You must be logged in to rate content!

11 minute(s) of a 636 minute read

12-11-2014

I am looking for someone who can Rebuild 1929 Rocker Arms Properly as I Need to have the Rocker Arms on my 1929 Chevrolet 194 Rebuilt. They need to be Welded up, then ground & shaped PROPERLY. Possible hardened as well. Would like someone who is experienced and will provide a QUALITY end result that will last me a LONG time. Any leads would be appreciated.

I talked with Bill (Billy Possum) over @ C&P Automotive, they no longer provide there Rocker Arm Rebuild Service as they are unable to find anyone locally that can rebuild the Rocker Arms with Quality Results.

Once I can find someone to do this service I will have my Rocker Arm Assemblies Rebuilt w/ New Shafts, Bushings, Springs, Clips, Wicks. From what i can see the Valve Adjustment Screws & Locking Nuts are in great shape, they all move freely and are NOT marred up. If the Rocker Arm Place can do this would like to have it all done in one shot so the bearings can be reamed to fit the shafts properly. I will be getting the parts from Bill, or one of his outlets

Need to debate if I want to PULL the Head and have the valves check and maybe the seats cleaned and filed for proper valve seating. and also look at new Spring Caps & Keys. Maybe NEW Valve Springs as well. Also will put in NEW Valve Push Rods & Push Rod Ends as what I have now is a mixed bag of the original 2 piece and some later one piece rods.

Also what about replacing the Valve Tappets ?? any way to determine if the ONE I have are worth keeping or need replacing ??

ANY and ALL help is appreciated... yeah the Engine was NOT REBUILT it was OVERHAULED, as we all know from reading my threads...

Ok found a few places that are experienced in the Realm of resurfacing the Rocker Arms. Also they will chrome plate the shaft or replace it will one of C&P 's Chrome Moly jobs. They tumble the rocker arms to reduce stress that has built up, which makes sense. they build up the surface and then contour the rocker arm valve face. they also will ream out the rocker arms and install new bushings, the bushings will be grooved and hole drilled for the wick feed. The bushing will be reamed to mount properly on the shaft. I am also going to replace the springs and clips. a few of the springs are beyond shot !! Will also put in new WICKS.

Man I am excited !! now just to get time to remove them and send them out. Said about 3 weeks turn around, so gives me time to do other things as well... ELECTRICAL

doing a quick look over the Rocker Arm Assembly... Looks like somewhere along the line someone welded some up, well tried to. Can anyone confirm that these are the RIGHT rocker Arm Assemblies that should be on my First Generation 1929 ??

Here are some shots of the Rocker Arms:

This is the First Cylinder from 3 angles

Rocker Arms to Valve Stem Head on Pictures

Shot of the Top Half

Also seems that the Arm can EASILY be moved around, not just side to side, but they can be rocked on the shaft [left to right]. Telling me the bushings are SHOT !!

On the Bright side, the Adjusting Screws & Nuts LOOK Great, they all spin and turn easily and threads look great. So these should be GOOD to GO !!

Pulled my Rocker Arm Assemblies off today and decided to check the TIPS out. Took some pictures, and then measured the Tips at their thickness point on the LEFT side of rib then the RIGHT side of the rib.

With a closer look you can tell that the TIPS were done with some sort of Brass/ Bronze Material, or at least that coloration and YES it is really soft, tested it with a file, real easy to file and really SOFT. Was done a while back as you can tell from the pictures. They are pitted, distorted and worn out, looks like the Valve Stems have been BEATING THEM UP !!

The numbers say it all:

Rocker NumberThickness Lt - . Rt (Diff)

Cylinder 1 Exhaust:---.278 - .271 (.007)

Cylinder 1 Intake:----.315 - .324 (.009)

Cylinder 2 Intake:----.270 - .276 (.006)

Cylinder 2 Exhaust:---.266 - .284 (.018)

Cylinder 3 Exhaust:---.259 - .276 (.017)

Cylinder 3 Intake:----.274 - .279 (.005)

Cylinder 4 Intake:----.247 - .249 (.002)

Cylinder 4 Exhaust:---.286 - .267 (.019)

Cylinder 5 Exhaust:---.245 - .261 (.016)

Cylinder 5 Intake:----.253 - .294 (.041)

Cylinder 6 Intake:----.279 - .278 (.001)

Cylinder 6 Exhaust:---.251 - .268 (.017)

Now a Picture Says a THOUSAND WORDS...

Smooth and Round they are NOT !! Well not anymore...

Also Checked the Bushings...

They are Split style bushing. You can see there is some pitting and wear in the bushing, all are the about the same.

They is some play, and some are a little Sloppy

Shaft OD---.714

Bushing ID-.728

---------------

Variance---.014

So NEW bushings as well...

Shafts, well they are a little pitted in places, and show some wear

So either some NEW C&P Shafts OR resurface & grind the ones I have (SAME COST)

When I go to have my Rocker Arms Rebuilt here soon I am going to double check the rest of the TOP HALF of the engine as well. Figure would be a good time to check tappets and replace if needed...

Is there ANY WAY to Check the Valve Tappets ?? For Fit Wear, etc... How can I tell if they are OK/ good or NEED to be replaced ??

Number Two on the TOP HALF Engine List is replacing the Valve Push Rods & Push Rod Ends, as of now I have a mix of Original 2 Piece Valve Push Rods & Push Rod Ends and some Single Piece Valve Push Rods. Would like them all to be original style and this will also ensure that they are straight. Going to go with the 'Billy Possum' C&P Automotive ones. 'These rods are exactly as the original rods in appearance, but are induction heat treated on the ends (about ¾”) to give longer life. The push rod ends are case hardened as were the originals'

Also would be a C&P Item 'One of the most common engine parts to fail. Typically the surface bearing on the camshaft fails due to metal fatigue. These case hardened tappets are ground with a shallow radius on the bottom to cause rotation, essential to long tappet life.'

I will do a VISUAL Inspection when i pull the rocker arm assemblies off. pull the rods, check em and check the Tappets/ Valve Guides for wear n tear and any flaking or deterioration.

Yeah not putting HIGH mileage on it, but want to make sure it is going to run properly and for a long time, and want to check everything while i am in there and it is apart. Not having to tear it all apart later because I did NOT check while I had the chance.

Now that I am having my Rocker Arms resurfaced & rebuilt, I am going to double check the rest of the TOP HALF of the engine as well.

Is there ANY WAY to Check the Valves (Intake & Exhaust), Valve Springs, Valve Spring Caps, Valve Keys?? Want to make sure they are in condition to run & operate. Any way to I cad tell if they are GOOD or NEED to be replaced WITH OUT Removing the HEAD ??

Yeah I am NOT going to drive my car a million miles in a year, but i do WANT it to RUN Properly and not have to be worried about something breaking or coming apart. yeah I KNOW it is an Antique and poo happens. just trying to be preventative and proactive. Since I am in there Want to check out the other parts as well !!

Figure look it all over check it out, assess it, and replace it if needed...

could also do a Leak down Test, see IF the Cylinders will hold Compression. I know that each cylinder has about 75 PSI when last checked. NEED to see if it will hold compression and how long it can or how long till it drops x amount of PSI.

Will also do a GOOD LOOKY SEE and see if there are ANY VISIBLE Sings of Wear n Tear. Double checking the CAPs n Keys.

Ok Went out Last night and looked at the Valves, Springs, Retainer Caps, And Retainers (keys)

Looking at them the end of the Valves look great, BUT I do not see the Keys that look like the picture on TFS of C&P !?

Are these the right valve Caps & Retainers on my 1929 ??

From the looks, they look like they have either been REBUILT or REPLACED, in the parts box I got with the car, there was a used valve or two in there and 7 Valve Springs. No Retainer Caps or Keys.

Thanks...

Intake & Exhaust Valve

Make: Own

Material: Extruded Steel

Head Diameter Nominal: 1 11/32

Stem Length: 4 23/32

Stem Dia: 5/16

Style of Stem Mod: Key

Tappet Clearance: .006 Hot Int & .008 Hot Exh

Spring Pressure: 45 lb Valve Closed

Valve Lift: .277

Are Stem Guides Removable: Yes

Are Oversize Valve Stems Made: No

Overhead Valve Lubrication: Yes

(Consider they are the same valves) Page breaks it into TWO columns, one for Intake one for Exhaust.

Here are some numbers I Pulled from my 1929 Hydrid Head tonight:

Intake & Exhaust Valve

Head Diameter Nominal: unknown

Stem Length: unknown

Stem Dia: .340

Style of Stem Mod: Collar

Valve Lift: ~.217

Spring Details

Outer Dia: 1.323

Wire Dia: .169

Cap Details

Cap OD: ~1.27

Cap Thickness: ~.108

My Numbers for Pictures

Stem Length: ~2.123 Valve Closed

Spring Length: ~1.801 Valve Closed

Compared to the STOCK numbers previously posted in BLUE

Larger Stem Dia

...means valve bores were bored out/ modified to fit new valve stem dia

Did a Valve Check today...

Removed Rocker Arms and then Measured w/ My Calipers the distance from the machined Head surface to the top of the stem. Surprisingly all are VERY close in Numbers:

Numbers goe with my RED Dims per my Pictures

Cylinder 1 Exhaust:...2.128

Cylinder 1 Intake:....2.128

Cylinder 2 Intake:....2.129

Cylinder 2 Exhaust:...2.129

Cylinder 3 Exhaust:...2.121

Cylinder 3 Intake:....2.103 <-- LOW

Cylinder 4 Intake:....2.136 <-- HIGH

Cylinder 4 Exhaust:...2.121

Cylinder 5 Exhaust:...2.130

Cylinder 5 Intake:....2.128

Cylinder 6 Intake:....2.124

Cylinder 6 Exhaust:...2.123

Cylinder 3 Intake was a little low, but IF they machined the valve seat, maybe this one had LESS material removed ?!? Where as Cylinder 4 Intake maybe had MORE material removed ? ?

Compare this to the Info Posted By Steve that the 1929 had a Stem Length of 2.000, would mean that my valve stems are just 0.125 taller/ longer than stock...

Figure: They SEAL & SEAT, Seem to function Properly...

I can live with that, unless there should be some concern.

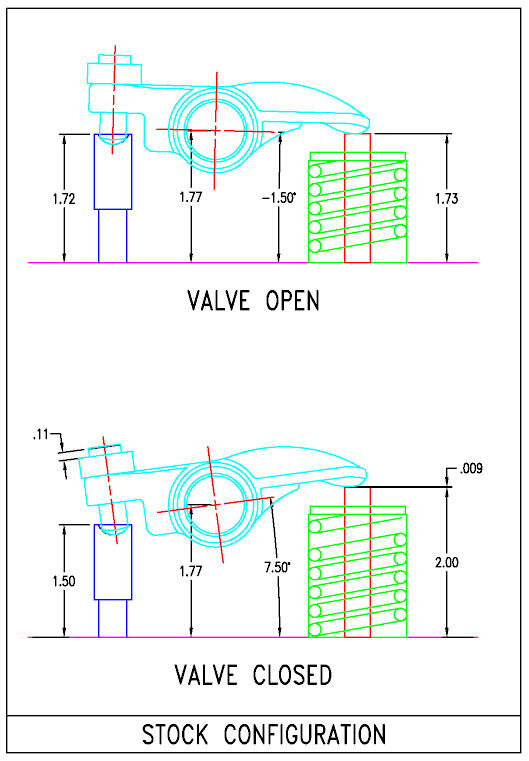

Did some calculations and layout this morning... Used the information I pulled from my Engine as well as the Info provided by members here. Shaft Centerline is Approx 1.77 Inches above Machined Head Surface.

Based on the STOCK numbers provided by Steve:

Stem Above Head: 2.000

Rocker Arm Angle Valve Open:-1.50 deg

Rocker Arm Angle Valve Closed:7.50 deg

Illustration and Layout - Stock

Based on the Current Configuration:

Stem Above Head: 2.125 (Avg)

Rocker Arm Angle Valve Open: 2.32 deg

Rocker Arm Angle Valve Closed:11.50 deg

Illustration and Layout - Current

Based on this information going from stock to the current configuration, the Valve Stems are approx .125" higher than stock, which changes the angle of the Rocker Arm by Approx 4 deg. and requires the adjusting screw to be adjusted by approx .11 in. Push Rods remain stock length.

Now does a 4 degree INCREASE on the Rocker Arm ANGLE have that much of an adverse affect on the operation of the engine ?!?

Remember this engine has only been idled by the previous owner, never put under load until i received it. I have put about 5 miles on it, and it seems to run great. Think once i get the rocker arms rebuilt it will be even better.

At this point I am going to leave the Spring Assemblies alone UNLESS there is Concern ?!?

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM