You must be logged in to rate content!

3 minute(s) of a 891 minute read

12-27-2017

Thanks guys, I'm very content with the progress so far.

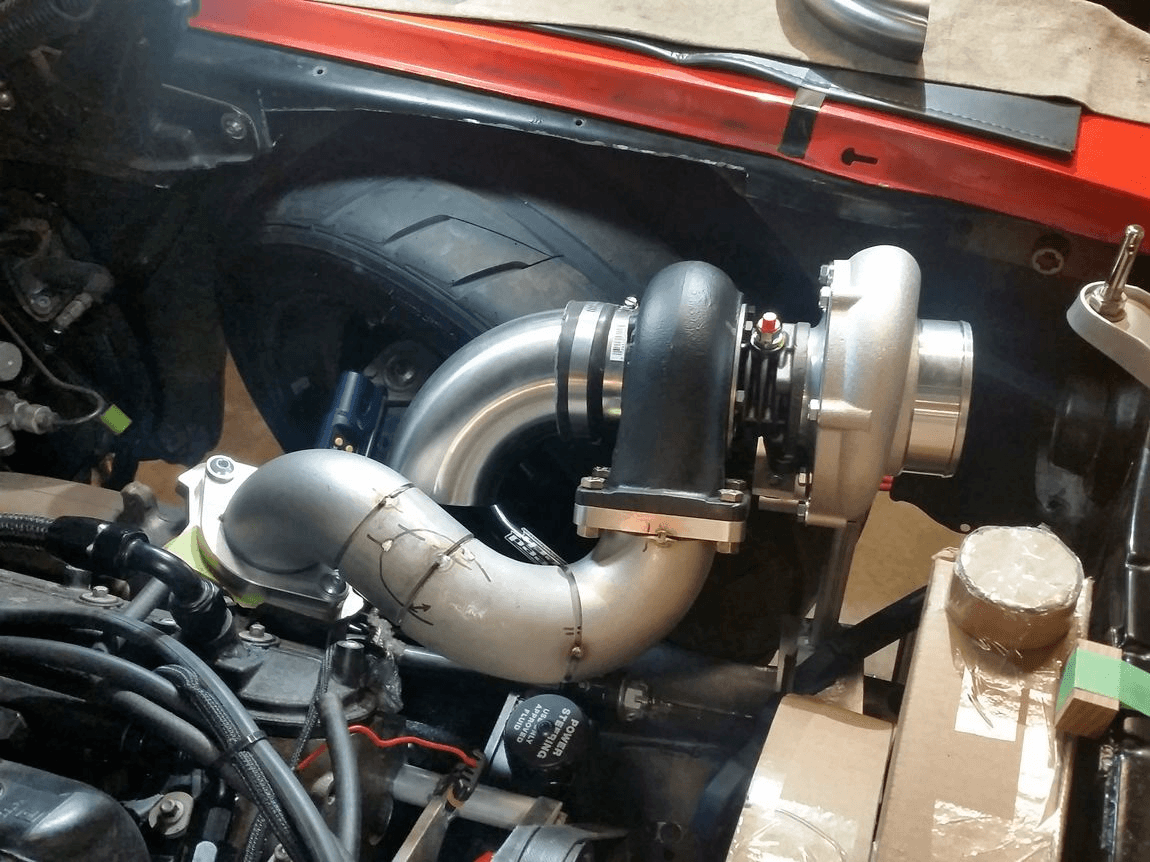

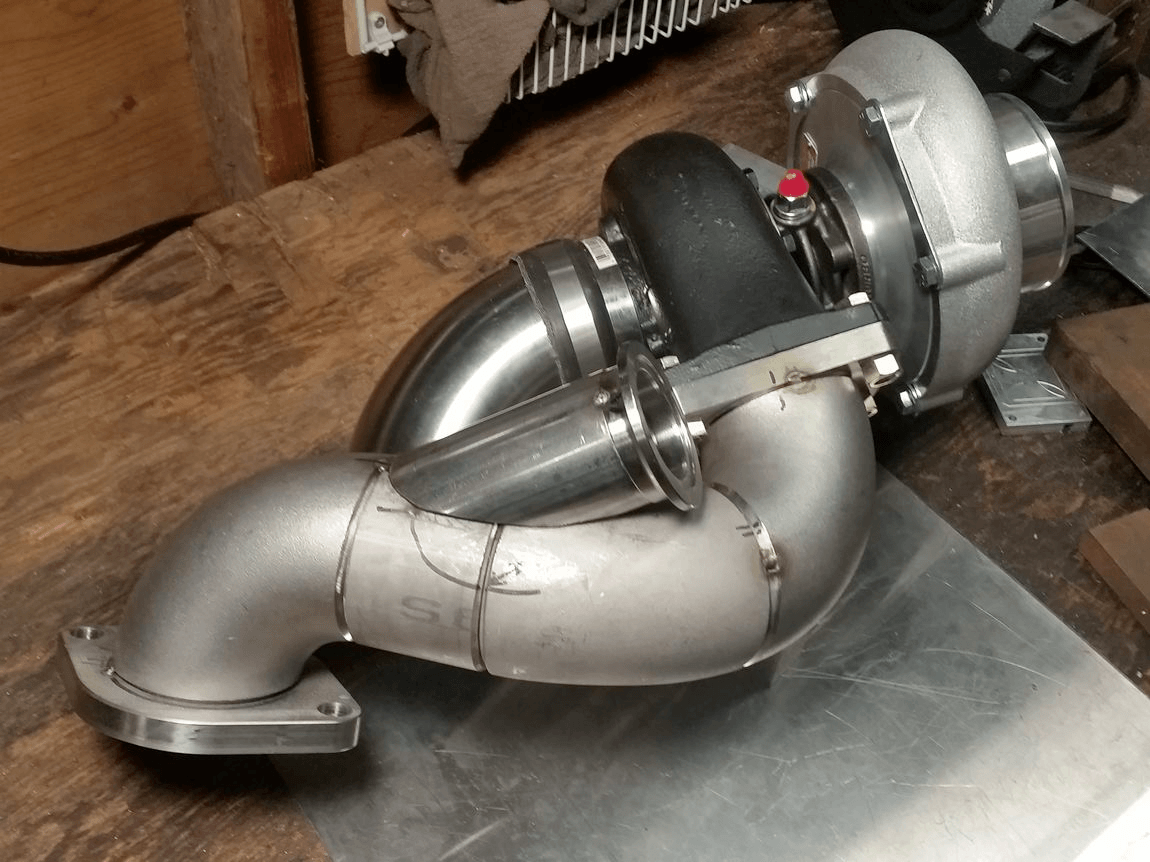

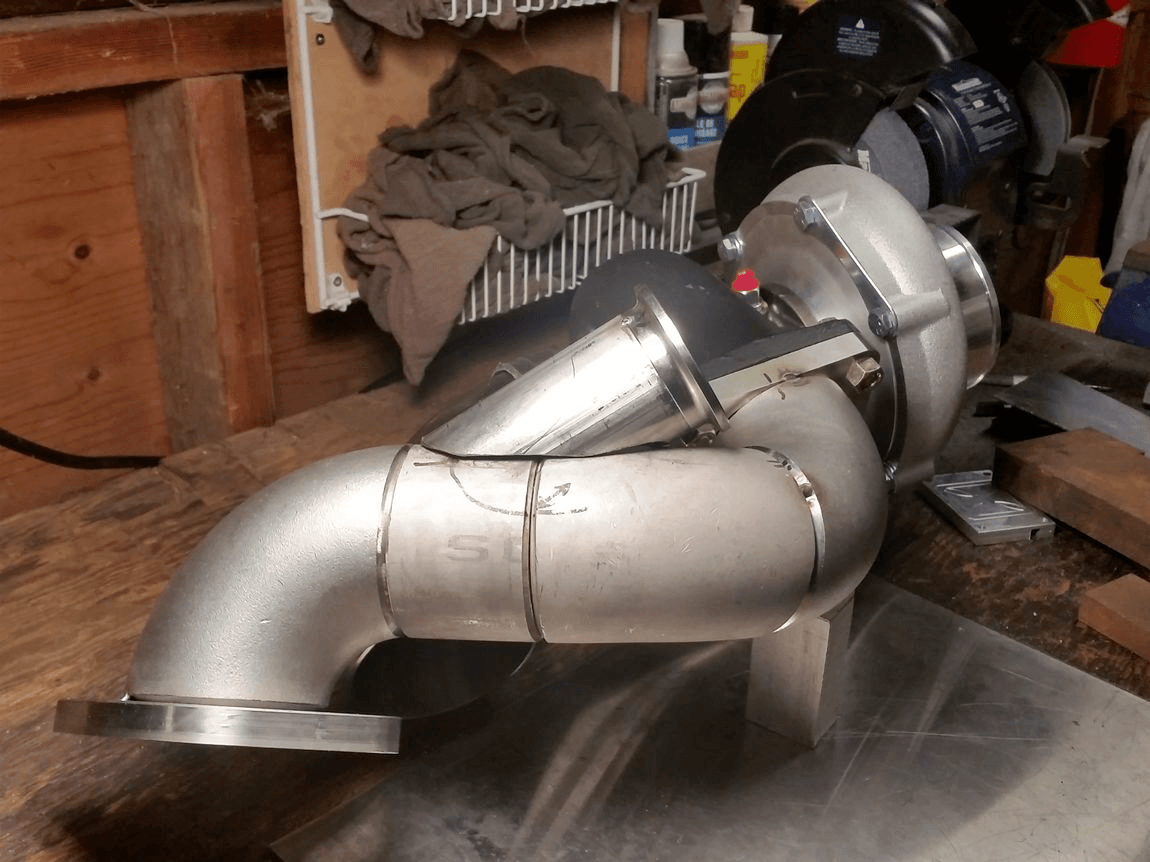

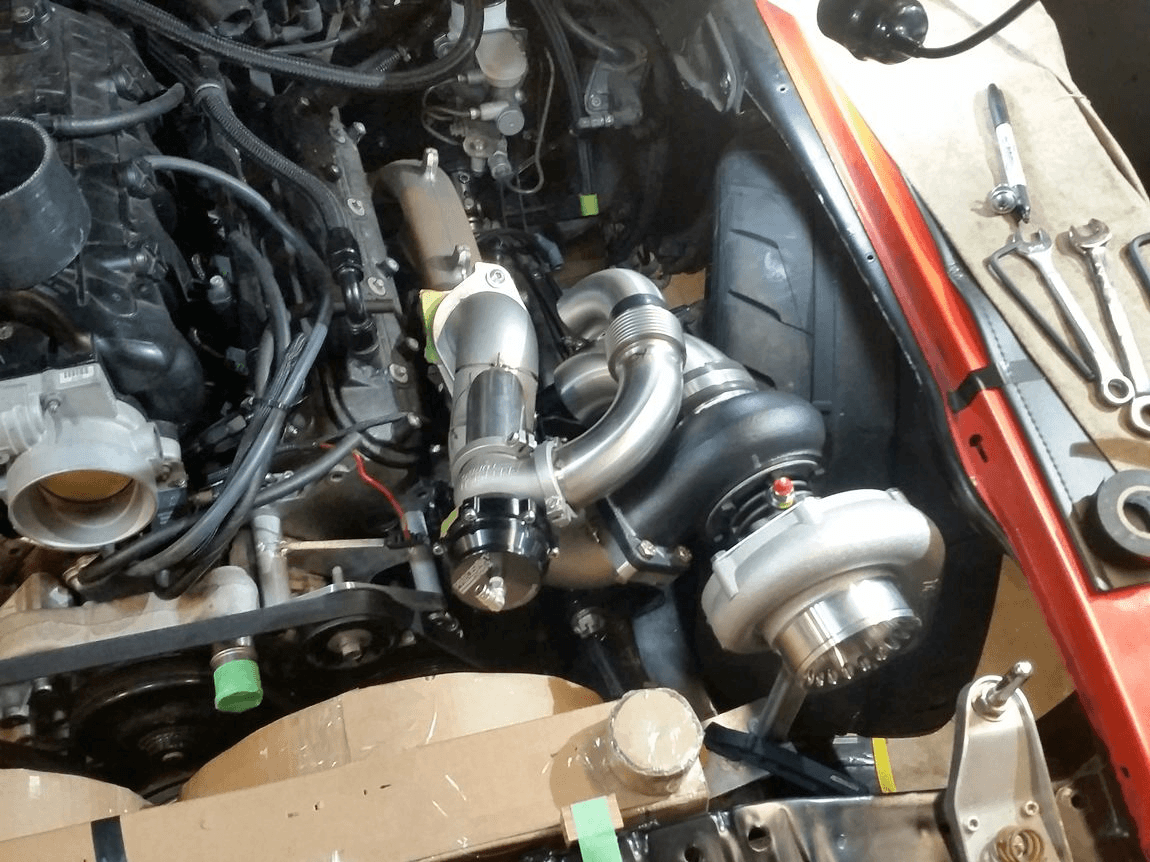

Andrew, no.. the turbo's currently are just supported by the piping. I'm sure to some this may seem less than ideal, as it did to me when I first started thinking about trying a twins setup, but that was the main reason I opted for the CTS-V manifolds, to move the flange further forward in order to reduce the length of the hotside piping and thus the cantilever.

This is also the reason I retained the 2-bolt OEM flanges instead of cutting them off and welding on more aesthetically-pleasing v-bands.. for some extra strength at the joint from the turbo weight. I'll also be welding the manifold flanges on the outside and inside, potentially with some extra gusset plates in the locations under highest tension.

The piping is also schedule 40, which is something like 0.24" thick, so with a deep chamfer at each weld joint and multiple weld passes I'm confident that almost that entire thickness will end up being made up with weld bead, making the piping itself quite strong.

For turbo weight, it's actually not that bad. The entire assembly as shown on the benchtop is reasonably liftable by one hand. There's also the fact that practically everyone else has made twins setups (with apparent success) having them supported only by thick wall piping or thin wall headers and tubing.

12-29-2017

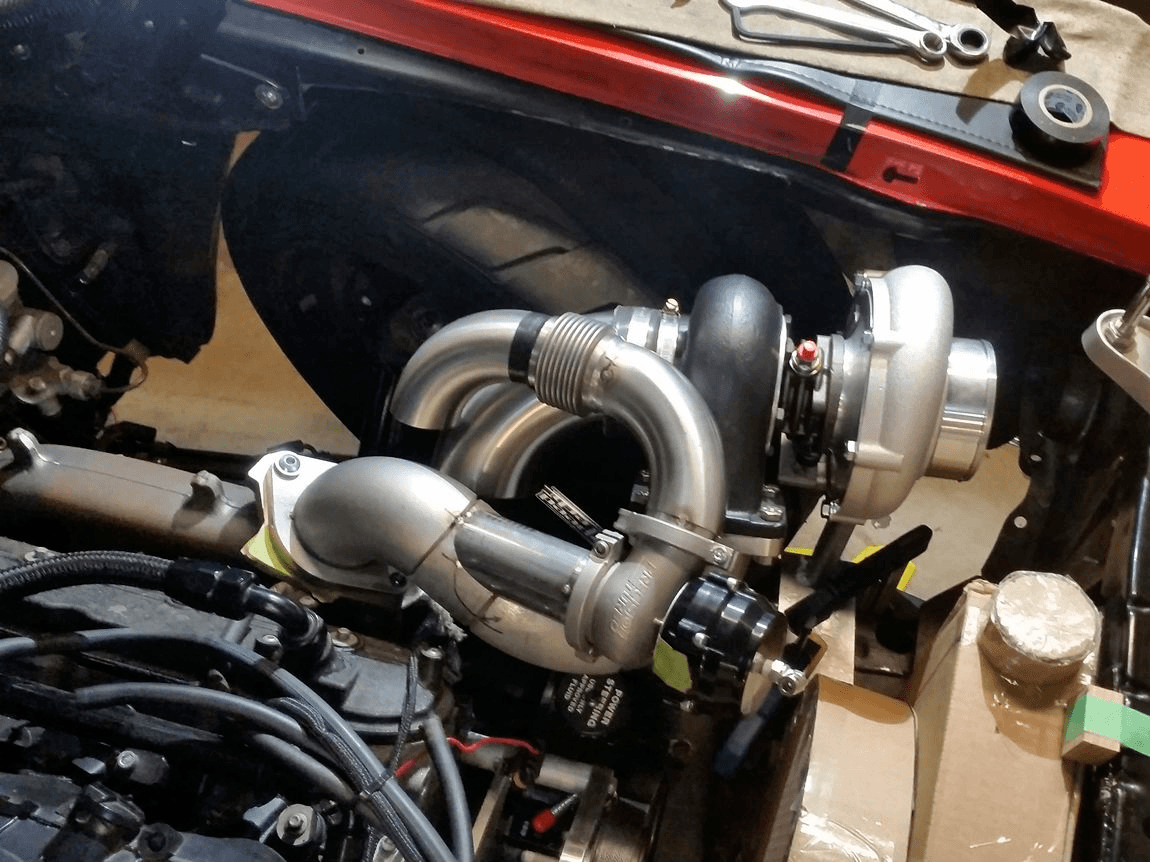

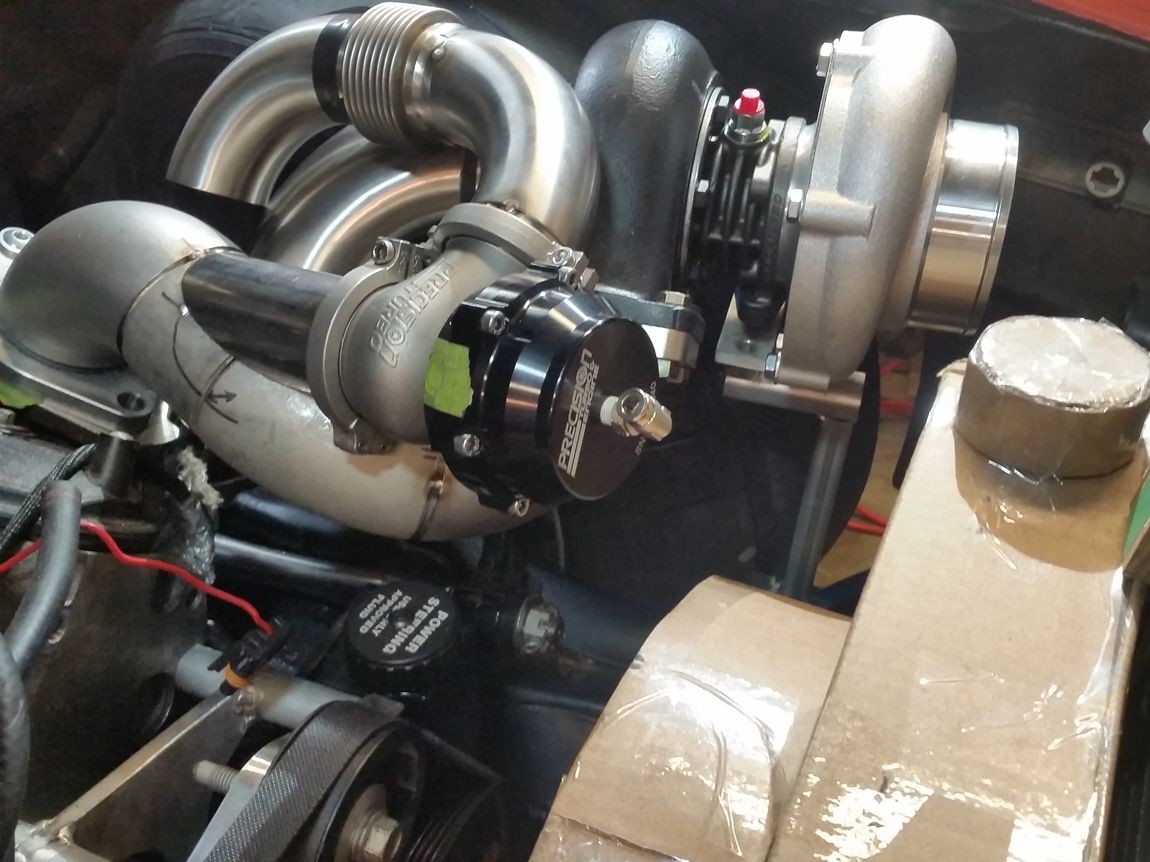

Yesterday I tried a different routing of the wastegate downpipe, routing it above the turbo downpipe to get that heat away from the radiator+fans and the turbo oil drain. I originally lightly mocked it up this way but thought it didn't look so good, but Mark brought me back to my senses.

I've ordered some 2" stainless bends that have a tighter 2.0" centerline-radius bend... the 2" piping in the pics below is 3.0" CLR. Tighter bends might make the wastegate piping appear less visually prominent. I also like that the wastegate feed pipe is now a bit more acute to the turbo hotpiping. I can still get at the crotch of the weld with some TIG torch tungsten stickout, so it looks tighter than it actually is.

Also awaiting more 2.5" schedule 40 elbows and turbo discharge v-band flanges, as well as Precision T3 flanges that match the turbine housing inlet.. so at the moment I can't really make any more mockup progress on the wastegate piping and downpipe, or any of the passenger side for that matter.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM