You must be logged in to rate content!

7 minute(s) of a 536 minute read

9-17-2010

on to progress

i torqued down the flywheel , poped in the pilot bearing , then got the disk and pressure plate on there :

thats when i hit a small snag , the pressure plate uses some funky size torx bit bolts, which i didn't have at the moment , so i just hand tightened it by hand till i get some proper grade 8 allen bolts tommorrow .

so i decided to just see how it looks when done

"one small step for man , a huge setback for porsche purists " :

i think at that moment i felt a teardrop hit the ground in stutgart

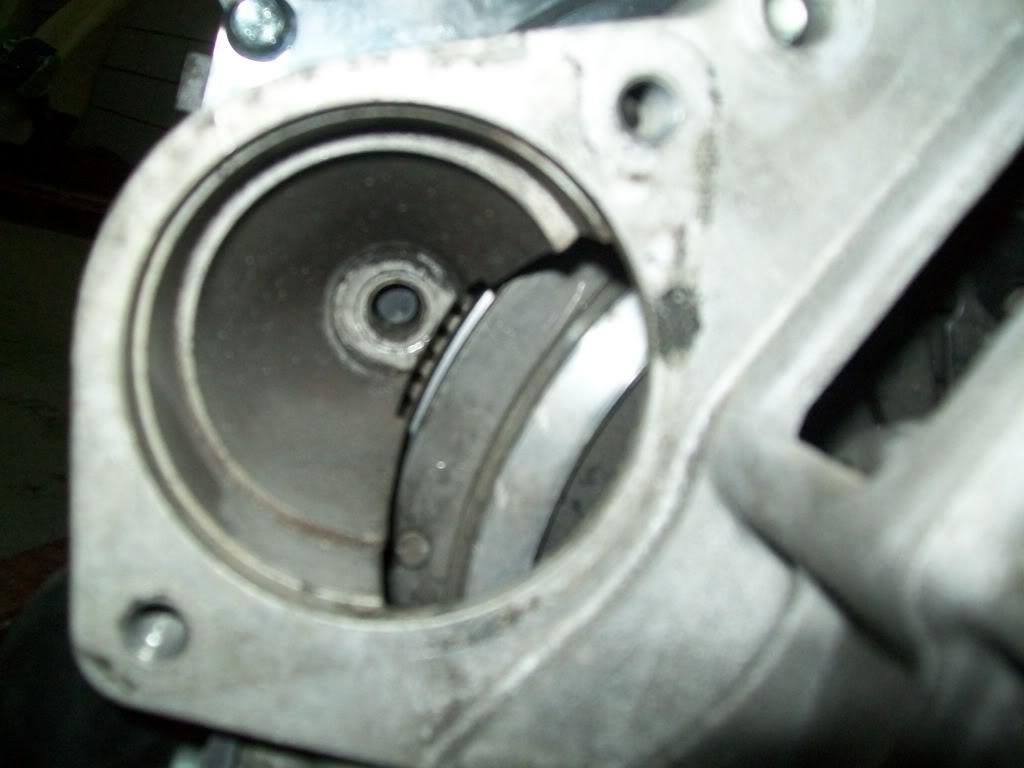

anyhow i almost had an "oh crap!" moment; when installing the trans on to the engine it looked like the starter ring would not fit into the bellhousing , but after a few words of pursuation it went in man do they have some tight clearances; you can see in the next pic the clearance between the ring and bellhousing is about nothing of an inch ( sorry for the out of focus pic but i could not get a proper pic no matter what i did )

i also made some templates for the heat shields that will cover the alternator and A/C compressor, i'll try to finish them soon using some sheetmetal or aluminum .

sooo, tommorow i'll get the allen bolts and finish bolting up the clutch , mate the trans to the engine , weld a few tabs on the lift cradle as well as castors and a jacking point to finalize it , then hopefully lift it into place in the car

and if i have time i should also mount the powersteering pump and figure out where to mount the reservoir ( its a GTO style unit with a remote resv. ) after that i have to take it off to compensate for the added thickness of the plate on the head by either machining the pad that the pump mounts to on the head or machining a bit off the back of the powersteering pulley so when i push it back on it lines up properly with the rest of the accesorries .

wish me luck

09.20.10

well got to work on it again last night , i got the new allen keys for the pressure plate and did the tape track to hold the fork in place ( thanks marky) as i mated the engine and trans together for the last time ( i hope ). i was not planning on doing much more other than a few odds and ends here and there ,,,, but

at 12:55AM monday the 20th of Sept. 2010 - one day ahead of schedule - the engine got a new home

pics of the whole process :

i rolled the engine into place under the car and started to lower the car on to it , when it got close enough i started to raise the tans end up into location to bolt up the trans mount , then proceeded into lifting the engine into place :

after bolting up the head plates / motor mounts i proceeded to cut the umbilical cord

and now i have a fully self suspended engine

so now i a acheived a major milestone in the project , and things should start rolling a bit faster from now on

funny thing is a i got a bit caried away with the instalation and never finished the lifting cradle , thats why you see me using the engine hoist and the rolly thing underneath the engine , but now i know how important the cradle thingy is.

so next up on the list :

- replace the bolts i used on the head plate with allen bolts ( looks cleaner / better

- swap the gto oil pan to the kevko pan and pickup i have

- bolt up the suspension crossmember and finish tightening the engine mounts

- install accessories like the alternator and waterpump and other stuff.

- finish fabbing up the heatshields on the ac compressor and alt.

- finish ( or atleast start working on ) the engine compartment mini harness

- route the heater hoses under the car

that should be enough to get the car down and off the lift so i can roll it back and start working on the interior and engine electrics and harness.

after that its on to :

- palce engine harness and mount PCM

- intake / throttle and injectors

- power steering and lines

- mount rear bumper and trunk lid

- finalize coolant tubes

- install new dash ( converting from auto to manual requires swapping the under dash assembly for the pedals )

- widndow and regulator

- check gas tank

- and it goes on and on and on

got cracking on it again and finished quite a bit of the things on the list above:

got the head plate bolts swapped out to allen bolts , swapped the pan and pickup tube, atttched the oil cooler lines, bolted up the suspension crossmember and tightened the engine mounts , mounted the alternator and bracket, installed the starter and the starter cable , bolted the driveshaft and tightened the axleshafts ( on the tranny side), and installed the swaybar.

up next is installing the headers and exhaust , water pump , tightening the axleshafts ( spindle side ) , bumper brackets , tightening the aluminum bumper , slapping on the bumper cover , and building the AC and alt. heatshields and i should be able to roll the car of the lift

i'm almost done with the bottom of the car but there are a few things i'm waiting on to really call it done. things like the ac lines and fittings to the compressor ,heater hoses ( still waiting on them) , and the mini harness .

i did get a few pics but its late and i'm too tired to upload and post them, will do it tomorrow

Nice details ????

Posted by Diggymart on 5/1/19 @ 2:11:40 PM