You must be logged in to rate content!

8 minute(s) of a 241 minute read

11-26-2016

Today i started by resorting couple of problems i had yesterday many around the intake, started by listing the bosch sensor catalogue and manage to find sensor with a wire and same characteristics now the conector can reach, i did not want to cut and extend the sensor wire that will change the ecu readings, than i made this adapter plate from AFM to 75mm cone filter, more to come.

11-28-2016

This was easier solution and i had the sensor sitting around so i used it, lately it seems everything takes much longer than it should, figuring out the intake location and finding parts it's been difficult, the throttle body flange is 83mm and AFM 68mm and needs a tight elbow and i need to connect a hose there for the idle valve and crank pressure, today i finally was able to find this aftermarket elbow so this should be my intake side, i still haven't test fited it but should work, there are couple of hard dirty jobs to be able to finish this project, more to come.

11-29-2016

Today winter arrive, overnight temperature drop in negative, and we got the first snow, so i did not spend too much time in the cold garage but i managed to assemble the drive shaft and remember Rabin's advised to use little grease to avoid boot failure, wanted to install it but i'm missing half of the bolts that mount it, so i'll try to find some tomorow, also i had to replace couple of light bulbs, not sure is it the quality or the conditions, but i'm replacing 2-3 bulbs a day, more to come.

11-30-2016

Today the temperatures dropped even lower but i keep the momentum going on this project, started by offering up the intake that i had mocked up, but it was to long it was hanging out of the hood, so i cut back the silicone coupler as much as i could, and found another coupler that i also cut down to make it fit, next thing was to make a mount because there is almost no space for the silicone coupler to move i decided to mount the AFM solidly to the throttle body that way the entire intake can move with the engine, the bracket or shelf took couple of tries started trying to make it from one piece, there wasn't enough material, then after screwing up couple of pieces this one came out close so i weld it and finish it smooth, i have to do one more thing to finish this intake, that is to drill and tap a large hole in the throttle body, because there is no easy way to attach it to the silicone coupler for the idle valve and valve cover breather, more to come.

12-1-2016

Small update today i spend an afternoon going parts store to parts store looking for the driveshaft bolts, they are specific strength 12.9 and length and no one has them in stock so i visited couple of car disassembly places and they had them but not removed, and did not wanted to get dirty and wet removing them, so i had to get underneath a 4x4 i chose it because it was the driest and highest to make easy acces, at the end i got them, couple of stores offered me grade 8 bolt but i know first test drive i'll would have snapped them, little clean up and i can install them, more to come.

12-2-2016

Today i decided to measure the temperature of the floor on the garage, and even i was surprised it measured( -5,7) celsius that is cold, never the less i started by cleaning the bolts i got yesterday, the best way to clean bolts i've found is to put them in a glass jar with a hand full of smaller nuts fill it with gasoline and shake it, all the grease and grime comes off, after that i lay a piece of trunk carpet and lay on it and install the driveshaft, for some reason the CV boot seams very close to the shifter linkage witch is strange, next i disassemble the intake, then i drill and tap an M18x1.5 and screw in a big nipple, decided to go with a screw in nipples to avoid leaks and they should hold up better then the press in ones under boost, as a final job i painted the bracket with primer, not sure which color to pain it, more to come.

12-3-2016

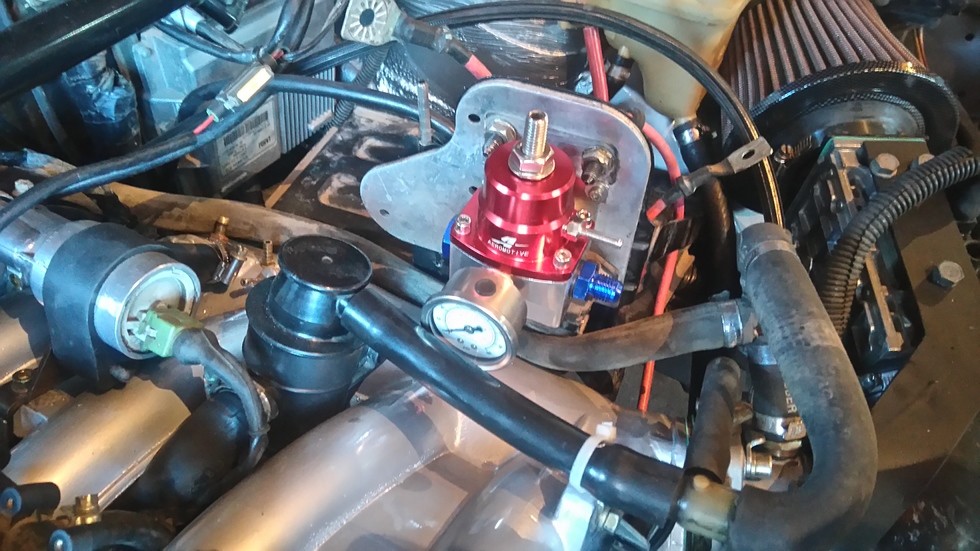

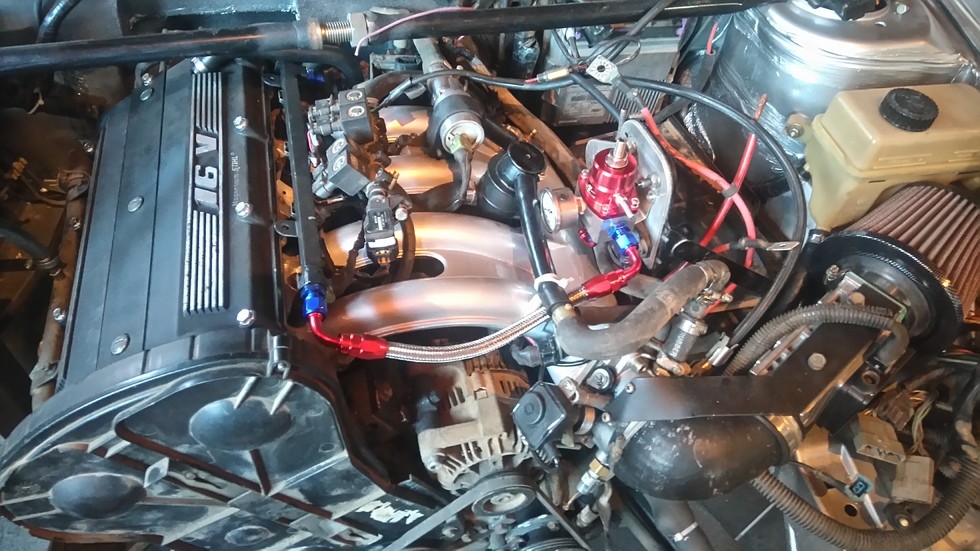

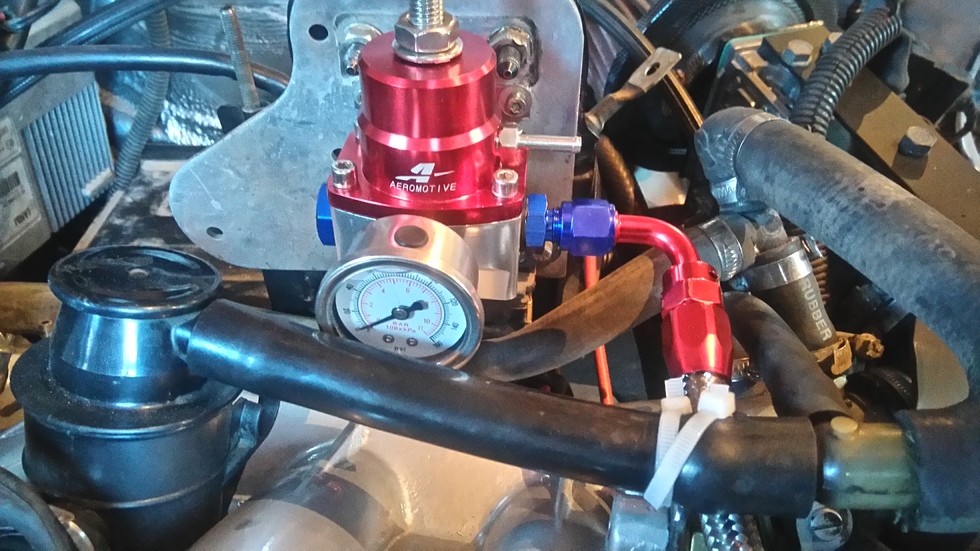

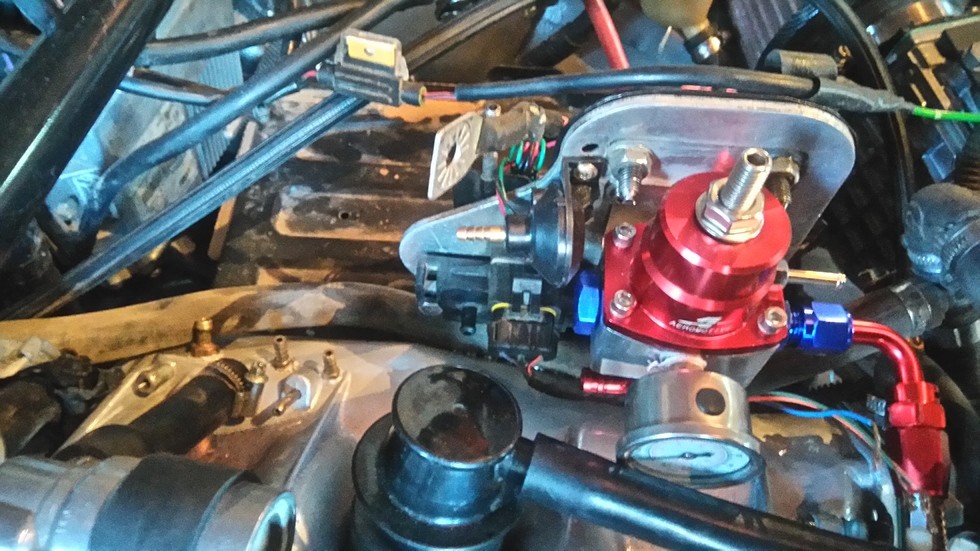

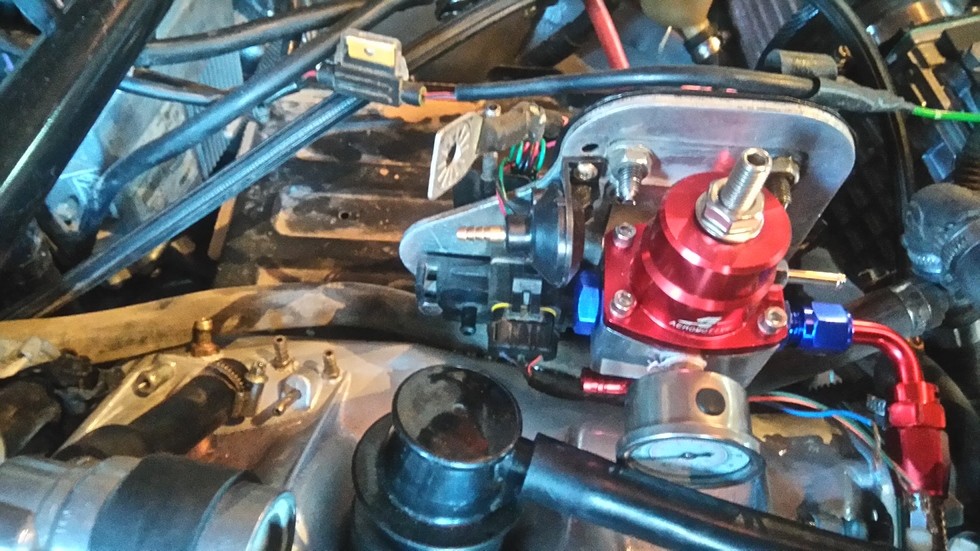

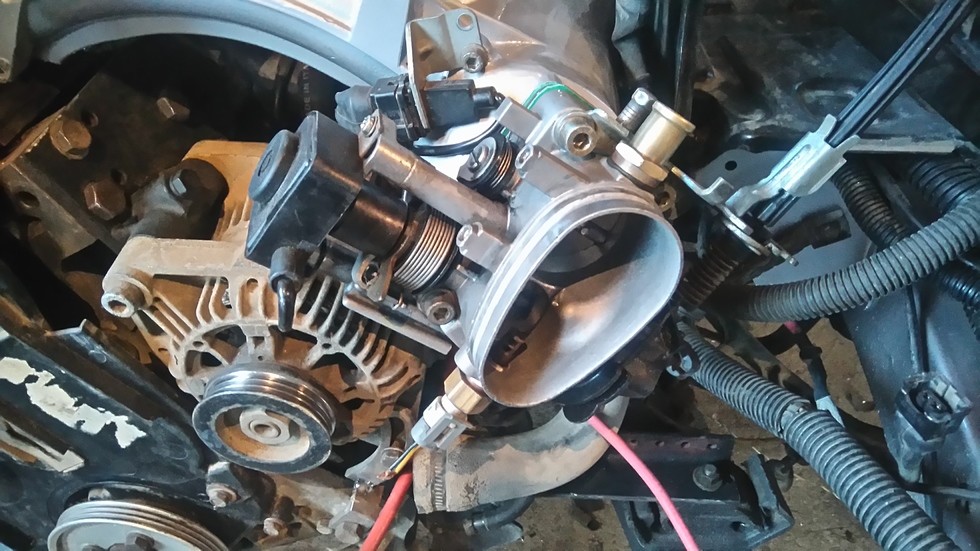

Today i've put in lots of hours working on the car, started with making mounts for the power steering pump, this took couple of hours and decided to finish the power steering system, first found a new supply oil hose, then i installed return line from the steering rack, and then band and install the high pressure line, had to make a loop to be able to move with the engine, and had to make a bracket for the line, and the original mi16 bracket fitted like factory, had to drill and tap a new hole, this way is properly supported because the radiator will be close i wrapped the lines in heat resistant insulation, then i made a restrictor for the vapor recirculation and found and installed the rest of the intake and vapor recirculation also maunted the AFM and filter, then i mounted the new fuel regulator and made an AN6 hose from the fuel rail to the regulator, this i the first time i'm assembling AN hoses, they are easy to assemble, last thing i mounted was couple of sensor, it's starting to look like a complete engine almost, i have a question, the alternator has one more wire is for sensing the voltage, where to connect it in the wiring loom?