You must be logged in to rate content!

9 minute(s) of a 266 minute read

4-27-2013

dad brought two new minis today one clubman and one clubby estate for £200

6-6-2013

haven't updated in a while purely as i haven't done much work to the car other than fitting the new skin and modifying this for my mk1 handle however i do have pictures of this that i will be able to update later haven't done much due to me having my gcse exams lately which i still have not inished but after the 19th of june i will be free to do as i please and will be coming down hard on my mini and will be working alot more hours to fund it i will be applying for 6th form and so i will have about a 9 week break before i go back to school as i beak up early hopefully in this gap i will be able to get this into my car by then so its just saving up to do for the re-spray and building off the subframes ready for when the car returns from the paint shop, this is a deadline for the cage as by the time im back at school for 6th form if the cage is not in the car im not sure if i will be able to finish it for when im 17 because as of the end of august i will be 16 and only have a year to do it left not so much worried about the work just the funds needed to finish it http://www.customcag...ll&type=Bolt in

picture update time and i shall be uploading more tomorrow as i intend to weld in the drivers side floor pan and if i do that quick enough i should be able to get the door step on and start to fab my jacking mount again without the jacking hole. on the passenger door i still have a bit of filling and handle aligning to do as the hole i drilled is slightly out which makes the handle not sit as flush as it should do but im sure i can sort this out no problem also i had to trim the door skin bellow the bottom hinge as this was too close to the a-panel and foaled also it gave me a bad panel gap but this was purely to do with the pattern part anyway here are the piccys

will also update to where im at now with the door as i have only a little more sanding and filling to do

also the above pics do not show the handle hole being welded up but this is also done but my camera ran out of charge so i was unable to get pictures of that or my welds ground down

6-7-2013

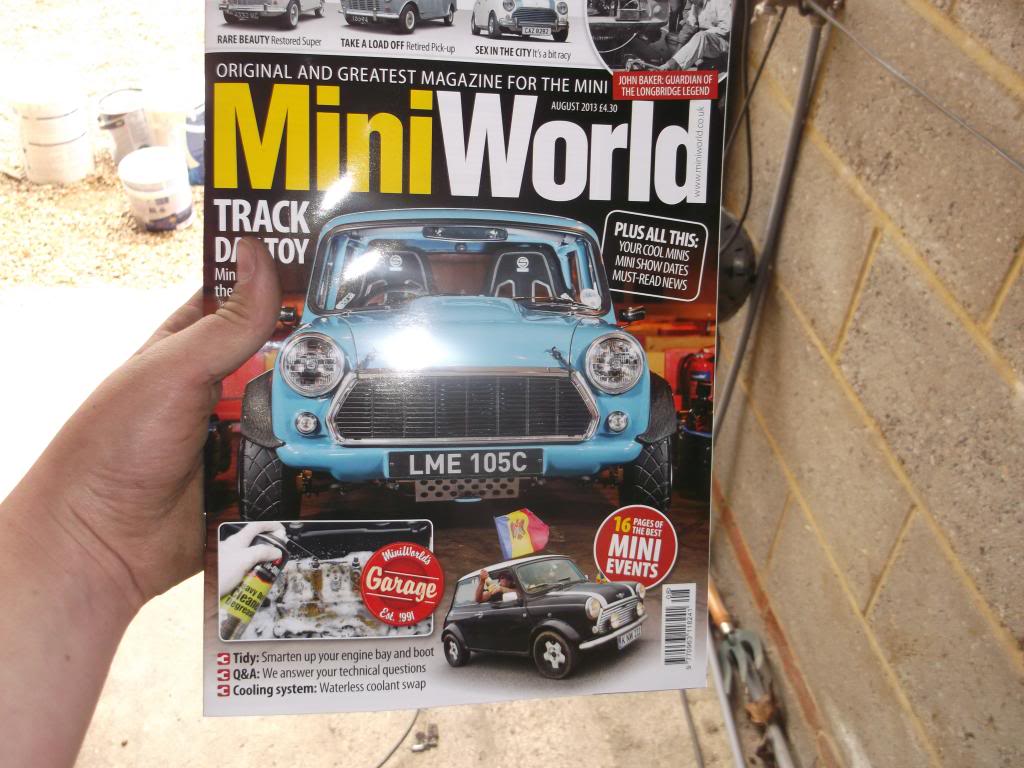

forgot to take any pictures of my door today but things went quite smoothly if im honest apart from the once again pattern panels being was off the mark however what did i expect, again i face the same problem with my door step not aligning in every bend at the back of the step closest to the door latch however i will do the same as last time and cut a slit until it pushes over and lines up but other than that all went well today need to pop down to halfords to get some more red oxide primer as i have run out, i was actually surprised at how much i was able to do today the floor where it meets the step needs some trimming as i welded in a new piece but left it high so i could grind it down level once the step was fitted also received my mini magazine and realized that the only tool i ever needed was the air chisel, this is one bad boy toy that i seem to get a little too carried away with however proves very useful when removing the spot welded on piece of the floor as even though i drilled out the welds it was still on tight but this proved no match for the beastly chisel this tool also came into action when i had to remove my brace bar and showed me how strong my welds are as the chisel ripped through the steel tubing and left my weld behind :) pictures >

6-9-2013

didn't get a chance to update work so ill do it now managed to fit the doo and then weld on the a panel and sort out the door step i also finished welding the floor pan and seam sealed this, today i will be fitting the drivers side wing and hopefully the rh sill if all goes well

dads car in the sun

progress was slow today and it being a sunday i like not to annoy my neighbors so i tend not to do any cutting and grinding so most of todays work consisted on seam sealing aligning and welding up the top of the a panel as flush as possible so little filler is needed, my exams are over on thursday the 20th of june and then you should really start to see the project coming on. however most of which will be going over things and finishing up in certain places as tomorrow i should be able to get my wing welded on meaning the only other major work that has to be done will be converting the drivers side door to a mk1, and re skinning and it will be the next and last whole panel welded in, then its time for the roll cage! how scary but good at the same time . so there are no pictures today as most of the work done was not important enough to be photographed although i did tack my wing in situ and it looks great to see my car with a whole face again most of the time it tends too look like something frankenstein would have created

. so there are no pictures today as most of the work done was not important enough to be photographed although i did tack my wing in situ and it looks great to see my car with a whole face again most of the time it tends too look like something frankenstein would have created

6-10-2013

managed to get my wing fully welded on today and my god was the fit at the front poor and so large i welded along the edge of the wing to give me a better gap didn't manage to get any pictures but it doesn't look much different from the clamped on picture but one more stage complete my car now has two wings on and a completed face