You must be logged in to rate content!

260 minute(s) of a 536 minute read

1-10-2021

2001 Porsche 996 LS1 Conversion Thread

Compliments of 1dirtyZ @ www.ls1tech.com

02.14.10

I know this might **** off a lot of other car enthusiasts , but heck thats a huge part of the appeal of such a conversion !

So after searching for a long time and doing all my homework and research I decided to go ahead with this project

Ill be putting an ls1 based engine in a 996 porsche ( 1999 to 2007 body style), this wont be a race car kind of conversion , but a proper daily driver with most amenities and systems working .

The plan is to have a dependable daily driver that I can take out on long cross country trips without worrying about breakdowns, initially planning on matching the original hp output, but instead of 420 to the crank , I plan on getting 420 to the wheels .

It will have air, heat , all power stuff , a proper stereo system with navigation , good gas mileage, and a comfortable ride and all the instrument cluster working . basically have it where if a person drives it they would never know it was a hybrid ( until you stomp on the loud pedal).

Ill be documenting every step of the process as best I can throughout the build process in this thread. This wont be one of my good enough engineering kind of builds where a week later the car is somehow blasting down the highway, instead it will be a long term project where I take my time and do it real right

This build will comprise of several steps , first of is getting the car into my garage and making it into a roller .

Next is getting the engine/ trans in and getting all the essentials working so that the car can drive under its own power.

Then comes the long task of fixing all the little odds and ends to get the final product.

After the car is done and running, i plan on getting a new shortblock in along with a set of turbos ( gotta use the intercoolers and ducts for something ) , but thats thinking waaaay ahead .

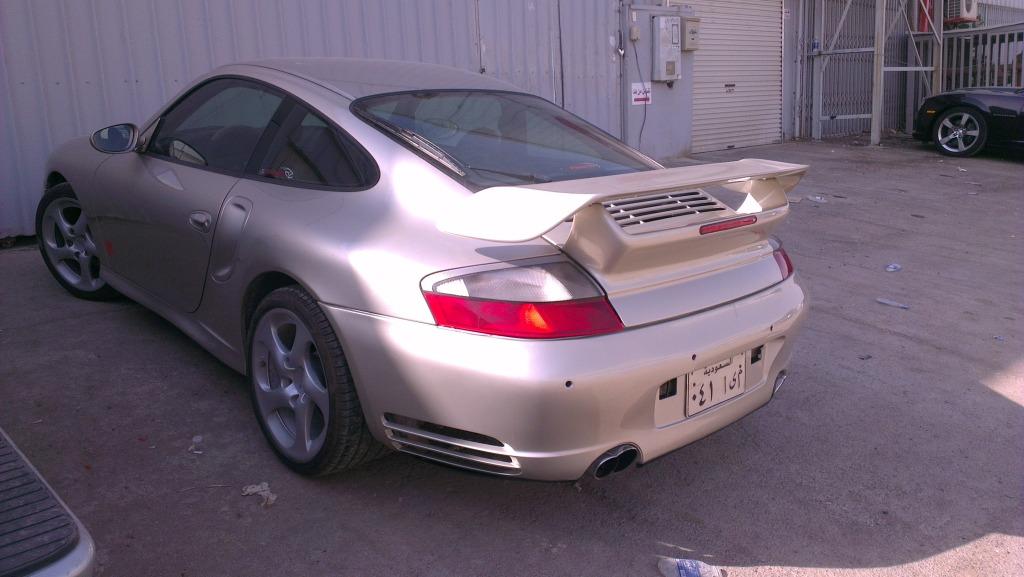

Any how , on with the build ; originally I was looking for a regular rear wheel drive 911- 996 for the project, but as luck has it I found a turbo awd one without the engine and trans. After doing some research, I found out that retaining the AWD is not a problem so I decided to go with this car:

The car had an engine compartment fire before, and now is missing a bunch of stuff from the driver rear side rear. I need to get control arms, knuckle, caliper and rotor. but first is getting the thing cleaned up to assess what I need to do. I already have the longblock sitting in the garage ready to be installed. But that will have to wait until I fab up some engine mounts and other stuff.

So to sum it up, I have to :

- Clean engine compartment

- Clean rest of the car

- Get a to order list going with priorities

- Start ordering suspension stuff and tranny

- Start mocking up the engine in the compartment

- Start building an engine cradle so I can jack the thing into place

here are pics of her first moments in the garage

and given how excited i am about this project , i immediatly threw in the mockup engine

engine compartment with a mockup ls longblock :

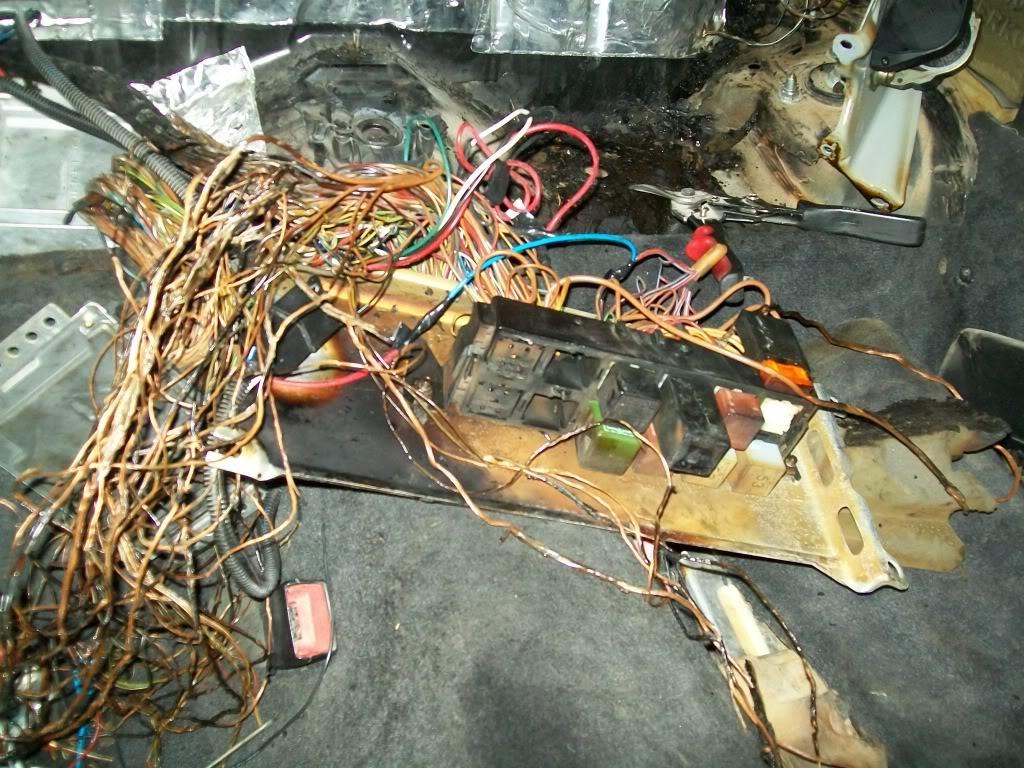

interior shots ( you can see the evidence of the engine fire inside the car) , and please forgive the dust and mess, the car has been sitting in the open with the window down for 2 years :

as you can see it has a loooong way to go , so wish me luck . i'll update this thread as i go .

02.15.10

well i intend to start tomorow , i guess i'll start with vaccuming and cleaning it out from the inside, then try positioning it properly in the garage and put it up on jackstands.

i guess tomorrow will be my tear down and measurement session

da plan :

- mock up engine insde the engine bay and see what accessory drive to use ( vette or f-body)

- put the car on jackstands

- figure out engine cradle design

- clean interior

- clean out engine compartment

i guess that's it for tommorow , unless i get carried away and stard welding stuff up

02.17.10

i got some stuff done last night

i managed to pop the trunk,,,errr hood ,,, the lid in front of the car to gain access to the battery compartment , took the steering wheel and seats out , vaccumed the interior ( still need to wipe down everything ) .

i then started cleaning up the engine compartment ,,,, lets just say cleanning after a fire is not cool

i took out what was left of the coolant expansion tank and radiator hoses ( check out the funky hose!)

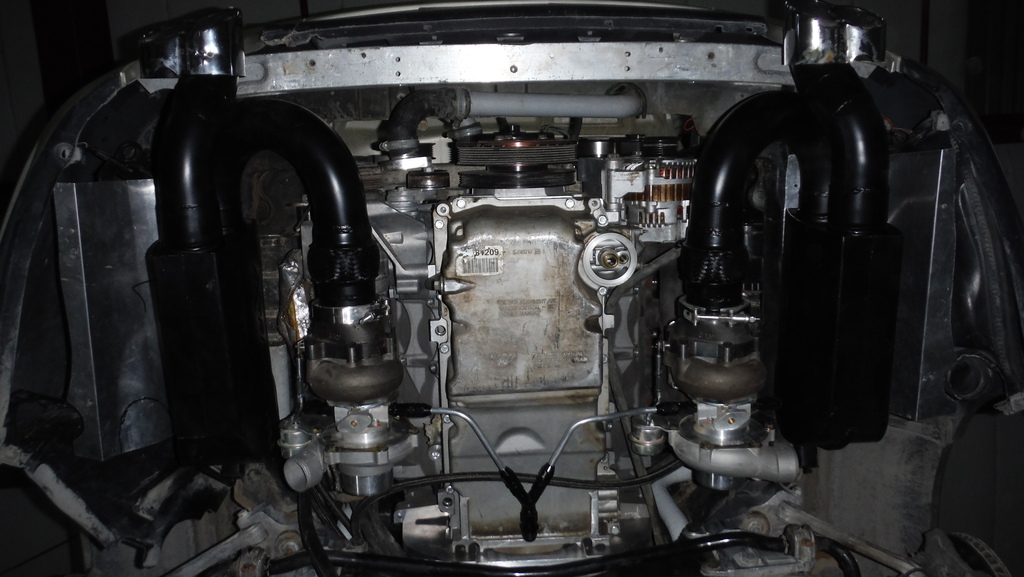

and started cleaning and scraping the whole place ( not done but getting there). this is a bit hard since i can't remove all the fluid lines ( a/c , coolant, fuel , vapor) cause its a pain in the @$# to do so , so i just moved them a bit just enough to gain access to whats behind them so i can clean and then paint the whole area. this is an ants-eye view of the engine compartment

the plan is to have it painted and then put some reflective sheilding/insulation in certain areas to keep the cabin cool. i also thre the mockup engine in again to see how its going to sit ( the car was now on the lift , aso i can better judge ), i seems its going to be fine ( but tight ) as long as i use a shallow accessory drive ( vette ) , problem is i can't judge exactly till i get a tranny in there. while i was cleaning the interior i found this :

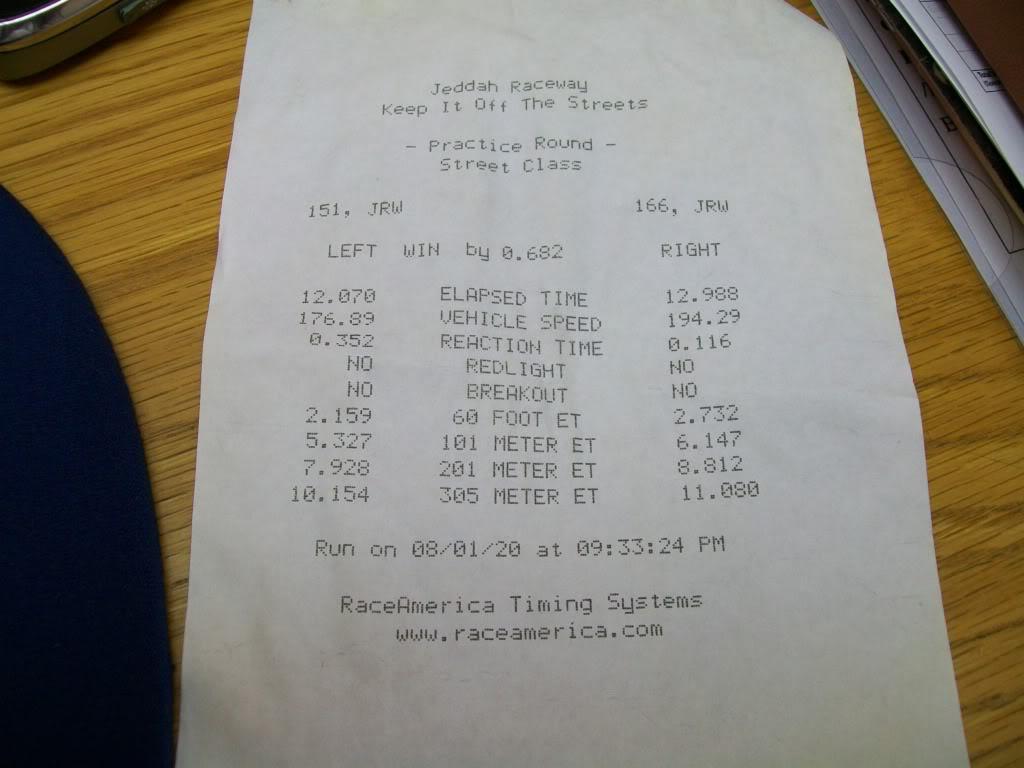

i'm not sure which lane the car was in , but i pan on beating either time by a full second (speeds are in kph and are109mph and 120 mph respectively)

so next on the seemingly never ending to do list :

- clean the engine compartment some more , probably with a sander

- paint it hi-temp black

- order the suspension parts

- take the wheels off

- remove the engine compartment cover

- remove the rear carpet inside

- start rough sketching an engine cradle

that should keep me occupied for a few days

02.18.10

well i managed to clean the engine compartment yesterday, its amazing what a wire brush can do

i still have a few spots left that have some gooey gunk i have to scrape off but its pretty much ready to be painted .

i also took the rear inside carpet that was melted from the fire and found a little nasty surprise ,,, lets say i have to scrape and clean some more in there ( sorry no pics , forgot the camera )

i also ordered the missing suspension stuff , should see it in a week or so .

i have to get some kind of adhesive insulation to stick in the engine compartment , and i guess i could start the mockup process now

made some progress today , i took out the rear carpet ( fire damaged ) and found a little nasty surprise underneath it; i found a puddle ( still wet) of melted foam insulation - it had the consistancy of tar.

needless to say it was fun removing that stuff with napkins

here is a before pic :

and after it was done ( still needs another coat and then some insulation ):

i also finished cleaning and prepping the engine compartment , should be ready to paint next time

i also have a pretty good idea how the engine cradle will be , it will utelize the stock engine mount location and wrap under the engine and attatch to the existing removable crossmember. the engine will use vette style engine mounts that will attatch to the cradle. that way all i have to do to remove the engine is unbolt the cradle and the xmember (6 bolts ) and the engine drops down just like the original did .

i should have the tubes bent and ready to be welded and installed by saturday i hope

02.20.10

to tell you the truth i'm not that worried about the rear end partying all over the place , porsche engineers have been slowly but surely eliminating the wild oversteer that these cars were known for since they first came out ; on the current 997 models the handling is nutural and not "oversteerish" ( i know cause i drove one around a race track ). so i have faith that this car will handle properly ( not that the new engine combo will not change some of the cars handeling charachterstics )

any how , back to the updates

i think i scored a stock muffler for the car , and i also got a set of sway bars for it too ( i'm missing the rear one ) , and man are they dinky !

i also finally decided on going with an ls3 accessory drive system ( G8 or holden style ) for ease of replacement and "shalowness"

i'm also contemplating on going with an Fbody oil pan instead of the GTO one i have now , cause the use of the fbody pan allows me to lower the engine a bit more . only problem is that it will have the sump in the back of the engine ( towards the front of the car ), which might cause oil starvation issues during hard launches. i'll be researching it some more.

anyhow , i started the mocking up process by first hanging the plastic engine with bungee cords in roughly the location i think the engine will be ( need to get proper tranny measurement or get the real thing in there)

i started with the idea of running two "L" bars that would attatch the short leg of the L to the original porsche engine mounts ( or to their location) in the rear corners of the engine compartment , and the long leg of the L would be welded to the cross member (located between engine and trans ). the idea was to have it angled so that it clears the alternator and A/C compressor .

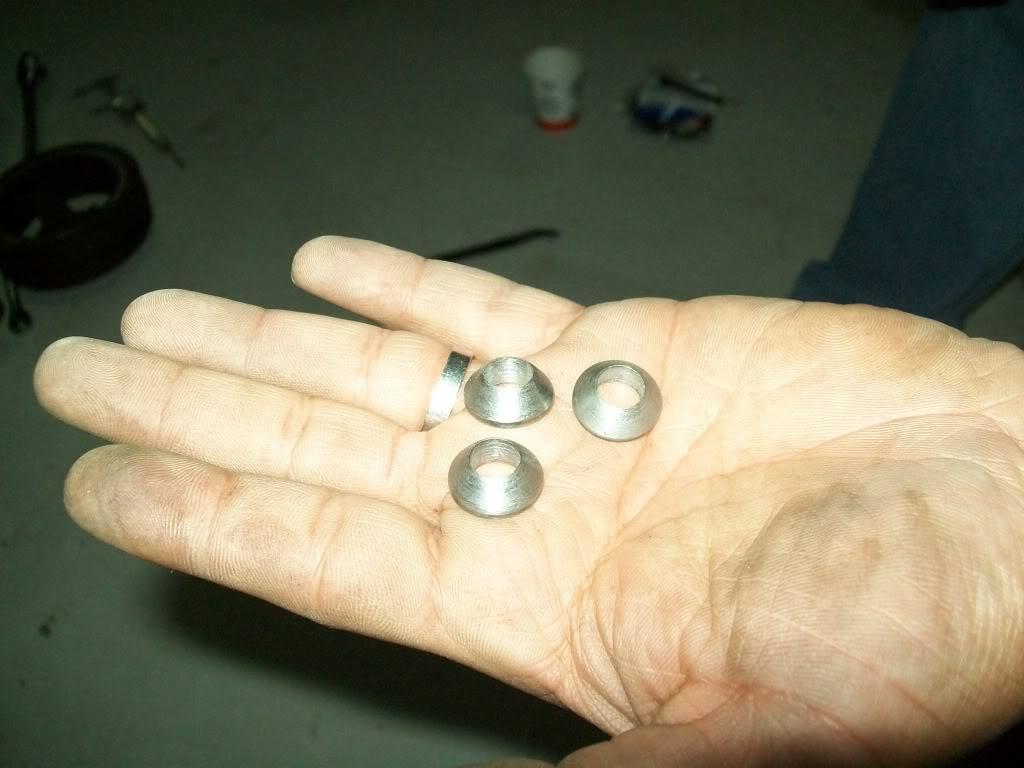

i was planning on using holden style pedestals and mounts ( just like on vette's) and have them sit on the long leg of the "L" :

but after messing with it for some time i decided to it was not going to work , first off the pedestals are not the same ( one is longer than the other ) from side to side:

(check out how the mounts are offset in the pics above , and the comparison below

second , they took too much space. when you compare them to ford or F-body mounts these stick too far out . here is how a ford mount looks :

another thing i noticed after placing the l bar on the real engine is that it would not work cause the pipe would hit the compressor ( you have to see it to understand how it happenes) so to make it work i now have to make new pipe that has two bends in it , kinda like this : (imagine another bend where my hand is )

and use f-body mounts so all i have to do is weld two tabs on the cradle and drill them , then attatch the mount to them . furthermore, i have the option of going poly later on if i need to .

so all in all , i think today was somewhat productive

next on the to do list :

- get fbody mounts

- bend new pipes for cradle

- get accessories

- find transmission measurements ( from mount holes to bellhousing edge )

- start figuring out which porsche wires i need to use

- install suspension parts as soon as they get here

02.22.10

i'm trying to keep everything in the same location when it comes to the accessory drive, so the cradle has to make its way around them . ( see below). i do have a remote water pump and all the fittings, but like i said , i'm trying to stick to stock .

i'm waiting to get some critical measurements from under a car with the trans intact so i know exactly where the engine will sit and wether to go with a remote pump or not. as for the trans it most likely will be a the stock six speed G96/50 that originally comes on these cars ( from the picture you posted they seem to hold up well )

by the way , what trans and clutch is that porsche using ( and what engine if it is different from stock) ??

otto , thank you so much for the offer , but i'll have to pass ( 1- i have them , 2- shipping will cost an arm and a leg ; i like in middle east )

irish , i plan on using both ls1 and porsche pcm's ; ls1 pcm to contol the engine, and the porsche one to do everything else, the plan is to connect vital signals from the ls1 ( like temp , map, oil pressure , etc ) using porsche sensors . that way all the pcm knows is that the original engine is still there

any ways , on with the updates

i decided to ditch the original design i had for the cradle in favor of a much simpler and more convenient one . simply put its a giant "u" from one porsche engine mount location to the other with two parallel bar running fron to back underneath

and from this picture you can see it does not show when the bumper is on :

the only thing i have to decide on now is wether to make it a completely bolt in cradle or weld it to the leading edge to the crossmember ( which is removable )

another concideration is a slightly different design which does not attatch to the crossmember and terminates just under the ls1 engine mount , this way i can use the porsche engine mount and solid mount the engine to the cradle ( i think this is how renegade does their cradles ).

i might sound like i'm complicating things right now , but remeber , i have to have space for the turbo's later down the road

either design i go with will have to wait a bit , since i did manage to score a stock exhaust , which i might use ( just have to go and pick it up tonight )

i'd like to place it on the car and see if it is possible at all to run it with the cradle design i have right now or not .

(why does it seem like i want this whole thing to be a bolt on process )

02.26.10

i do beleive i will need an extra pump to help with circulation some time later down the road. and i will be running an oil cooler from the begining, i just havn't figured out where to place the cooler .

any how , here are the pics of yesterday's progress:

motor mount :

crossmember plate :

engine block plate :

how it all looks :

03.01.10

got the suspension parts in today , but upon installing them found out i was missing a few important bolts ( alignment excentric and a few others) but no biggie , will order them soon :

here is how the stuff looks on the car ( going to be a roller soon ! ):

i also messed around with the cradle some more , now the "U" part is finally done :

and this is where the original porsche mount will bolt up to the new cradle :

next up will probably be the parallel tubes that the engine will sit on , i have to cut and weld these on next . those should go from the "U" part to the plate i have on the crossmember , i won't make any "pedestals" yet untill i get the headers and trans in.

another option that i'm really contemplating ( well thinking of as a backup plan) if the trans measurements i got were not correct and the trans ended up pushing the engine further towards the back of the car ( from pics i saw the tranny sits on to and past the cross member towards the back of the car- but the measurements i got place it just ahead of the crossmemebr) is a new cradle like andy has.

the parallel tubes under the engine would just extend past the crossmember ( either above it or through it) all the way to where the original trans mount bolts and attatch there . then the tranny can be slid forward a few inches ( can do that cause there is a drive shaft i can shorten infont of the trans) and mount it to the cradle. that way i have a complete suubframe for the engine and trans ,,,, but that's just me thinking way to far ahead

i also did not get the exhaust yet , waiting on the owner to call me to get it

any how , next up on the list :

- use regular bolts for now to finish bolting up the suspension

- slap the wheels on there to make it a roller ! ( end of stage 1 )

- weld up the two bars underneath to finish the cradle

- fab up a bar that holds the mock engine inplace teporarily so i can get rid of the bungee cords

- install the stock exhaust ( if i get it today )

03.02.10

i just had a "DOH!" moment last night ,,,, i just figured out i can't run the cradle like i intended ( to the crossmemebr ); if i do weld it to the plate i made on the crossmember it will be rigid on that end and flexible on the porsche motor mount end !

so there are two options: first, run it from the original mounts to under the engine and stop just before the crossmember ( then maybe attatch it to the block on the bellhousing surface with a plate ).

second option is redo the "u" part where is it soilidly mounted to where the original porsche mounts are ( remove those and replace with a plate ) and then attach the other end to the crossmember plate , and use original F-body motor mounts.

either way is easy , and i might just end up doing them both and choosing later down the road which one to pick

aside form that , i'm done with stage 1 ! the car is a roller now !

i just need to get the correct bolts for the control arms ( just put temporary ones now ) later .

after i put the thing on the ground i couldn't help but check how the crossmember i made would look from behind the car , so i slapped on the bumper ad what do you know ! it doesn't even show when looking at it from about 1 foot above ground! ( you could see it through the exhaust cutout in the bumper)

and incase you are wondering how much space is there to run the stock exhaust , well here it is :

this is how much space i have with the intake on , notice how unlike on 993 models ( the older body style ) i don't have to flip the intake and use the funky looking elbow on the throttle body . but due to how slanted the engine cover is , i can't run a carb style intake and elbow cause it sticks up too high ( unless i use a sheetmetal elbow that is super low- and before you say edelbrock,,,, i checked - the stang has a GMPP carb intake and edelbrock ultra low elbow- sits about 2 inches too high ) :

as you can see , its pretty tight when it comes to belt clearance , but i can't make a %100 judgement untill i have a tranny in there , but worst case scenario is i have to notch the brace and reinforce it ( which i really don't want to do ).

and why is it every time i look at this picture:

i can't help but see this in my head :

so i guess from the looks of it i can't make any real progress in the engine compartment side untill i get a trans in there ( or do some measuring myself on another car ), other than that , i can just build the other cradle and tack weld suff .

so , next up :

- finish the cradle

- build the damn brace i've been talking about forever to hold the engine

- strat looking into the fuel and return lines.

- take the center console out as well as the pedal assembly

- order more stuff

03.06.10

any how , got some work done last time :

took the bar that was attatched to the stock porsche mounts off as well as the mounts . i then started the other cradel by bolting in these plates inplace of the original mounts :

i then welded a nut to each end of the "u" :

and drilled the plates so i can attatch the two peices like this :

i also notched the two tubes going front to back , i just need to weld them on .

the block hugger headers came in too, and i'm not diggin'em

they exit right at where i want to run the bars holding the pedestals :

so i guess i'll just have to wait till i get the vette shorty headers in . they angle rearwards ( or forwards ) and away from the bars .

and on a side note , i found out that i can run two bullets horizontally on top of each other in the space where the original muffler sits all while maintaining the proper exit location for the tips , which gives more room inside the engine compartment or atleast a better chance to quite down the engine .

03.13.10

a little progress to report

got the other cradle (v1.1) kinda done

i first had to get two "L" bends to form the pedestals, then instead of notching them i drilled a hole on the ends and cut through the hole : (looks like the professor charachter on the muppet show )

then i placed the L on to the main hoop and tacked it on :

i plan on welding the other bit that had cut off so it looks like the pipes go through each other , this way a have a mounting point for a two hook or the exhaust .

anyhow, here is how it looks when both sides are on there:

i then sliced the other ends of the pedestals at an angle so they sit flush on the motor plate:

everything is tacked on there , i need to fully weld those bars ( except the motor plate connection - that waits till i get a tranny) but i have to wait till i get the TIG welder back from a buddies shop .

after welding that , this version of the cradle will be almost done

i guess next up will be the V2.0 of the cradle, got everything cut and notched to fit , just need to weld it up when i get the time.

other than that , i started messing around with some wiring diagrams,,,, not fun

so as soon as i'm done with the camaro and the race in a week , and the vette headers come in , i should be back on track

i'm also thinking of using an MR2 electric powersteering pump ( just like in the Audi build thread here), this way i can run the ac compressor and alternator (using a BMR mount ) using belts , and keep the belts on a level below the rearmost crossmember or brace and run a remote EWP and the electric PS pump , this way i can pull the engine towards the rear a bit more ,,,, of course this all depends on the transmission ,,, which is not here

but its nice to have more options.

03.23.10

jmarsa, i thought about that but moving it forward a few inches only alters the angle slightly and shouldn't affect length much .

marky, i would really appreciate it ! thanks!

ls1450 , the engine is an LS1 but it will run the LS3 stuff like the balancer and water pump and other stuff.

on a side note , i just got off the phone with efren from LA dismantlers and they hooked me up with the transmission as well as EVERYTHING i needed for the conversion from automatic to manual . they should have everything ready to ship in a couple of days

that should keep me busy for a while

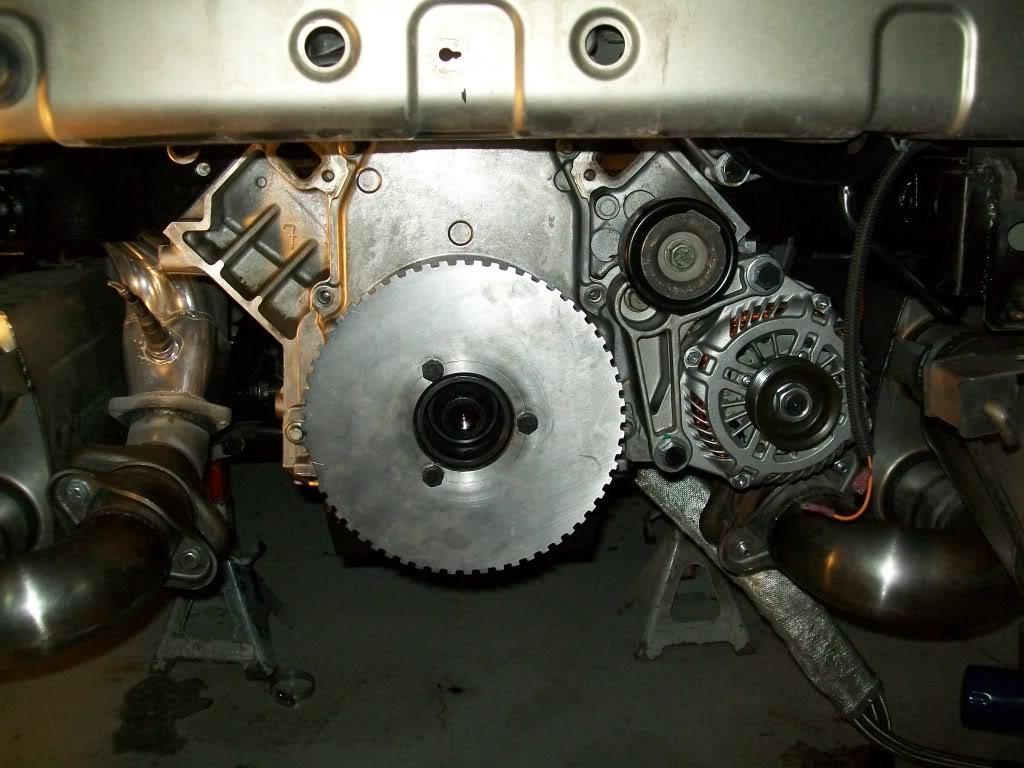

i'm also doing some research on the electronics i'll be using from the porsche , so i've started with the equivelant of the crank position sensor. on the porsche the sensor is mounted on the bellhousing and the trigger wheel is on the back side of the flywheel ( unlike the ls1 where the reluctor wheel is on the crank in the engine) .

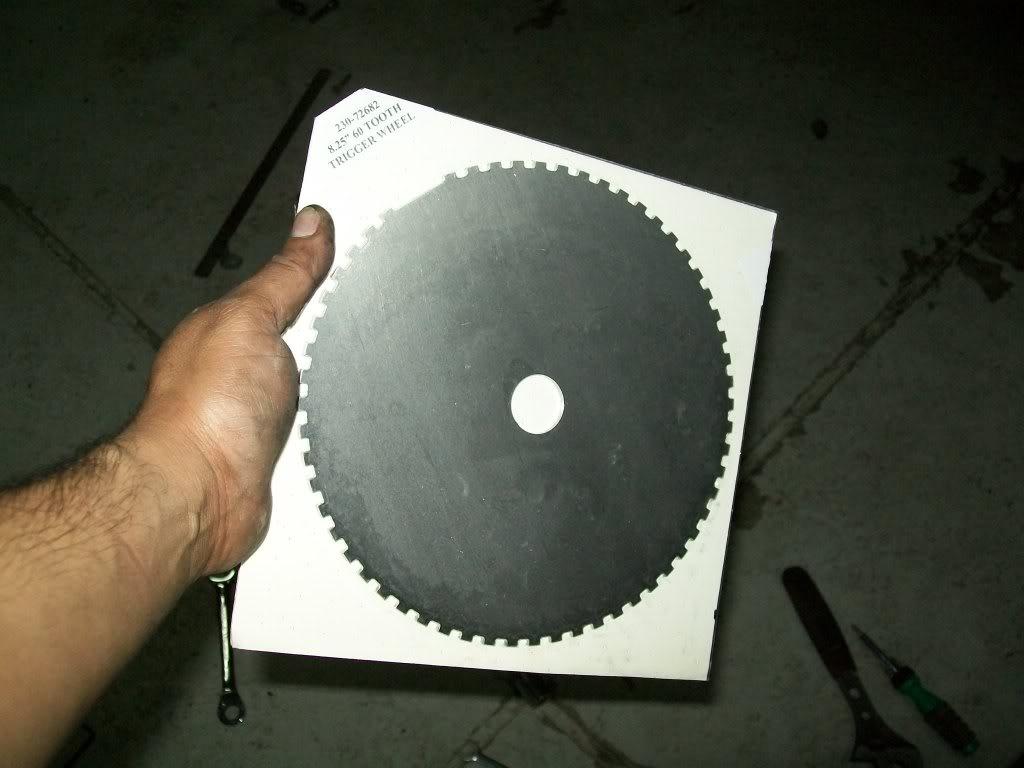

from what i gathered i don't think i can use the porsche setup , since most of the adapter kits make their own flywheel which does not incorperate the trigger wheel ( wich is a 58toothwheel (with 2 missing teeth for a total of 60).

so i found some sites that sell a 58 tooth wheel which i can bolt on the front of the balancer, or press fit them on the back of the balancer like this :

or machine the teeth on the balancer itself like this :

if i was going to use this method i most likely have to use an SLP pulley cause of the deeper or taller walls they have which should make it much easier to machine

or machine the flywheel back side like this :

but i'm not favoring this cause it might throwoff the flywheel's balance .

off course with all these methods i have to fabricate a bracket to hold the stock porsche crank sensor.

04.03.10

not much going on right now , i took the center console , shifter mechanisim , and E-brake cable all out , i also took out the stero and cd changer , and the climate control unit , and i'm in the process of removing the dash in anticipation for the new pedal assembly ( it comes as a whole peice connected to the bracing behind the dash .

the headers also should be here today and that (along with getting the stock exhaust ,,,, which i did not )should get me rolling again on mounting the engine.

i was also contacted by LAdismantlers sayign all my parts are ready

http://www.ladismantler.com/index.ph...em&inv_id=2263

they should ship out monday or tuesday !

so , next up on the list

- remove dash (tons of fun right there )

- mount headers and mock engine in and finalize both engine cradle designs

- seperate the wires i need from the porsche wiring harness.

- figure out what else i need to do

04.07.10

well finally some progress to report

i finally got the damn dash out ! man is that thing a pin in the rear ! 10 gazzilion screws and then some !

also vette shorty headers cam in today ! and might i add they are blingy :

i put them on the mockup engine and started thinking about crossmember placement and exhaust routing . the headers fit nicly and clear everthing around them using this cradle .

the plan is to run them so they face towards the back of the car like so :

and have a 45deg. elbow right after the flange so the exhaust becomes horizontal , then it makes a 180 deg. u turn towards the front of the car into a 10" muffler or bullet (wich will be horizontal too), after that the exhaust exits the muffler and makes an upwards sweeping uturn into another bullet or muffler that will be 17" long and sits right above the other muffler/bullet. after that the exhaust can either go straight out to the tips or i can run it into the stock muffler for more noise reduction .

another thing i noticed is that with this cradle i have no clearance issues between the motor mounting plate and the header, but if i go with the other design cradle (using the F-body motor mount ) it might touch or be too close to the header. so the solution would be to use the vette style aluminum pedestal and doughnut mount for a clean and nice fit.

i should have the welder back in a few days , so i can finish up this cradle and start mocking the engine and exhaust on the other cradle too ( don't ask me why i'm doing things twice , i don't know )

on a side note, all the trans stuff should be shipping out tomorow !

so , next up is :

- order mufflers and u bends for exhaust system

- weld up first virsion of cradle to make it officially finished

- strart tacking together the second cradle and see how everything fits

- remove pedal assembly

- figure something else to do while i'm there

04.12.10

well a minor setback but not major i guess;

in my infinite wisdom i welded the engine pedestals to the hoop i made without double cheking pan clearance ( i went off the side of the block ) . i later noticed that the oil filter kicks out a bit and it would not clear the pass. side engine mount .

so to cure this i had to cut and grind the welds i made the engine mount plates ( the "L" ) and reweld them at an angle - basically a few inches away from where they were before . this was the best way to do it since it still gives me the room i want to run the exhaust .

and to further clear things up , i can not use the F-body mounts with the vette headers ( they touch ) , so if i am to go with the other design , i have to get some vette mounts and pedestals .

so i guess now i just have to wait for the trans and exhaust bends and stuff to show up so i can finish the bottom part of the car ( i know i 've been saying that for a month now )

04.21.10

well i have some good news and some bad news,,,,

the good news is that the transmission and other things needed for converting the car from an auto to a manual showed up ! :

,,,, the bad news is that my worries about not being able to push the transmission further towards the front of the car became true.

it is so cramped where the transmission mount is that is almost impossible to push the tranny forward more than where it is stockbecause of how the coolant pipes are routed.

now i didn't think of this option last night when i was under the car , but i might be able to relocate the transmission mount further if i notch the floor pan and push the hoses into the recess therby clearing some room to relocate the trans mount . but that has to wait till i go back there.

any how , its a good thing i didn't weld up the mounts according to the measurments i had before . and guess what !!!??? i have to redo the cradle again !!

the reason for redoing it is that the oil pan will hit the bar if i use the stock trans location. here's what i mean :

so ,,, the new mounts will be much simpler , i just have to get some 90 deg. bent tubes today and start chopping away .

after that is done and i'm happy with where the engine sits i will have to start looking into where i have to notch the rear brace ; the engine will be moved so far back that in order to run a water pump and power steering i have to clerace the brace a bit to make them fit . here is how the engine should sit compared to the brace when done :

(don't mind my "air gap" oil pan )

the brace should be notched to about where the spot welds are in the bottom pic or where the latch starts in the top pic. , offcourse after notching it i have to run a brace ( most likely a tubelar one ) from one side to the other to maintain the integrity of the body.

and in another moment of "DOH!" i noticed that the AC compressor and mount i had on the real engine ( which i was using for measurements for accessory drives) was of an F-body ,,,, and the bracket and AC i am intending to use are off an LS3 ,,,,, which means the engine is going to be overall narrower than what i had annticipated,,, which means i can't cut the brace till i get an accurate measurement .... (man this measure twice, cut once stuff is killing me ! )

i should have the tranny in the car by tonight , and i will know then if i can relocate the coolant hoses or not. i decided to try and focus on the bottom side of the car first and leave the top part ( interior, dash ,wiring , etc.) for later till i can get the car off the lift . that way i can roll it out somewhere whare i can have more working room next to the car.

04.25.10

One small step for man , one giant leap for sam-kind

Trans finally in the car, and like I said before moving it forward is almost impossible ,,,, if i use the stock transmission mount

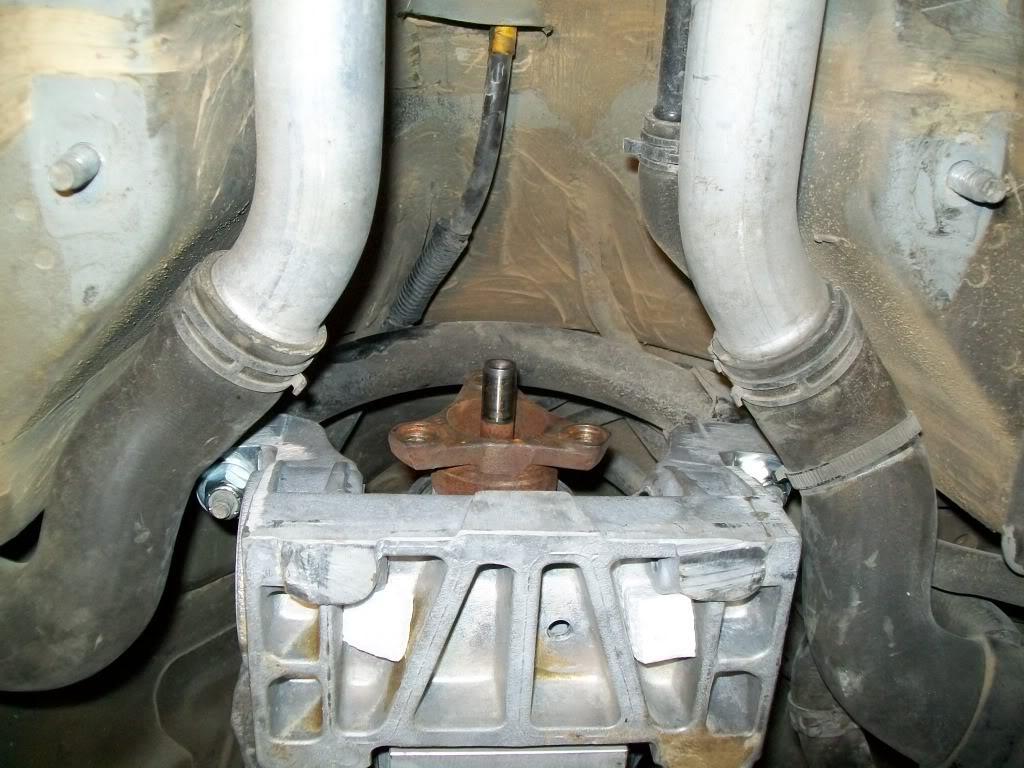

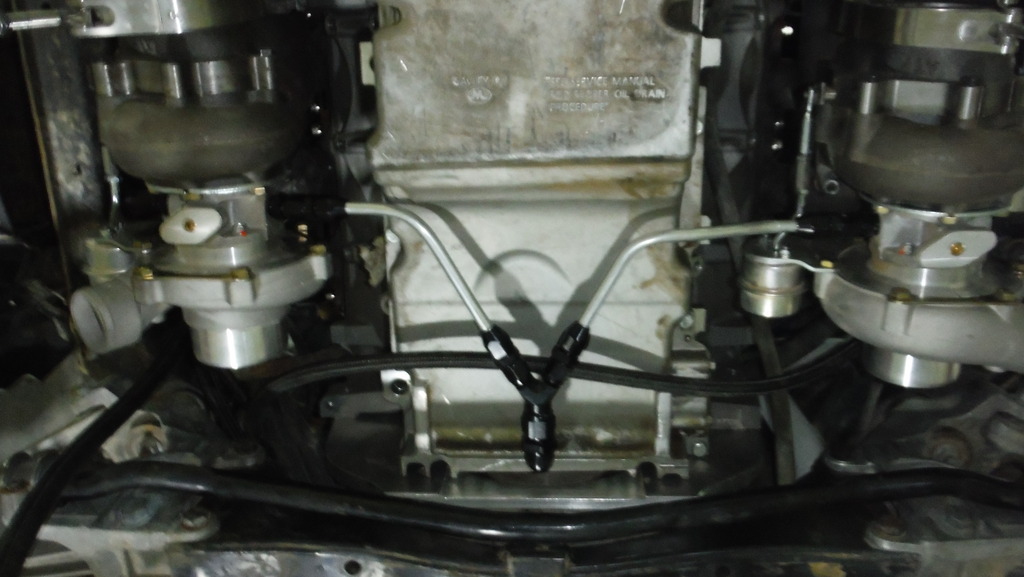

I’ve been messing with an idea of another trans mount (fabricated) that would get me those precious inches of clearance, but more on that later ( I just started thinking about it and I have no idea if it would work or not , I have to go back to the garage and physically check it). here is how the original trans mount looks like :

now,, i said before that i might have to redo the cradle because of interfernce between the cradle and oil pan , but now that i'm thinking about it , why not just notch the pan abit ( all i need is about 1"-1.5" of clearance) , or get a custom pan made that would be a bit shallower than this one (all this assuming the trans stays in place).

i guess now i have to start messing with the trans mount and see what i can do there. after that is done i can focus on the engine compartment again and locating the engine in there. ( guess no new cradle for now )

04.26.10

more progress !

i got the original trans mount and xmember off and saw how much i can slide the tansmission ; i think i got about 5 inches of clearance ! enough to install the engine without needing to cut the brace.

here it is before :

and after :

removing the original mount will get you this nice little pad that porsche so kindly made removable ( 4 allen key bolts hold it on to a flat part of the trans):

i'm not going to take it off since it will be part of my new trans mount, it will have two tabs bolted to the sides and going down to a regular gm trans mount (poly) like so :

and the nice people at porsche also added four beefy studs under the car ( just like they knew someone would need them someday ) right infront of the transmission to use as a mounting point for the new trans xmember ( here is one on the left side of the picture ) :

and here are all 4 :

now it isn't all smooth sailing , there are a few issues to deal with :

first off is the shifter mechanisim on the transmission hits the E-brake and strater + cable , it's not the shifter lever itself but a counter weight it has on it (see pic ) that is hitting , the solution would be to cut it but i don't know how that would affect shiter "feel"?

here is a better pic of the part :

the other issue is the driveshaft length , but that is not a huge problem since i can have it shortened ( it already has a loooong splined end)

last issue is the cv joint angle , i'm doing some reading on how much is too much angle and if these are 930 style cv joints or not ( 930 joints can handle a good amount of angle).

here is the befroe angle (stock location ) :

and the relocated angle :

what do you think?

(note , did some onscreen measurements and it seems the angle of the axle is around 12 deg.)

so , right now i'll just make the trans mount without cutting anything on the car ( so as to go back to stock location if need be) . it'll most likely be a plate that bolts to the 4 bolts and has a tab running under the trans mount .

if the relocation process fails , i guess its time for the sawzall !

04.29.10

easy, i looked into different axles and just like you said there are options

i do agree the weight distribution comment , but over all moving the tranny that much is just too much of a hassle. soooooo, the next best thing is to move it just a bit!

i turns out if you flip the trans mount around and machine the small pad on one end that interferes with the transmission case, you end up moving the tranny forward about 2 inches !

here are some pics :

and the result :

cool thing is the cv axles are just slightly changed from stock , shifter works without interference and i get better weight distribution ,,, all while using stock parts

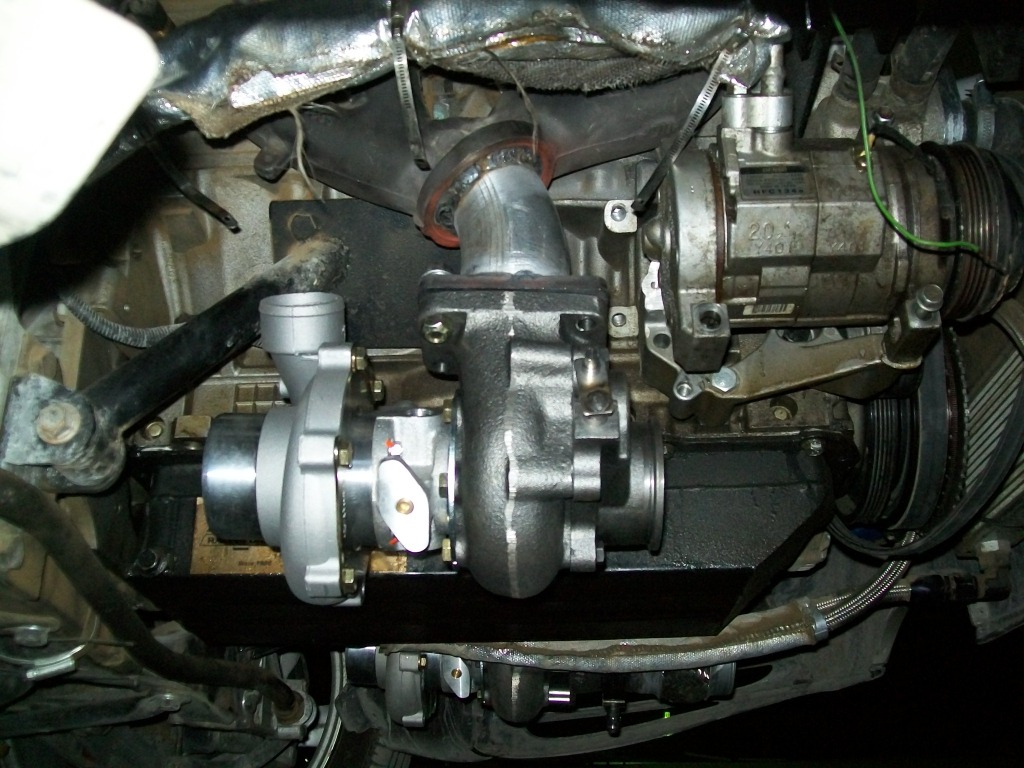

more progress news, i finished cradle V3.0 and they look like this :

and header clearance :

only thing that worries me with this design is the stress or leverage that is placed on the part itself.

so after thinking some more and noticing that the engine now is sitting almost flush with the brace , i though why not do it like the porsche engine was mounted ,,,, soooo here's my other other other engine mount idea :

it fits nicley and lines up with the original mounts , i just have to make sure i can have everything lined up first ; the motor plate will cause both the water pump and alternator mount to be moved forward . so i plan on machining the waterpump mounting surface the thickness of the plate to compensate and pull the pump back in. the alternator bracket is not that easy ; i can't machine the back side of the mount cause there isn't enough material , so the solution is to bolt it as is , but move the alternator back by machining a bit off the alternator tabs and getting a small spacer to compensate . ( sorry forgot to take pics of that )

so more on that later

04.30.10

the motor plates were just there so i threw them on . i totally agree that using only the waterpump bolts is not a great idea in my opinion. i am thinking in the same lines you are when it comes to building a new plate ,,,, actually i have that already done for another project i was toying around with :

i most likley will use more mounting holes on the plate and even use spacers on the passenger side head to tie that in with the plate as well.

i've also been toying around with another accesory drive idea :

the plan is to use a remote waterpump ( fittings on the block water outlets would be much shallower than the pump itself) as well as an electric powersteering pump. by doing so i can have the accesory drive - which will consist of an alt. beltg and an A/C belt - run under the brace , while the water and steering pumps be located somewhere else .i've looked into MR2 pumps , and after some deep research , i found out that skoda Fabia's, Seat Ibiza's , Mercedes A class and BMW mini's all have electric power steering pumps,,,,, then i found the big surprise : the poreshe 996 GT3 CUP had electric power steering from the factory! which means i might find a bolt in electric power steering if i look hard for it

so now i'm researching more into the electric power steering route to see if i can use it or not and to see if it is reasonably priced to go with

05.16.10

back to working on this again,

the adapter finally showed up !

and the flywheel that makes it all possible

i placed the adapter on the tranny and found out i need to cut it from the bottom to clear the crossmember , if i didn't do so it would hit the crossmember and i would need to pull the trans towards the back an inch or so .

i already took it to a machine shop and told them to take out 1.5" from the bottom , i should have it back today.

you can see here how it touches :

i also ordered some bushings from welderseries that showed up yesterday , so i should be able to finish the motor plate soon and start moving on to other parts of the build . i also plan on going with a different oil pan , this one just sticks too far down for my liking . found a place called kevco that can build any design pan you want , so i'll be hitting them up for one that is 3.5" deep and is basically a rectangular box with baffling .

also ordered the GT2 clutch conversion ( basically ditching the leaky, bulky , assisted slave cylinder with a manual one), makes life much easier when plumbing the clutch since the original 996 setup used a hydraulically assisted unit that was driven off the steering pump. another benifit is the better clutch feel , since it makes the pedal a bit stiffer ( the stock one felt tooooo soft and almost had no feedback).

i also finished running the clutch hydraulic lines from the rear to the driver footwell , i just need to get the pedals and reservoir in there and finish connecting the hoses.

05.19.10

more progress

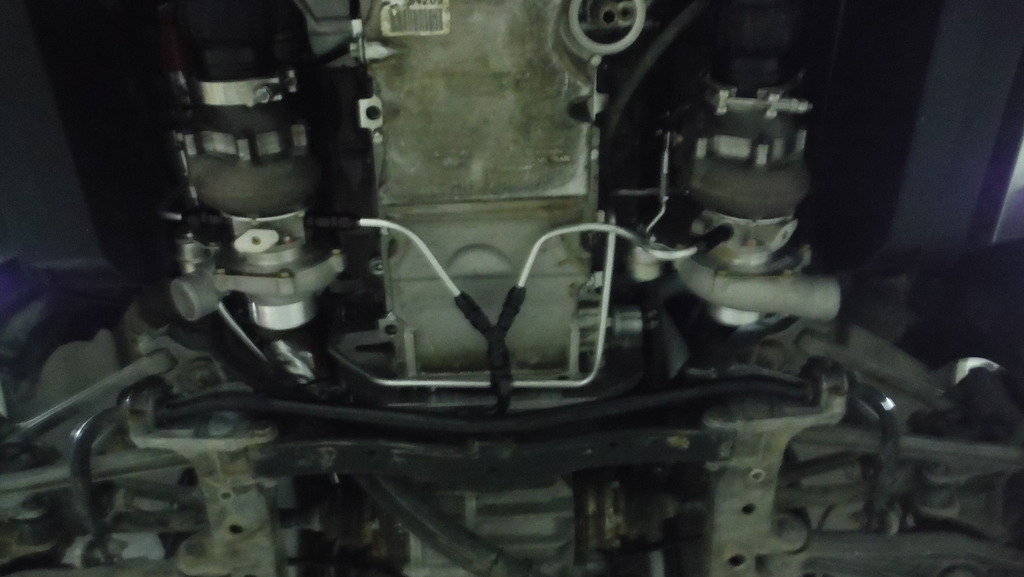

i finished the engine mounting plates and bushings last night , here's the driver side mounting point . this bolts to the frame where the original engine mounts used to rest :

and here is the bushing sleeve that i welded to the motor plate :

and here is the finished product on the driver's side :

and here is the passenger side mounting point :

and the finished (for now ) product :

i just have to do a bit of grinding here and there and cut the top parts to clear the intake to pretty them up and make them look nice . and when i'm done with all of the mounts , then its off to the powdercoaters !

so now the engine is suspended by itself , i think that should be considered a milestone

next up : making the mounts that will be located between the engine and trans; they will use the two bolts on the side of the engine (above and below the bellhousing dowl ) and extend down to the suspension crossmember , where i'll weld up some tabs for the another set of bushings, think of it as extra insurance

after that i guess i can start tackeling the accessory drive and/or the exhaust . which should be interesting for both .

found this exhaust idea while messing on google (<---- gotta love google images!)

or i might go with an x muffler like the magnaflow 12469 in place of the original unit .

05.21.10

a bit of progress today , and a minor setback

first off the setback : found out i have the whole pass side e-brake assembly missing. the only thing there is the the cable and the upper brake shoe :

i also could not get the stupid axle ( from the auto transmission) off the spindle , guess the splines were pretty rusted in there , so it was off with the spindle!

on the other hand i finally seperated the wires i need from the engine compartment :

and i think i should repaint the calipers since they are off now , (well the rears at least ) and they are rather faded .

thats it for now , i have to finish up the mounts between the trans and the engine and then i should be done with the hanging the engine .

after that i guess it would be time to start fabbing the exhaust and messing with the accesory drive.

05.28.10

Nothing much to report ,

i'm just waiting for the next batch of parts to show up. i ordered a magnaflow muffler PN12469 with dual inlets and outlets , the muffler is kind of an "x" design inside but without the pipes actually opening into each other . this would be the muffler that sits infront of the balancer where the original stock muffler used to be.

another thing i ordered is a couple of mufflers from extreme mufflers , these are "U" mufflers that have both inlet and exit on the same side.

http://www.extrememufflers.com/index...p_image&pID=54'

these mufflers will be on both sides of the engine and will flow into the "x" muffler.

also ordered an engine harness, and drive shaft for the tranny, coolant expansion tank , exhaust flex coupler, as well as the missing brake caliper and emergency brake parts. and i should get the exhaust flanges from the machine shop tomorow .

the oil pan has been shipped as well

untill then , i guess all i can do is cut the brace and start routing some wires and hoses.

05.30.10

Here a couple of cell pics ( sorry for the quality ) of what i did last night :

will get better ones soon

on a side note , found out that a stock F-body alternator will not work with an ls3 alternator mount.

06.14.10

sorry for the lack of updates , but i've been busy andout or town , plus i've been waiting for the batch of parts i ordered to show up.

here's what i did so far:

i cut the brace and welded patch panels to close the holes , i also found out that the muffler i ordered (magnaflow p/n 12469 ) is not the design i was thinking it was : apparently it was dual inlets aand outlets that merged in the center of the muffler , i was hoping that it would be two seperate paths that crossed in an x pattern but did not open up on each other.

any how here are some of the parts that already showed up :

and here is the ultra sexy kevko oil pan and integrated baffeling :

EVOms GT2 clutch hydraulics conversion :

and here is how the brace looks like after cutting and welding the patches:

ike i said i'm still waiting on some parts to show up like the harness and extreme racing mufflers and the GT2 solid bumper braces so i can begin fabbing up the exhaust and brace reinforcement and the rest of the brake parts . i'm also am waiting for the driveshaft to show up along with some other things here and there

so as for now , all i can do is build up the mid mounts ( between the engine and trans - to help support the two just like a mid plate) as well as route a few hoses here and there. after that i should start thinking of where and how to route the LS1 wiring harness and clean up the existing wiring in the engine compartment.

06.23.10

time for some updates,

been waiting for parts to show up, and most of them are here now;

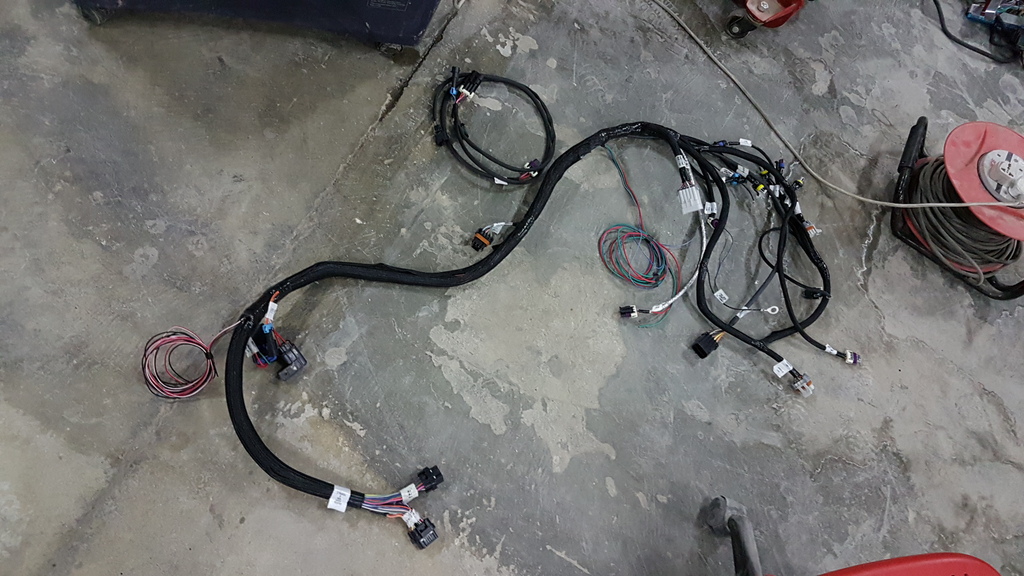

the wiring harness from ls1wiring.com is here

and so is the 360 deg. swivle thermostat housing ( i was hoping it would be smaller than that , but oh well,,, )

the front driveshaft also showed up , and it seems i have to shorten it by 3 to 4 inches!

here you can see how the kevko pan fits , and how much clearance that got me :

and since i had some time on my hands while waiting , i decided to make something ,,,,,, you guessed it ! MORE ENGINE MOUNTS!

the thinking behind these mid mounts was that the front plate provides side to side bracing as well as lifting the front of the engine, while the trans mount kinda provied front to back bracing ( i say kinda cause its a huge floppy rubber donut mount), so i thought adding a bolt-in mid mount would not hurt anything and would provide front to back bracing ( helping to prevent the mounts on the face of the engine from bending ).

i started off with making two plates with tabs on them for the bushing , these plates would bolt to the suspension cross member on both sides:

i then started building the part that connects the plates to the block , it just a simple tube with a bushing on one end and a plate that bolts to the block on the other :

i like welding stuff

this is how it looks when done on the driver's side:

and on the pass. side :

and how it looks from under the car :

and here is a shot showing both front and mid mount :

so i guess i can scratch building the mounts off the list now

there are a few more parts on the way ( brakes and "U" mufflers ) that have to be here before i can continue , as well as some other assorted thingies here and there.

so when those show up i will start on the other things on the list :

- start fabbing the exhaust system

- finish bolting up the brakes and e-brake

- build the cradle that will be used to lift the engine/trans in place

- finish plumbing the clutch hydraulics

- start working on the coolant lines

- probably make some more engine mounts

07.06.10

major mile stone acheived last night !!!!

i caught the martha foaking rat in my garage !

(i actually caugth two but this $hit ate the other one - all of it except the head and tail end ! )

other than that some parts showed up but not all of them. got the caliper , most of the ebrake parts , puke tank, sway bar links , and hood struts in today , but the whole brake thing is on hold till i get one itty bitty part

i'm almost done with the engine cradle that will be used to move the engine and trans in place :

also finished mounting the GT2 solid bumper mounts , making the rear bumper a stuctural peice :

mufflers should be here any day now , so when they show up i can start with the exhaust system.

i probably will start routing the coolant hoses for now untill i get some more goodies in .

07.12.10

got the oil cooler/fan assembly in , this will most likely be fitted on the decklid :

the mufflers also finally showed up from extreme mufflers , and man do i like'em !

as you can see they are two "U" mufflers and two bullets , they are both as free flowing as they get and the plan is to use one of each on each side.

the headers will face backwards and i will not use the stupid stock flange on them , i'm going to port the lip on the original flange cause its only 2.5 inches in diameter ( seen here :

and will weld a small extension with a 45 deg. angle on it ending with a ball flange , i was going to go with flanges but using ball flanges offeres better fittment and is more flexible when it comes to pipe missalignment . after the ball flange there will be a U back into the muffler then the gases make another u turn and exit the muffler into the bullet muffler and the exhaust tip. here is approximatly how the mufflers will be placed :

and the extension and ball flanges that will be welded on to the headers :

and here's a weird occurence , as soon as i finished cutting the metal donuts to make the 180 turns the pipe split at the seam :

but that wasnothing that the TIG welder couldn't fix

the oil cooler lines , remote filter and fittings should be here very soon as well as the rest of the brake parts , so finishing up the bottom side of the car should be happening soon

so the plan tomorow is to:

- port out the header flange so i can weld on the 3 inch ball flange.

- weld the rest of the exhaust and figure out where to mount the hangers

- put bait on the mouse trap to catch the other martha forking rat that i saw today

- i might just lay the harness in the compartment and see where i'll route it into the car.

- clean the mess i made over the last few weeks

07.13.10

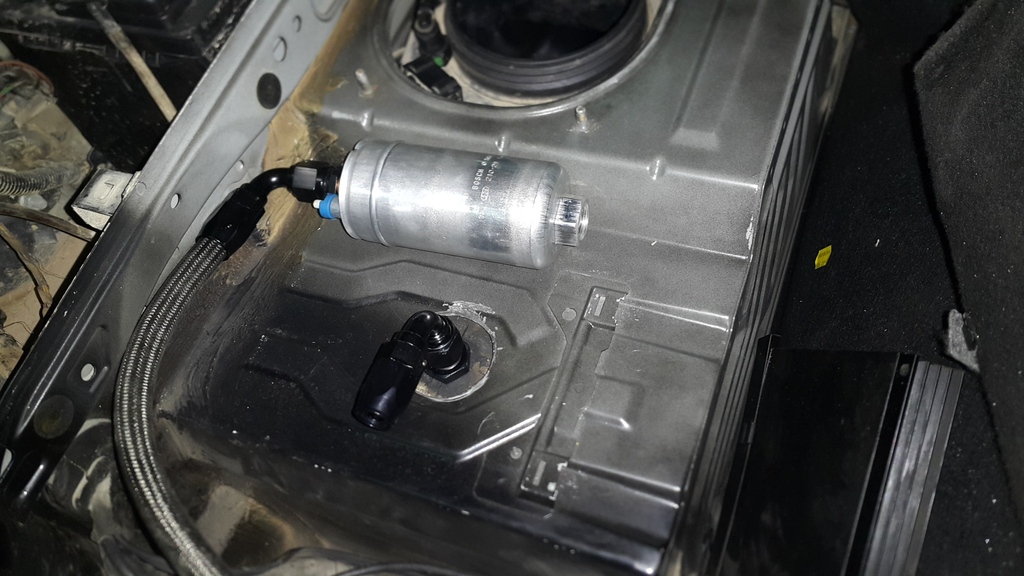

on with the build , i got some oil filter fittings in today as well as the remote oil filter housing , fuel filter and lines as well as fuel line fittings .

i didn't get much done today cause i got there late , but i did manage to weld the 45 deg extensions on the headers :

and finished welding both 180 deg bends to the ball flanges :

and yes ,,,, i did bait the trap

07.15.10

i'm almost done with the exhaust now

here is how the final product looks:

and this is how it looks on the car :

and here is how it looks from behind :

i still have to finish one more weld and place a couple of tabs and both muffler assemblies will be done .

next up is figuring out where to place hangars and getting some porsche tips, then later put some heat shields on them for some added comfort .

next up on the to do list is to finish the brakes , coolant lines and i should be mostly done with the bottom side of the car.

07.18.10

i guess i can say i acheived one of the milestones of this project; i am completly done with the exhaust. ( well,,, i still have to do the tips )

i finished welding the last muffler and hangers , and to tell you the truth i'm impressed with what i did

rear view :

and a side view ( i actually have more clearancce than stock ! )

i also started thinking of where to mount the cooler and oil filter . and after many minutes of head scratching and staring at the engine compartment i came up with this location :

and the oil cooler will be next to it and stretch across the bumper. i also plan on using some quick disconnect fittings from the oil pan to the oil filter for ease of removal .

07.19.10

so now its on to other things

i still have to measure how much the driveshaft needs to be shortened , and i really need to work on the hoses under the car which includes clutch ,fuel , coolant, heater , and p/s lines.

any how , according to my list the next thing to do is :

- measure and cut driveshaft

- oil lines, filter, and cooler

- finish routing the hydraulic lines for the clutch

- start on the fule line stuff

- i guess i will delay the harness for a bit , i want to do all the electrical work at once.

- install some heat shields around the mufflers

should keep me busy for a while

08.11.10

i finally have the rear brakes done , all i have to do now is bleed them and later down the road paint them and add the "porsche " stencil to them :

gotta love the rusty rotors

i also figured out where to mount the oil cooler :

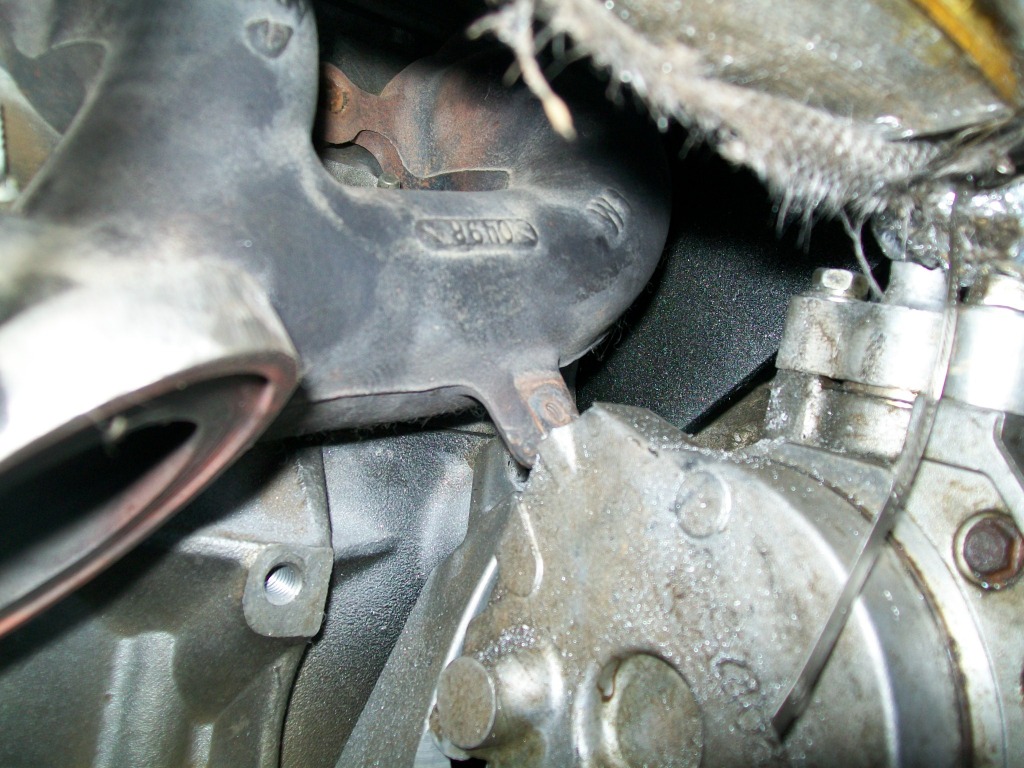

i also had to clerance the oil filter pad to clear the belt :

here you can see how close the belt would run by the oil filter:

i also found these cool hose seperators from summit , nice and clean :

also got the puke tank and vette filter/regulator mounted in place :

and here are all the fittings on the filter :

all i have to do for the fuel system is run a hose to the fuel rail and attatch the return line and that should be it for the fuel system .

also looked at the cooling system plumbing ; for the heater hoses i'll be using an ( of all things ) f-body heater hose assembly wich fits and tucks in real nice under the puke tank and connects to the stock porsche stuff . and on one of the hoses i have to T in the puke tank itself just like on vette cooling system. all that is left to do for finishing that is a couple of under car soild lines i ordered to show up.

as for the rest of the cooling plumbing , i decided to just get some stainless steel pipes and elbows and make my own coolant lines after messing with countless rubber hoses, this way i guarantee myself a better fit and one less thing to go wrong in the long run.

so next up on the list is finishing the fuel lines , fab up some heat shields to seperate the headers and mufflers from what ever will be above them as well as isulate the cooler lines, alt. and A/C compressor where they get real close to the exhaust .

i'll also see if i can the heater hose done as much as i can without the parts i ordered .

08.23.10

some updates to report :

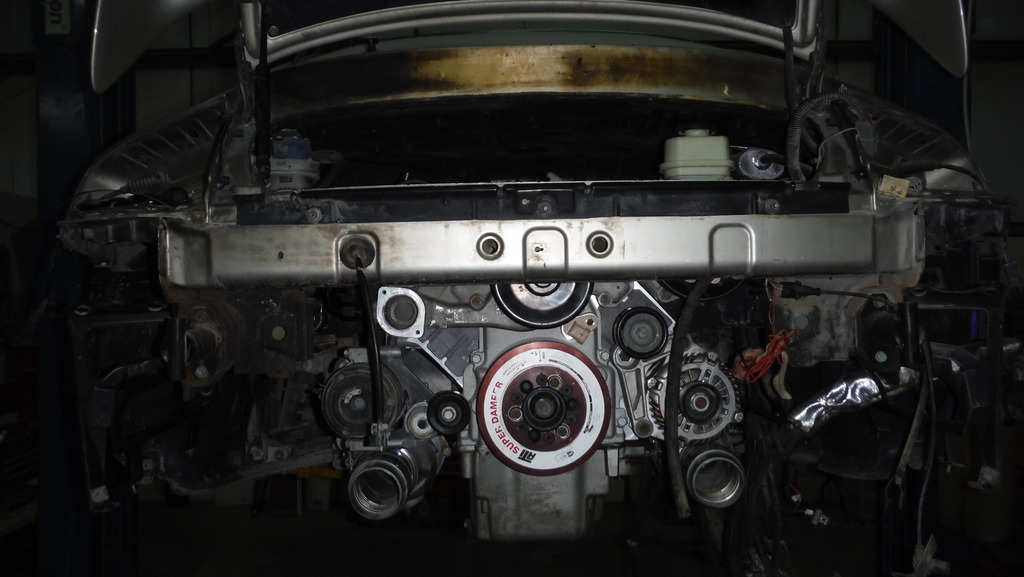

i took everything off the car in preperation for painting the engine compartment and putting the real engine in there. i also just got the coolant hoses and engine mounts from the powdercoaters today ( the hoses are silverish in color but for some reason they show up white in the pics) :

i also just finished painting the engine compartment ( just need one more coat to make sure i covered everything):

and i finally cleaned up the old porsche harness and cut/removed what wires i don't need , now they are nicely tucked out of the way:

and to cap all that i installed the GT2 slave conversion from EVOMS that gets rid of the bulky original clutch slave cylinder ( which by the way uses the power steering pump to provide the "assist" ) , evoms basically sells you all original parts along with their adapter bracket for the actual slave:

off course there has to be a hitch .,,,, i ordered some clutch fork shaft needle bearings and bushings a while back , and for some reason i can not find them !

so i reorderd them again and am now waiting for them to show up,,,, which means no engine trans mating ( and lift up ) untill they show up

i also finalized A/C hose and heater hoses routing , the heater hoses will be just like the

original porsche design and routing ( waiting for the metal hoses to show up too) , while the A/C lines will be routed in a way that they go over the trans , but more on that later .

so , next up on the list :

- paint compartment

- make a mini engine harness for the starter, porsche sensors , and other thingies

- fab a stainless steel section of coolant hose to tie into the original hoses

- install adapter plate and clutch on the the engine

09.15.10

some updates to report :

clutch fork stuff finally showed up!!

i started working on the stainless coolant tubes ( i want to run as little rubber hose as possible ) should have it knocked out tonight.

i also mounted the driver side intercooler bracket / bumper bracket.

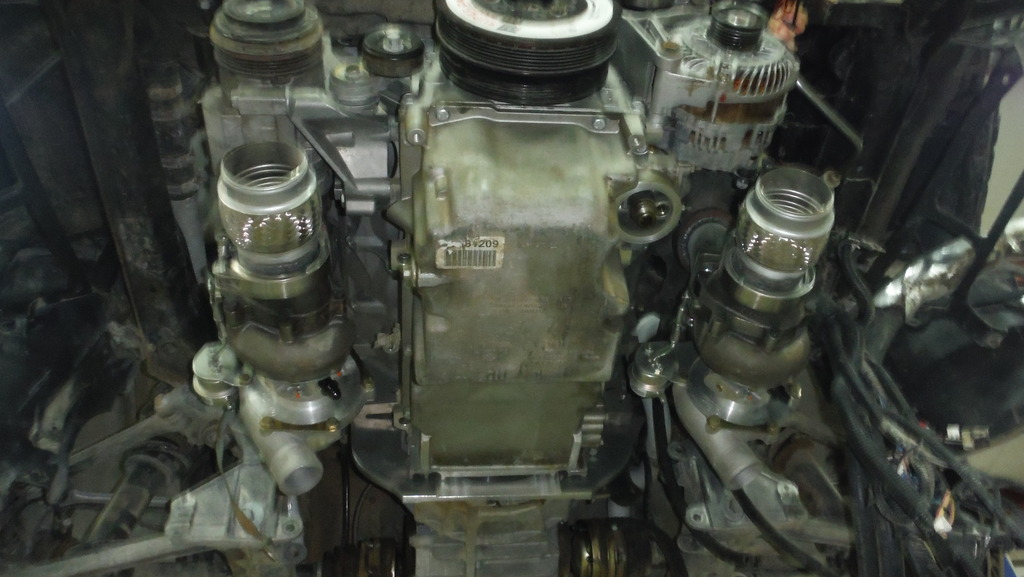

also got the original coolant hoses in place as well as the axles:

other than that ,,,,nothing

now that i got the clutch stuff i can get the engine inplace finally

more to come soon !

09.16.10

finally some progress

i had to build a new lifting cradle cause the first one i made was,,,well,,,, kinda flimsy

this one is made from much thicker material. this is really important cause you can't install the engine alone or remove the tranny by itself cause of how the flywheel fits ( more on that later ) so you have to mate them both on the ground then lift them as one unit into the car. This will have castors installed to make it easier to move the combo around and will have a jack adapter welded somwhere near the center of weight of the combo :

almost finished product :

i finally finished the clutch fork thingy

and i took the engine off the stand to install the adapter and flywheel:

notice how the flywheel is larger than the adapter opening , which means you have to install the adapter then the flywheel , then slip the trans on to the adapter studs ( can't do that while they are in the car) .

and here you see the engine on the lifting cradle :

so tomorow i have to:

- torque down the flywheel bolts

- pop in the pilot bearing

- and bolt up the clutch and tranny.

- lift up the engine/trans into the car.

- install all the accessories on the engine

- hook up clutch lines and shifter cables.

- install the powersteering pump and measure how long the lines need to be .

09.17.10

on to progress

i torqued down the flywheel , poped in the pilot bearing , then got the disk and pressure plate on there :

thats when i hit a small snag , the pressure plate uses some funky size torx bit bolts, which i didn't have at the moment , so i just hand tightened it by hand till i get some proper grade 8 allen bolts tommorrow .

so i decided to just see how it looks when done

"one small step for man , a huge setback for porsche purists " :

i think at that moment i felt a teardrop hit the ground in stutgart

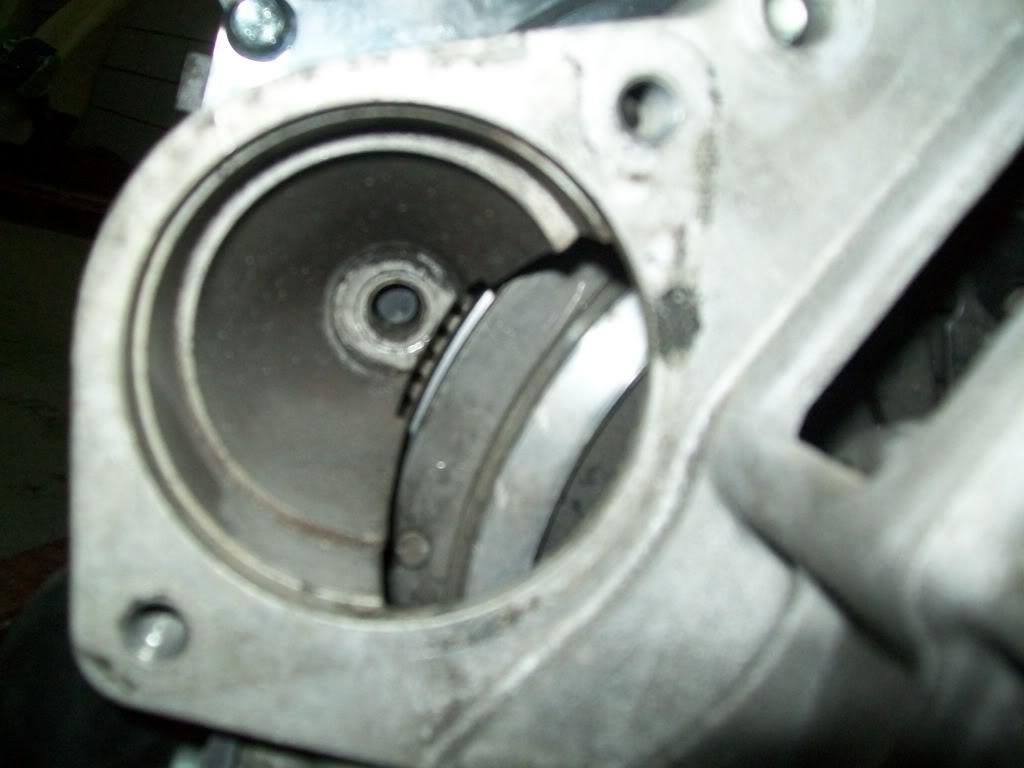

anyhow i almost had an "oh crap!" moment; when installing the trans on to the engine it looked like the starter ring would not fit into the bellhousing , but after a few words of pursuation it went in man do they have some tight clearances; you can see in the next pic the clearance between the ring and bellhousing is about nothing of an inch ( sorry for the out of focus pic but i could not get a proper pic no matter what i did )

i also made some templates for the heat shields that will cover the alternator and A/C compressor, i'll try to finish them soon using some sheetmetal or aluminum .

sooo, tommorow i'll get the allen bolts and finish bolting up the clutch , mate the trans to the engine , weld a few tabs on the lift cradle as well as castors and a jacking point to finalize it , then hopefully lift it into place in the car

and if i have time i should also mount the powersteering pump and figure out where to mount the reservoir ( its a GTO style unit with a remote resv. ) after that i have to take it off to compensate for the added thickness of the plate on the head by either machining the pad that the pump mounts to on the head or machining a bit off the back of the powersteering pulley so when i push it back on it lines up properly with the rest of the accesorries .

wish me luck

09.20.10

well got to work on it again last night , i got the new allen keys for the pressure plate and did the tape track to hold the fork in place ( thanks marky) as i mated the engine and trans together for the last time ( i hope ). i was not planning on doing much more other than a few odds and ends here and there ,,,, but

at 12:55AM monday the 20th of Sept. 2010 - one day ahead of schedule - the engine got a new home

pics of the whole process :

i rolled the engine into place under the car and started to lower the car on to it , when it got close enough i started to raise the tans end up into location to bolt up the trans mount , then proceeded into lifting the engine into place :

after bolting up the head plates / motor mounts i proceeded to cut the umbilical cord

and now i have a fully self suspended engine

so now i a acheived a major milestone in the project , and things should start rolling a bit faster from now on

funny thing is a i got a bit caried away with the instalation and never finished the lifting cradle , thats why you see me using the engine hoist and the rolly thing underneath the engine , but now i know how important the cradle thingy is.

so next up on the list :

- replace the bolts i used on the head plate with allen bolts ( looks cleaner / better

- swap the gto oil pan to the kevko pan and pickup i have

- bolt up the suspension crossmember and finish tightening the engine mounts

- install accessories like the alternator and waterpump and other stuff.

- finish fabbing up the heatshields on the ac compressor and alt.

- finish ( or atleast start working on ) the engine compartment mini harness

- route the heater hoses under the car

that should be enough to get the car down and off the lift so i can roll it back and start working on the interior and engine electrics and harness.

after that its on to :

- palce engine harness and mount PCM

- intake / throttle and injectors

- power steering and lines

- mount rear bumper and trunk lid

- finalize coolant tubes

- install new dash ( converting from auto to manual requires swapping the under dash assembly for the pedals )

- widndow and regulator

- check gas tank

- and it goes on and on and on

got cracking on it again and finished quite a bit of the things on the list above:

got the head plate bolts swapped out to allen bolts , swapped the pan and pickup tube, atttched the oil cooler lines, bolted up the suspension crossmember and tightened the engine mounts , mounted the alternator and bracket, installed the starter and the starter cable , bolted the driveshaft and tightened the axleshafts ( on the tranny side), and installed the swaybar.

up next is installing the headers and exhaust , water pump , tightening the axleshafts ( spindle side ) , bumper brackets , tightening the aluminum bumper , slapping on the bumper cover , and building the AC and alt. heatshields and i should be able to roll the car of the lift

i'm almost done with the bottom of the car but there are a few things i'm waiting on to really call it done. things like the ac lines and fittings to the compressor ,heater hoses ( still waiting on them) , and the mini harness .

i did get a few pics but its late and i'm too tired to upload and post them, will do it tomorrow

09.21.10

sexy oil pan and lines

axleshafts and driveshaft and another angle of that sexy oil pan ( don't you think i have an oil pan fixation

forgot to mention that i installed the dipstick

10.06.10

sorry for the lack of updates , just been busy with other stuff and just found out that the racing season here will kick off in about two weeks ! ( great job BIC for telling us that just now )

For some reason , routing the coolant hoses is kicking my butt! i don't want to do a hack job on it and just run some flexi hose deal , i'm trying to make it look decent and somewhat OEMish , which doesn't seem to be easy !

so , there are two sides to deal with regarding the cooling system hoses in the engine compartment ; pass. and driver sides.

on the driver side , you have the two heater hoses ( still waiting on the stupid metal hoses - the first time the mail service i used lost them , and now i''m still waiting for the replacements) , main porsche coolant line , T from the main coolant line to the expansion tank, and the "L" to the waterpump outlet.

on the passenger side , you have the porsche main return line , the funky stainless hose i made , and the thermostat housing .

on the driver side - after many a head scratch and visits to parts stores , and countless $$$ spent on some really weired looking hoses - i decided to do the following :

from the main porsche hose use a rubber coupling to the funky tube i built , then run a 90 deg rubber elbow into the "new" thermo housing . why a new housing ??? cause the freaking angle and size of the orginal one was giving me a hard time , so it was just easier to go to a machine shop and tell them to make me a straight up housing with a 1-3/4 neck.

here's how the 1-3/4 stainless hose looks like :

and how it looks in the car :

it terminates just before the thermostate housing location , so now all i need is 90 deg 1-3/4 elbow and i'm set ( sorry no pics of the housing or the end result yet)

as for the driver side ,,,,, it gets a bit more complicated ,,,, so to solve this i decided to use a few rubber hoses as possible . i fount a small plastic coupler that has a nipple so i can conncet the main line to the expansion tank , and from that plastic paice i'll run a stainless hose along the engine compartment wall to the water pump outlet. kinda like this :

but then i realized the just where the bend is is the air intake tube hole , so the hose can't run there . so the solution was a few 90 deg. bends to snake around the engine mount bolts and then back to the rear engine compartment wall. this is how the other "funky" looking stainless tube looks like : (trust me the welds look much prettier in person )

this inturn will lead to the other stainless hose ( i'll make these all one peice later on ) i made which is the water pump outlet hose.

for that hose to work it had to clear the engine cover latch ,,,, wich means more elbows!

well since it will take quite a few words to explain , i'll spare you the novel and snap a few pics soon

moving on ,,, i also got the inner fenders in a few days ago and bolted them on and i also got the AC pump fitting in , so i can start routing the AC hoses now

and i machined a fitting/adapter to mate the stock porsche oil pressure sender to the side of the remote oil pump mount .

and i ordered a CTSV powersteering pump setup so i can finally be done with the steering and its hoses . also ordered was an ATI| balancer and a starter to alternator to main harness cable ( oem porsche ) , those should be here in a week or so .

another cool thing i found out is that i don't need a boost guage

i always wondered why i could not find any aftermarket boost guages for this thing,,, and found it odd that there isn't one on there . well it turns out there is one and its a digital one on the dash information panel ( saw it in action last week on another porsche )

i'm still working on the ALT. and A/C heat shields , and also started to work on the upper heatshields ( kinda isolates the coils and other stuff from the headers).

i know its alot of talk for not so much progress , but i will make it up to you guys

as soon as i'm done with this coolant crap , i'll slap on the harness and intake, connect the fuel lines, and maybe take the car off the lift and start working on the interior for a change .

( and no ,,,, i still didn't work on the engine compartment harness )

10.09.10

i think i managed to hit a small milestone last night ;

the car is off the lift and rolling at its own free will

funny thing is like all ls1 conversions ,,,, i need to lower this one as well

check the fender gap in the rear !

and i just noticed something while i was pushing the car into place , the damn thing is light! so light that i had no problem steering it with one hand while pushing it and while at a standstill. this is causing me to possibly rethink my powersteering plans

i also almost finished the driver side coolant tube , its now all stainless with just a few sections of rubber for when the engine vibrates:

here it is before welding it :

you can see how i had to cut back the outlet tube on the water pump a bit to give me more room . i also got the thermostat housing from the machine shop , i had them make me a straight outlet that is 1-3/4 OD to make life easier for me : all i have to do is get a a 90 deg. elbow that is 1-3/4" od and be done with

offcousre after all is done and finished i'll be taking everything to the powdercoaters to get a nice coating of black or silver maybe.

here is how the new thermostat housing looks like :

but there's only one problem : the neck is too long , so i'll be taking it back and shortening it along with the porsche oil pressure sensor adapter that i made ( taking it back cause i told them to machine the threads on the wrong end )

the sensor will be located out of the way on the side of the remote oil filter.

and i finally got the alternator to starter cable done now i have to get a block grounding cable fabbed up and i'll be happy

so now that the car is on the ground, i can take a brake from working under it and focus on the top part , some of the things i'm planning on doing now :

- install intake manifold and throttle body

- plug original oil sensor hole

- get some waterpump bolts and permanently mount that thing

- hook up fuel lines

- modify then lay the ls1 harness in place

- get a throttle cable made

- remove the existing under dash brace ( need to do so so i can swap to a clutch pedal)

- figure out where to mount the PCM

that should keep me busy for a while till i get some under car parts in ( like the balancer and heater hoses )

10.16.10

moving on ,, i got some work done last night

i finally got the dash brace out ,,, after many nights and days un bolting and un screwing and looking for hidden bolts and screw , i finally got the dash out , and i have enough bolts and nuts and screw to re build the titanic

here is the after math

and here is what i got out

i was happy i was done with removing it ,,, but then i realized something !! the damn thing is identical to the new one except for the clutch pedal bracket and bolt!!! i could have just bought the bracket, pedal, and a few other dodads and just bolted them to what i had and be done with it ! i guess is should have researched ( and poked my head under the dash ) a bit more

http://i896.photobucket.com/albums/a...p/100_2469.jpg

another point in the project i reached and was postponing is the gas pedal deal; the porsche uses a pedal unit that bolts to the ground , and has a cable that runs out of it and up into the dash ,,, which is fine till now and looks promising ,,,,, untill you find out that the cable is only about a foot long and ends under the dash at the TPS sensor !?? why wouldn't you just incorporate the sensor into the pedal assembly ??

here is how the pedal unit looks like :

it basically has a cam inside that the cable runs over , then goes out to the sensor , which has another cam and the cable is attatched to it :

at this point i don't know if i should keep this unit or go with something different , the problem with this unit is that it does not have that much travel , which leads me to think it won't open up the LS1 throttle all the way . on the other hand , it would be nice to keep it and keep the sensor working , and find some way to use them both so i can retain the stock tps signal for later use , plus this being an automatic car before, it had the benifit of a kick down switch built in to the pedal ! you never know when that will come in handy ( finger is pointing to it )

either way the cable routing is pretty straight forward , from the throttle body it will go back and up into the hump behind the passenger seats ( there is a hole already there- just above the intake manifold) and work its way on top of the driveshaft tunnel ( and under the carpet ) towards the shifter , then goes through the center of the dash anturns into what ever solution i come up with for the pedal

anyhow , i'll keep banging my head till i find a solution cause only then can i bolt up the dash .

furthermore, i installed the steam vent tubes on the engine , i'm planning on running two vents ( front and back ) and have them tied together and connct to the puke tank. the reason for that it that the engine sits pretty flat if not tilted backwards ( think hard acceleration ) and having the vents plugged just seemed it would cause steam pockets, so i used two cross over vents front and rear.

i also got the ATI balancer in finally and plugged the oil sensor hole in the block , and bolted in the porsche oil pressure sending unit on to the remote filter thing ( sorry no pics ) and got the shortened thermo. housing inplace , and finished the driver side coolant tube , here is a picture of the finished product in place :

up next on the list :

- figure out the throttle cable/pedal delimma

- once that is done , bolt the stupid dash back in place

- connect the vent tubes together and tie into the expansion tank

- clean and install the intake, fuel injectors, and rails

- finish up the coolant hoses.

10.24.10

i did try out the porsche gas pedal and its a no go it just doesn't have enough travel - it moves the throttle body about 1/3 of the way only.

so i'll be ordering the pedal soon and and have the cable made locally to the length needed.

furthermore, i did bend the aluminum sheets that will be used as upper heat shields, as well as the ones to be used for the alternator and A/C compressor. also sent the injectors in to be cleaned and should have them back today.

i should start getting back into it this week ,

i should have the intake all cleaned up and installed along with the injectors and rails.

also should start putting the dash and berace back in , which should be a fun process

11.06.10

time for a minor update:

i made a set of upper heatshields to seperate the coils and top of the engine from the heat generated from the mufflers right underneath it , its basically a bent sheet of aluminum with notches cut into it to clear the plug wires:

and here is how they look on the car (before notching) :

also got the caddilac CTS power steering pump in , but for some reason when i bolted it on the engine it was sticking out about 3 grooves out ( serpentine belt grooves ), so i got a hold of a '08 caprice pump ( we still get these over here, thery're the holden veresion) and stood them next to each other and still the same result,,,,, only difference is the CTS pump is mounted on a bracket and theCaprice bolts right to the head , so we'll see how that goes when i get back to it

i also got the ls6 intake cleaned and prettied up

almost looks like new !

and i got the injectors back in from cleaning, these are green top ford units ( i think they are 43lbs /hr IIRC) , so i'll be slapping those on the stock rails i have somewhere here and then bolting them up to the intake. that and bolt up the lokar throttle cable bracket

meanwhile , i did bolt up my sexy black 90 mm throttle to the intake to see how it looks in the car :

and might i add it looks sexy

seriously , i had to do so to double check throttle elbow/ intake clearance ; i was worried that the latch assembly would be too close to the throttle body so i installed it and put the engine cover back on , and luckily i have enough room

(sorry for the crappy pic)

furthermore, i also started on making a new radiator hose on the pass. side of the compartment , the one i have now is 1.75" and is somewhat in the way of the intercooler hose route ( in the future) and is rubbing on the engine mount plate bolts. so i decided to make a 1.5" tube that snakes away from all that and is a better fit in the compartment, plus it standardizes the hose sizes in the engine compartment . i also installed the steam vent tubes on the engine ; i used two stem vent tubes one for the back and the other for the front. i did that because the engine sits so flat i was concerend that under acceleration i might get some steam pockets at the rear of the engine , so this was a little added insurance .

moving on ,,, i finally got the dash brace all in what a pain in the a$$ ! i keep reminding myself how much easier this project would have been if this was a manual car to begin with , but oh well ,,,

i didn't install the actual dash cause i was still debaiting and thinking about the pedal issue . like i mentioned before, i ordered the lockar pedal and i got it in , its a bit smaller than what i anticipated , but not by much. however after getting it in and seeing and thinking of how to mount it i came up with the following conclusions: i could either build a bracket to mount it in the stock location and have it sit a tad higher than the stock location and loose the TPS sensor signal ,,,,, orrrrr ,,,, just use the stock one!

how you ask after seeing it and seeing how messed up those germans made that pedal assembly , well to make my life easier and others who might be doing the same project in the future i decided to use the stock pedal assembly and just install it like it was before and with the sensor connceted and all that , but the only diffference is that i would drill the top of the pedal horizontally and place a long through bolt that whould would act as the mounting location for the cable end ( think of the bolt going across your toes when your foot is on the pedal ) , the cable would be held in place with a bracket in on the trans tunnel or under the dash and the wire that moves exits it to the pedal , the closest i could think of is a gokart pedal assembly. the cable would mount on the right side of the pedal and close tot he tunnel , which should make it out of the way of my foot

another benifit is that i can change the pedal ratio just by relocating where the bolt goes in on the side of the pedal ( the higher up the pedal i mount it , the more travel i get , and the lower the less travel i get

that sums it up for now , like i said , its a bit slow since i'm putting more effort into the camaro now that the season is ramping up, but i will be working on this nontheless

so next up :

finish as much as i can with the interior , which means :

-throttle pedal and cable

-install dash

-hook up master cylinder and fill clutch hydraulics up

-center console and seats

then there is the rear of the car :

-install intake , fuel lines, and throttle and other related stuff

-start building the mini engine compartment harness

-install the standalone harness and mount the PCM

-finalize coolant system ( still have to route the puke tank hose and the steam vents into the puke tank )

11.26.10

well i've been busy with the camaro and the race that just took place in bahrain , then i went camping and just came back a few days ago , so sorry for the delay in updates

anyhow,,,, i think i can call the clutch hydraulics done now; i finally hooked up the reservoire to the master and the master tot he rest of the plumbing. all i have to do now is fill it with fluid and bleed it . also i can scratch the shifter and e-brake off the list sice i installed them both too.

also installed the dash pad finally , the weird thing is that it went in quite easily and i only have 3 screws left over

i didn't install the center console cause i still have to route the throttle cable - and fab a bracket on the gas pedal ( more on that later).

i also decided where i want the pcm, it will be in the cabin and right where the porsche unit would be. here is how it looks in place :

and how it looks when covered with the stock carpet :

i just have to drill a hole on the pass side rear bulkhead ( just above and to the left of the pcm - in the pic above) to route the harness through .

moving on ,,, i got me an ls2 fuel rail and slapped it on the intake along with the injectors , but when i tried to install the intake the top of the fuel rail (crossover tube ) hit the top of the engine compartment , so i guess i have to get some aftermarket rails for clerance reasons

also finished connecting the vapor tubes to the puke tank , as well as puke tank to the coolant tube .

so thats what i got done recently , next up is taking the powersteering pump bracket to have 4 mm machined off its back ( so the pulleies allign) and installing it . after that i have to do the p/s lines.

also on the to do list is drilling a hole in the rear bulkhead to pass the harness through, clean up the harness , and mount the pcm

also have to fab a bracket on the pedal and under the dash to hold the throttle cable

furthermore , i guess i can roll the car back on the lift so i can :

- install the balancer

- install the alt. and A/C heatshields