You must be logged in to rate content!

8 minute(s) of a 280 minute read

3-8-2013

So, the engine bay is starting to come together. I've eliminated so many things over time, but still found a bunch of things I could get rid of or hide or change. Logan made a really nice black-anodized aluminum oil reservoir that fits the spot where the deleted ABS was. We sanded the engine bay a bit and sprayed the primer coat today. Should have the BB color coats on tomorrow and the clear on Sunday. I got a new set of fender liners (usual thanks to Ray Crowe ![]() ) to put in when we're done.

) to put in when we're done.

I'm spending some time getting **** about the nuts and bolts that hold everything together in the engine bay and on the engine itself.

Gordon

3-9-2013

Tim and David... Good. Any drawbacks?

REVLUC... Thanks, buit you have the car. ![]()

Here are a few pictures of the bay with 2 coats color. We filled a few of the holes that won't be used.

Gordon

3-18-2013

We're in the final stages on a bunch of things. The motor build. The new exhaust. Wheels and tires. So, Logan has me occupying myself with some of the last details.

Don't want an air plenum to feed the throttle bodies. Don't need it. But I do need to cover the throttle body air horns (which I'm having re-anodized from blue to matte black) with some kind of filter. These are triple mesh screened filters and that should be fine.

Gordon

Should look like this, but with the air horns in black.

3-19-2013

No plenum... If my goal was horsepower, there would be a turbo in there. ![]()

I guess I should add that there are quite a few different kinds of filters out there, including some that are waterproof, and they are definitely helpful in keeping mice out of the intakes. If this doesn't work the way I would like it to, I can always add an air box, but I am trading a bit of power for no plenum and hard pipes.

I shouldn't have been so flip in my reply. There are a lot of filtering options with screens of different sizes and materials so that you can eliminate most particles from getting into the throttle body. I am going to use as little filtering as possible to be sure I am safe.

Plenums need flitering as well, but help make power by being slightly pressurized and therefore being able to feed the throttle body more air especially at high rpm. My car is not dry-sumped and so my rev limit is about 8800 rpm under normal driving conditions with a few bursts to 9,000 or just a bit more. I will probably lose a little power between, say, 7,000 and 8,800 rpm, which I hope to make up through better exhaust gas scavenging. Lenny's car will be dry-sumped and he should be able to run 9,500-10,000 rpm and can use all the air he can get up top and a plenum is the only way to go.

As I have said time and again during this cars life, I am trying to end up with a simple and reliable motor that makes good power and sounds great. Whenever I drive a new car, I am amazed at how bad they sound and how indistinguishable they are one from the other. You used to be able to tell that a Porsche was coming by the way the flat air cooled 6 sounded. Good luck with that today. So, why spend $50,000 on a stereo and only listen to Lawrence Welk playing a senior home? ![]() The sound of 3 throttle bodies sucking air is great and I want to hear it.

The sound of 3 throttle bodies sucking air is great and I want to hear it.

3-19-2013

I've got the new Speedlines and Toyo Proxes R888's on and my off-roading lift kit... The 285 rears look nice. Also, here are a couple of pictures of the third plug bung being machined and inserted.

Gordon

Here is the only shot I got of the wheels and tires.

And here is a housing being machined for the third plug and with the plug bung inserted.

3-22-2013

Here are the finished housings with the 3rd spark plug bung inserted above the trailing plugs at the top of the side and the housings have been machined for much larger cooling passages. There will be 3/8ths inch aluminum hard lines directly plumbed into the holes in the housings flowing coolant to enlarged passages inside the housings.

The drawing below shows the hard coolant lines going into the housings...

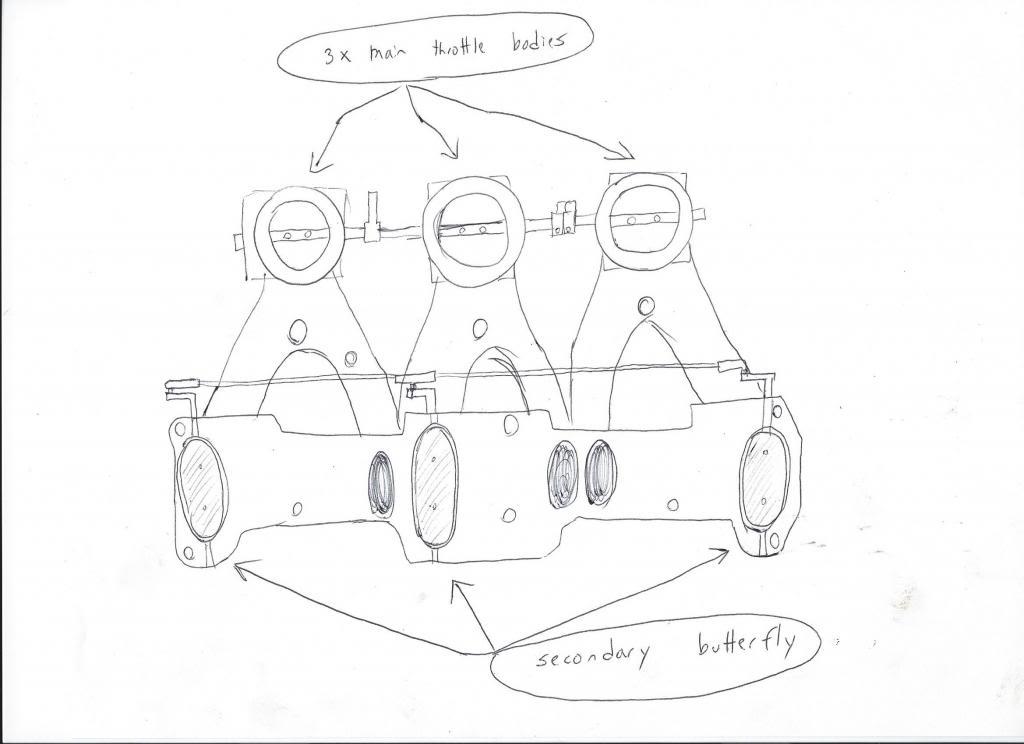

And, here is a drawing of the intake and induction side showing the ITB's and runners down to the intake ports and secondary butterflies in the secondary intakes. We got the idea from the way the Vette's LT5 motor has 2 butterflies and runners per cylinder. It will give us much better flow control and along with the 3rd spark plug, we should further improve gas mileage.

3-24-2013

Here's the finished short block. Now, we need to get it in and build the intake and add the ITB's, finish wrapping the in-bumper muffler in DCI Extreme XT5000, and hook up the exhaust cutout, and finish the little stuff, like the oil reservoir, and tune. Another Deals Gap down to the wire build. Should be buttoned up by the 5th and putting some miles on it.

G

3-26-2013

Diabolical... No worries singing Logan's praises here. He's an artist and unlike any tuner I've worked with over the years. Most just sell you a 500 whp A-spec, slap WI on, and load the PFC map. I'm fairly knowledgeable and have ideas I want to try and Logan and I communicate well and he comes up with things or I do and he makes them reality. I think the engine will be done shortly and there's then little left for me to do. The transmission redo, some bracing and paint is about all. I think the final engine design and specs are really interesting not just in power, but hopefully in reliability, gas mileage, lower maintenance costs and ease of maintenance.

Nice job!

Posted by Diggymart on 3/13/19 @ 9:54:43 PM