You must be logged in to rate content!

4 minute(s) of a 891 minute read

5-2-2018

Little things... like the driveshaft slip yoke. The new T56 Magnum (converted to F-body tailhousing) has the same output shaft length, but 31 spline not the T56 27 spline. Luckily the trans came with an uber nice billet nitrided chromoly slip yoke, which I wanted to try swapping myself. I've never done any U-joint stuff.. so no better time to learn than the present. Before even giving it a go, I measured the old/new yoke dimensions... even tho the new slip yoke is longer overall, it has the same bearing-center-to-shoulder length, and the spline depth is actually broached even closer to the bearing center. I also checked that the new yoke can still insert into the tailhousing up to the output shaft seal... so in theory this slip yoke should fit just fine with the same F-body tailhousing.

If it works, it can't be ghetto right? Last thing I wanted was this driveshaft to get loose and roll around, land on something and get dented...

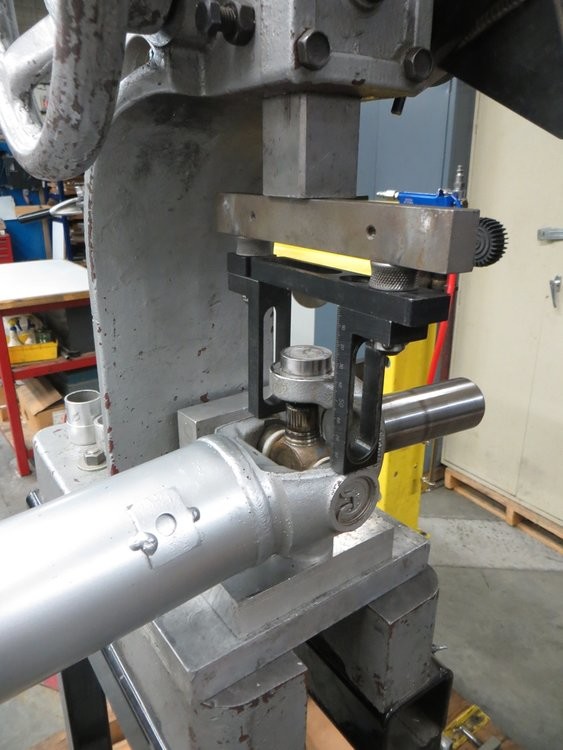

One of the many helpful things about work's shop.. an abundance of random aluminum slugs and tubes for pushing and receiving...

I managed to push the opposing bearing end cap about 3/4 of the way out (still inserted about 1/8" deep) but it was still in there tight enough to need more than a softblow hammer knock, and I didn't want to start trying to grab onto it with vicegrips...

In order to push out the other side's end cap, I needed a weird contraption to push on the shaft-side yoke instead of poking the 1st end cap back in, undoing the work I just did. So I angled the shaft appropriately and made a C-shaped pushing tool to push..

Which ended up working quite well. Unfortunately it was STILL not quite enough clearance to wiggle the U-joint out of the yoke.

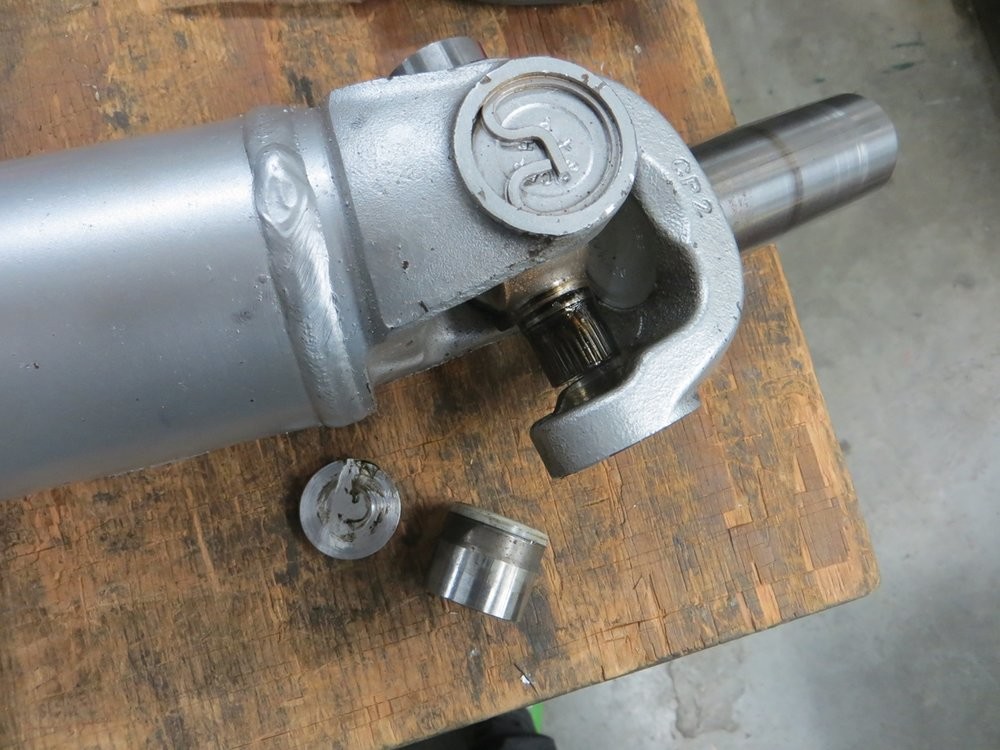

However there was enough gap between the end of the U-joint cross shaft and the inboard end of an endcap for me to make a thin spacer, to then have the cross shaft push the end cap out...

Worked like a charm!....

And used the washer again to easily take the second end cap out of the slip yoke...

Reassembly was super straight forward. The end cap snap rings used in the previous yoke assembled into the new yoke, however they preloaded the bearings just a biiiiiit too much for my liking, so I'm going to try and find some thinner snap rings, maybe 0.055", 0.050", or even 0.045" thick, depending on what's needed to not allow play but have the bearing just slightly slicky...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM