You must be logged in to rate content!

8 minute(s) of a 620 minute read

2-29-2012

Scooter402 has done a fantastic job of answering today, that's it, I'm calling in sick tomorrow.

Honestly, he did great. The information he gave answering about the accelerator pump only being on the primary side is spot on, exact. The teaching next is going to lead us to the need of the accelerator pump on a carburetor and his answer was perfect as to what would happen on the vaccum secondary carb with the screw stuck into the slot, forcing the secondaries open would cause a terrible hesitation when the secondaries are forced open.

He was right on with the altitude issue. Altough the vacuum secondary carb does work with the demand of the engine, it cannot alter the mixture of fuel to air which is at it's optimum around 14 parts air to 1 part fuel. The air is thinner, thus we need to thin out the fuel entering into the air. The only way we could do that would be to downsize the jets before hand. The jets regulate the amount of fuel being released into the air stream. The air has changed but the fuel hasn't with the setting still at sea level.

We will cover jets later also. When we're done, these will no longer be a mystery either.

This is all taken care of in fuel injection. The oxygen sensor reads the excess fuel to air ratio and cuts back on the fuel being released by the injectors as the altitude changes. I have to admit, technology has it's advantages.

Later I have the vacuum secondary canister, the rubber diaphram and spring that is changable to match your vehicle's needs, broken down in pictures. It will give a view inside so the words will have a visual meaning.

Are we having fun yet??

Hold on to your metering block pics. There will be a individual study done on metering plates and metering blocks, yours, being fabricated, most certainly has a place on this thread and I look forward to seeing what you've got going on there.

It took a couple hours but I down loaded enough pics to see and know about the vacuum secondary canister and how to modify/adjust it to meet your needs.

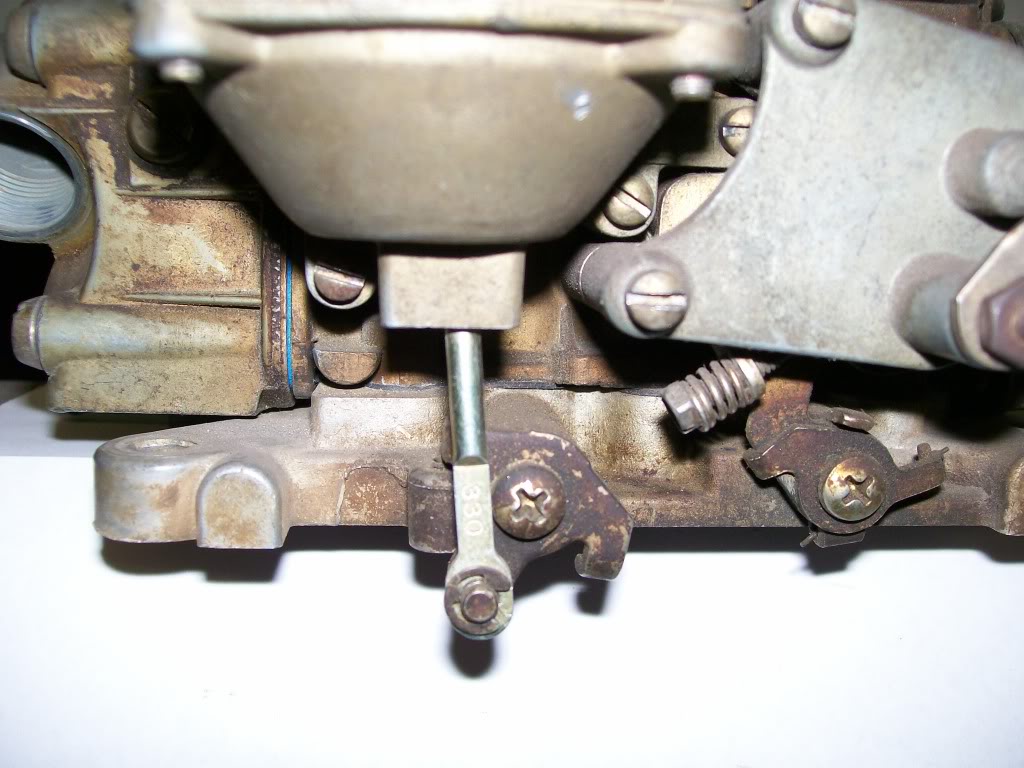

First, a close up of the canister in the relaxed position. This is at idle and just going down the road.

Now a close up of the canister in the full throttle position. I know I've mentioned this before, but here goes, the only way this can pull open the secondaries is because the primaries are wide open, and the linkage has been moved forward on the slot we saw in the previous pictures. The linkage has allowed this to happen.

Here it is removed from the carb. You can see the top and the screws that hold the top in place.

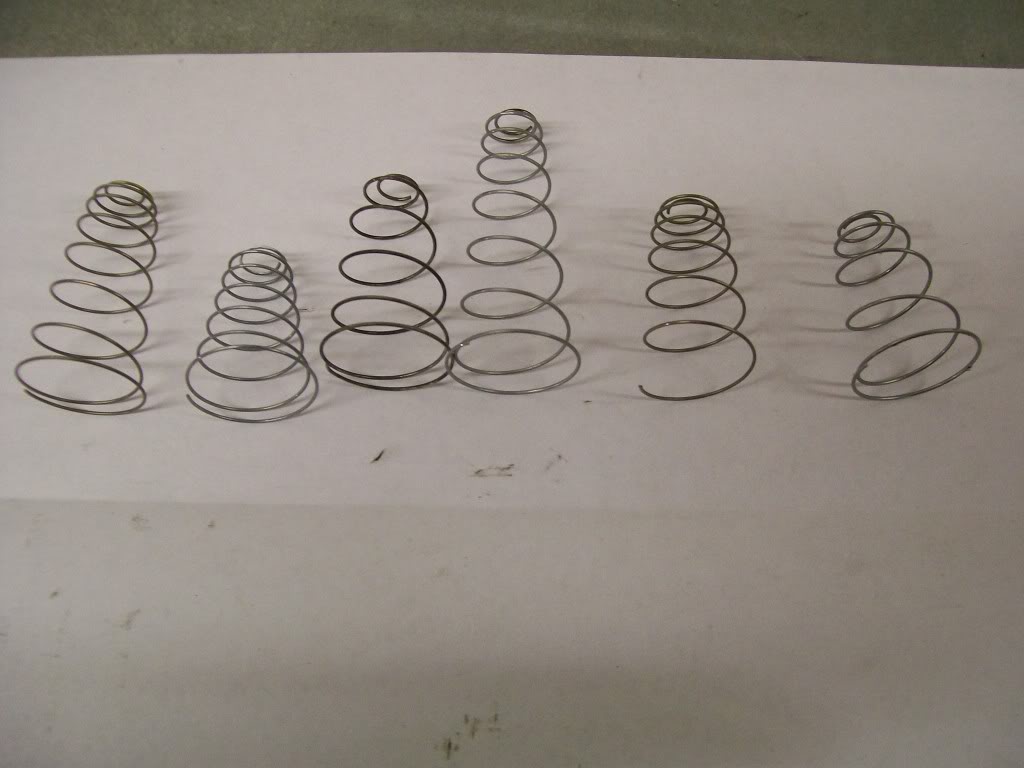

Now disassembled. We have the canister, we have the rubber diaphram and a spring.

Here is the side that mounts to the side of the carb. Notice the o-ring hole. To be honest, the original Holley uses a small cork like gasket instead of a rubber o ring, I just didn't have the original gasket last time I had this apart. This hole is the passage that once bolted to the carb it has a direct opening to the primary venturies located above the throttle plates. This means that the vacuum supply is called a "port" vacuum source. If the vacuum source is located below the throttle plates, it would be called a "manifold" vacuum source. Notice the hole for the vacuum to work through.

The difference being, a port vacuum only comes into play once the primary throttle plates are opened up. This is perfect for the secondary vacuum canister. It reads the amount of air passing through the primaries. Once there is the right amount of air passing through, there is enough pull/draw to now pull the diaphram upwards. The draw has to be strong enough to depress the spring you see in the picture above.

The more air passing through the primaries, the more vacuum is created, the more vacuum created, the higher the rubber diaphram raises in the canister, the higher the rod raises that is connected to the rubber diaphram, the higher the rod is raised that is connected to the secondary shaft, the more the secondary shaft is rotated, the more the secondary shaft is rotated the more the secondary throttle plates are opened, the more the secondary throttle plates are opened, the more we

hear......whhhhhhhoooooooooaaaaa. That great 4 barrel sound we all love to hear.

Earlier I mentioned the truck vs race car carb needs and how they are different. I used the two different carbs, vacuum and mechanical types to create an illustration.

This time I'm gonna use a truck with no trailer vs a street performance car. Both with a 350 engine, turbo 350 automatic transmission with no high stall speed converter and no higher than a 3.73 rear gear.

Both vehicles are perfect for a vacuum secondary carb. Both vehicles will allow you to put your foot to the floor from standing start to 100 miles an hour.

Ok. lets watch the tachometer on both vehicles, the car is going to rev much quicker to 5000 rpm than the truck. The car is going to require the secondaries to open at a quicker rate than the truck for optimum performance.

We've already established that if the secondaries open immediatly as if the screw was in the slot, we would have a major hesitation, there is no accellerator pump for a shot of fuel on the vacuum carb. We want the secondaries to open as soon as possible without the hesitation, but not open so slow that we are waiting for the seconaries to open.

The answer is to change the spring in the vacuum canister holding the rubber diaphram in place. Order the Holley vacuum secondary spring kit, you'll get about 6 different springs. You also get a chart showing the tension of all the springs.

Now, remove the canister, remove the top, compare the spring in the canister to the ones in the kit. Find yours on the chart provided. Now install the spring with one step less tension than the one already in the canister, go for a test drive.

The goal is to work your way to the point that the car hesitates when the secondaries open, then install the spring that is one step up from that spring. This should give you the soonest possible secondary opening without hestation. This may take a few trial runs, but you be one step better than the guy who doesn't do this. This is one of many steps that's gonna get the most out of your carb.

The same process goes for the truck, find the earliest opening without hesitation.

Not to change the subject, but a thought came to mind when Scooter402 mentioned he had gotten to page 20ish.

I wondered, hmmmm, with all the different projects on this build, I don't recall what I was doing on page 20.

Then I thought, out of all the projects, does anybody have any favorite parts that stand out the most for you.

I'll start.... My favorite project, the one that when I look through the pages that makes me sit back and say, now that's sweet, wow, it would be the building of the crossmember. I still look under the truck, even tonight, and say, wow, that is awesume.

Anybody else got one?

Ultimate classic truck right there

Posted by CCmyVW on 12/26/20 @ 4:17:42 PM