You must be logged in to rate content!

8 minute(s) of a 241 minute read

12-16-2016

It's been two weeks and i haven't had any free time to work on finishing the car, and it's frustrating because is so close to being finished, so i've made the decision tomorrow to use every minute that i can to work on the harder thing first and start buttoning every system on the car one by one, more to come.

12-17-2016

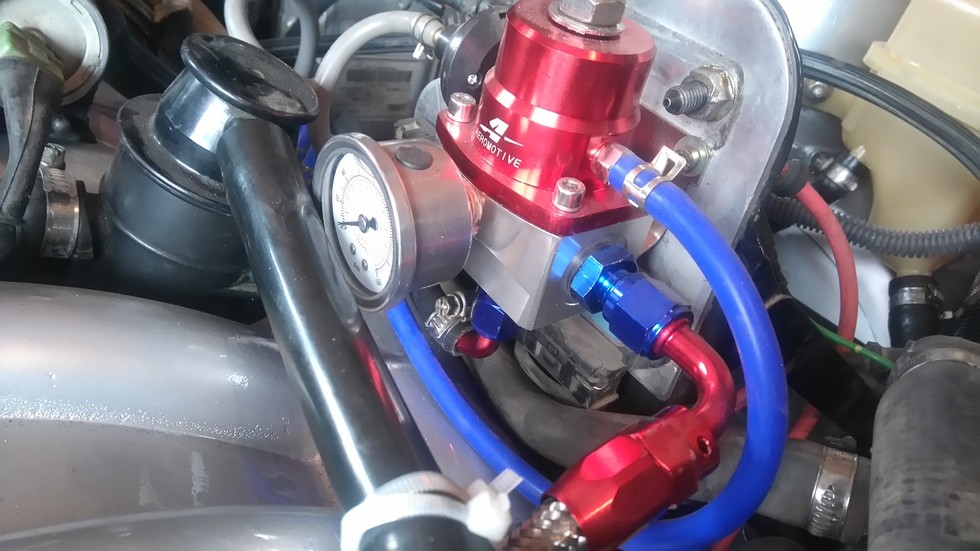

Today didn't go as planned, i started working on the fuel system started mocking up the fuel filters and got dirt in my eye, its far from the first time it's happened but i wasn't able to remove it, so i went to a eye doctor, and had to wait in a line half a day, so only work that got done is i installed couple of silicone vacuum lines, the gray one is for sensors, and the two blue are for fuel regulators, LPG and petrol, only open vacum port is for the power brakes, more to come.

1-6-2017

Happy new year and happy christmas to you all, i really should stop predicting timelines for finishing projects, because it seems i can't keep them, in the meanwhile santa left couple of presents for this project, in form of exhaust temp gauge and proper titanium heat wrap, this couple to the Air/fuel gauge should allow me to properly tune a mixture and stop me hurting the engine, on another note we got proper winter weather now -10 to -20 centigrade and lots of snow, this is the first time in my life i've had to use a shovel to clean my cars.

1-16-2016

The weather started to linger around the zero and i start to spend some time in the garage, but not working on this project, my brothers little 206 started to sound like a train when stopping and started locking up the wheels easy, i'm sure his driving style doesn't help, so i had to replace the brake pads and shoes and had to cut the rear drums, had a hell of a time trying to get them off, adjuster bolt stuck and had big ridge on the edge, you can see, new to me lathe that i bought, it's a 1K62 has a 10kw main motor real beast.

1-17-2017

Yes Mike i do like it, you can see by the finish it leaves on the brake drums, may be old but is very powerful and precise.

1-24-2017

Today i had couple of hours to spare, most of the i spend cleaning the parts room, which was a mess, i also did this, removed the thick fire rope and wrapped the exhaust header i proper titanium heat wrap, it should help with under hood temperatures, it wraps nicely but need to be pulled tight to avoid wrinkling, the stainless steel tai wraps that came are too short so i had to couple two to reach, and use a stainless hose clamp at the end, more to come

1-26-2017

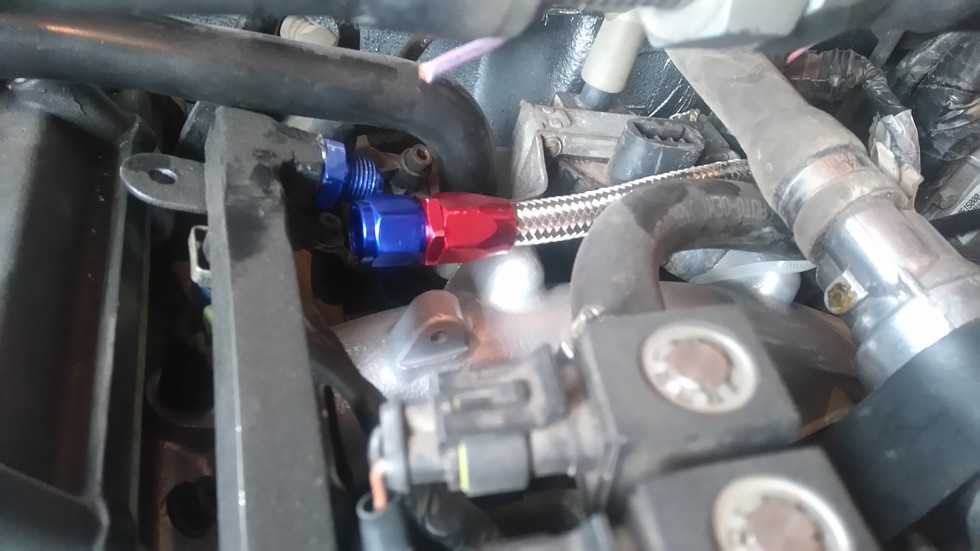

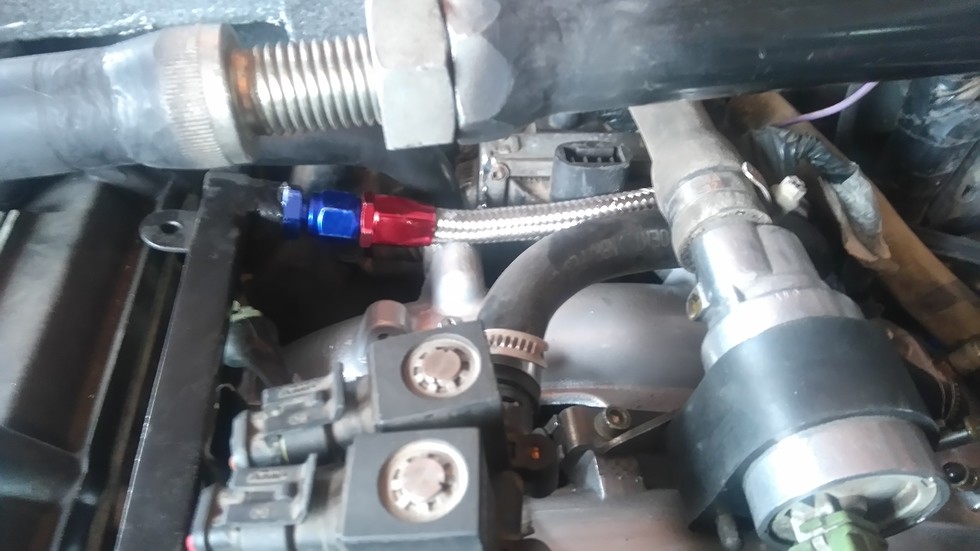

Today i had a real plan, i'll hurry back from skopje and i'll start on the fuel system, half way back on the highway just as i speed up i heard very loud noise from the side windows like someone is throwing rocks at me, stopped and this is what i found, the windshield moldings somehow got unglued, and the metal clip in the middle was gone, andstarted whipping on the windows, this being my daly had to fix it, so instead of working on the mi16, i end up spending two hours gluing the molding and finding a spare molding for the middle, while waiting for the glue to set i managed to assemble the AN6 fitting on the braided line, and i decided to use rubber line for the return because there is very little pressure in the return line, more to come

1-30-2017

Today i've put in couple of hours of work on this project, started with the fuel lines, i was able to connect the return line at the regulator and hard line without any problems, but the supply line was hitting the ignition coil bracket, so i had to remove the coil and trim the bracket, and then i was able to connect it to the fuel rail, and started mocking up the fuel lines, but i'm missing couple of fittings, so i moved on the radiator hoses, and i was able to find all hoses only one needs a coupler in the middle, more to come.

2-2-2017

Today i started by finishing the cooling system, after i connected all the coolant lines i decided to do a pressure test before i fill the system with coolant, started with the hand pump but i wasn't getting any pressure rise so i grabbed a nitrous bottle and a regulator and connected it, there where many loose hose clamps, i had to remove the battery tray to access some of them and after an hour tightening every hose clamp, the system was holding 1 bar of pressure without leaks so i filled the system up with G12 coolent and i had a leak, that is really strange, holds air but leaks liquids, decided to leave it, it should stop, after that i mounted the intercooler and radiator support, after that mounted the fans and passenger side headlight left the drivers side one because i need access to the wiring there, then i reinstall the battery tray, you can see all the space available in front of the engine now, it should make for easy timing belt replacement, more to come.