You must be logged in to rate content!

14 minute(s) of a 461 minute read

4-2-2012

Yet another day, yet another parcel!

MiniSpares order arrived half an hour ago. Really impressed with their service as always. Specified delivery between 16.27-17.27 (hows that for accurate timing!) and it arrived on time. Perfect!

So onto the pics...

The order breakdown is above this post anyway so won't go into details

Mainly fixings etc. Two chunky bags are the ball joints. them have arrived assembled but need taken apart to lap them in as they are a bit rough inside. Easy to do though with the aid of my drill :)

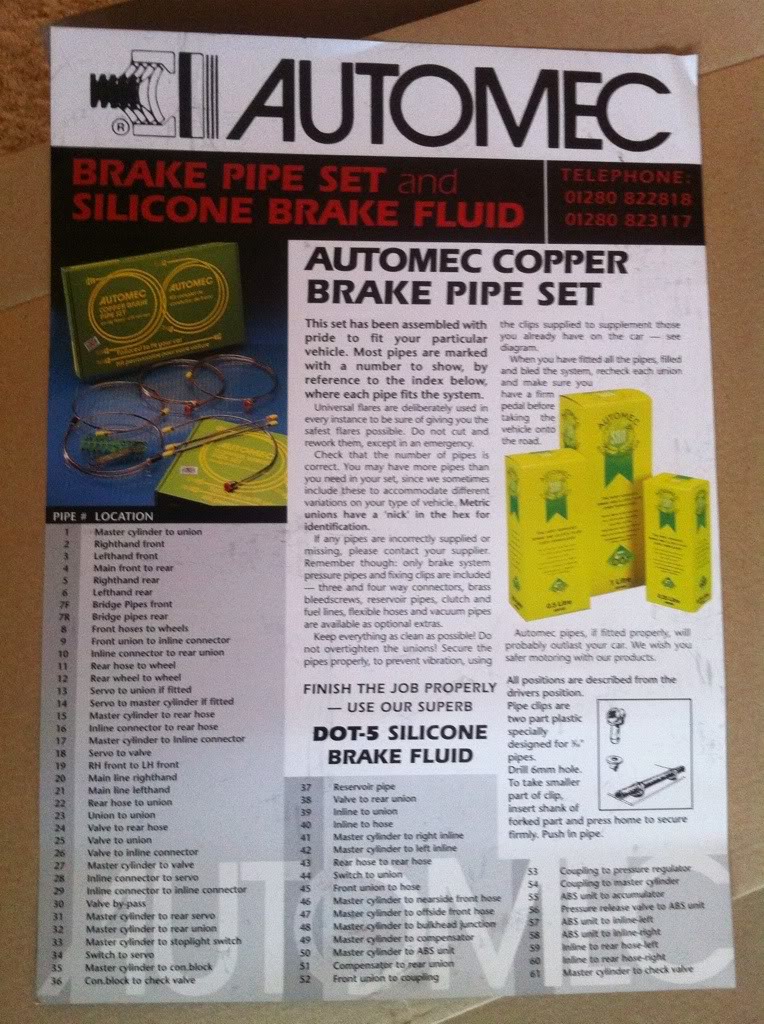

Brake pipes are a cooper/nickel mix (commonly known as Kunifer) which is easy to bend by hand and harder to kink. Making it super easy to install! (he says hopefully....)

They come pre fitted with all the end fixings and labelled with a guide to where each one goes. Much easier and way less labour intensive than making your own!

And something i didn't expect was this. Set of plastic clips to attach it all to the car underbody :)

I also got loads of nipples ( ;) ) for radius arms, wheel hubs etc etc to keep everything greased up easily!

Should get the battery cable and a couple other bits fitted tonight :)

Well tonight I got some more done with help from my mate Greig.

Got the battery cable installed but no pics as its under the car and its dark under there....

Ive decided to put the engine in from below, along with the subframe, seeing as the car is in the air anyway. This meant we could get the brake servo in without blocking the path of the engine. Win!

So put Greig to work on that...

and then we thought what to try next and decided to do the lights. Two pairs of hands are definitely better than one and we managed. Needs fine tuning when its all back down on the ground on a flat surface but they fit! Just need to mod the outer rings a bit to fit over the now larger inner rings.

So more progress as ever. Running out of things to do when I have no subframes but hopefully PPS will have the front one done by the end of the week so I can get torn into it over the weekend depending on my workload.

Thanks to Greig for the helpage!

4-4-2012

So I haven't progressed too much with everything over the last couple nights. Lights are continuing to be a pain but determined to get them done.

Only pic of progress to show that Ive got is I managed to get the grip tape fitted to the pedals. Looks ace and hopefully will make gripping them much better.

Before/after photo....

and both done :)

Notice the height of the brake pedal. Way higher than the clutch and the throttle pedal is even lower than the clutch. Sounds weird but it makes heal and toe far easier. You only do it under braking and as a result your foot is at the perfect height to roll onto the throttle instead of up and onto it in many modern cars.

Hopefully PPS will phone soon saying the subframes completed and I can get it all reassembled, engine on and then installed in the car.

4-11-2012

Another wee while out at the car tonight. Got my dad to take my hubs and driveshafts into his work at Jaguar to get one of the lads in the workshop to take off the hub nut. The wonders of the proper power tools!

So with the hub nut off I managed to separate the shafts from the hubs. The dust covers on both sides were well split and grit and grime had invaded so they needed cleaned out badly.

Took a bit of brute force to get it all apart but was all part of the fun. Ball bearings were shooting left right and centre but thankfully found them all again.

So here we have separated....

All laid out and cleaned!

Then this is a before shot. Going to give this the once over with wire wheel and a drill to get rid of the crap and then deox gel, clean and paint.

Was going to get more done but will go out another night to finish it all off for this side.

4-13-2012

Another evening down. More good progress.

Continued on from the other night and got my second driveshaft separated from the CV joint. Then cleaned it all out again, thoroughly coated it all in Deox gel, left for an hour while I cleaned other bits and degreased and painted them!

So this is after wire brushing...

and this is after deox gelling. Doesn't appear much of a difference but theres no rust to come back through the paint now

and the CV joint cleaned. See above post for the before!

and painted everything up. I know some paint is on contact surfaces but I'm going to scrape that off with a new blade before reassembly. saves time masking up etc.

Also when everything was under deox gel I tried to get my ball joints taken off the hubs. Unfortunately that ended in me snapping the vice clean in two......its safe up to 1 ton too!

So I may get out to work on it tomorrow night but if not sunday/monday will be next time Im out. I gave PPS a phone the other day and after being assured I would get my subframe back within 'at the absolute max, 2 weeks' 2 and a half weeks later its not been touched. Hopefully I can get it back sometime next week...

4-20-2012

Managed to get a couple hours in the garage tonight after 9. Aimed to get a driveshaft and CV joint reassembled and managed it easy enough.

Getting the bearing into the cage/race was a bit of a pain. Then realised I'd forgotten to grease up the bearing channels. Once I had done that it was unsurprisingly, much easier.....

So here the race, cage and bearings reassembled in the joint

then greased it all up with the perfect sized sachet that came in the kit

I then gently tapped the driveshaft into the CV joint to locate it. I made sure I had the new gaitor in place BEFORE i did this otherwise I would have to take it all apart again to put it on. One thing if you are doing this yourself is to make sure the inner race has the machined face with the 1mm inner section in from the outer face pointing TOWARDS the driveshaft itself. This allows the driveshaft to locate itself in this race face. This is important to get right.

and then I popped the gaitor over the CV joint itself and sealed with a heavy duty tie wrap. Job done!

And the whole driveshaft almost ready to be refitted. Need to do the point joint end next but that should be quicker as Ive got the method now.

Oh and I also found the bracketry for my throttle pedal, so thought I would bung that on. I like it but not decided whether to keep it or just grip tape the throttle pedal to match the others. We shall see.....

Haven't managed to get anything done today/tonight as I was too busy doing a 3000 word essay due tomorrow on propaganda for uni

However PPS finally phoned today at twenty to five saying the subframe was ready. So I went down straight away to collect it much to their surprise. No discount even though its two weeks late though......

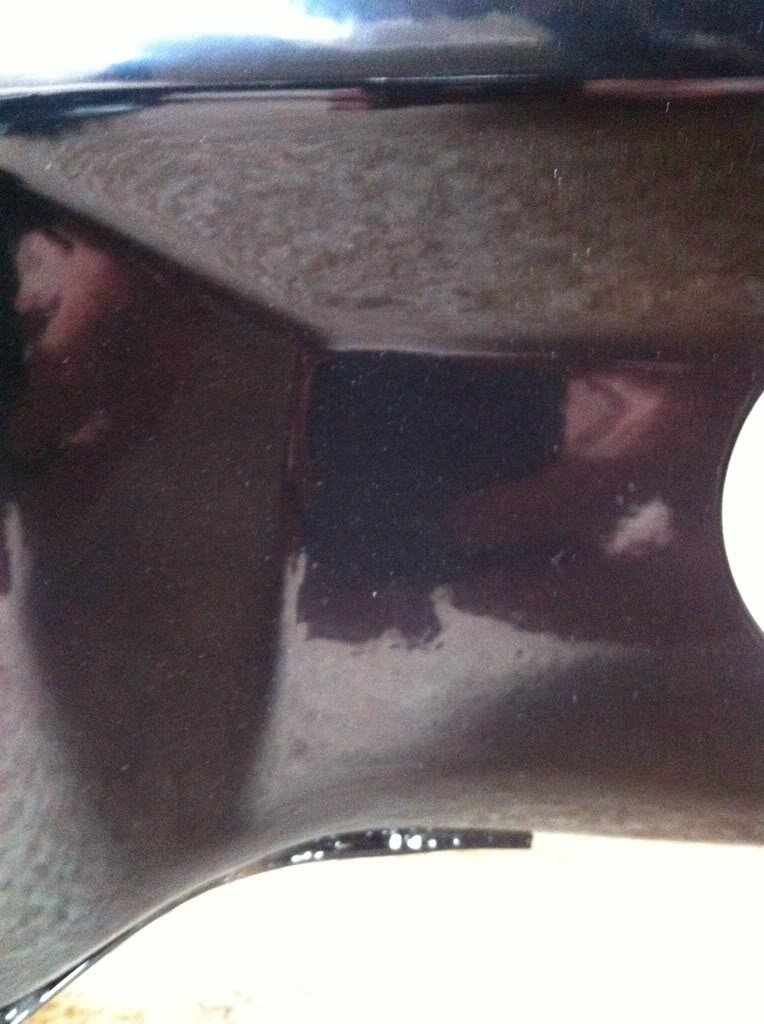

It is stunning! The finish is beyond amazing as stupidly tough. Much tougher than Hammerite or any other paint. The gloss of it is awesome too so no need to polish up! Im glad they managed to get inside the towers done so well as its pretty tight in there but I shall let the pictures do the talking now.....

So as you can see, epic finish! Just need to drill out some of the holes and retap the threads of the captive nuts on the towers.

Need to give it a wipe down and a few layers of tough wax before fitting to keep the dirt at bay. Definitely need the rear frame (once it arrives) done in powder too

Managed to finish off my epic essay this morning so went to the garage all afternoon as a reward. Before that though I got a couple coats of wax onto the subframe to protect it from the elements a bit more before reassembly.

and then got cracking. This was the hubs state as it came off the car. LOADS of curb caked on and loose rust that needed chipped off.

So this was if after the drill had attacked it with the wire brush on it.

and then given its first coat of black hammerite

Then cleaned up the other drive shaft and deox'd it then realised my top arms had some rust patches coming through already. Probably due to not being thorough enough with cleaning before painting. So I stripped them back to bare metal and redid the deox'ing. Leaving these overnight to fully dry off

and started putting the bits back onto the subframe

Loving the yellow and black contrast on it

and here it is almost ready to be put back in....

Not sure when I will next get out to work on it but hey ho, will keep going with it!

Comments

I LOVE Mini Coopers. Wow fantastic detail / photos here!

Posted by Diggymart on 1/22/19 @ 4:17:19 PM

Congrats BOTW what a beauty!

Posted by Diggymart on 2/6/19 @ 3:15:15 PM