You must be logged in to rate content!

31 minute(s) of a 66 minute read

12-31-2020

Project: Cheerio..Yum Yum

Compliments of joezeeuw @ michiganvw.org

The story goes like this:

About a year and half or so ago I owned a little mk3 gti and I was happy. Then I just happened to stuble across a car in the VWVortex classifieds. At that moment everything changed. Suddenly, I could care less about my mk3 and all I could think about was this car. Within days I already had a pretty good idea what direction I would take it and was close to finalizing a plan to purchase the car and have it shipped from southern California.

This is that car:

I made some cosmetic modifications and today it looks something like this:

However, the engine has remained untouched:

From the very start I knew I wanted some sort of carb setup. Soon I had decided on a 16v and began tracking down the necissary parts. Original plans spiraled out of control until I had planned such an all out race motor that it would be undriveable and most of all compltely out of my price range. I eventually decided I wanted something that was fun, yet reliable and would be useable both on the track and cruising around town. I had a 1.8L 16v that was in need of a rebuild. I priced what it would cost to get it up to snuff with some slight performance tweaking. Then I discovered that for less than the parts alone would cost I could have a brand new, factory relliable, 2.0L ABF 16v long block. For those who don't know the ABF is the last evolution of the 16v installed in european mk3's. There are many minor differences from the US spec PL and 9A but basically it's a taller ABA style block with a better flowing head. They were factory rated at 150 bhp. Apparently VW actually tweaked the power down to 150 via the ECU so as to not compete with the VR6. People have been able to get 170+hp out of them with some simple, bolt on modifiactions.

To me, the choice was simple. 170 factory reliable horsepower already assembled? Hell yes.

So I ordered one up and it arrived today.

I threw it on the stand and bolted up some of my goodies I've been collecting.

Looking at the above pic it may appear as though it's ready to slap in, but getting it all to work together is going to take quite a bit of time and fabrication. But I hope to have it all together and tuned by the track day in the spring.

10/3

OK so the plan is to get everything all fitted into the car first, then disassemble it, make everything look good and then re-assemble. I've been playing a little trial and error trying to figure out a belt and pulley system for this thing. I've got a combination that puts the alternator and crank pretty much in line, but the water pump pulley isn't quite right.

Anyone know if there is a pulley that has a deeper "hat" than this and what model I can find it on? Or do I need to change the other two to match the WP?

I've also been trying to save some money on parts by fabricating my own. When running a 16v on carbs you need a fancy expensive water neck to clear the carb setup. I attempted to make my own, this allowed me to make the nipple on the bottom a little longer to compensate for the slightly taller block. My welding isn't the prettiest.

I also made a block off plate with a port for the breather system. Here's all my progress so far. Notice the highly modified accessory bracket. Might look a little haggard right now but I intend to get it all cleaned up and nice looking once it's all finalized.

10/7

Update: Still trying to source the necissary brackets and pulleys. In the meantime I've been working on my crankcase evacuation system. When running carbs it's difficult to tap into manifold vacume since there is basically nothing pre-throttle plate and tapping into the manifold after would throw everything off. Most people just run a line from the crankcase to a filter or catch can. With the many advantages of actual crankcase evacuation I started looking into other options. The pimpest would be to run a dry sump oil system, but that's $$. I ended up deciding to borrow some old school technology from drag racers. It might work it might not, we'll see. Here's how it (hopefully) will work:

I just have to weld this little guy into my header.

the exhaust gasses passing by will draw my crankcase gasses out of the block. Simple enough. To prevent sucking too much oil into the exhaust I made this little separator/catch can.

I put a little baffle in it to hopefully get the oil to collect.

Think it'll work? Oh and sorry environment.

Motor comes out after chili fest.

11/5

Update:

Motor is out

The dirty bay

power washed it and removed the battery tray and other unecissary brackets. Notice the lack of a brake booster.

Got everything out of the cockpit so it doesn't get burned from all the welding and such that will be taking place

Just need to get a tubing bender so I can reroute one of the fuel lines, the other will be removed. I've got pretty much all the parts I need for the motor so I'll be putting that in soon so I can start test fitting everything.

11/13

I set the motor in the car and began addressing some of the obstacles.

The first was that the header I have was made for a regular PL or 9A 16v. The engine I'm using basically is an aba bottom end which means it's something like 16mm taller. Initial test fitting revealed this difference caused the header to interfere with a bracket holding the steering rack.

My solution was a combination of grinding down the bracket as much as safely possible, and shimming the rear motor mount to pivot the motor to the rear a little.

The modified bracket:

The amount of clearance after the modifications:

There's a good chance I'll end up with a little rattle on decel but I'm hoping the Techtonics race mounts will keep engine movement to a minimum.

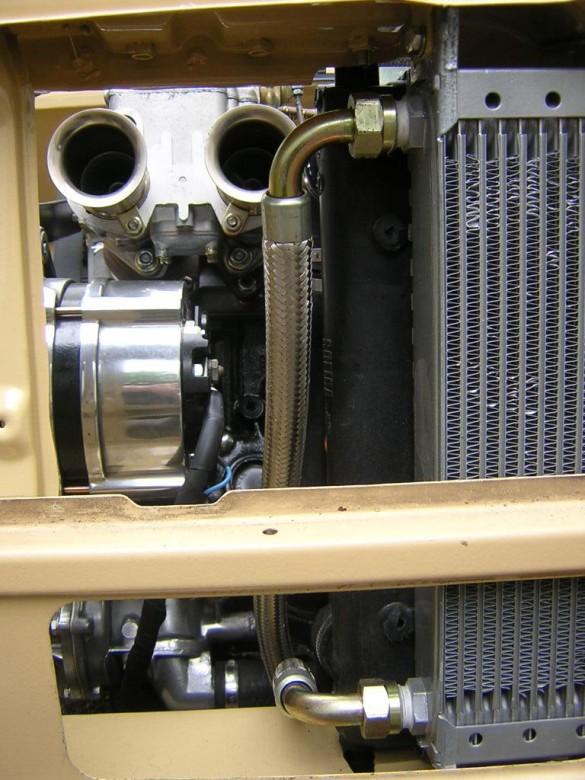

Next up is the upper radiator hose:

It's not all that visible in the picture but it is touching the #2 stack. I'm thinking I'll have to move the radiator as far forward as possible, get shorter stacks, and/or a hose with a super tight bend. I'm going to do some research first before I start hacking up the core support.

Other than that I had fun putting some parts on and seeing how it will all work together.

Plenty more little obstacles to keep me busy for awhile.

Until next time.

11/18

So I ended up deciding to just slightly notch out the rad support and angle the offending end of the radiator forward a bit. I would have liked to move the whole thing forward but the radiator cap would interfere. The radiator being on an angle bugs me a little but I think if I fabricate a nice little sheet metal cover it will look nice.

Then I started experimenting with hoses. I made this one with a metal section which looks pretty cool but would interfere with the air filters.

I found a hose with a nice tight angle to it. I think something to this effect will work best. It barely clears my old school filters.

The nice thing is that I didn't severely modify anything or spend hundreds of dollars so I can switch it up later if necessary.

1/8

Finally I'm back to work on the car.

Huge thanks to Drew for helping me gut my bathroom down to the studs and rebuild it into a down right respectable room.

After a few trips to the local parts stores I found some hose sections that fit properly. I'm going to be looking into some more discreet clamps.

I made some block off plates for the reverse switch and rear coolant flange. Yes, after much debate I am blocking that coolant outlet. I'd like to hear everyones feedback on this.

I managed to fit an electric fan in front of the radiator. This one required some custom brackets but it was worth it to get such a large fan to fit.

As for the crankcase ventilation system I explained earlier it looks like this:

Hose comes from the blockoff plate and to the driver's side inner fender

Over to the collector.

And down to the header collector where the vacume is generated.

And that pretty much completed the fitments stage so out came the motor.

Now many of the engine and it's related parts will be getting some sand blasting and painting/powdercoating.

Meanwhile I need to remove all the body sealer before the shell is sent to the sandblaster.

I'm currently looking into some body shops around town. Right now I'm liking Star Collision/Star Customs on Plainfield. Anyone had any experience with them? Other suggestions for a quality shop willing to take on some custom work?

2/3

Lil update here:

Removing the body sealer was hard work...

Luckily I had help from Steve

Once I had that all stripped I sandblasted the whole bay. Big thanks to Bill D. for the equipment hookup. With all that metal exposed I immediately got it over to Star Collision. This is what they had done as of Friday afternoon. So far they have been really great about communicating and making sure it turns out exactly as I want it.

I've been busy smoothing, polishing, planning all the various engine components. I gutted the trans, smoothed all the casting flash, and sandblasted it. It will soon be powdercoated, quaifed and re-assembled.

2/20

Body work in the engine bay is done.

Big fat counter-rotating props to Steve and the crew at Star Customs. The communication was excellent thought the project which was completed in less than a week and a half and most importantly the quality of work was top notch. Here is a little montage:

Before:

After:

The engine is coming together nicely as well but I'm not quite ready to show pictures of that.

4/2

Sorry it's been so long since I updated the thread. I've been plugging away here and there, sourcing odds and ends. I got the Quaife back fully rebuilt. Then I set out to get the trans assembled. Big thanks to my boss Dan'l for helping me out with questions. I had the case powder coated. It was supposed to be a wrinkle finish but ended up just sort of textured. I was a little bummed about that but I think it turned out pretty good.

All new bearings and synchro rings

All assembled with a few extra touches to set it apart from the run of the mill silver spray paint.

The brown was matched to the color of my interior in case you were wondering.

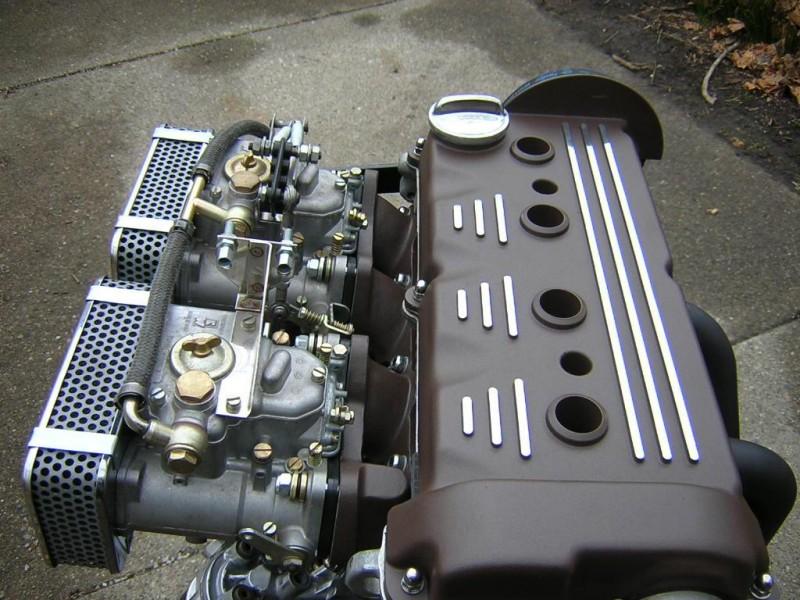

And here's the engine. it's pretty much as it was in the previous pictures. Just a little paint, powder, and polish.

There is still quite a bit of work to be done in the bay before it can all be dropped in. Ed "booger_4kq" came over and helped get through a lot of it. We got the air box mounted, accelerator pedal modified and installed, and we got the brake setup finalized.

Here is the finished product (less paint). I made a little spacer to bring the master cylinder away from the pivot point of the actuator rod. Then we fabbed a new, longer pushrod, and got the brake light switch fitted.

The rolling stock will be receiving some changes. This is version 3.0 for the RS's. New stuff this year includes .5" wider lips, chromed bolts, and polished center caps. I still have to polish the other three caps but this one keeps me motivated through the tedious work.

And here are the gauges I'll be running (VDO of course). I made the little bezel which fits into the center vent hole so I can still have my 8-track player ;D

Thanks to everyone who has helped thus far and your questions and comments are encouraged.

Till next time....

4/16

Got the fuel system all set up. Mounted in the factory fuel pump location is a Carter 4070 fuel pump. It's internally regulated and requires no return line. ThumbUp

Normally a mk1 fuel filter is in the engine bay but I wasn't having that. So I made a little bracket and mounted it where the fuel accumulator used to go.

I tore the rack completely down. cleaned, lubed, and painted it then put on some fresh tie rods and boots.

Got the brake setup all mounted and bent up some stainless steel brake lines

Here you can see the fuel feed line as well. I welded the little metal tabs on the left in there before the body work for that OEM look.

Then Ed came over last night and we got quite a bit done.

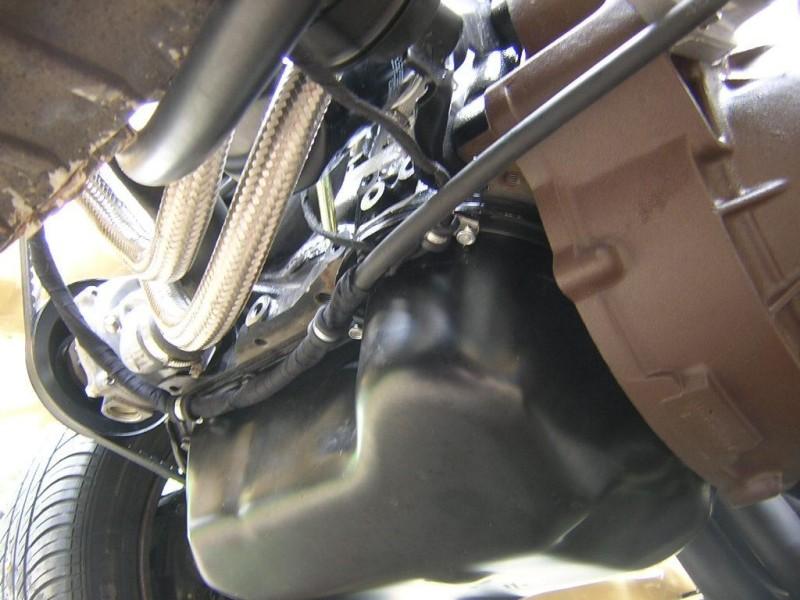

Here is the engine and trans all assembled. I forgot to picture the lightened flywheel and Sachs clutch but the are in there.

We slid it under the car just as you see it and lowered the car down onto it. The whole thing went great and there were no accidental scratches of any kind. :clap:

It looks quite warm and cozy there in it's new home I think.

Ed agrees

It may look like it's almost ready to run but there is still quite a lot of work to be done including fabricating the entire wire harness forward of the firewall. But the list is slowly shrinking and I'm happy with the progress so far. Thanks for the help Ed.

5/7

Been making steady progress on the car. The engine is mechanically ready to go, just needs fluids. Yesterday Ed and I worked a solid 10 hours on it and we got quite a bit done.

First off all let me say thanks to Ed Mealoy for all his help lately. If this car makes it to Motorstadt it will be because of his hard work and enthusiasm.

On with the pics!

One of the main projects for me yesterday was finishing up the plug wires. It's been something I've been working on since the start of the project and they are finally done. They are actually modified blue ignitors with a custom sleeve.

While I was putting the finishing touches on the engine Ed went to work sorting out some wiring.

This man loves a good current track wiring diagram

Battery in the trunk mounted in a cheap POS battery box that I wish I never bought

At the end of the day we had wire harnesses made for the entire front half of the car. Now we just need to run them, put ends on them, then pull them out, wrap them, and final install.

So barring any catastrophic screwups there is a good chance I might be able to debut this thing at Motorstadt. Which makes me happy.

Hopefully the next update will include video of it running.

5/14

Yes it was another sucessful Saturday for Ed and I. Here's a little pictoral of where we are at so far.

Here's the exhaust, same setup as last year only I added the flex pipe and bends to mate up to the new header.

We wrapped all the harnesses in OEM Mercedes wire loom tape.

Ran two harnesses up along the fender here

And one off the rear of the motor

Pics of the completed wiring....

Ed's "office"

Coil wire goes into the firewall... (note: dist wires seen are temporary)

And over to the "Ignition command center" as I've dubbed it. I made the bracket so the controls on the ignition module will be easily accessible through the back of the glove box

After sorting out a couple silly and totally expected mistakes we got it running around 11:00 last night. It's loud as funk but runs quite well even with the carbs just baseline setup.

Still allot to do before Motorstadt but it's nice to know it will at least run.

Thanks again to Ed for his help and to Stephanie for allowing me to spend my Saturday working on it.

5/29

We took it for it's first drive tonight. Still allot to sort through. Only problems were the shifter needing alignment, and a leaking E-bay rebuilt distributor. Oh and the exhaust is insanity loud. There's no way I'm going to make it to the east side with my eardrums intact. Something will have to be done. No more side-exit exhaust I'm afaraid. Here are the only pictures I took all weekend. Sorry for the crappy update.

6/6

So I added another glasspack to the exhaust and did a lil side dump. It's more quiet at idle but as soon as you get on the gas it a loud, raspy bitch. I'll probably have to go to some sort of chambered muffler but this will have to do for now.

Spent all day Sunday on the wheels. Polishing the center caps and torquing down all 120 bolts. Somehow I misplaced 3 of the nuts but the BBS whore himself came through and helped me out, thanks Matt. Then today Ed mounted and balanced the tires on Betten's sweet new tire equipment, thanks Ed. And finally, they are on the car.

Motorstadt is still a big question mark at this point. I plan to give it a good shakedown in the next couple days here. Hopefully all goes well.

9/8

The car has been performing well over the summer. I've been having fun working out the small bugs as I go.

A fresh interior is now in the works. Pictured below is the original back seat of the car. The seats will be retrimmed with the large swatch in the centers and brown vinyl on the sides/bolsters. I tried to match up the original material and that is as close as I could get. They just don't make patterns that cool anymore.

The work is being done by Buckskinz here in GR.

10/19

So I got an uplifting PM from a Texer today. The guys name is Jeff Bynum. He and his dad have built some of the nicest dubs out there and he has had two PVW features that I'm aware of. At H2O he unveild his new creation, a mk1 jetta coupe.

Anyhoo, I ran into him at the show and shook his hand. I thoght that was cool, didn't think anything of it. Here's the message he sent:

12:52 AM 10-19-2006) Jeffrey B: Joe,

Just wanted to drop you a line and let you know that your car was one of the primary inspirations for building my Jetta Coupe, and I have really admired it. I also wanted to apoligize for being preoccupied (rude) on Saturday at H20. I didn't even realize who you were until after I got home and saw a picture of you driving your car (in C2motorsports vortex thread about A1 Jettas). I feel like such an ass. I wish I had shot the breeze with you about your car.... I think your engine bay is *t*i*t*s! Kinda like your taste in wheels too

Anyway, just wanted to say you have a mad nice car, and hopefuly I'll see you at another show, and can makeup for me being rude....

Jeff Bynum

As for the car the seats are done and in and they look great. It's also got a new drop in the form of some H&R ultra-ultra low coilovers. Finally, the stance I wanted. Oh, and I got a new sticker +5hp!

No pictures yet, you'll have to come and see it at Chilifest.

4/1

Well my initial plans of running in the track day ended up being shot down both by the lack of time and money as well as a wedding I had forgotten about. Oh well, next year.

I did go out to check on the car where I had it stored under a tarp. The moisture trapped under there was not kind to the car at all. Body looks good but under the hood and on the suspension it seems everything that wasn't 100% protected developed surface corrosion. This includes all the polished alluminum stuff. Basically all the acessories are going to have to come off the engine for re-polishing and touching up areas with rust. Age is a bitch. It sucks to see something that was once so fresh and clean slowly deteriorate. Anyway, with Stevo's car taking up so much time and me being somewhat busy with the pickup I really can't give this thing the attention it requires. So I'm moving it to some indoor storage indefinatly. Which could be a week, could be months. We'll see.

Brand new H&R coils rusty??

On a more positive note I did try out a new tire setup. In the world of 15" wheels the lowest profile tire available in the US was a 195/45. Recently people have been importing a smaller size 165/45. It's all the rage at the moment with the stretch crowd so I ordered one up too see if it would work.

Obviously, a 165 tread is wayy too small for a 7.5" wheel but it's a asthetic trend.

After mounting this one I was thinking nahh it's just too ridiculous. Then I saw this picture and hope was restored:

However, after putting it on the car I think I'll pass for now. For it to look right the car would have to be much lower and the wheels spaced out a bunch. I think I'll keep the tire but not on this car this year.

7/1

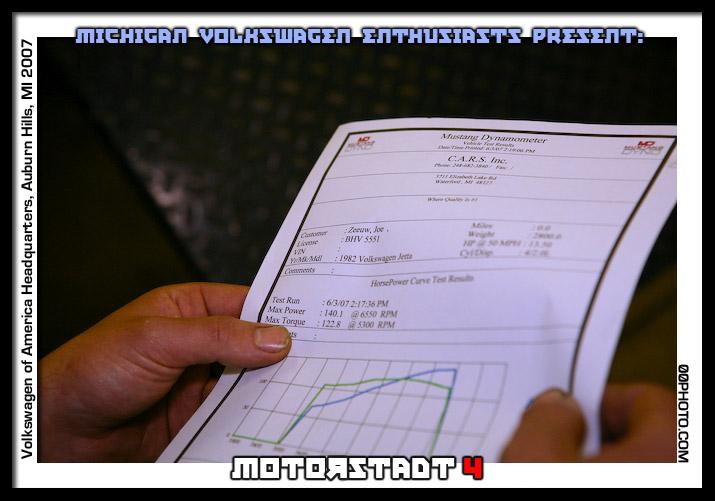

A little update on what's new. The dyno run went really well. Car put down 140whp and 122 wtq. I was psyched.

Matt's bro took some video:

The second one is my fav. and just happened to be the best pull.

One area the car was definatly lacking was braking. The stock solid rotors and spongy brake lines were long overdue to be replaced.

I went with some vented cross drilled Zimmermans and PBR ultra ceramic pads mainly because I got a killer deal through work. Added some stainless brake lines and some fresh fluid and we were all set.

I noticed a major improvement in braking and pedal feel. I can drive much more confidently now. Which of course lends itself to higher speeds

On the cosmetic front my long awaited clear turns finally arrived from Germany. These are hard to get ahold of even in europe. Thankfully a nice guy I met on the Vortex who lives in Germany helped buy them and get them to me. You don't even want to know what I ended up paying but I think they look very good. The headlamp and turn now have a much more one piece appearance. Perhaps some silver bulbs are what I need to complete the package.

After:

Almost ready for H2O! Cant wait.

8/14

Anyway, here is the whoring as requested.

Matt, we will be taking the truck so we can bring our bikes.

Mac-whoa

10/28

The car officially left yesterday. It was tons of fun and I will miss it.

Love these builds !

Posted by Diggymart on 1/2/20 @ 3:09:32 AM