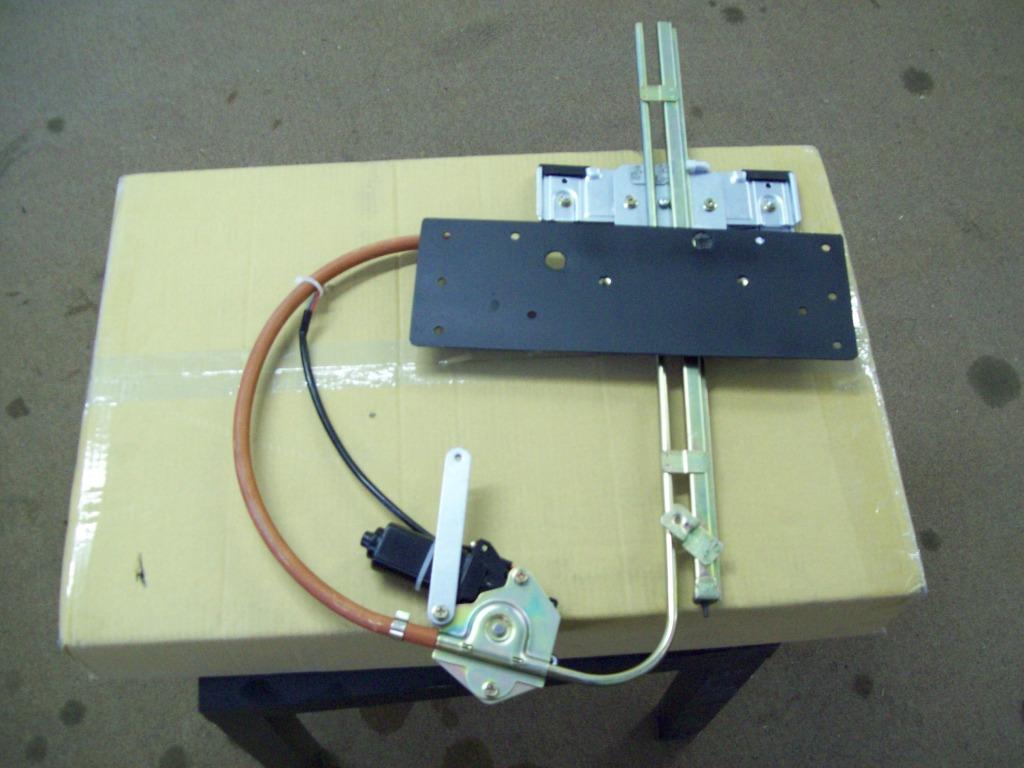

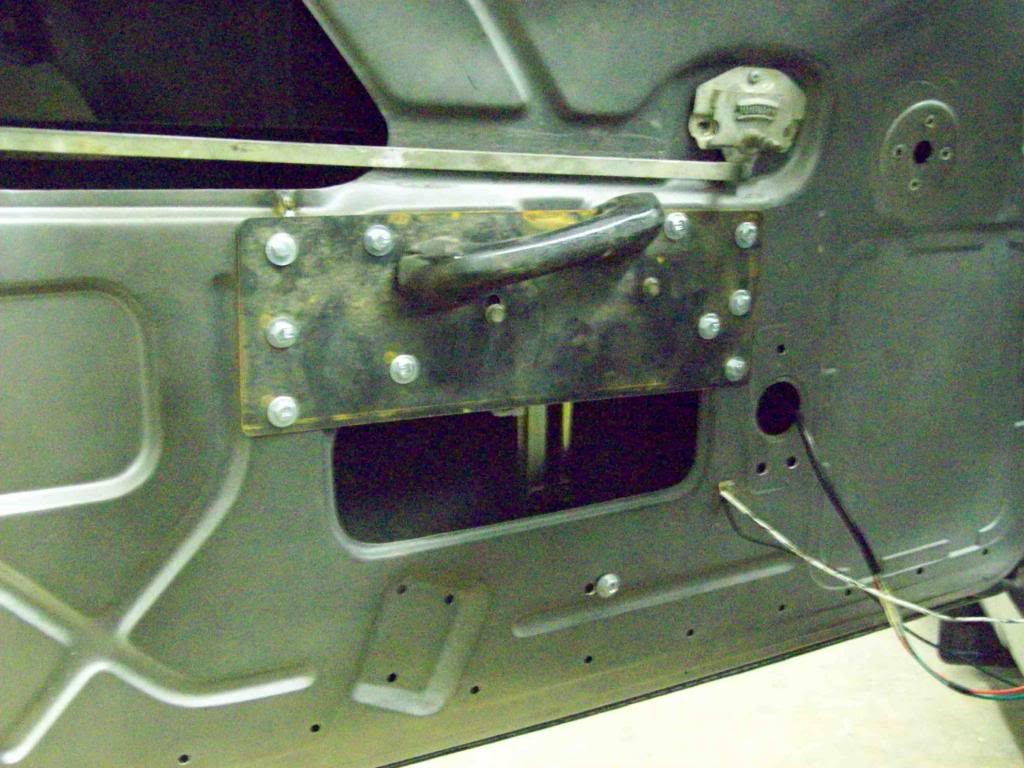

Here are the preliminary pictures of the Power Window Conversion, and I will be posting some pictures of the One Piece Door Glass Conversion also, but that will come just a bit later.. I am waiting on the tempered side glasses to make it in, along with the new channel and belt line weatherstrips to make it in.. The one piece glass conversion is a very easy converion, along with the Power Window Regulator Conversion..

Here are some pics of the power window regulator assembly that I have chosen, because it will fit into the factory inside door opening, and also offers alot of glass support and stabilizing during operation

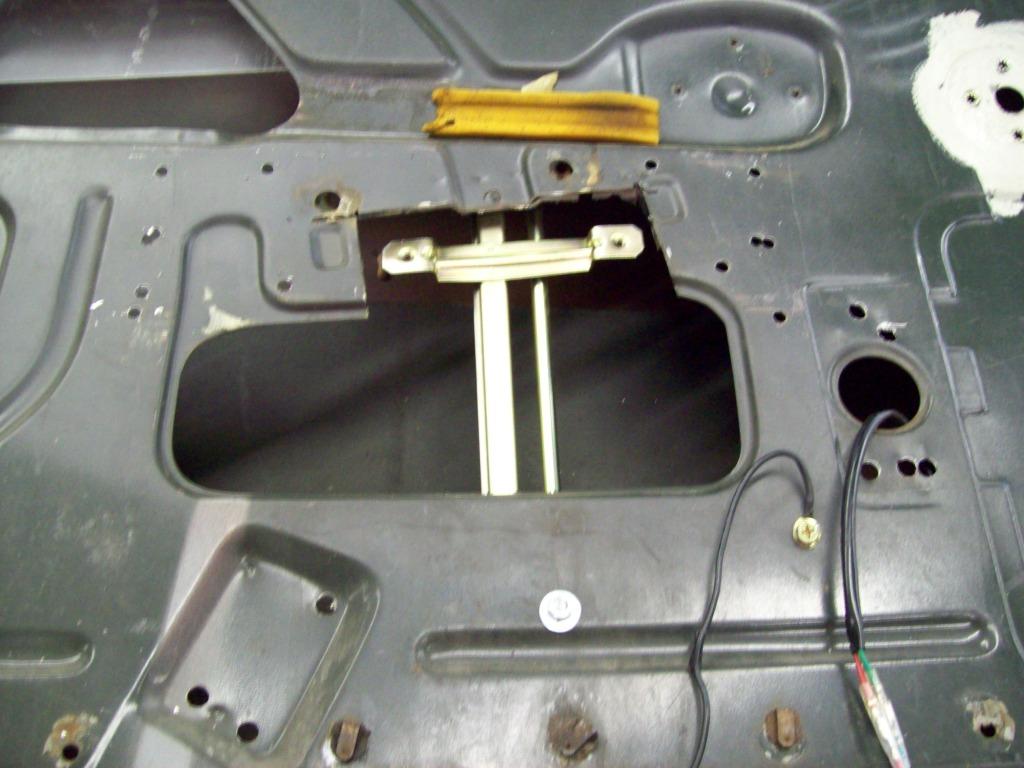

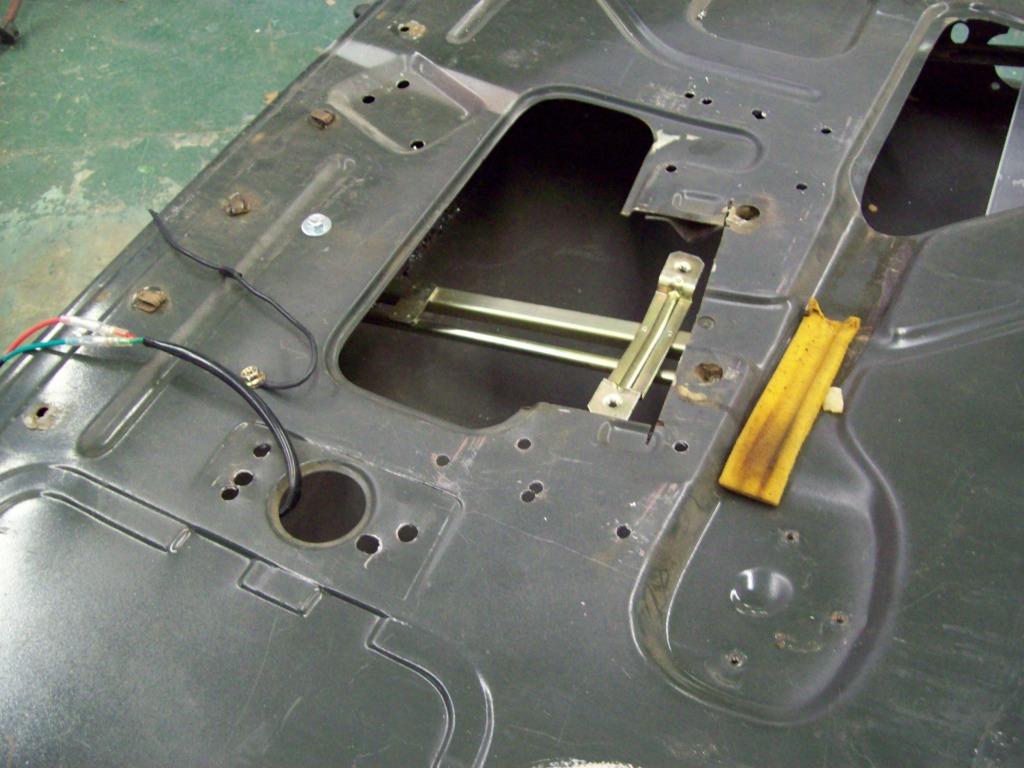

Here is the cut necessary to make the regulator work out to be in the right postion and run angle.. It is a very simple cut, and the supplied regulator mount plate/brace will work as a template for the new brace holes, because it used key reference points on the door to position itself for drilling.

As you can see the original arm rest mounting is not affected, and this new plate actually addes additional rigidity where the arm rest mounts.. The power regulator kit can be used with the original glass and vent window for the guys that like the OEM look.. We will also have a power window switch that actually converts your window crank handle into the power window switches, and works just by bumping the handle up or down.. I am not a big fan of the typical rocker style power window switches and mounting that typically comes with this type of conversion, but our supplied rocker switches are actually compact and pretty nice looking.

I have an idea to modify and brace the IPD air dam, so it would be more of an adjustable splitter.. I am thinking that I will be able to bring it up and behind the bumper a bit, and have the adjustable splitter wing at the bottom of the air dam.. It would have the turn buckle style adjusters, and would extend forward enough to outline the shape of the front bumper.. I hope that make sense, because that is what I have in my head.. LOL

It would be something like these rough pictures below, with more of the finished look of the turn buckles on the last picture.. I will have to cut out the holes that are in the IPD air dam, and put them on the opposite side, so they will be the proper direction to function and brake coolers. I am am not sure on the 2 or 4 adjuster setup, but this will give you an idea of the direction I had in mind to the IPD alterations.

Keep in mind that these pictures are just rough cuts, because I like to get a Cardboard and duct tape look, before I waste too much time fabricating something that I will just throw away.. I dont have the actual height of the air dam set, because I cant do all that until the wheels make it in, so I can set it up for the proper ride height.. I am expecting that it will be less bulky, because it will have to be brought up a bit more into the bumper/body.

11/10/2012

I lowered the car down on the 215/35/18 front tire, and this represents the ballpark ride height, and it appears the air dam might not be that far off.. I might end up going with a slightly larger tire, maybe a 225/35, but I wont know until the wheels get here.. I dont have any wheels that will fit over the 14in brakes at this time, so the suspension is obviously not loaded, but here are a few pictures of the Air Dam at the approximate ride height.

There is a 4.5in ground clearance with the center of the air dam at this ride height, and I think that is a great start for being a rough and adjustable first mounting, so it could work out just fine. That is if the look is worth the effort of course.. It hasnt quite grown on me, but I think I am getting there, it all the cut outs and hardware works out fine.

I am waiting for a few more of the exhaust pieces to make it in, but here is the X-pipe and flexible joint setup I am planning on running.. As I have said earlier, I will be solid mounting the mufflers and tail pipes to eliminate any chance of body rattle, due to the tight tolerances I have set up with the exhuast tips.

I plan running an electric dump setup for an open exhaust option, but I am going to run the dumped exhaust through the same tips, rather than just exit on the ground underneath the car. I think I have the room, and can do it, by adding a custom Y-pipe just before the mufflers, so the unrestricted exhaust can go through the rocker tips, while bypassing the mufflers..

At this time, it appears that this is going to be the bulkiest part of the exhaust, when it comes to running it back, so things should work great with a ground clearance.. This narrow exhaust setup will fit up in the center floor board relief, and shouldnt be more than a half inch below the pinch weld on the rockers, which is the lowest part of the exhaust.

I was messing with air dam mock up a bit, and I think this will look much better.. I have extened the splitter out about 1.5in further than the bumper, and it appears to give it a bit more dimension, rather than just have the appearance of the splitter just beind cut off at the edge of the body. I have also cut out the brake cutouts, and mocked them up on the opposite side.. Once I feel comfortable all this will work, I will add the steel reinforcement to the air dam for its mounting and splitter mounting, along with make it fit the fenders better.. I will not blend/bond this unit into the body, because I want to be able to remove it and service it at anytime.. I also dont want any ground clearance accidents affecting the body of the car, so it will definitly have to be a seperated piece.

11/12/2012

The wheels are getting closer to being completed, so I can finally set this car back on the ground. I dont have any wheels that will fit over the 14in/13in front and rear brakes, so I cant wait to get them in.. You can see the custom logo'ing that is being done, and along with that, the center caps will have the Swedish Ops (Special Builds Division) logo.

After all that is done, they will then be done in a Brushed Aluminum finish and clear coated, for that Unfinished Machine look the rest of the body is going for..

All the cool stuff should start coming in shorlty, so I will have some great update really soon..

11/13/2012

Got a delivery today.. It came fully accessorized and run/PCM tuned, so it is basically turn key at 538 horsepower LS6, so look out.. LOL The standard Swedish Ops (Special Builds Division) car will be a 375 horse LS1, which is more than adequate for the job.

11/16/2012

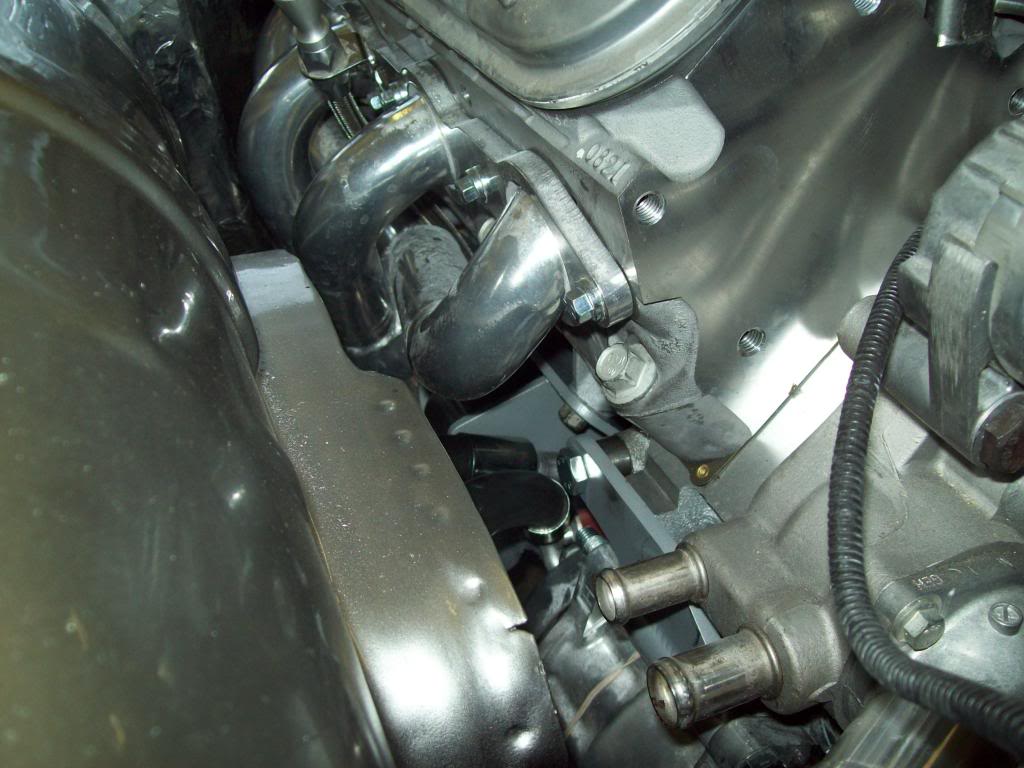

Got a couple of items in today... I recieved the uncoated version of the Swedish Ops/Sanderson LS Conversion Headers, and they came out pretty nice.. They will not be offered in stainless, but will come with a coated option. As you can see, the spark plugs have great access, so maintenance and tune up will be very easy.

Here you will see the final production Swedish Ops/Speedway Engineering Mod-Light 9in rear end assembly. I have the 13 Wilwood brake kit attached to it, and it is complete with an emergency brake set up.

11/17/2012

I tried the production rear end assembly today, and it all looks great. I didnt button everything up tight, because it will have to be removed for powder coating, right after I get all the rest of the car buttoned up.

I have the offset of the wheel about dialed in, and I think the flares are going to work out better than I had hoped.. I havent finished them out yet, because I wanted to make sure they wouldnt need any tweeking for the final production rear end assemblies. These pictures are at a slightly loaded ride height position, sort of like you would have someone sitting in the back seat, or a load in the trunk

The final header tweek looks like they will work out perfectly, so we will begin final production on these also, and they will be alot cleaner looking bare metal or coated header, than what is pictured here. Keep in mind, these headers drop in from the top, after the motor is already installed, so there isnt alot of the typical header installation issues.

Now that these items are dialed in, I can start the firewall kit install and do all the finish welding to the rest of the car, so it should be full steam ahead now.. I cant wait to get the new motor set in, with all the engine bay welded, cleaned, and prepped, because it will finally feel like progress is happening.. There are so many behind the scenes things going on, and now that they are almost at the end, production on all the cars should be a breeze in the future.

11/19/2012

Here are some pics of some of the new motor set in, and with some of the finish welding on the firewall body, and all looks pretty good. I cant get good shots of the headers that will show the clearances, but there is plenty off room.. The passenger side pictures looks like the headers are right on the body, but they arent, and they drop in from the top with no issue. There is plenty of room for engine torque, along with servicing.

You can see that there is plenty of accessory room in the front of the motor, along with plenty of room behind, so you can reach all the bellhousing bolts along with other needs like wire routing.

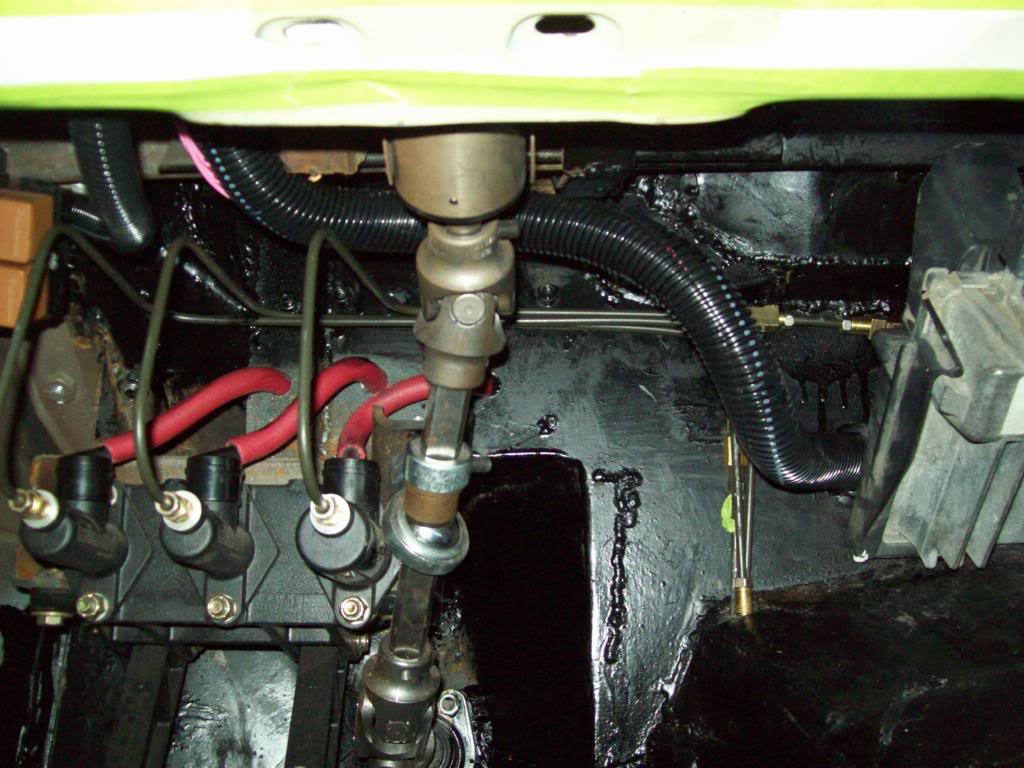

11/20/2012

Here are some pictures of how the steering shaft works with the Swedish Ops headers, and it all lays out quite well.. I still have to mount the firewall bearing/stabilizer, and this actually passes the steering shaft through the firewall, while stabilizing the whole shaft.. This actually keeps you from having to make a huge hole, and then come up with some sort of rubber boot, so it should simplify things greatly. For all of you that might notice there isnt any rubber dampening in the steering shaft, there is an option for that, but I didnt order it yet.

I dont know why I cant get pictures that show the proper cleanances with this camera, but there is plenty of room between the headers, steering shaft, and body, which should be noticed in the various angle pictures.. Also, the motor mount/stands are only the mock up, so they are not very clean. I just wanted to make sure that all was good with accessorie clearance, before I locked in the production models.. The final production headers will not have the welded joint you see pictured, and this kit is only this way, because they wanted to make sure the shape of the pipe was good before locking the tubing jig in place.

You may also notice a pretty tight tolerance between the Altenator and Rack and Pinion, but there is more room than it appears in the pics also.. I am working on a couple of more things to get a bit more clearance, because I like the F-Body/Camaro accessory setup better.. The Corvette setup mounts the Altenator high on the motor, and way over to the side, so it is much more bulky looking at the top.. The torque from forward load on the motor, will actually pull the altenator up and away, while the reverse torque will bring it toward the rack. Luckily there are way more instances for heavy forward engine torque, so I dont think I will have any issue.

I tell you what, Pull Ties are about one of the greatest inventions for mockup, because I can hang and map everything witout any wasted fab work or material. Here are a few pictures of how I see the exhaust system laying out.. I am waiting on some mandrel bent pieces, so I can build it all, but this is where the key components are going to be placed.

I tried to get some pictures that would show how tight it all is, but I am apprently not a photographer, so this is what you get instead. There is clearly not enough room in the floor pan for the exhaust to totally disappear, but it rides high and tight, so there wont be any ground clearance issues. With all the placements pictured, I can get my fingers between the X-pipe and mufflers, and those are the bulkiest pieces.

11/23/2012

I have the offsets of the wheels sorted out, and I should have them real so, and then I can get this car on the ground. I can see where the Wheel Mate tool really comes in handy, because it would have been nothing but a bunch of confusion and guessing, when trying to get proper wheel offset. I have the car set at about ride height at this point, and I think it will look pretty good.. I have about a 6.5in bottom of the rocker ground clearance, and a 6in pinch weld clearance, and I think that will be about what I am looking for.

I need the body guy to show back up to get a bit further on the body work, but I am still going to drive this thing regardless if the bodywork is done, so it wont be a hang up for testing. As soon as the wheels get here, and I finish up on just a couple of more things, it should be ready to move under its own power, but I was hoping most of the body would be sorted first. No time to wait, because I have too many other projects waiting on results, so it might be running down the track in all its multi-color glory.. LOL

11/25/2012

I am really debating on having this guy make the seats and interior panels for Volvo X, because I think Machine/Industrial look would go great with the build style I am trying to achieve, and the workmanship is off the wall. The only questions I have for him at this point is, can he make them a bit more complete looking around the bottom skirting and the side bolsters?

I think these would look great, if there was a bit more dimension to the sides, along with a taller back rest/head rest area.. If the sides were a two panels sort of boxing, that would offer a bit more bulk/dimension to the outer profile of the seat, and would make them look more like a conventional seat body. And if there was some way to make the back taller, and then incorporate some sort of headrest (perhaps Adjustable Headrest), that would put these things over the top, because they would appear to be a more functional seat.

For drivability, there can be some snap on pads like pictured in the first seats, and then for the shows, the pads can be removed.. He also makes some kick ass door/interior panels, along with custom matching consoles.

I really like the skirting on this couch he makes, so I am wondering if he can do something similar to the bottom of the bucket seats, rather than just have them end at the bottom

11/28/2012

Here is a layout of how I see the exhaust working out. Of course I didnt order enough of certain bends that I needed, and had too many of some I didnt, but I atleast had enough to complete one side. I am waiting on the electric exhaust dump to come in, so I can see if I can blend into the system, so it would run the muffled and open exhaust through the same side tips. I would like the option of open exhaust at times, but dont want the exhaust system to look like a complete mess trying to achieve that.. I am thinking I can add the Exhaust Dump Y pipe right before the muffler Inlet, and then add a directional Y just before the tip..

After I get all the exhaust run where and how I want it, I will then determine where the bolted joints will be, that way it can be disassembled/installed easily. Eventhough this is all stainless steel, I will more than likely send it out for some sort of coating..

11/29/2012

Here is my idea for the Intake Setup.. I think that once I get the remaining pieces, so I can run it back to the filter box, it will all tie in nicely. I am need two 30 degree bends so I can cut back to the box in the proper place, but of course I didnt order those. I am trying to make this where it all looks like it isnt out of place, so I have some of the basic runs mimicking the fender angles, so when the hood is open, the Intake Tubes and the Fenders compliment each other. I think that it takes little feature like that, so you have the capability to have something as an uncommon option, but it appears that it was made for it.. It is these little features that go un-noticed in the day to day, but makes it apparent when someone is using cookie cutter items that are one size fits all.

I had to split two 90 degree pieces to make my Y section (I guess it would actually be a T), and that turned out to be a bit more complicated than I had thought, because I had to factor in the angle of the outlets from the Y section before they were cut. I did my best with the tools that I had, but I think it came out pretty damn good.

Now that the Y (or T) is done, I was able to lay out the rest of the angles, and cut the material I needed off the ends of the bends, to get the overall curves to fall where I needed them. It took a bit of trial and error, but as long as you cut off a little at a time, you are pretty safe.

11/30/2012

Well it is just my luck.. It looks like I am going to have to re-configure the Air Filter Box, because isnt right in appearance/shape for the intake tubes I have made up. When I did this air filter box, I used the OEM heater flange that connects to the cowl vent because I thought I wanted a factory configuration, but the factory offset is way to far off for what I need to look right.. I will still use the flange, but I will have to build some sort of new box that will center it all out, and will allow my new intake tubes to attach efficiently.. It is much easier to build a new box, than try to configure a secondary intake runner setup, especially when I am just using a Chop Saw and a 4.5in angle grinder to get all this set up right. I am beginning to think that I need to get a bit of new equipment, and learn how to use it, but I dont have the time right now.

I have done my best to make the Intake Runners flow with the body contours of the fenders, that way everything looks complimentary when the hood is open.. I think this is about a close as I am going to be able to get it, and I wish the need for correct proportions and contours didnt bother me so much, because it would have made this task alot easier. This whole intake unit will be mounted directly to the top of the motor with some nice and hidden mounts, so it should all be very stable and flow well.

12/1/2012

Well I think I got the Air Filter Box set up the way I want it, and it seems to fit the body great.. It will have either one air filter, or individual filters per tube, but I am not sure yet.. Now that I have the body of the air box done, I can take it to my local parts store to see that filters will work, so I can make the baffles and resting points.

I did my best to make this thing fit the body of the Amazon, so much so, that I actually used curves and contours from the parts off the car.. I normally like to use already existing contours, because you would be surprised how out of place things can appear if you are just slapping foriegn features to the body. I made air box mimic the cowl left to right curve, and also added a compound duplicate curve to the side, so I think it really completes the firewall nicely.. Infact, you can see that the air box rest in the heater box relief of the Amazon pretty nicely.

The next thing I have to do after I locate air filters, is to figure out a good looking mounting feature for it.. I plan on hard mounting the full assebly to the motor, and then have a boot/gasket that makes the sealed connection to the firewall, sort of like the Trans Am shaker hood mount gaskets. I am not sure if I want to make some sort of closed/solid sides for the inside of the unit, run some straight machined leg style mounts, or build some sort of erector bridge sort of mounting on the side.. I am guessing that I am going to have to stare at this thing a bit, and then deal with that aspect just a bit later.

Also, I have not trimmed the bottom of the box yet, so it might appear to sit a bit low.. I was waiting until I find out what filters I can run, so I can then determine the depth of the box. I plan on making the filters load from the bottom of the box, so any seams and hardware will be hidden. I dont think I will have any problems making the bottom look satisfactory and functional, after all , it is on on the bottom.

Here is a bit of the work it took to get this, and I am sure it wont do alot of you any good, because this is a one off piece for this car, but there still might be something to share.. This was all made with the 4in angle grinder, and some basic tools..

12/6/2012

I have been struggling trying to find a valve cover setup I liked, and there really arent too many options for the LS motor, other than some Fabricated/Welded Covers and a few various other styles.. I kind of like the old 327 Corvette finned valve covers, so I thought I might like these, because they would fit the era of the car, but I am not sure about them yet.. In order to use them, I am going to have to work out some of the poor cast finish grinding marks, and they are just a bit bulkier than I wanted..

I ordered them in the Cast form, because I didnt want any polished parts under the hood or painted parts, because I am going for a natural metal finish look. The polished version might be a bit cleaner in the finish work, so that might be the way to go for others that like this style.

I have the machine shop working on a throttle body attachement collar for the intake tubes, and this collar will be welded onto the Y tube, so I can get rid of the rubber boot and clamp system that is typical here. The collar will have an internal double O-Ring set up that will seal the joint between the throttle body and intake tube.. The whole assembly is hard mounted to the top of the motor, so there wont be any virbration or engine torque forgiviness needed for the O-ring joint.

Here is something I am working on for a template, and I am sure there will be alot of people that will object to this look, but I als dont know how I feel about it yet, because I still think it needs something... I cant seem to find a decent intake cover for the plastic intake, and I am not real big on some of the aftermarket replacement intakes, because they are really just a bulkier version of the original.. It couldlbe painted, or even add a carbon fiber touch, but that isnt really what I am looking for..

I made this intake cover as a starter, and I think there are several options for it, but it still seems a bit plain or off.. I was thinking about having the intake cover painted body color, while having the intake tubes powder coated in an Aluminum look coating? I could also use the center of the intake cover for some sort of Air Brush logo'ing or badging? I could potentially add some fins that would blend into the valve covers? Not sure yet, because this is just a starter.. I think it has some potential, mainly because it will hide all the injector B.S., along with a bit of wiring and accelerator cable.

I still have to bring the Filter Box down into the center section, so the rearward part of the cover/filter box isnt completed. The air filter box will more than likely come down to meet the intake cover just behind the valve covers, and this will tie in, and curver around the back..

I couldnt stand it anymore, and didnt want to come to the shop tomorrow with a plain situation, so I made some fins up real quick.. I think this might be the ticket, but it will need just a bit of refining. I will make a better close out front panel later, and it will follow the contour of the front engine assembly/intake, which I think will compete the custom fit better..

The fins can be made real easily by stacking flat bar, and tack welding them together on the bench.. Just stand one up, lay one down, stand one up, lay one down, until you get the fin count you want..

12/8/2012