You must be logged in to rate content!

3 minute(s) of a 636 minute read

6-14-2019

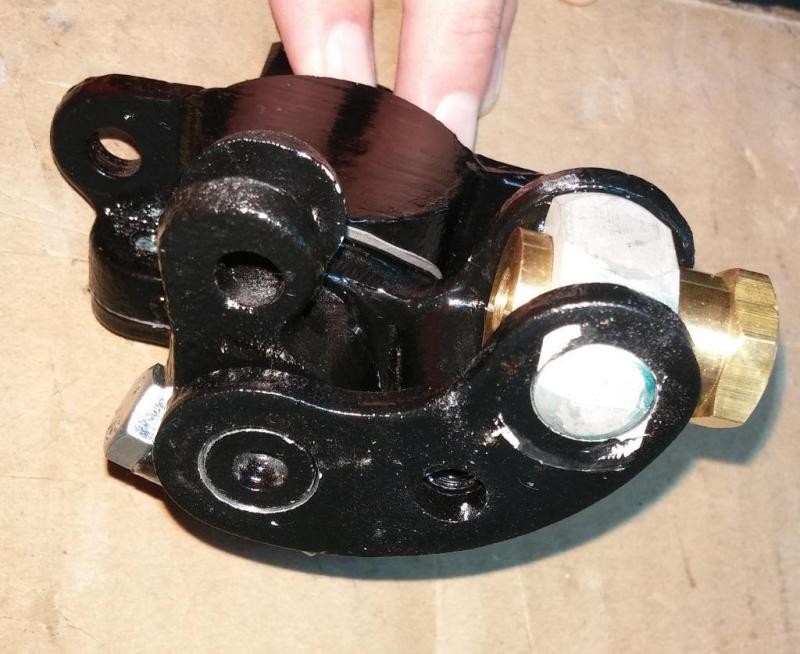

ended up get some custom gaskets made, a local company cut me some graphite gaskets to my dimensions. these are high temp, high heat gaskets so they should be perfectly fine. plus being graphite reinforced with steel mesh they should hold up just fine. they are made to be compressed and once assembled worked great.

while assembling i also put some high temp grease on the parts that need to move.

everything was going fine until i tried to thread the rod end bolt into the new brass bushings for the trunion. one ended up breaking, they were really hard to thread out, as the bolts were mangled and bent up pretty bad, i tried to straighten them out, but seems the were a little weak, but at 90 years old, hey. i did some looking and hunting and found many rod ends but the ones that were 5/16" to match are all threaded 18 threads per inch and the ones on the car and mating hardware are 24 threads per inch. luckily i found a company that makes blanks in various lengths. so i bought 3 5/16" diameter by 3 inches long. this gives me one to tinker and learn on and 2 for the brake assemblies. the blanks will have to be drilled for the clevis pin, and then threaded the full length of the bolt. yes all three inches. they should be here by this weekend, and then i will tackle those !! but got most everything else assembled on the front brakes. once i get those rod end completed i can complete the assembly and hopefully installed on the car !!

also installed the repainted front fender supports. what a difference, will touch up the bolts and paint them black as well to blend in.

called and talked to the plater yesterday, he said the reflectors should be done in the next day or two. said they are looking really good.

they will be all polished nickel, ready for Bill @ Uvira !! hoping to get them out to him within a day or two of receiving them from plater.

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM