You must be logged in to rate content!

6 minute(s) of a 462 minute read

5-23-2016

so my water neck was leaking. I went to the weld-master Austin to fix it. now I need a higher pressure rad cap for the dyno pulls.

6-25-2016

Hmm where was i? oh yes...

so last time i updated this i was driving around, using this as my daily driving. i made a tune that i could get around with/daily drive with. thank goodness i have experience on nistune and for the fast king videos. so my work took me down to Texas for a few weeks. Dallas through San Antonio.

it was while i was down here i got the bug to finally get a tune. so i called up a few shops, they all wanted too much. anywhere from 750+

i feel that a good tune for just 1 map should cost no more than $600.00-max

so i for some reason called sound performance and they were in that range, so after a few weeks i made my way to Chicago to finally meet the rollers(properly).

when i got to sp it was hard to find at first, it's hidden behind some warehouses, so i had to do a lap to find the cars.

just a few of the cars i seen when i got there. a real professional import shop, the last of a dying breed indeed.

so after a bit got strapped down and got to business.

So thankfully the dyno guy allowed me to personally make some tweaks/checks/adjustments while trying to tune this mfer. i finally tapped my wide band into the aem unit. brought a filter for my iaac unit. did my best to adjust the idle screw on the throttle plate.

things were going well then hit a skid mark when the dwell started acting up.

So we checked the spark and adjusted the timing.

Still no dice, then he fixed the dwell got it rev then disaster struck.

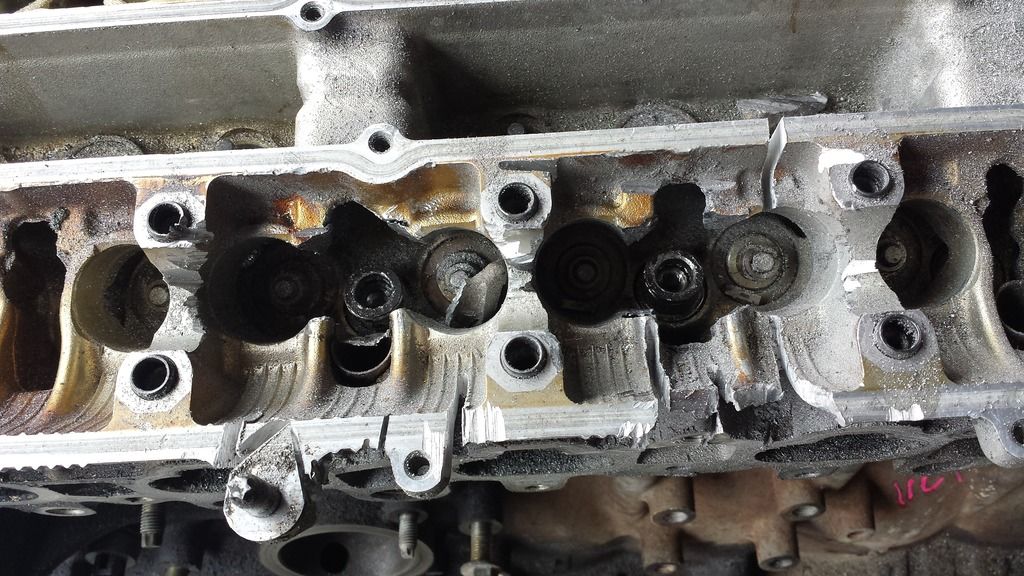

my rings went kaput. did a compression test and only 1 cylinder was healthy, one was 30psi and one was 60.

so that was my tune for the day, i finished out at 263whp on 9 psi. (i need a ebc controller for the aem).

so i got a few qts of oil from the guys and made my trek back to Missouri, defeated but not done, i vowed to come back.

im thinking the rings went because of poor crank case ventilation, i plugged the pcv valves and ran 10an lines to an oil catch can with no vacuam.

i was also told the filter on top of the can was way too small.

Now(currently) it huffs white smoke and some oil out that same filter.

so now it was time to go 1.5jz. i got home and that next week sourced a older gs from a local junkyard.

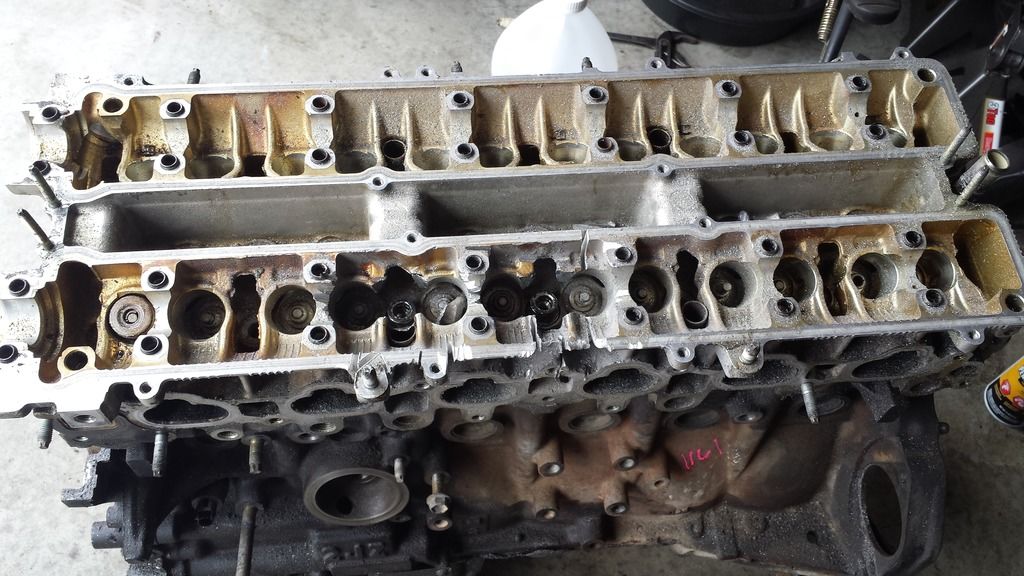

so here we are again, faced with a 2jzge, and once again not 1 but 2 of the bolts don't want to cooperate.

so i had to get smarter than the bolts and mutilate them from within the block. luckily they were right next to each other.

then finally finally, the block was freed!!

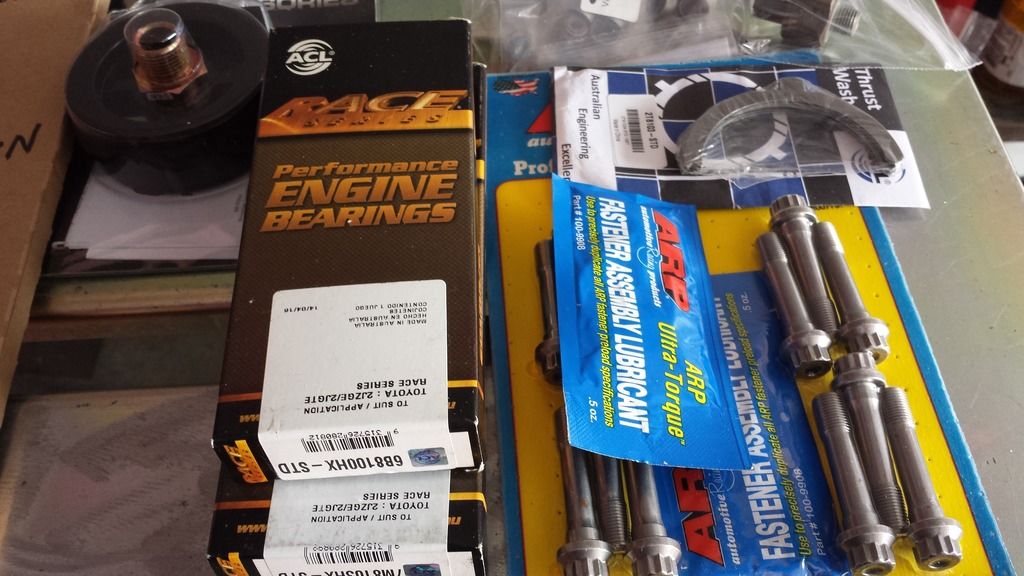

so now time to purchase some goodies and send this block away so i can get it back together in a timely manner?

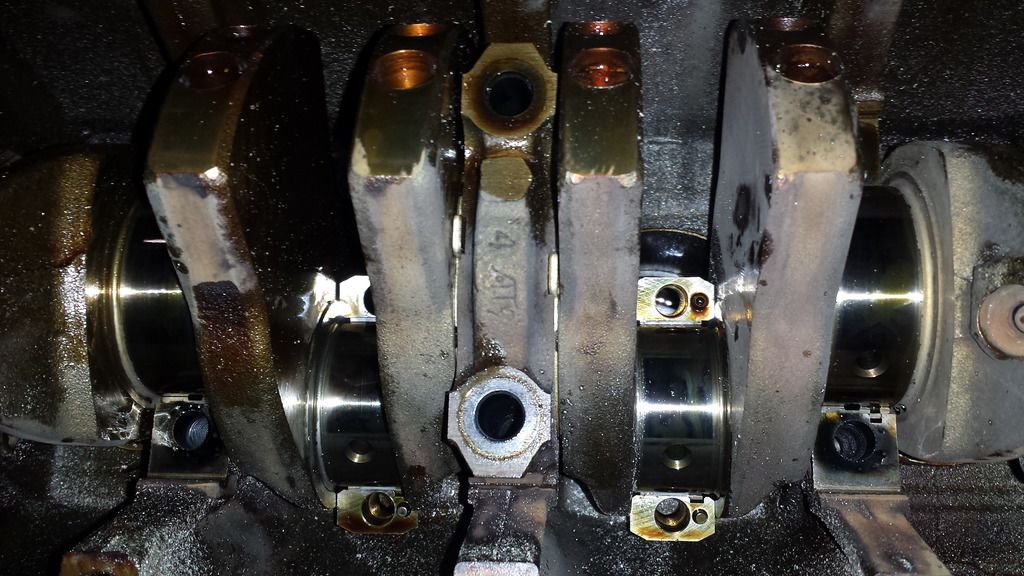

never disassembled an engine before. so this is new territory for me. but looks like the bearings were not shot to ****.

im just looking to do a stock rebuild with stock size rings and some better x-bearings.

This thrust washer bearing thing is the most biggest problem i forsee for me.

and that is all i have so far, waiting on the machine shop to get back to me. he is charging me $250.00

-hot tank

-clean pistons

-polish crank

-hone cylinders

-install piston rings

Great project!

Posted by Diggymart on 11/1/19 @ 10:59:41 AM