You must be logged in to rate content!

5 minute(s) of a 891 minute read

5-28-2018

Finally got started on the exhaust today. Wasn't really sure what to expect, other than I need to run 3.5" duals and make whatever fit compromises I need to in order to make it work.

Here's some new and some previous leftover piping. Up top is 3.5" oval tube (2.5"x4.125") from Vibrant, upper left is 2.5" tube to make compound oval bends with vs expensive mandrel bent oval tube. Bottom left is some 3" tube to finish off the downpipes to the subframe rails, and right is a bunch of 3.5" round tube for the rest of the dual exhaust...

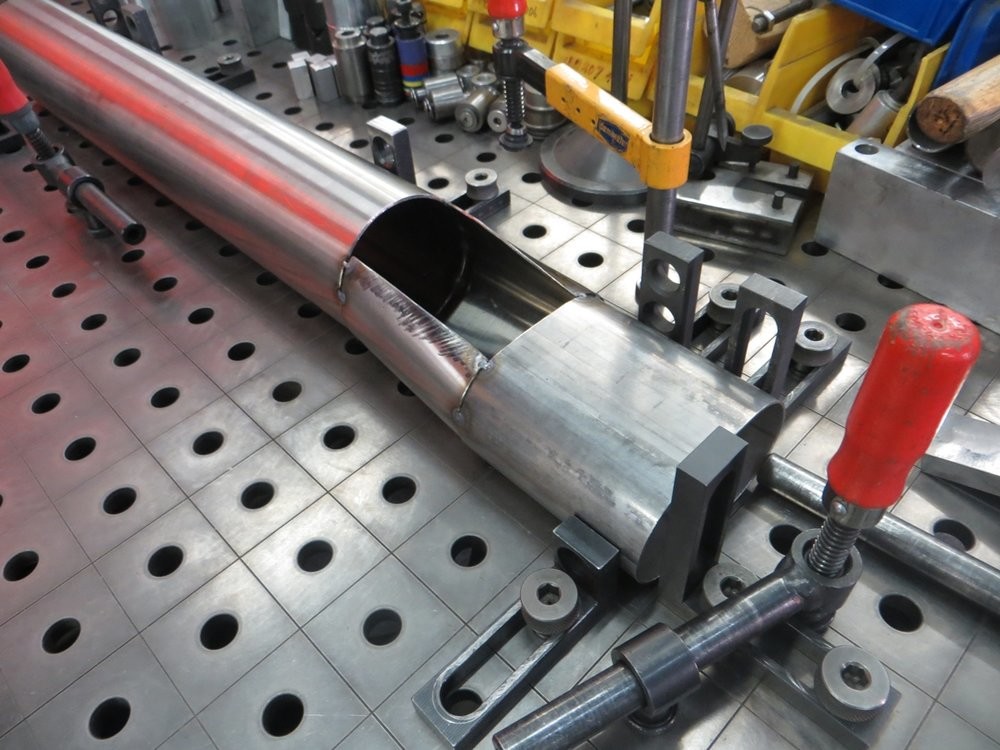

I wanted to see how bad it would be to make my own 3.5" oval-to-round transitions, since the formed as-bought ones are hella expensive. It was a bit annoying but okay. An additional reason I decided to make my own at least for one pair of them, is right round the driveshaft loop cross-member I wanted the underside of the tubing to be flush to give the most crossmember clearance...

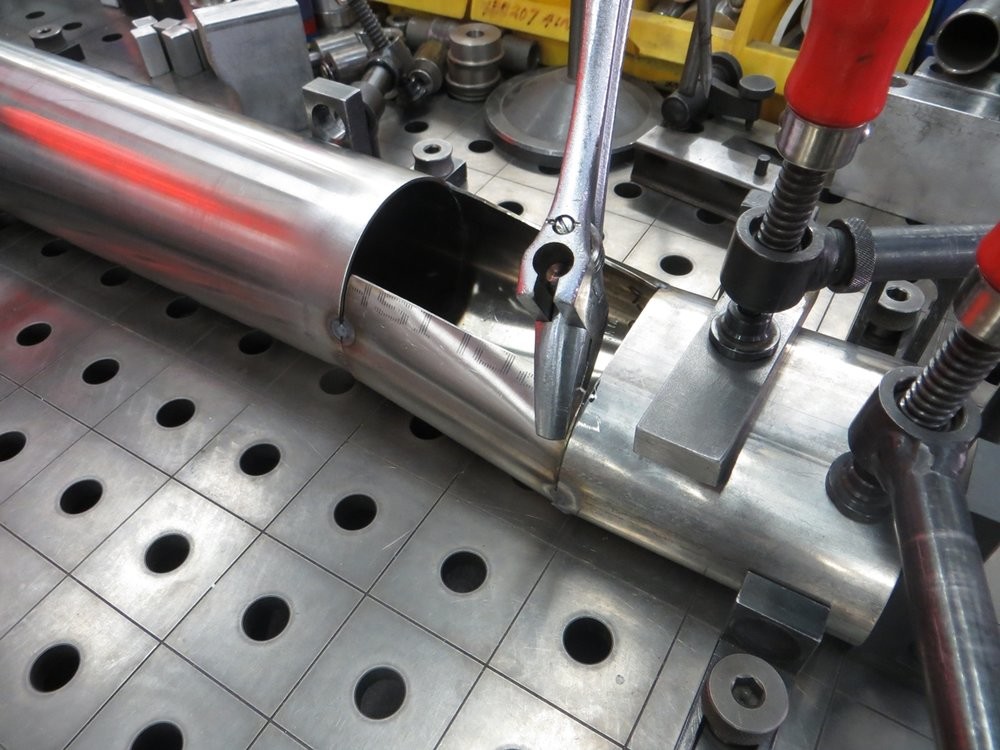

Got the sliced 2.5" straight tube formed to be close to the respective 2.5" and 3.5" diameters, then slowly tack welded around the perimeter as I hammered it to fit...

Sometimes needed a bit more persuasion so out came the adjustable wrench...

Close enough to trim and weld some sheet on there to close it off.. I'm sure I'll bottom it out on speedbumps and scratch it up anyways...

The moment of truth.. how low was 3.5" round and oval tubing gonna hang below the floorpan and driveshaft crossmember??!!??.......

Apparently not that low! I'm SO GLAD I raised the driveshaft tunnel up a handful of inches way back when.. it allowed me to jam the 3.5" round tube close together and underneath the driveshaft...

There's a 1/2" gap all around the 3.5" round tubing to the floorpan. I have an idea to pin the two dual pipes together and have flex joints at the firewall, to keep the exhaust movement under the floor at a minimum...

This shot shows the muffler outlet aimed a bit too much to the center section, I since tweaked it a bit more outboard. Hard to get a pic directly in line with the muffler/routing but idea is to have the exhaust not touching the axle tube at full suspension droop.... JUST barely "not touching" haha.

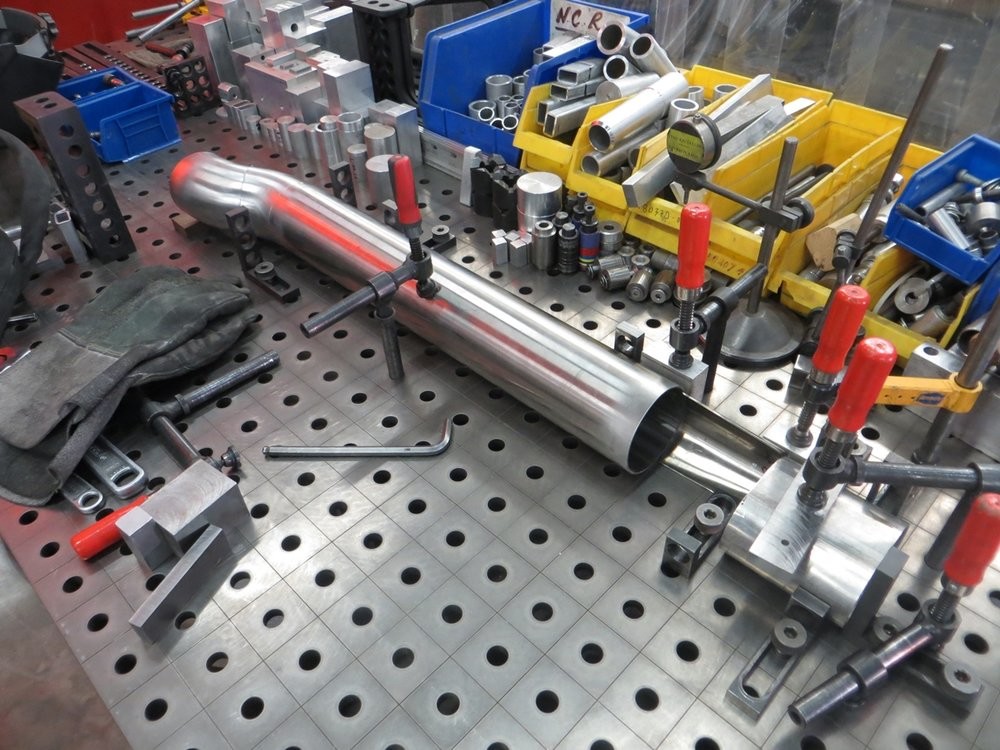

Duals ready for sub-assembly welding at work, while I figure out the oval tube routing from inboard under the driveshaft to outboard around the transmission and the trans cross-member...

Again hard to take a pic in line with the tubing, but the bottom of all the tubing shouldn't be hanging more than 1/2" below the subframe rails.. closer to 1/4" below ideally.. while there is 1/4" vertical clearance to the trans crossmember and minimum 1/2" clearance laterally to everything else (trans cross-member, floorpan, seat bolt anchor plates, etc)...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM