You must be logged in to rate content!

7 minute(s) of a 190 minute read

4-24-2013

Oops!!! Took apart a buddies motor thus weekend. He said when it died, it died.

one rod had beaten so much stuff that it looked worse than those rods from the west coast Tuning fiasco.

4/26/2013

Finally ---

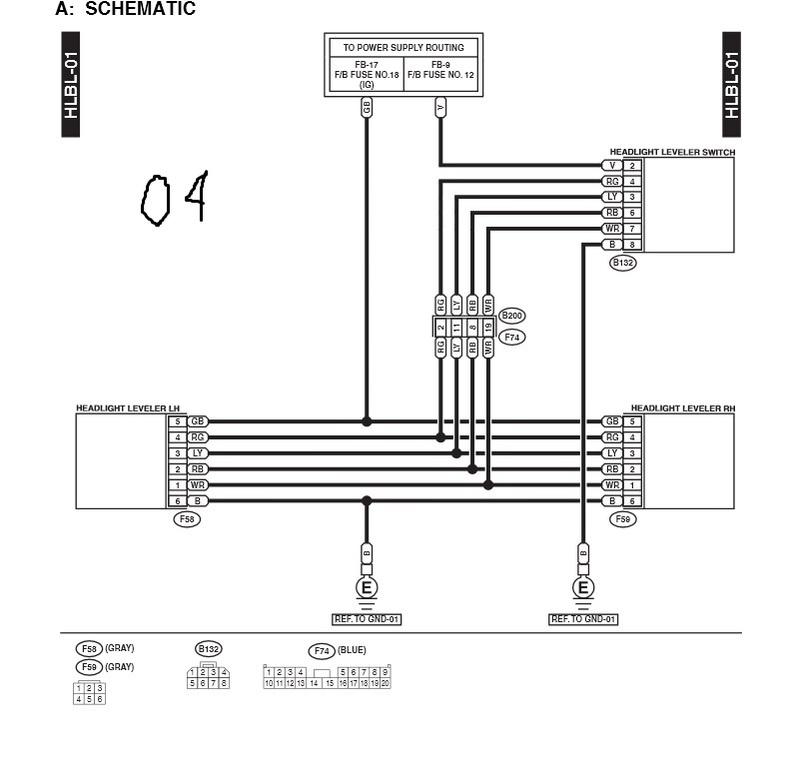

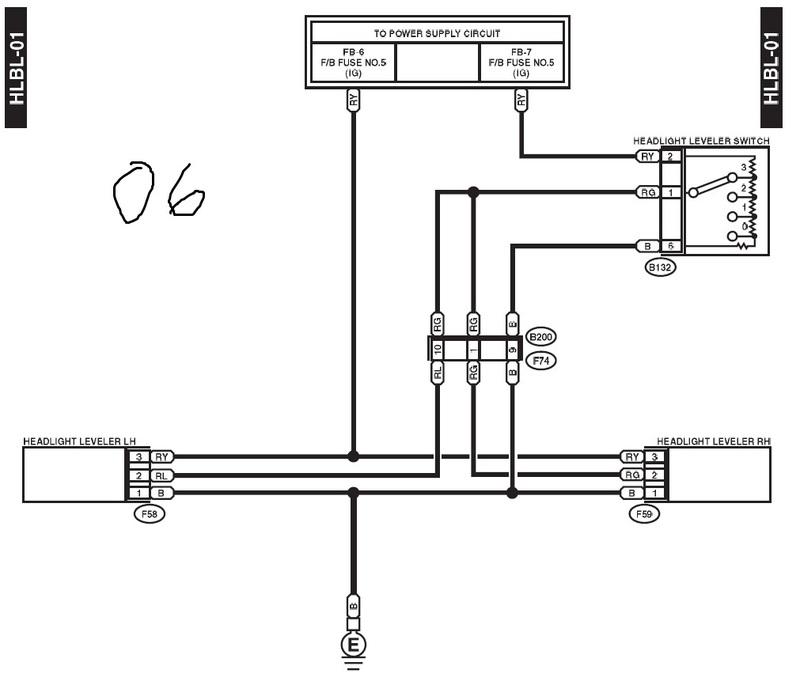

Brian at iWire got me headlight plugs and levelers from an 06 STi harness he had merged. $20 shipped. Doesnt get any better!

If it was easy, everyone would be doing it. Final conundrum of the swap. I think it should still work, just running the 4 position wires from the 04 to the single of the 06. As long as the resistances inside the position switch are the same, should be no problem. If it is, a 06 switch would be an easy swap.

5/9/2013

E85 tune scheduled for the 17th of June.

Gotta do some small things before then.

Oil change

Boost leak test

Check / change plugs

Grab some corn fuel and migrate south to visit the P & L crew and Junior.

Tinker with knock control some more. I still dont like how its working. Working 5 14hr days has taken its toll on my motivation level when i finally get home Friday

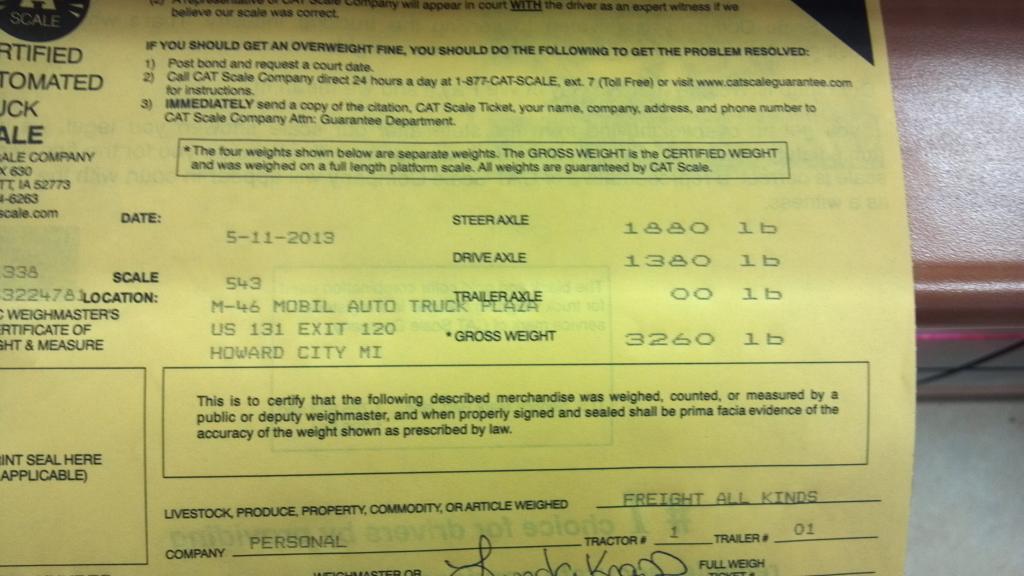

5/11/2013

Track day weight, plus me @ 225 fully dressed.

Full tank of fuel

Full interior

No spare tire

Jack going in dumpster at the track

Battery full size but rear mounted

Aluminum DS

Stock wheels with 245/40 DWS (should grip well in this effing rain  :rollseyes: )

:rollseyes: )

Ironically enough the 04 STi from the factory has a 1893 and 1380 split.

3260+225 = 3485

5-12-2013

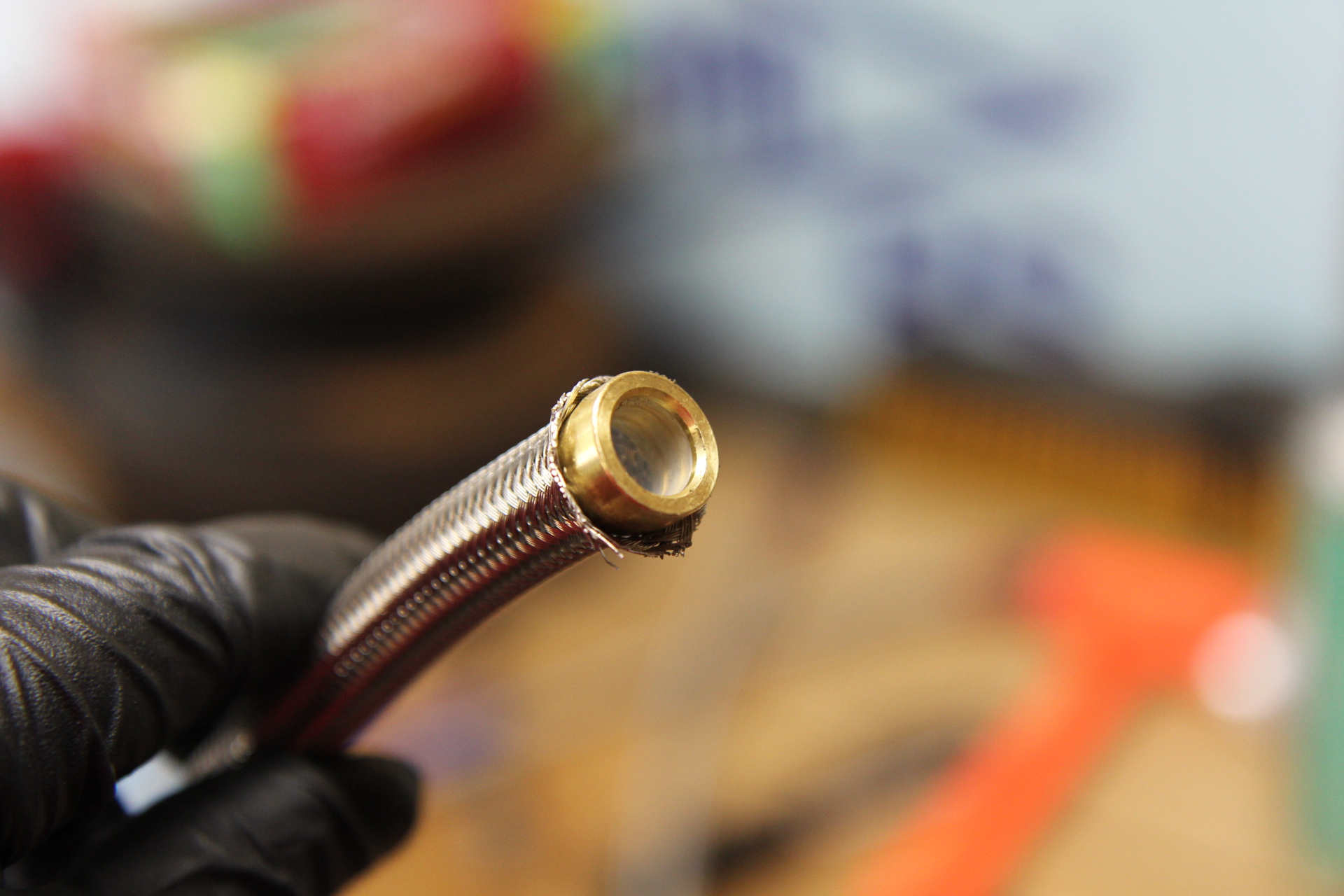

The cost of doing things right is astounding. Just to get Teflon fuel lines in the trunk to the exterior of the car was almost $400. That was with summit brand because i couldn't justify 600+ for Earl's. oh well.

I think I'm going to fabricate up a fuel cooler that mounts in hood scoop location because i Have the extra fittings and hose.

They are E85 compatible however they are also permeable, and I'm tired of smelling gas in the cabin.

It's also going to allow me to change the way everything is ran; right now it is spread out way too far. The reason I did not change it before is because I was just trying to get it done in the way I had it worked. Now that I can afford ( both time and money) to get nitpicky I am. I want to get my fuel trace sitting up near the seats and parallel to the back rest, and get my y block after the pumps back up into the cabin.

I have already found one thing that I wish I would have purchased different though. No matter how many times I build it sitting there looking at it I always seem to be one or two fittings off. In this particular case I think a 45 would have worked better than a 90. Having said that at $20 a piece I cant afford to just swap them out.

Ditto that that's exciting! Congrats!

That is for

13' -8 hose

10' -6 hose

9 -8 straight fittings,

3 -8 90° fittings

2 -6 90° fittings,

1 -6 straight

Finally another inline filter so i have 2 to protect my pumps, plus the big fuel lab one post pumps

I had an idea while driving that I am going to swap some -8 stainless onto my catch can, it will all be free and extra so might as well.

5-15-2013

Teflon hardware showed up today, there is a big difference in size of hose, so i grabbed what i thought was -6 hose and a fitting to try it out before bed. 2 hours later i have 2 fittings done. One took hour and 50 minutes because i was trying to use a -6 fitting on -8 hose.

2 bloody thumbs and a lot of swearing later i realized there was smaller hose in the box. Even using the right stuff the -6 is much harder than -8 to put together. -8 was a breeze. -6 has issues getting the male piece through the olive and pressing the Teflon out enough to fit. the teflon likes to kink easier on -6 too.

Hopefully will finish up tomorrow now that ive got the hang of it.

5-18-2013

You got it! I will do a DIY, because there was a LOT of learning as I went.

The last fitting took me 90 min I dont know if the 2nd hose I had was a different batch or what, but I couldn't get the olive over the Teflon to save my life.

Step one, is cut and flare out the Steel casing to put the olive on

The "vise" side was automatically flared by the Grinder, worked out good. The other side was nice and tight.

Put both fittings on the side that stays tight, so that you dont have to force it over the steel.

Put the Olive over the teflon, and push against your work bench to bury it.

Pull up the fitting

Lube up with water the other end, and push through the olive

Flip over, repeat, and tighten down.

Spilled gas over the carpet and the backing so I gutted that, I am going to make a nice one this summer w/ a grounding block / +12V on the bottom so that I only 1 wire going to and from the battery

5-26-2013

Just got home - went out for a bite to eat afterwords.

Watching the videos is almost embarrassing at how slow I shift, and makes me appreciate some of the other guys on here who can really cut gears.

This was the best video for the night, I kinda give a description on the video, but I had mostly 1.95-2.05 60' times with avgs in the mid 8s for the 1/8th mile.

Best time was a 1.89 60' with a 8.293 @ 88 mph.

I learned right at the end that I need to let the turbo build a little longer, and ride the clutch a fuzz longer.

I also KNOW that my audi ruined my manual habits, I never push in the clutch all the way without thinking about it, so that doesn't help. Final complaint. 3rd never wants to play nice with 2nd.

All in all still fun, but not going back till I am back from P&L for E85 tune, dont want that clutch slipping on dyno.

"Just imagine that car in detroit, people would shoot back"

Wow nice

Posted by Diggymart on 4/3/20 @ 2:24:09 PM