You must be logged in to rate content!

4 minute(s) of a 312 minute read

3-26-2011

No offense taken. You are in fact seeing an optical illusion, every singe piece of pipe is the exact same size with the only exception being the one on the hot side. The hot side pipe starts out at an identical size to the ID of the turbo outlet, runs for a short bit and necks up to the size of the APS FMIC pipes (2.75" OD).

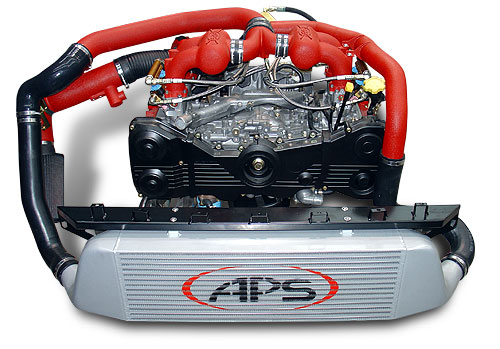

For reference, here's a pict of the APS FMIC system (from their website):

We only modified two pipes, the hot side pipe form the turbo to the first silicone piece and the cold side pipe which was previously the hot side pipe. We totally replaced the original APS cold side pipe because APS used larger sized pipe on that piece and we didnt want the size to bounce around (similar to what you are saying would be an issue). Beyond those two pipes we didnt touch a thing on the APS kit.

To make the cold side pipe (the original APS hot side pipe) we cut the original pipe just after the rear (nearest to the firewall) hanger so that we could re-clock the pipe in a way that allowed it to line up with the TB.

3-29-2011

Since its been a few days I figured that I would post a quick update. My old exhaust consisted of a Cobb muffler and a TurboXS 4" downpipe with a 100% custom (fabbed by me) mid pipe. Since my mid pipe was extra long so that it could go from the TXS shorty down pipe to the muffler with a single piece of pipe it was going to need cut and welded to fit the standard sized Moore down pipe. Yesterday I cut the mid pipe to fit the standard location flange on the Moore kit, welded the flange back on the mid pipe and call it a day.

Now that the exhaust is finished I think its fair to say that things are pretty much winding down on this build. I decided to email Phil from Element Tuning today so that I could get my tuning appointment scheduled for the morning of Thursday April 28th. Its always a good feeling when you have an exact date when things are going to be back up and running.

I am still missing a few small items needed to finish the car but once I have all my parts things are going to go really fast. I really only have one easy weekend worth of work and I should be ready to go.

At this point, I am pretty much looking at this list:

Final install of the turbo (oil feed and return have not been hooked up yet)

Install the Moore Performance Intake (as soon as it shows up)

Install the new pipes and reassemble the FMIC (as soon as they show up)

Install the front bumper

Bolt up the power steering pump (waiting on the intake)

Plumb the meth jets

Plumb up the boost control system

Install the Oil cooler

Configure the hydra for the new setup (WBO2, TPS and initial map for startup)

Prime the oil system (the oil cooler and turbo both need a bit of TLC before startup)

Initial startup (idle tuning)

Light cruse testing on the road (basic driveability)

So far I am extremely pleased with everything except the hose I used for the fuel system. I was told by JEGS to purchase a "special" lined hose by Earls that would supposedly keep most of the gasoline fumes inside and unfortunately it does not do a very good job at all. After I get the car tuned I think I will swap at least the line in the back of the car with PTFE teflon fuel line. This will minimally keep the fumes out of the car and which would be a major improvement.

Nice!

Posted by Diggymart on 2/4/20 @ 8:31:02 PM