You must be logged in to rate content!

8 minute(s) of a 241 minute read

11-8-2016

Today first i went to the hardware store, only thing for heat shield was this 10mm rope, i'll probably replace it when the proper stuff arrives, and then started mounting the engine, its becoming easily every time i do it and after more then 50 times it was in less than half an hour, then i connected the clutch line and bleed the system, the pedal feels strange, i have to adjust it and find a way to test it, after that i mounted couple more things like the coolant neck for the block, now i have to decide how to go forward, should i install the bigger pieces first and then shape the rest to adapt or should i start with the wiring loom and the shape the hoses and other pieces ?

11-9-2016

Today i spend couple of hours in the garage, did lot of work on the intake manifold, did lots of grinding outside and inside, almost all done on the outside but for the inside it was much harder, and i'll have much more to do, when waiting for the tools to cool down, decided to install the shifter, it went in as it should and works perfectly, short and precise with the mechanical feel like the bolt action on a rifle, the intake is one of the last big pieces that need to be finished to be able to finish this project, on another note i was looking on the roadkill page they had a article for the italian, france car show, and looking thru the pictures, number 52 i see a mi16 engine with red valve cover and black inlet manifold, very familiar, than in picture 88 i spotted savo's mi16 with the hood up, looking great, i was very pleased to see such a deserving car getting the attention it deserves more to come.

11-11-2016

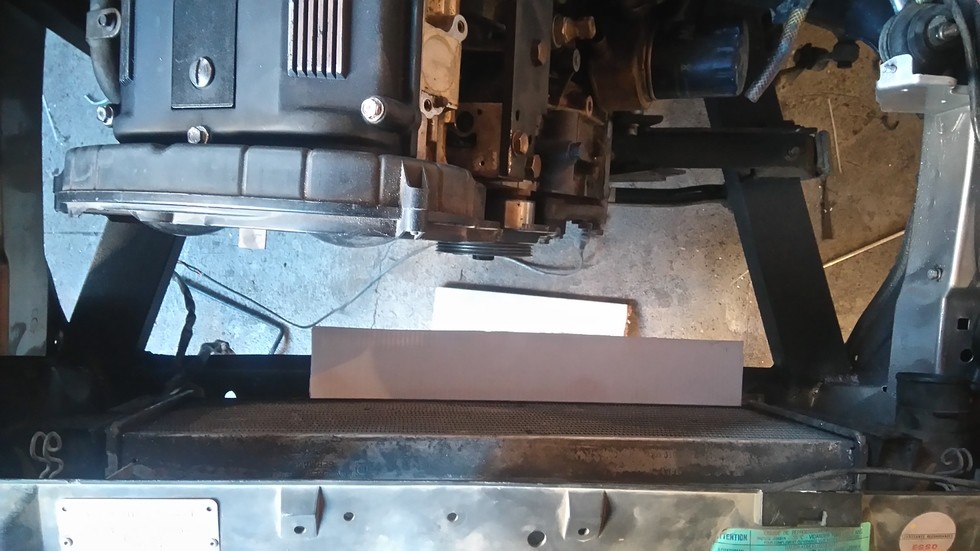

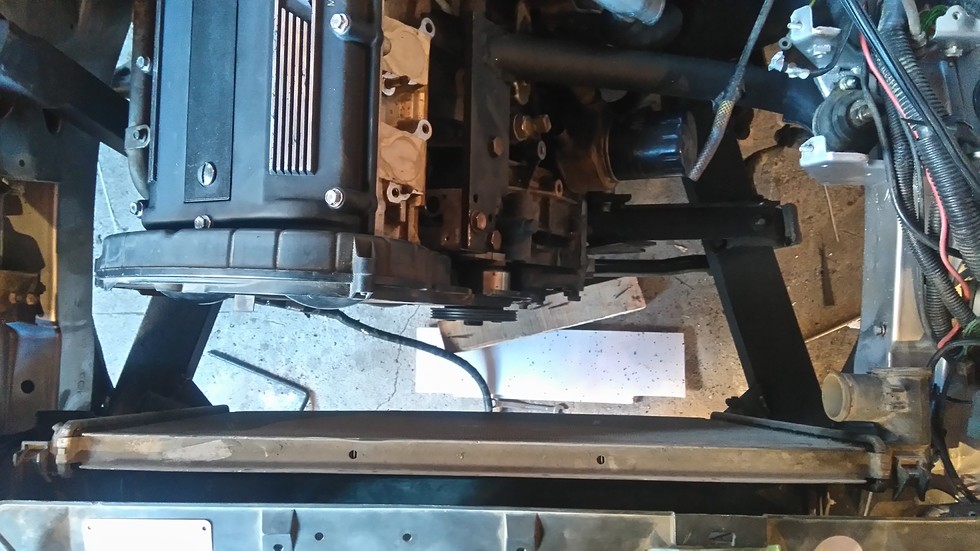

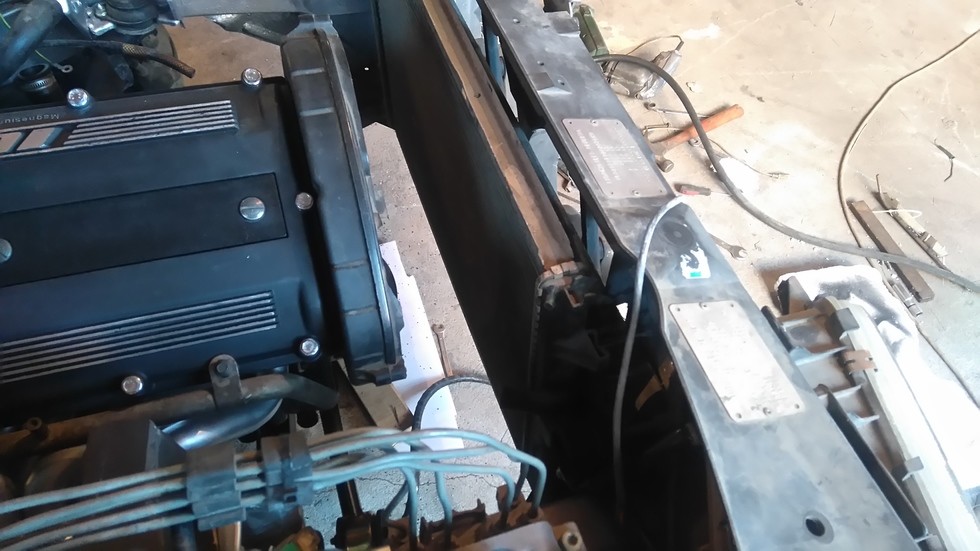

Last two days I've spent a lot of time on the intake manifold, the reason is there is a lot welding slag and splinters, and being so tight i can use only air tools which don't take a lot of material quickly, so it a very slow progress, in between working on the intake, i did finish couple more things, first of which was to make a new panel for the center console, this use to be storage but now the tunnel is in the way, priestly i make one of wood and one of aluminium, to aluminium one distorted when i was cutting it so the new one i made from steel, little harder to work with but should hold its shape better, then i mounted the sway bar, all bolted as it should, and then i started mounting the cooler, intercooler and radiator, started by cutting little from the radiator support and mounted it to the car, then i started on tha radiator, and the bottom mounts were missing the frame so welded couple of mounts and drilled holes for the factory grommets at the end i painted them to stop them from rusting, i need to make couple of air ducts to channel the air to the radiator, as a priority i'm putting the inlet manifold because i need a friend of mine to weld it for me and that is one thing that is out of my control, so better done sooner than later, the interior panel is all done and painted and apart from couple of gauges interior is completed and the engine bay is coming along also, more to come

11-14-2016

The last couple of days have been very busy for me, but i've been using every free minute to finish anything i can on this project, some of the things i did was, i install a new distributor cap and wires, then i install the battery tray and the LPG ecu after that i started laying the engine wiring to see how they fit and quickly realized that the hole where the engine ecu wires pass thru is gone, is use to be where the distributor cut out is, so i drill a new one next to the one for the abs wiring, then i started with the air bleed hoses, at first i reuse the original mi16 hose that use to go from the throttle body to the radiator, i placed it to go from the top of the thermostat housing to the expansion tank and was going to cap the other nipple, then decided to run another line from what use to be the backside, there was a bleeder screw so i just find a fitting to tread in the M6 treads and from there it was a simple hose to connect them, the intake manufolt is taking very long time to preper for welding, more to come.

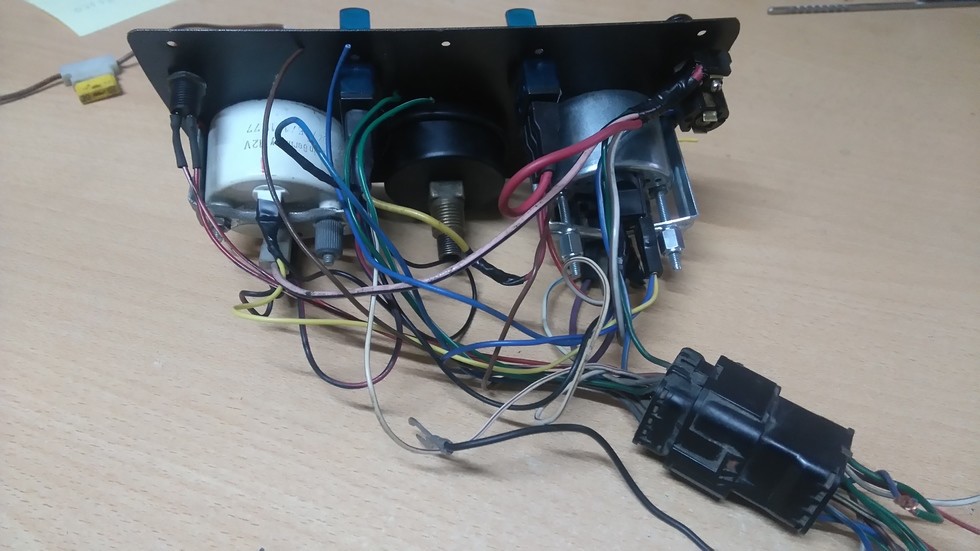

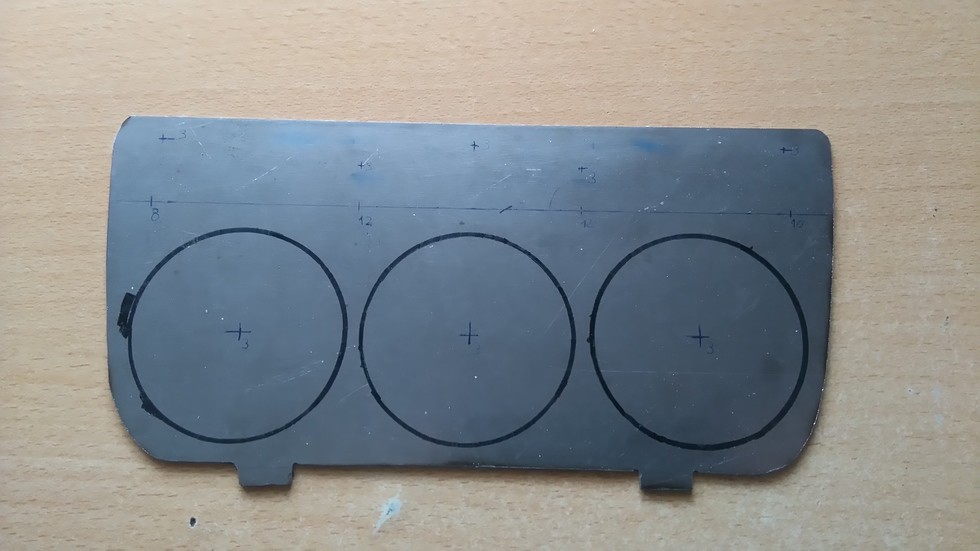

Today i finally finished grinding on the intake manifold and i made a new piece to cover the hole, only thing left is to have my friend weld it for me, also spend couple of hours on the wiring, i clean some of it but i have way to go, basically all the wires that use to go behind the engine are cooked, and are been replaced with new ones, i also relocate the fuel pump fuse and relay in the ecu box and that left me about 1,5 meters extra ecu loom that i need to hide somewhere, i also finish the new center console cover, the temp gauge corresponds with the temp sensor i install in the differential the center pressure gauge is going to be connected to the coolant system, this is something i've learned to observe over the years and last simple voltmeter to fill the hole, i may install another temp gauge for the gearbox or exhaust temps, the black switch on the left is a high amp switch for the second fuel pump, the illuminated blue switches are for manually switching the cooling fans, 1 speed and 2 speed, and the the last is empty, to be use later, i've wired them to a connector to be easy to remove them if i have to remove the console, it was a long day my hand are all swollen from the grinder kicking back and my ears are ringing from the compressor, more to come.