You must be logged in to rate content!

9 minute(s) of a 358 minute read

7-7-2014

Update,

I've been grinding down the welds around the scuttle today, it's came out really well. Here's a few pictures of progress.

Ground down with a 60 grit soft pad on the grinder, and then I went over the lot with the power file using a 120 grit belt to smooth it all down -

Then I shaped the flanges properly using the power file, sanded the scuttle closers and the edges down and applied some zinc primer -

I'm also in the process of removing all of the paint from the bulkhead. I'm up to the bulkhead crossmember now, so I'm going to finish that off tomorrow. Will treat any surface rust with Deox Gel and then zinc prime the lot, seal it up, and then apply some regular primer.

Will be picking up the last of the panels I need from Minispares tomorrow, seeing as it's an event so will be getting some discount !

Another few weeks and she'll be off for some paint (hopefully)

7-9-2014

Parts Update,

We went to the Minispares event yesterday, was a good turn out. Got a nice discount and some free food !

I've got all the panels I'll need to finish the car off now so will get cracking with that on the weekend. Here's a few pictures.

The panels -

Also bought all the rubber mountings I'll need to re-fit the front subframe when welding the front end on -

And here's a picture of some Minis that were there -

I've also nearly finished stripping the front bulkhead back to bare metal, so some progress / pictures of that coming soon !

7-12-2014

Update,

Well I've finally finished sanding down, treating the surface rust and zinc priming the bulkhead. It's took a good week of doing a few hours before work and most of today, but it looks really good !

Here's a few pictures -

Just need to sand down the outside of the drivers side inner wing, prime it and then that's the front end ready for the new panels !

I also removed this bracket from the bulkhead -

As you can see it's really corroded, was thinking about buying a new one and welding it on, but it doesn't do much. I had a look at my dad's car and it's only got one relay sitting on it, so I think I'm going to leave it off, it will de-clutter the bulkhead which is always a good thing !

I've also had to take back the two wings and bonnet I bought from Minispares. I checked them over when I got home and they had quite a few dents in them, plus the bonnet was a really poor fit ! Should have known really with them being Magnum panels.

Anyway I've now ordered the Heritage alternatives to those panels (which I should have bought in the first place), hoping they'll be a better fit. I'll see how the Magnum front panel fits and if it's as bad as the bonnet was I'll be sending that back and buying the Heritage version too. Will put some photos up when I have them.

7-13-2014

Update,

I decided to flip the car over today as I wanted to clean of the remaining under seal from the tunnel and boot area. Here's a few pictures.

Flipped on her side (uncle and grandad looking impressed with their efforts )

)

State of the underside, plenty of surface rust appearing on my welds -

Cleaned up all of the under seal -

Then I sanded down, treated the surface rust, zinc primed and then primed the passenger side floor pan. Will repeat this process on the rest of the floor tomorrow, then I'll seal it all up with some Tiger Seal -

That's all the progress we've got done today.

I've also been thinking about colours for the Mini to be painted in, I quite like this -

I think it's Willow Green with a Snowberry White roof. I'll be pretty much going for the same style as this, low, wide and nicely stance'd with the wheels poking out of the arches. Looks the dogs in my opinion, let me know what you guys think !

7-16-2014

Update,

Been making some more progress throughout the week, here's a few pictures.

Firstly I welded up a couple of the drainage holes as they were quite pitted. Cut out -

Cad template -

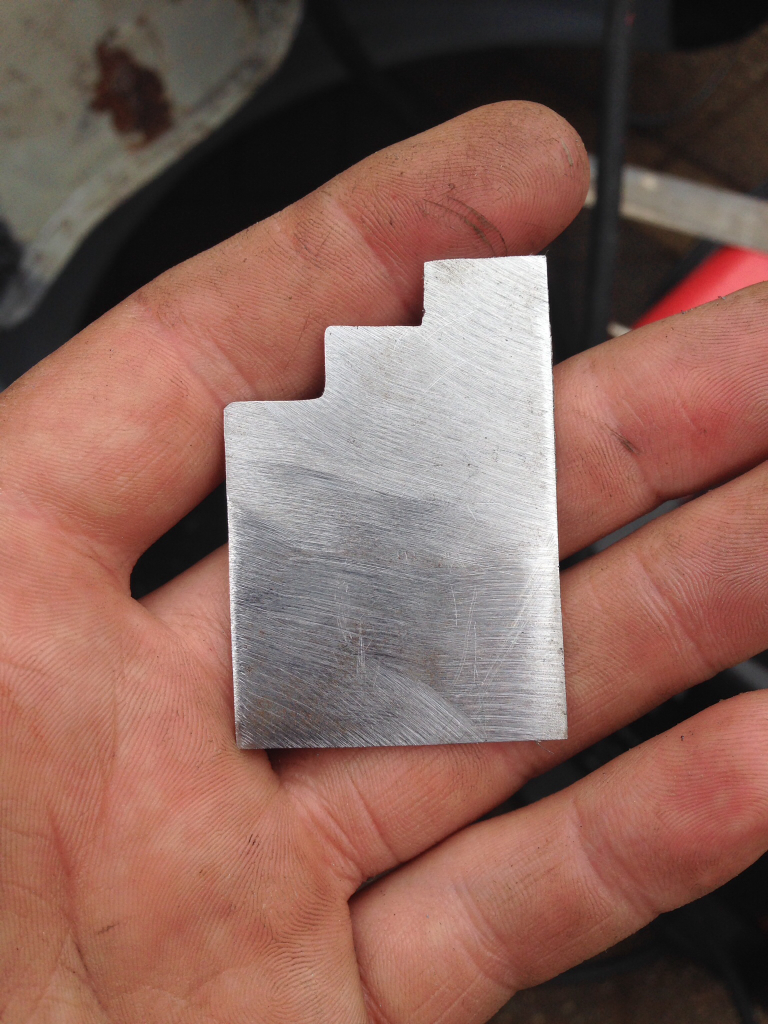

Transferred to steel -

Welded in and tidied up (no picture of the other hole welded up as forgot to take one, same thing applies though) -

Then it was on to the mammoth task of cleaning up the floor pan, (I haven't done the boot floor yet though). I sanded it back, treated the surface rust, zinc primed and then applied some regular primer over the top -

Next job was to seal it all up, I masked out where I wanted to apply the sealer so I could get nice straight lines -

Sealer being applied -

Rubbed in and the tape removed -

Same process for the bottom half -

Very happy with the outcome, I'm also going to run a thin bead where the outer sill is plug welded to the floor and also around the seat belt bracket in the tunnel, just for added protection. Will do this tomorrow as I ran out of time today.

Just this to sort out now then I can flip her back over and get started on the front end -