You must be logged in to rate content!

3 minute(s) of a 891 minute read

12-27-2017

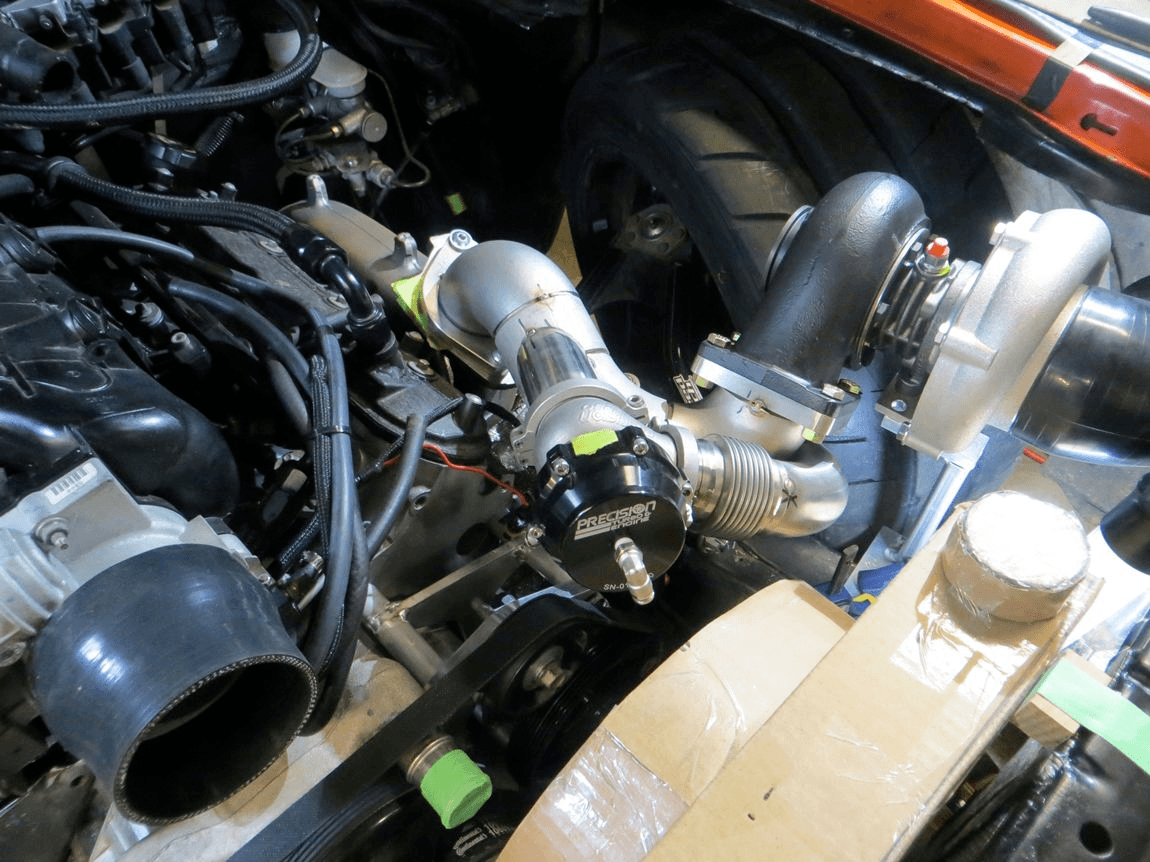

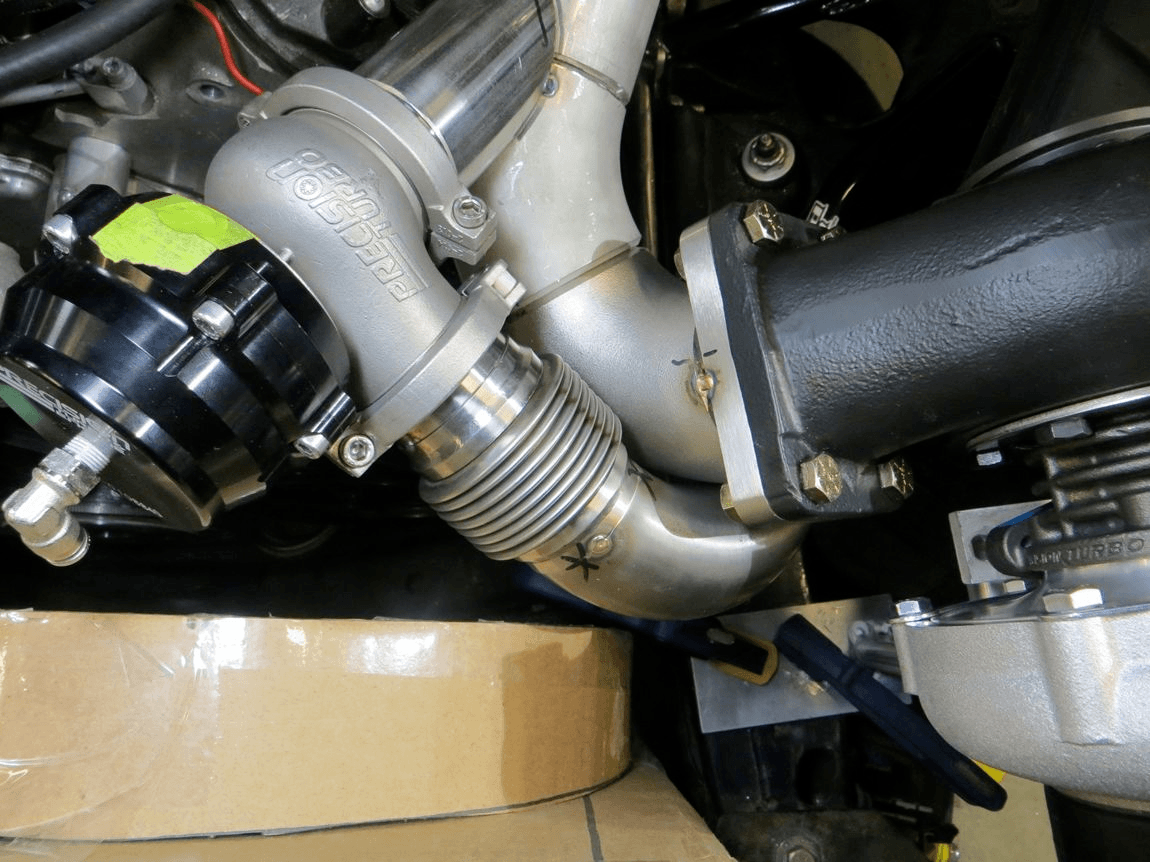

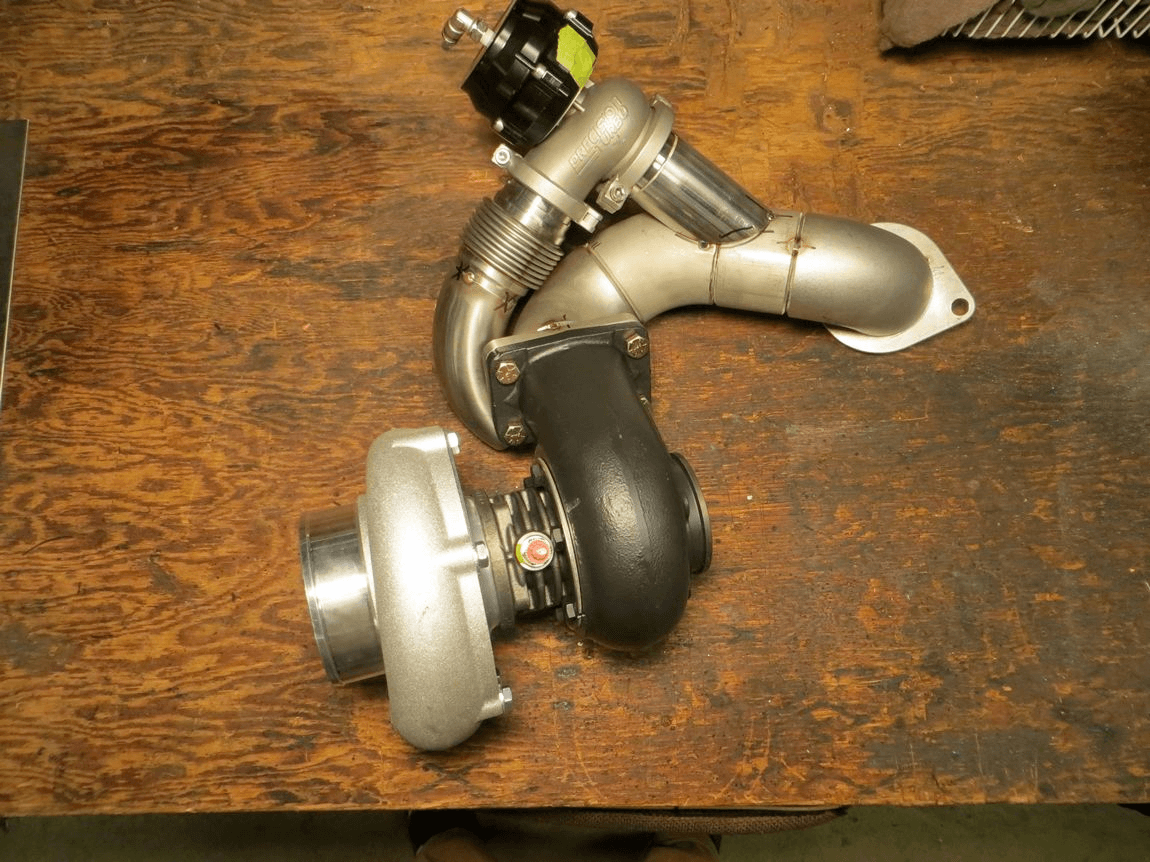

And the last bit of work I got done this afternoon.. a rough cut of the wastegate routing. I put it in a place that should be easy to mirror onto the passenger side, and didn't cut a thru-hole in the pre-turbo piping, I just tacked the wastegate piping on for mockup purposes for now. I think the wastegate downpipe should wrap under and merge back into the turbodownpipe nicely.

The pre-wastegate hotpipe is 0.188" wall schedule 40, so it's also on the thick side, but I think I will add a gusset just because the crotch weld in the front will end up being pretty sharp.

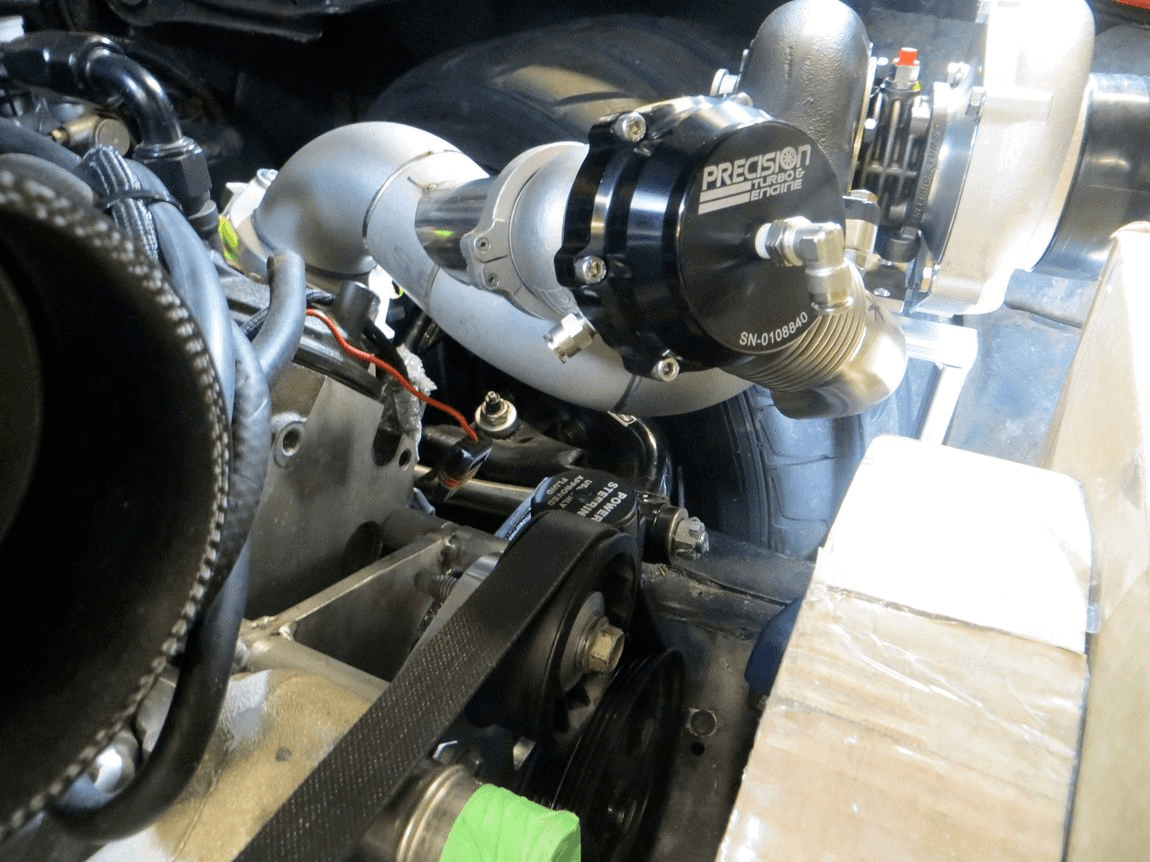

There is about 3" of airgap between the pre-turbo hotside and the P/S reservoir cap, which should be far enough considering there will be relatively-cooler air blowing in that area from the rad fans. I may still make a heat shield or heat tape the top of the reservoir cap.

There is also 1.5" air gap between the wastegate downpipe and the mockup of the radiator fan. The rad+fans mockup is generous (3.5" thick radiator) but the fans are also placed pretty high up, I could move the fans down a bit in real life, as well as the option of moving the rad down ~1" as well.

There was no good way to take a pic of this, but there is a minimum 1/4" gap between the wastegate downpipe or bellow and the pre-turbo hotside.. I think with the bend welded to the turbo downpipe, even with head expansion and vibration, there's no way this bend would rub on the pre-turbo hotside.

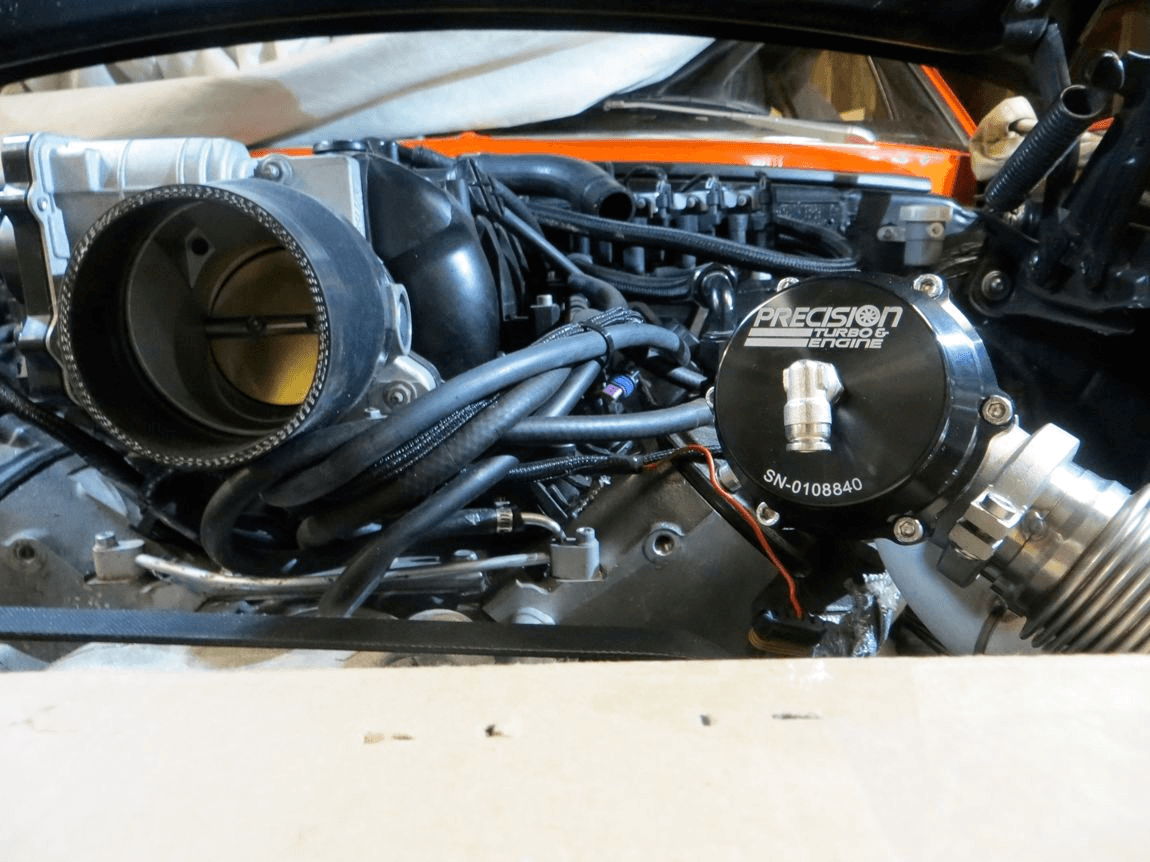

And of course, I went thru the effort to make the Precision logo horizontal

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM