You must be logged in to rate content!

4 minute(s) of a 210 minute read

6-5-2012

I have a heck of an update. I decided to do a wire tuck... I'll be EvoM's first to do a writeup on it so you all can accomplish the simple task with some guidance.

But before that:

I got my Energy Suspension Bushings pressed into my LCA's, which I just happened to polish:

I went a little crazy with the Vibrant stainless T-Bolt clamps. I'm sick of couplers flying off to say the least.

Oh, and I sanded/sprayed my LICP a textured graphite grey:

Now for the wire tuck.

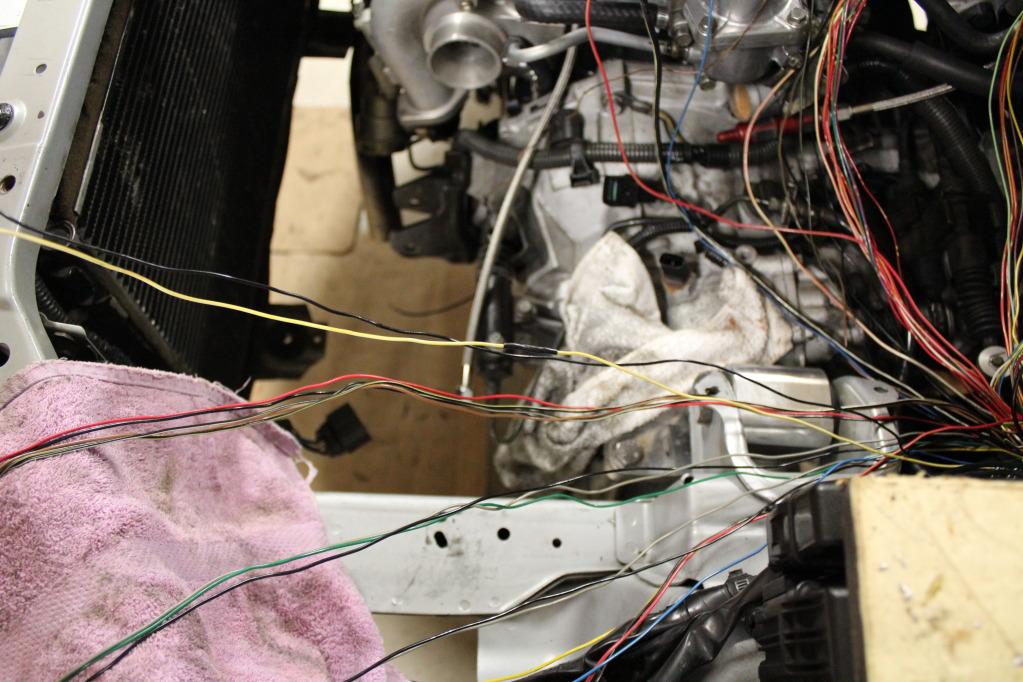

First, my soldering station:

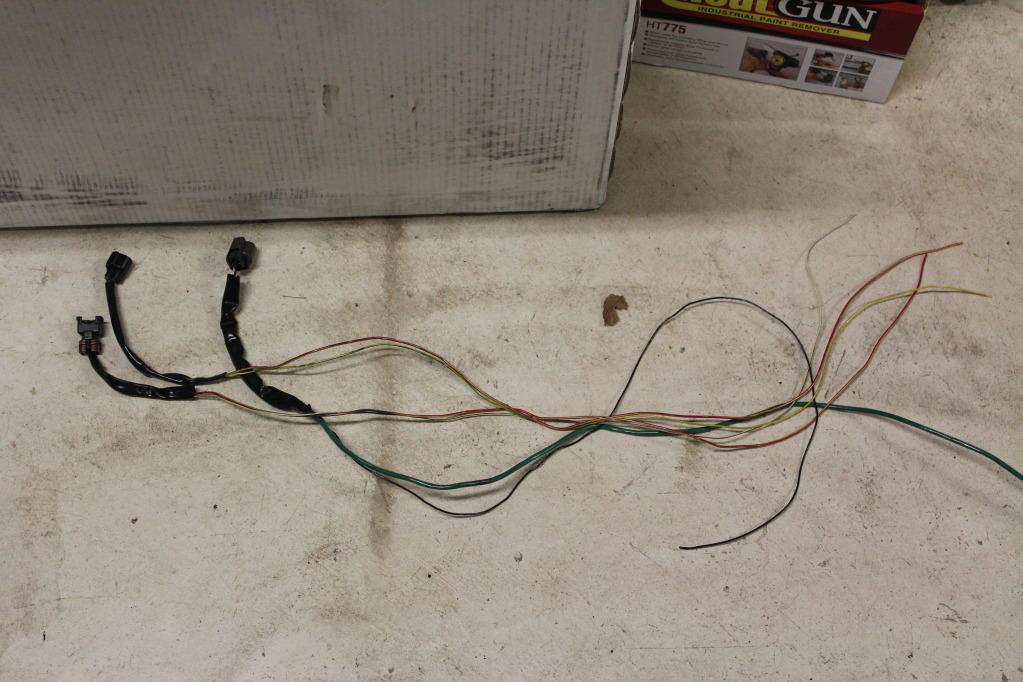

The first step in this is de-looming all of your wire:

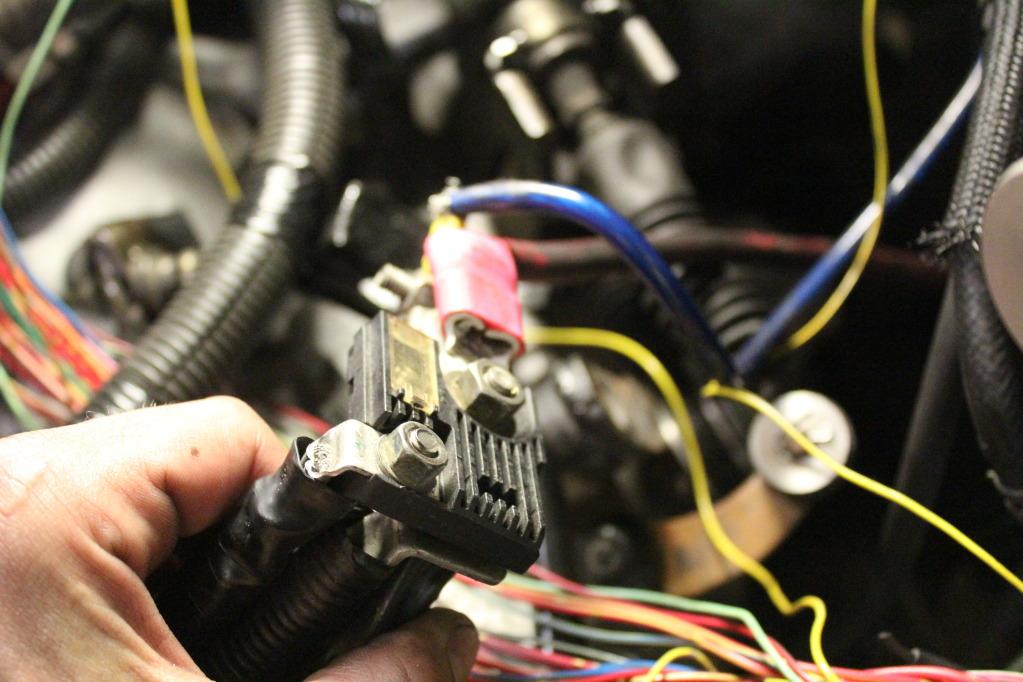

I had a drain in my car before and I could never find it. I then discovered this wire, which was completely burnt and bare. It was the ground for my passenger side coil pack plug.

Some more de-looming:

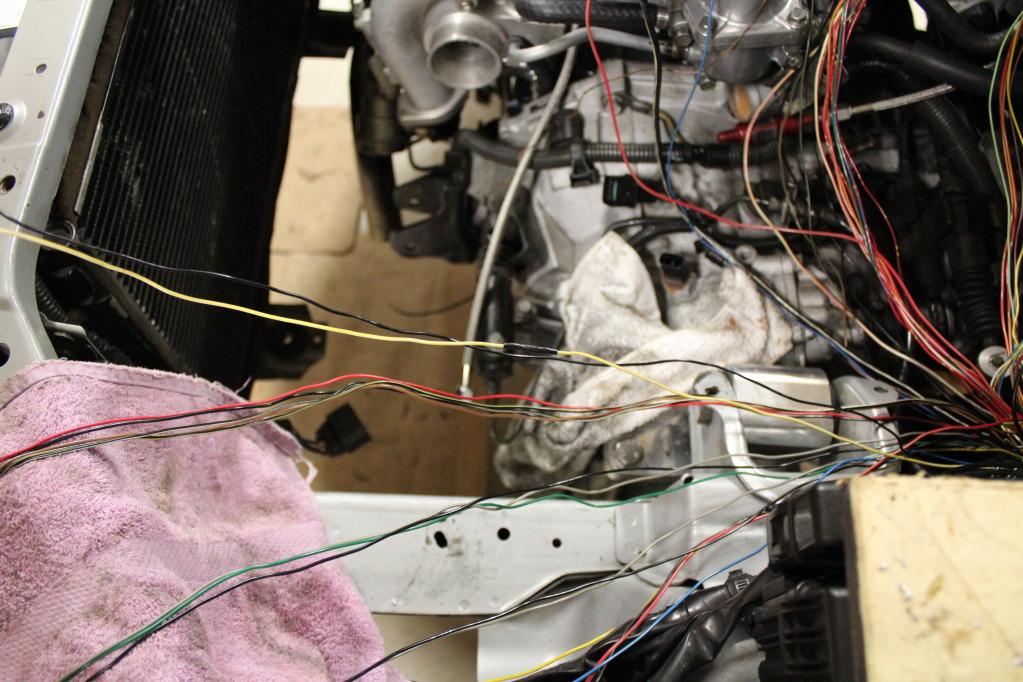

Taking pictures just to know which few plugs work best when routed together:

The three EGR Plugs you (barely) see on the far left I wanted to delete and shrink wrap off, as I'm not using my EGR system any longer.

Done:

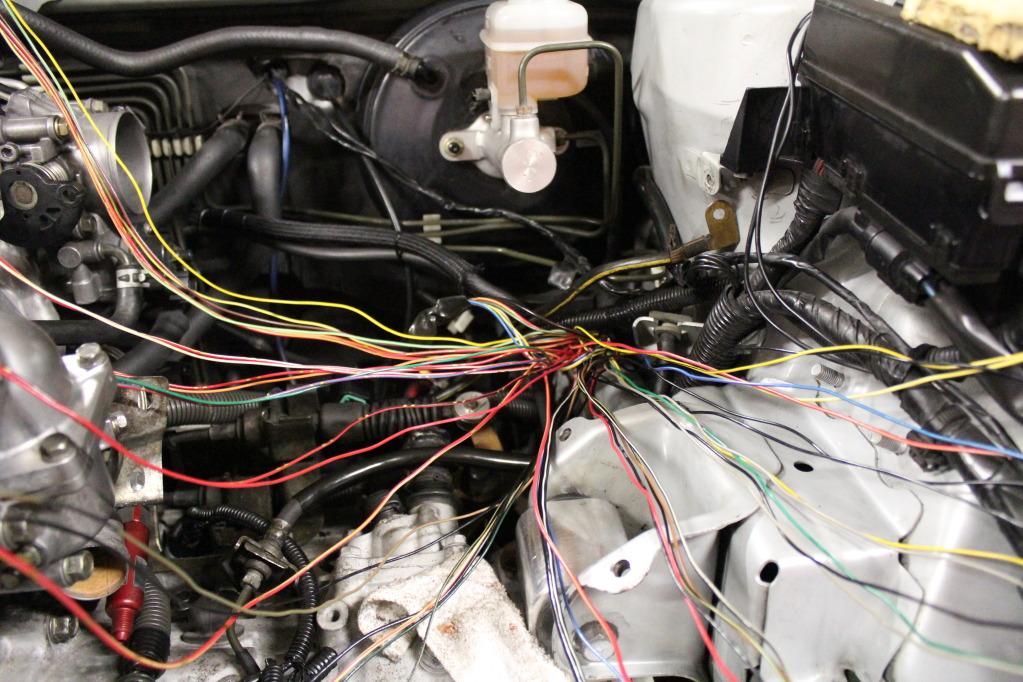

Starting to organize each plug's wires separately so I can individually loom them:

Uncovered my battery relocation piece:

Getting more organized:

All separated:

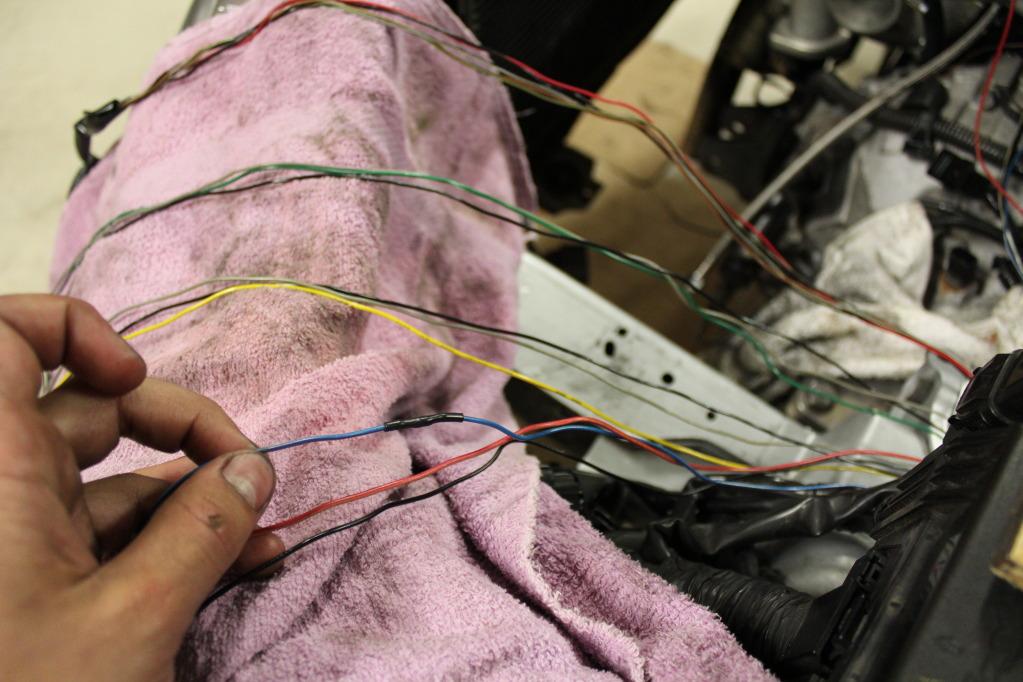

And a close up:

Believe it or not, to separate each plug you only need to cut two wires.

There's a blue wire and a yellow wire that screw up everything.

The yellow:

The blue:

Cut these, and while they're cut, re-route everything so that all looms are individually free from the source. Then, you're good to go!

I'll be picking up loom tomorrow and will route everything and cut it to length, and update with final pictures.