You must be logged in to rate content!

10 minute(s) of a 462 minute read

4-14-2015

well a lot had happened since my last update. so let's recap!!!

so I got the wrong upper control arms(they were for a mk3). but I later sourced the right ones, and stuffed the uppers with urethane.

I then managed to pick up a sway bar, end links, tie rod ends and boots.

I then had to proceed to sell my body to come up with the coin for some new lower arms.

yes I got them ad a hook up (so 5 and change). and NO I couldn't find it in my heart to burn the rubbers out and stick the urethane in these. so they are running the oem rubber.

so finally I was able to install all the parts and get the car moving again. I DO have a rear main leak but since this is my daily now I have to come back to that later on.

here's the pics of my all new front suspension!!

so pressed for time(I always am) I did some other things in prep of my nyc road trip, like

-extending my dump pipe(my first weld actually)

- switching out my waste gate for a bigger spring.

-re upholstering my armrest(****ty job but my elbow thanks me).

and doing a fuel pump relay so the pump doesn't rely on the car harness for power(straight to the battery)

then LATER ON. I finally did the resistor jump and I finally had a tach. this triggered my air bag light, which I swiftly covered that and that damn flashing traction control lights with electrical tape!!

so I finally took time to tackle this damn transmission mount issue. this was my latest rendition of the stock 300/400 modded one.

so I wasn't feeling this fitment. and I was also trying to stop the squeal that sounded like it came from the driveshaft when I always start out in first or a low gear shift.(so ****ing annoying).

I found out I can fab up/use a earlier "82-86" celica 5 speed tranny mount. well I couldn't find a 5 speed mount. but I did find an auto mount which at first looked identical to the manual one.

so I cut both sides and tried to graft them back together with some additional welding metal, this isn't to look pretty and this is only my 2nd ever welding experience so...

and finished product. yes I know it looks like ****. but guess what??? the welds hold and I put a lot of metal on this to make it sturdy. I do plan to make a leaner one soon. just needed this in the mean time. and still the noise is there.

that's what ill do in a few weeks

but here is the driveshaft noise!!

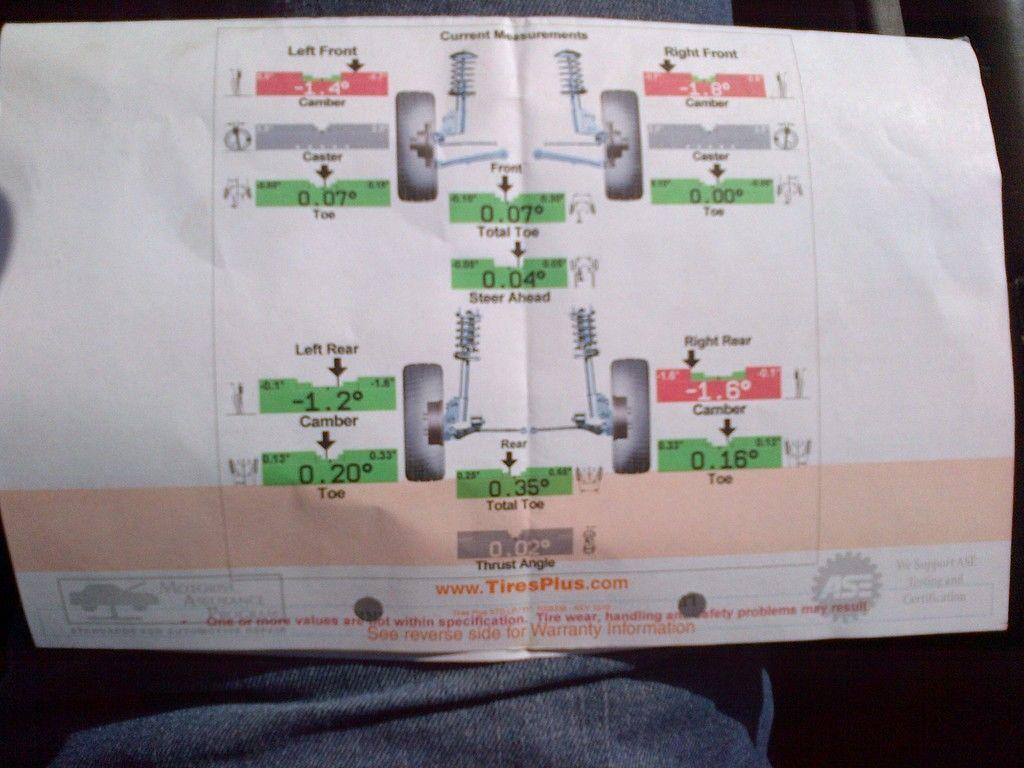

so I got to nyc and everything was fine EXCEPT. on my way back, all of sudden my rear tires went to mush(mind you I did get an alignment after doing my front suspension).

RIGHT-

LEFT-

and it was that accursed toe. my alignment guy said he did his best with my rear toe. but the components were worn(20 years plus right)?

so a quick order for some new tires and these bad boys were placed.

sad day because I couldn't get a rear sway bar this round.

well the first and only fitment issue I ran into with these is the traction bar holes were not big enough. they required some enlarging.

so we get to some more adjustable bolts that were seized in place. luckily I was crafty enough to fix this issue, I brought a new tool-mate.

with this I quickly made mince-meat out of these old hags!!

just say no to rusted/seized adjuster bolts!!!

so I didn't need any of the old bolts as the adjustment is in the arm themselves(as they should be). ao went and brought some new hardened bolts/washers.

so all was well in the "toe" kingdom of suspension. then off to the alignments rack(2nd time in a month).

here are the numbers I came up with. apparently my front caster is off(says my front right is further than my front left(scratches head).

still won't ride perfect like my Nissan, wtf gives!!!! heres a comparison by the same tech.

but fear not!!! I finally located/ordered some front camber plates(go me)

so before I did that toe stuff. I wanted to keep my cabin temps lower. and if you seen what I did to my shifter tunnel you know it was inadequate for long term use. so with my new welding powers. I rolled back the carpet, made a template of a cutout, and got to work.

got rid of the paint so template could adhere.

and here is the finished product.

while I was at it I decided to make a short shifter.

so this shifter was a TEAM effort. as I did the top/thread weld and my local welder guy finished the rest.

and iam super happy. it feels great and no more "iam a trucker" complex!!!

so I was in pa last week and there was an accident, and the cars were allowed to go back on the highway on the shoulder. anyway the semis in the right lane didn't move enough and I creamed a rock on the shoulder. didn't see this till I got to Indiana.

and finally there is some rust boiling here. you guys think I should just replace the whole panel? or cut the rust, and pull out the ding??

Great project!

Posted by Diggymart on 11/1/19 @ 10:59:41 AM