You must be logged in to rate content!

4 minute(s) of a 210 minute read

6-6-2012

I worked on the harness a little tonight.

I thought this was hilarious. A 3ft wire that literally only needed to be about 8".

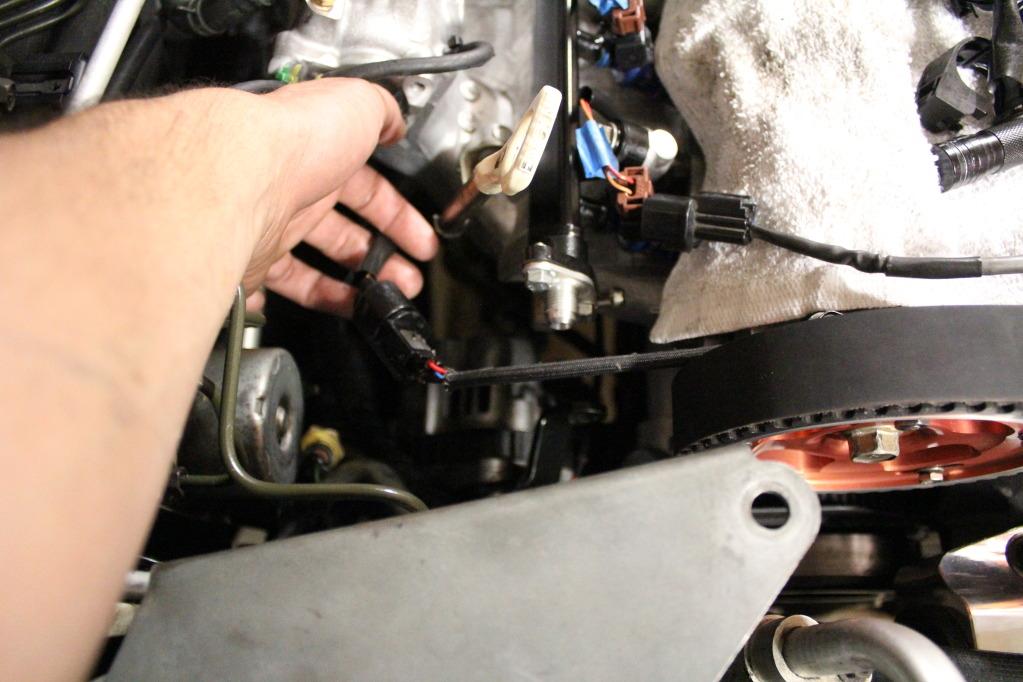

I first ran each separated harness in their "hidden" locations.

Injectors:

CAS:

MAP Sensor:

02 Sensor:

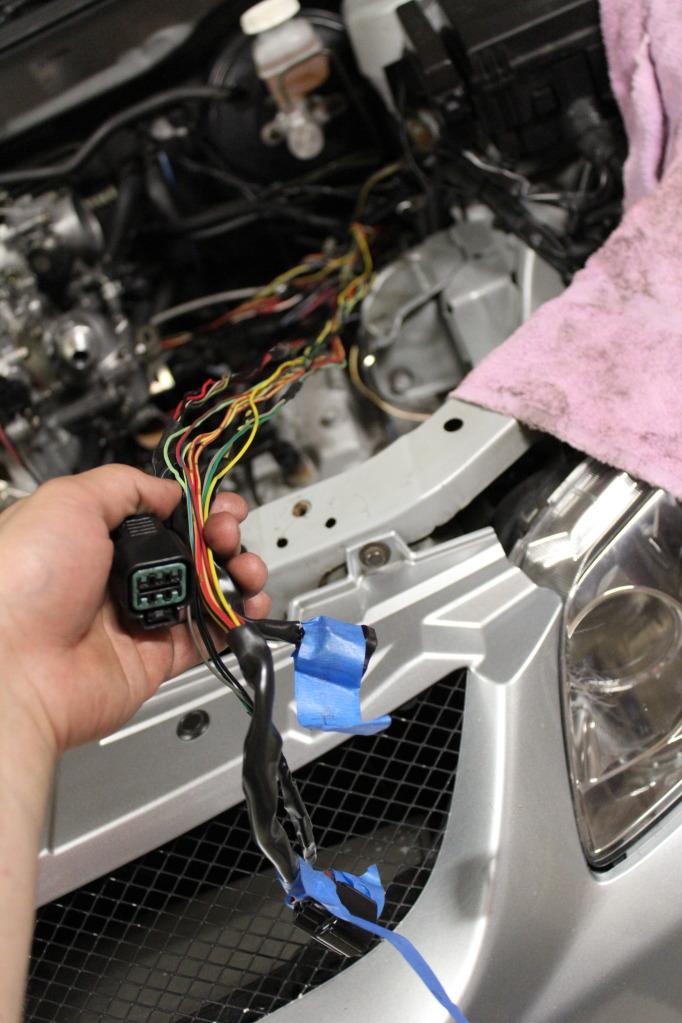

In doing this, I noticed there were three plugs that were WAY too long. Because I don't want to cut any wires for reliability purposes, I chose to neatly rap up their excess and place it in the main harness. It really helped clean everything up without cutting anything.

One plug that was far too long:

And the other two:

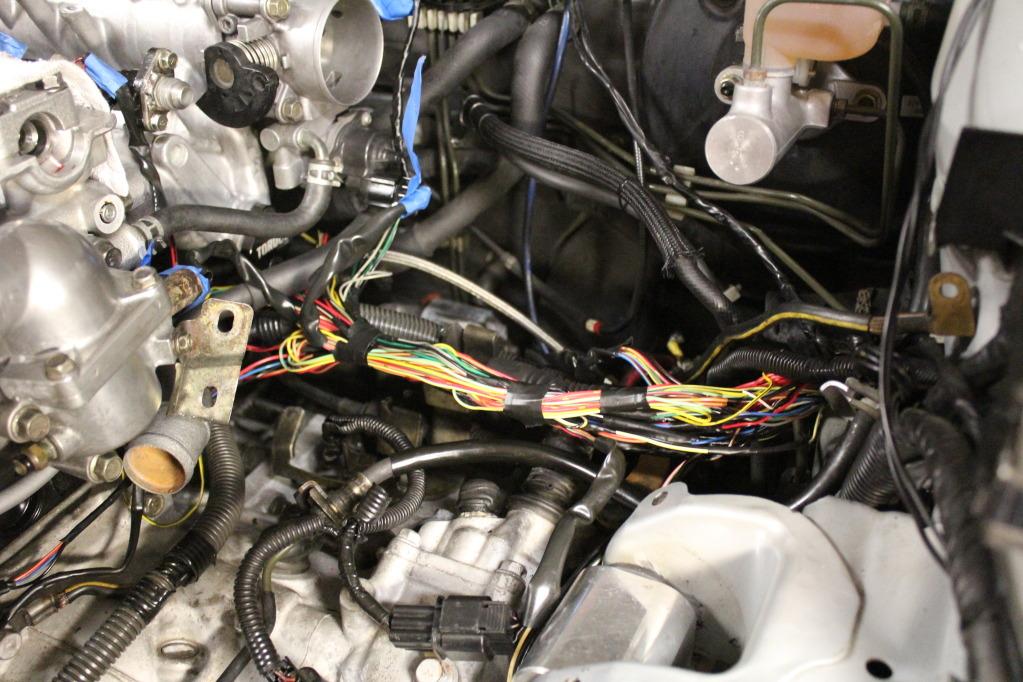

Everything routed and hooked up for a test fit:

After everything was hidden, I then connected everything into a "main harness" type of deal to add strength to the harness.

I then took it all back of and did a pre-loom wrap job:

This is the final routing I chose for everything, but didn't feel like re-routing it again after I had sealed it all up. You get the idea, nonetheless.

6-9-2012

I took a break from the wiring stuff and mounted my AFPR. This is the only decent place I found that I could put it.

Oh, and since I'm all about spool/torque, and since I couldn't stand the idea of not going T3, AND since I hate stock frame turbos, I bought a Cast T3 kit with Bushur O2 housing and Dump tube.

I'll be running an HTA 3582 (with a .63 housing) and have a goal to hit full boost by 4000 RPMs on the 2.4L. The big stock frames are far too laggy without the punch up top that I'd like to have.

Keep in mind this setup probably won't go on until next Winter, I still want to be prepared ![]() .

.

I may have Curt Brown work his magic on this manifold as well. We'll see.