You must be logged in to rate content!

4 minute(s) of a 312 minute read

1-28-2011

Well, it appears that I dont have any leaks in the trunk area. I did some more testing tonight and everything seems to be holding well. I am on to getting my hydra setup with an output to feed into the fuel pump controller. I have an email into Phil to find out what pin I need to access the INJ8 output. I will post more info on that soon.

1-30-2011

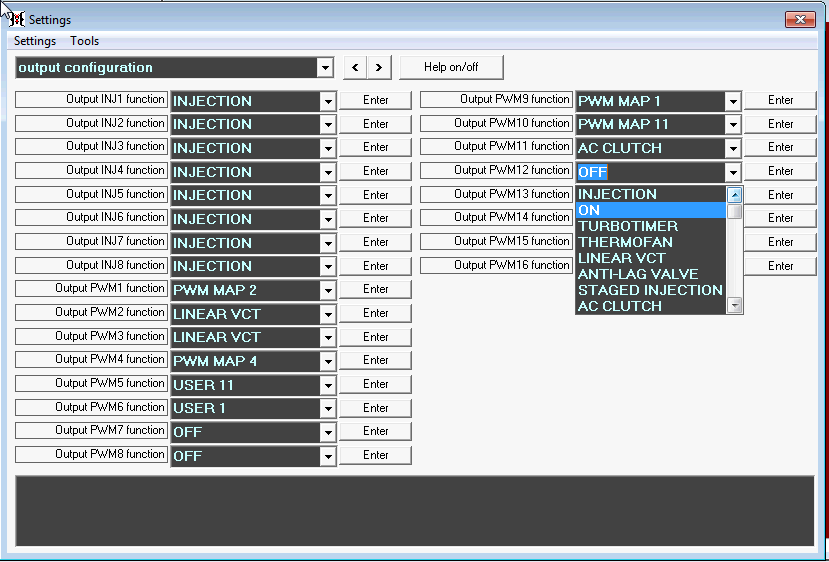

So let me tell you a sad story. I have been going over the XLS doc from the Hydra EMS website for several days and was not having any luck finding the INJ8 pin. My method for finding the correct pin was to set my multimeter to read resistance (Ohms) and hook up one lead to the chassis (ground) and the other lead to a wire inserted into the spot on the Hydra harness that I thought was connected to the correct pin. I would then open up the Hydra software and go to "Settings 1" and then to "Output Configuration". I used the interface in the Output Configuration to flip the output function for one of the pins between on and off. I was expecting the meter to beep and show a reading indicating that the pin was grounded while the output setting was configured as "On". UNFORTUNATELY AFTER THREE DAYS OF PULLING MY HAIR OUT I FIGURED OUT THAT MY DAMN METER IS BROKEN!!! In the end I discovered that I had the pin I needed on the VERY FIRST attempt. F***!

Moving on...

After calming down a bit (I was really upset at that meter) I settled on using the PWM12G output instead of INJ8 like I was originally planning on doing (no real reason, thats just the one I used). I also decided to use the "USER5" user definable logic (single variable triggers it) to control the output. PWM12 is a ground based output meaning that when the condition is true it grounds the pin out (other outputs are positive based). By the way, PWM12 is connected to the A11 pin on the small blue connector.

After verifying that A11 was in fact the correct pin (I used a spare meter and the method described above) I wired up the "override" input on the Aeromotive fuel pump controller. I then disconnected the fuel pump from the controller so I could do a quick test to see if the hydra could command the controller to go to full blast. With the car powered up but not running (no motor in the engine bay) I manually switched the output function on PWM12 from off to on which made the "override" LED light up on the controller. Thinking that it was a complete success I decided to try a full test.

I reconnected the power to the A1000 and placed its output hose (a -10 fuel line) deep into a empty gas can. I powered up the car and proceeded to flip flop the PWM12 output from on to off. Unfortunately the fuel pump controller was not working correctly. The "override" LED would light up when it should but the controller would not actually go into full blast mode. I decided to try a quick test by manually shorting the controller's override pin to the controllers ground source and it instantly went into full blast mode. The issue was clear, the ground source from the Hydra was not strong enough to actually activate the controller.

To fix the issue I installed a small DPDT relay that activates using the PWM12 output. When activated, the relay shorts out the controllers ground source and the override pin and the results were perfect! I then setup the USER5 logic control to monitor boost pressure and activate PWM12 when boost pressure was over 3PSI.

Nice!

Posted by Diggymart on 2/4/20 @ 8:31:02 PM