You must be logged in to rate content!

4 minute(s) of a 636 minute read

5-26-2019

Nothing like the right tool for the job! I look at all the hand tools passed down to me from my dad and the other tools like my lathe/vertical Miller, that I’ve acquired myself and think sometimes that when I’m gone, they’ll probably be thrown away because not to many will even know how to use them. My own son, who’s fairly mechanical and a industrial electrician foreman, has told me he’s looking to purchase a farm in TN somewhere that also has a multi stall garage. While I know he loves raising cattle and horses, I asked him why a big garage. He proceeded to tell me he figured my wife and I could come visit during the winter months and I could set up a restoration shop. He said he feels he’s missing out on a lot of things he could learn from me and having me there would be good for all of us. Sometimes I still think there’s hope for some of the younger generation!

5-28-2019

Since i am waiting for my headlamp reflectors to get plated i decided to do a once over on the front end and pull the brake trunion assembly and check it completely over. since i have realized the PO did a lot of paint over and NOT rebuilding all the assemblies and pieces.

i removed the drivers side assembly and decided to tear it completely down and strip, prime, paint the parts and rebuild completely.

while tearing them down i learned QUICKLY that these things probably have NOT been apart since 1929 when they were initially put together !!

looks like the PO attempted to remove a few screws and stripped the heads out !! that was NOT fun, had to soak them for a while and the use a screwdriver and hammer to tap them around to spin them out. these were the 2 flat head slotted screws on the flat plate. the passenger side screws were easily removed !!

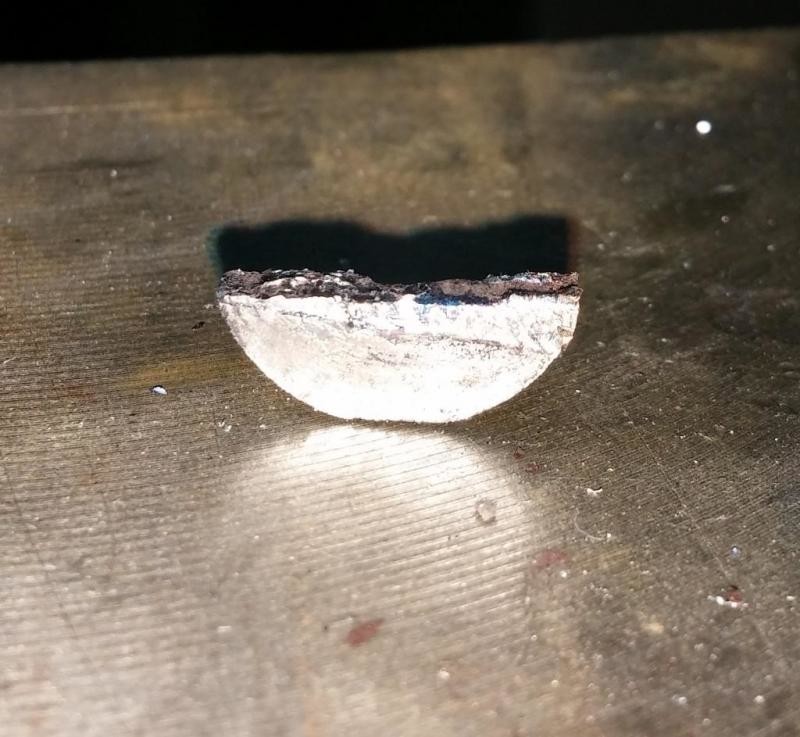

then the woodruff key that was in the shaft for the pivot, that thing refused to come out !! i soaked it twice for a few hours each, nothing, tried to tap it to rock it loose, tried a small screwdriver to hopefully rock it in the keyway, nothing. had to resort to heat and vise grips. took a good amount of heat and several attempts before the key finally gave up and popped out !! BOTH sides were like this.

shot of the key, notice the corrosion

top view of corrosion and attempt to rock it with hammer, screwdriver, pliers

keyway in shaft

finally got is all disassembled and laid out on the bench

plan to strip, prime, paint all the parts then reassemble and install on the car.

one assembly tore down

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM