You must be logged in to rate content!

6 minute(s) of a 891 minute read

11-19-2017

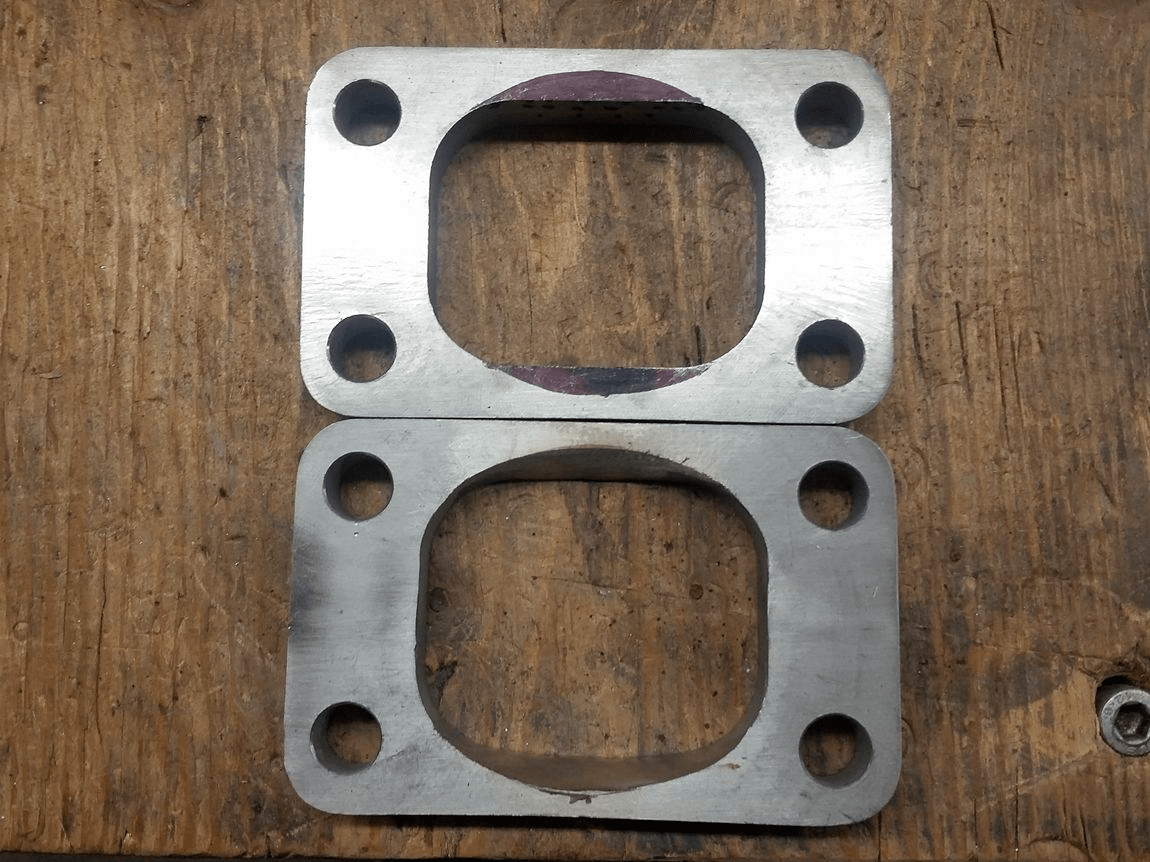

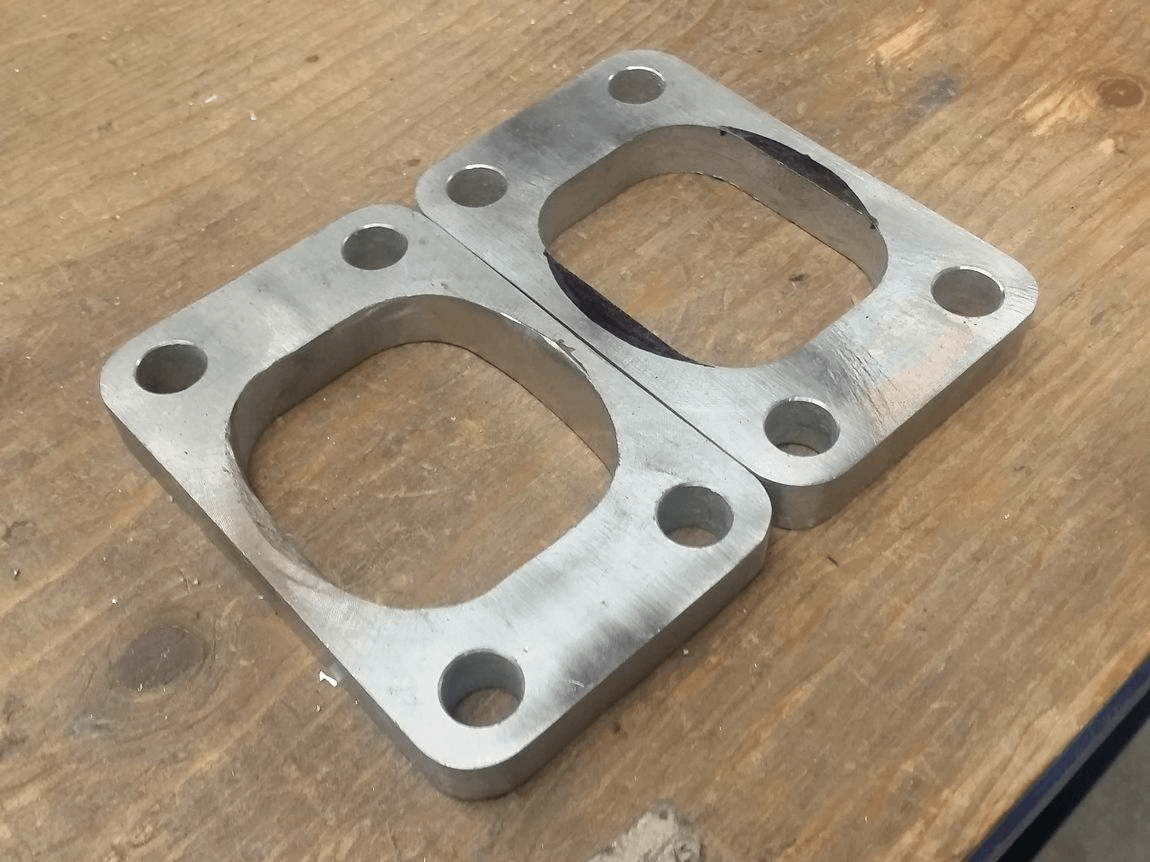

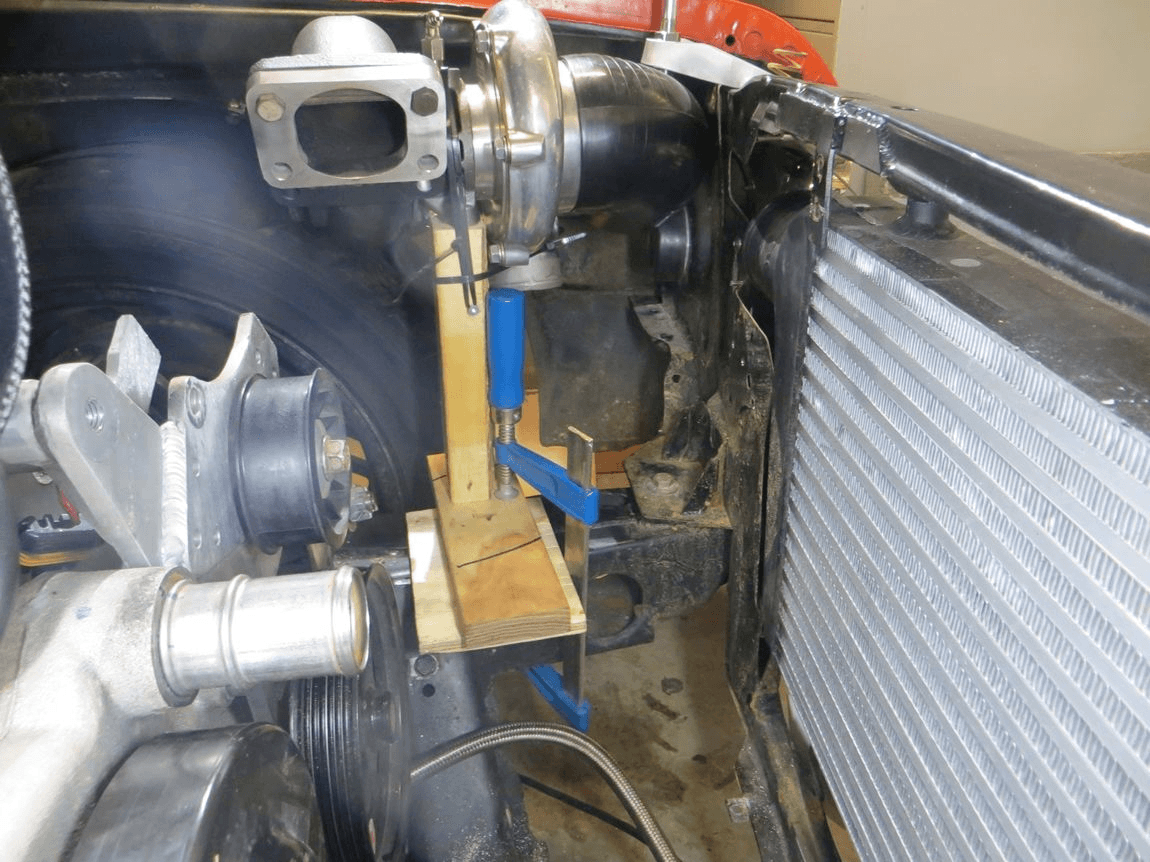

It was pretty easy to do some manual porting of the T3 flanges, took about 15 minutes a piece having the big shop compressor running flat out with the belt sander and a couple 40 grit belts.

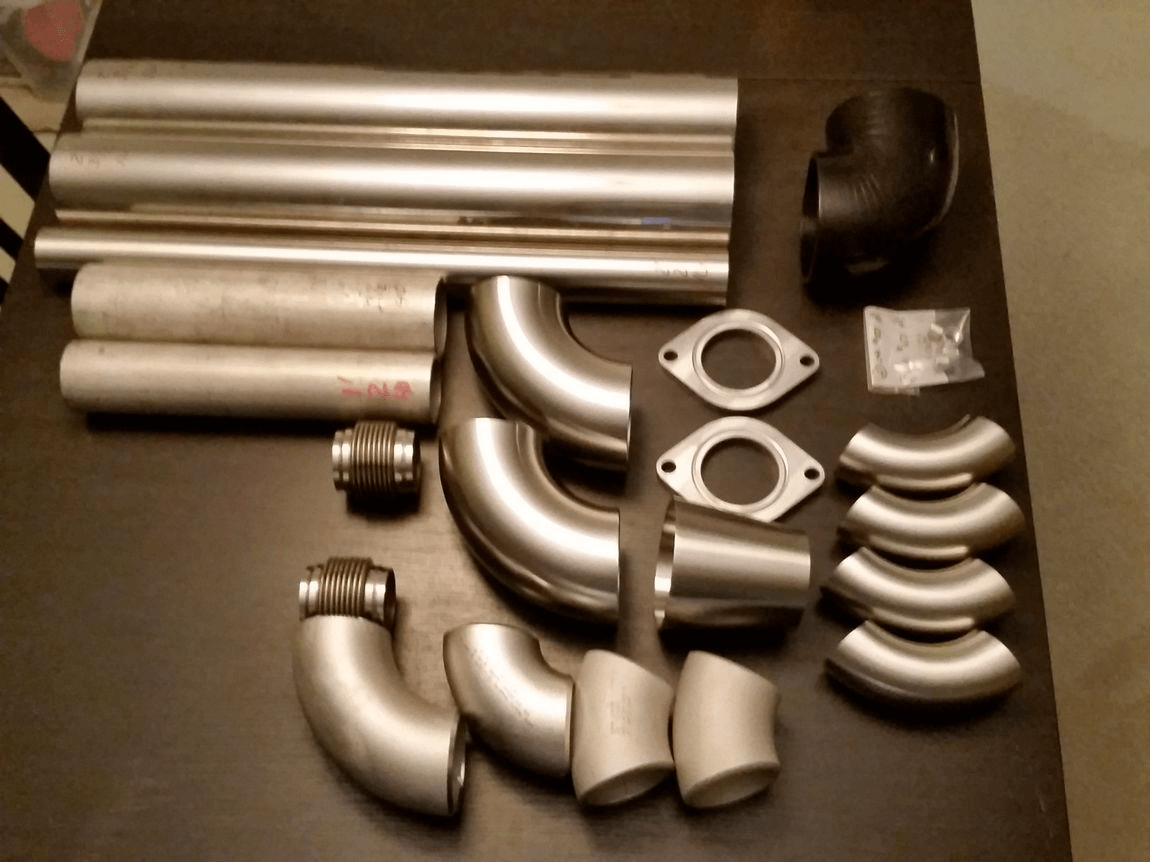

Received another order of stainless which should round out the raw materials I need for plumbing to the turbos, then turbos down to firewall (including wastegates). Man the 16ga piping is nice stuff.. hope my welds end up being good enough to do the material justice.

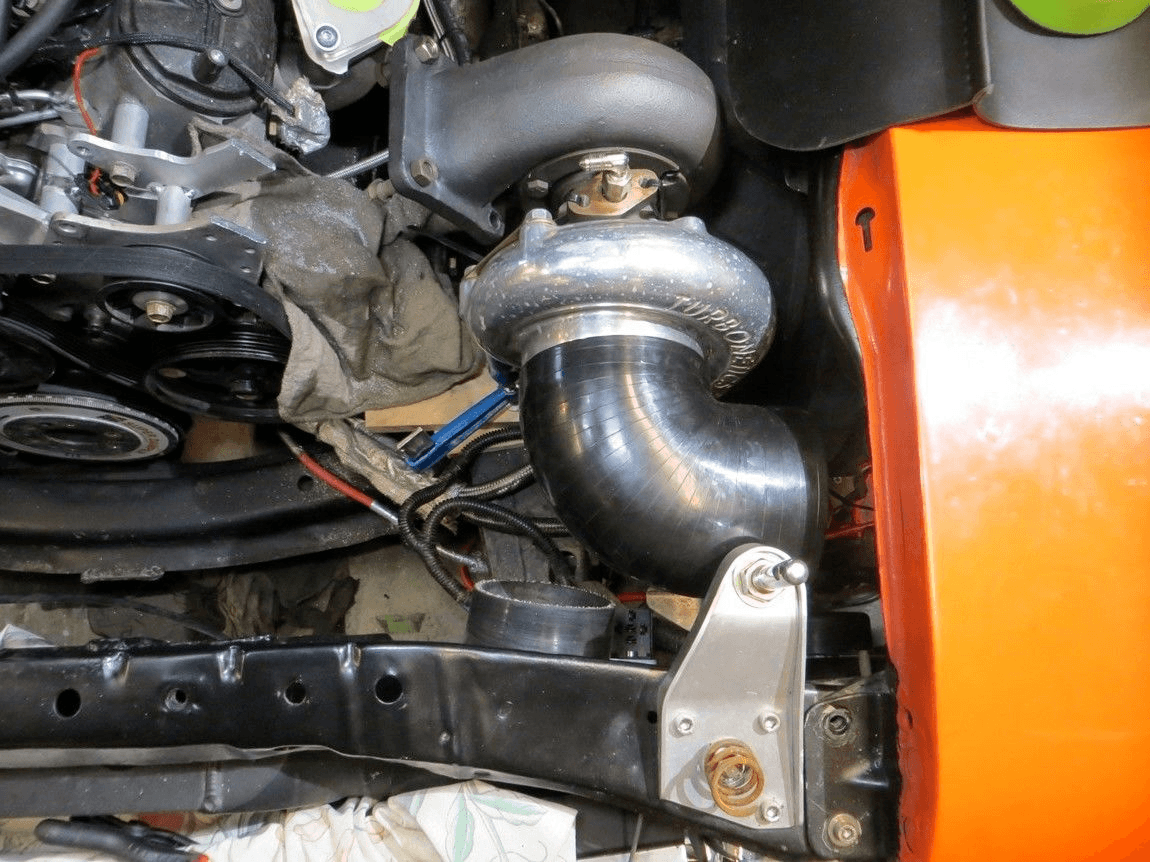

Also grabbed some SS304 CTS-V exhaust flanges off a CNC exhaust flanges maker on eBay, they see good quality and fit well. I like the widespread bolt pattern for supporting the cantilevered weight of the turbos and piping, versus the added annoyance of welding v-band flanges onto the manifolds again.

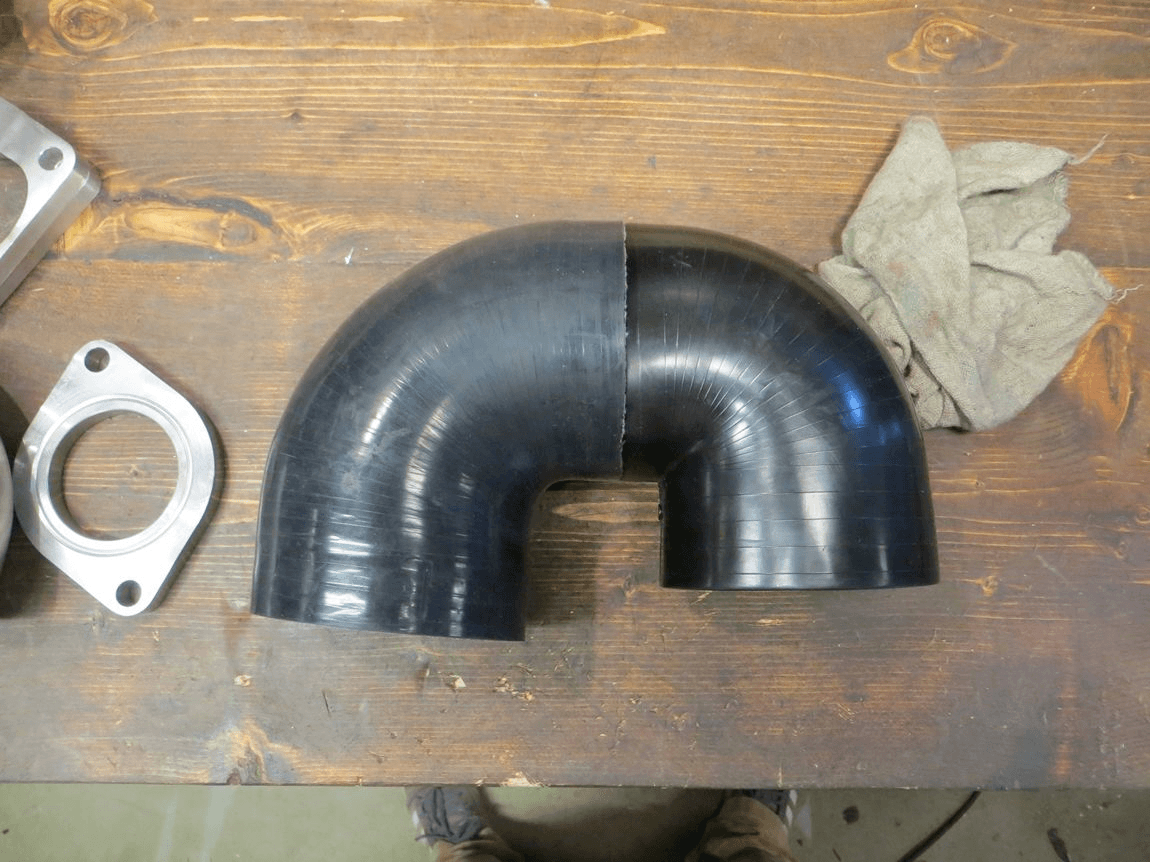

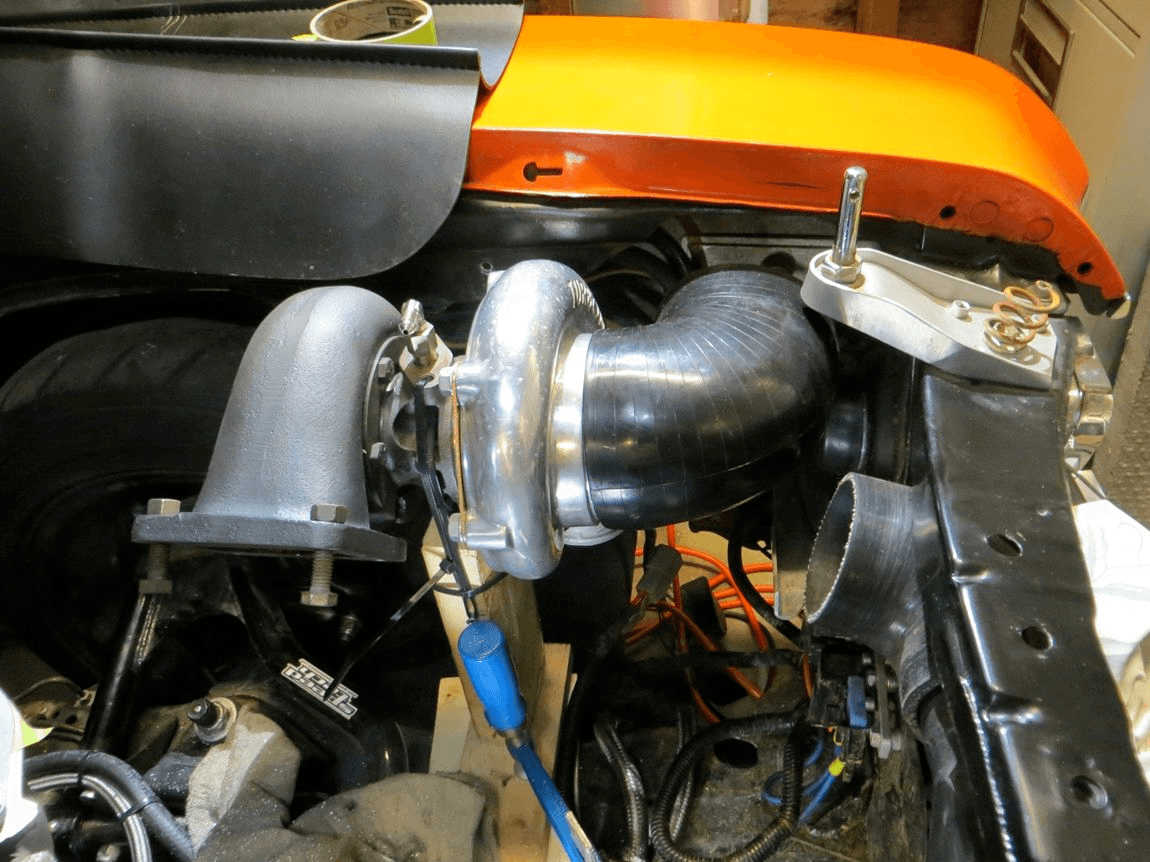

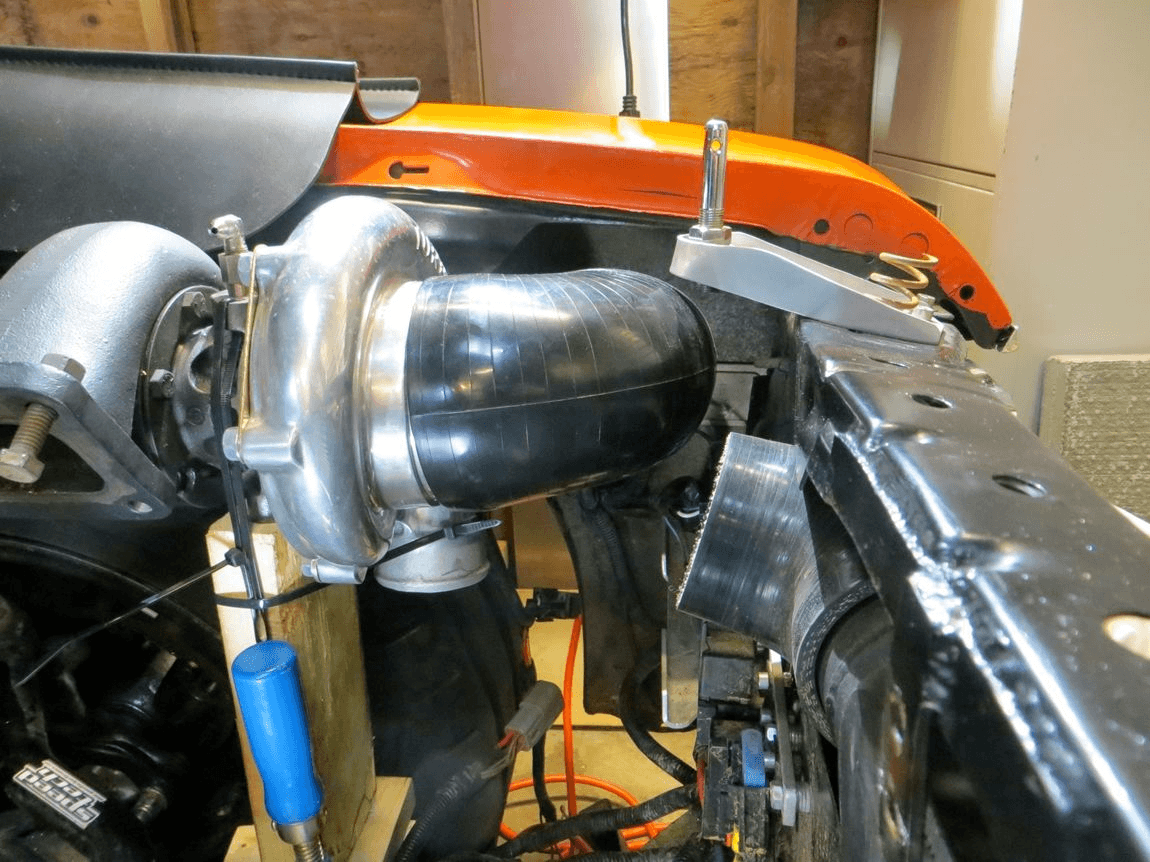

Also grabbed this Spectre tight radius intake elbow to maybe gain a couple inches of room to the rad support. Not sure if I'll use it, but an interesting option to try that I'll have to confirm the need of when I start modifying the inner fenders.

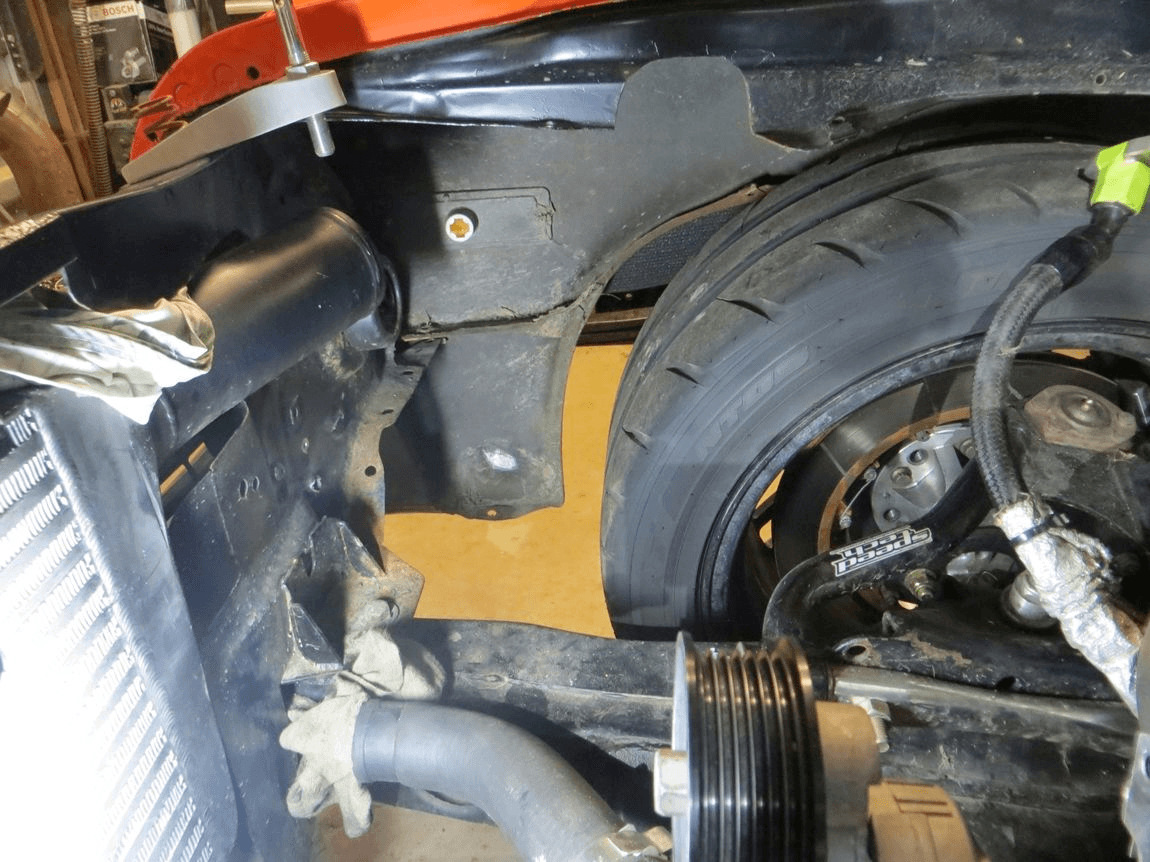

Finally stripped the engine bay of everything old turbo setup, and all the wiring and everything essentially forward of the tires.

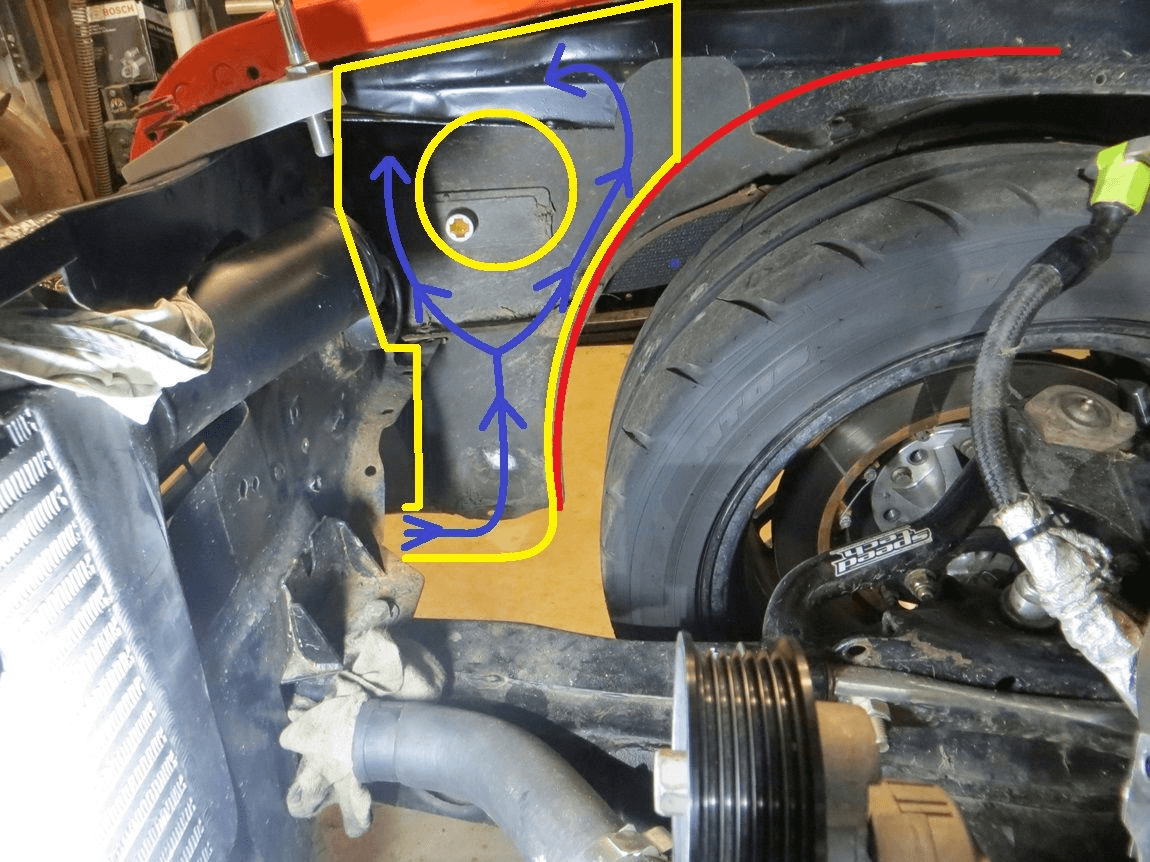

An idea I'm playing with is sealing off the area behind the headlights and corner lights from the engine bay heat, and having ducts from under the bumper direct air up into the air filter area located behind the headlight.

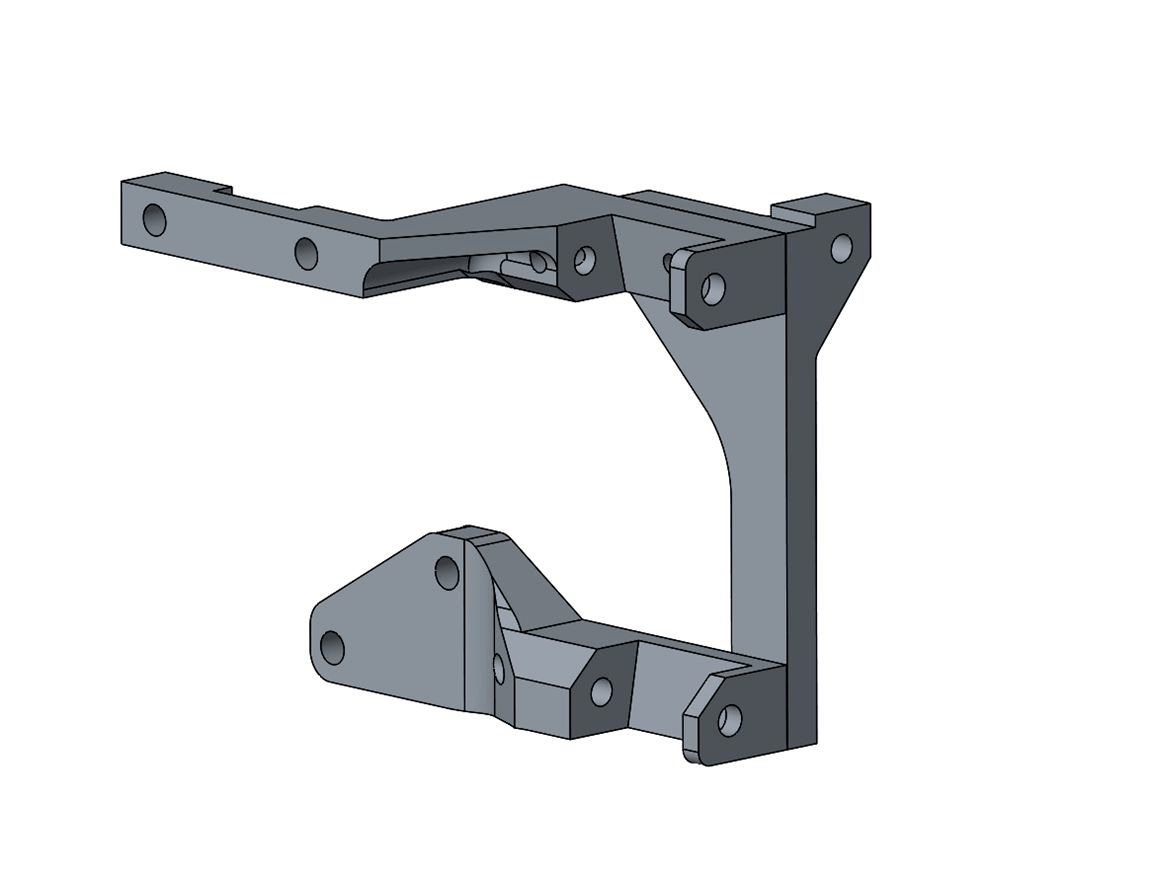

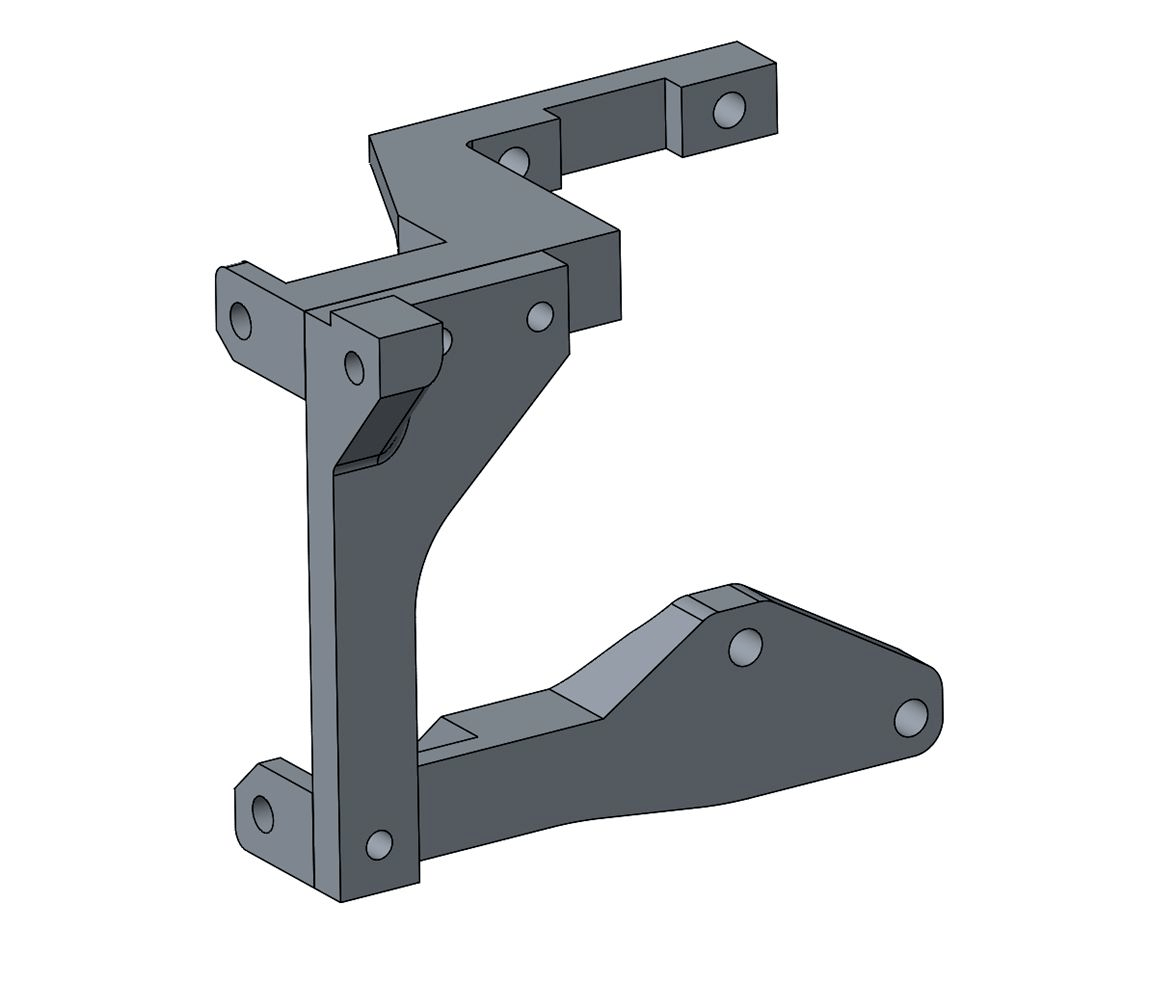

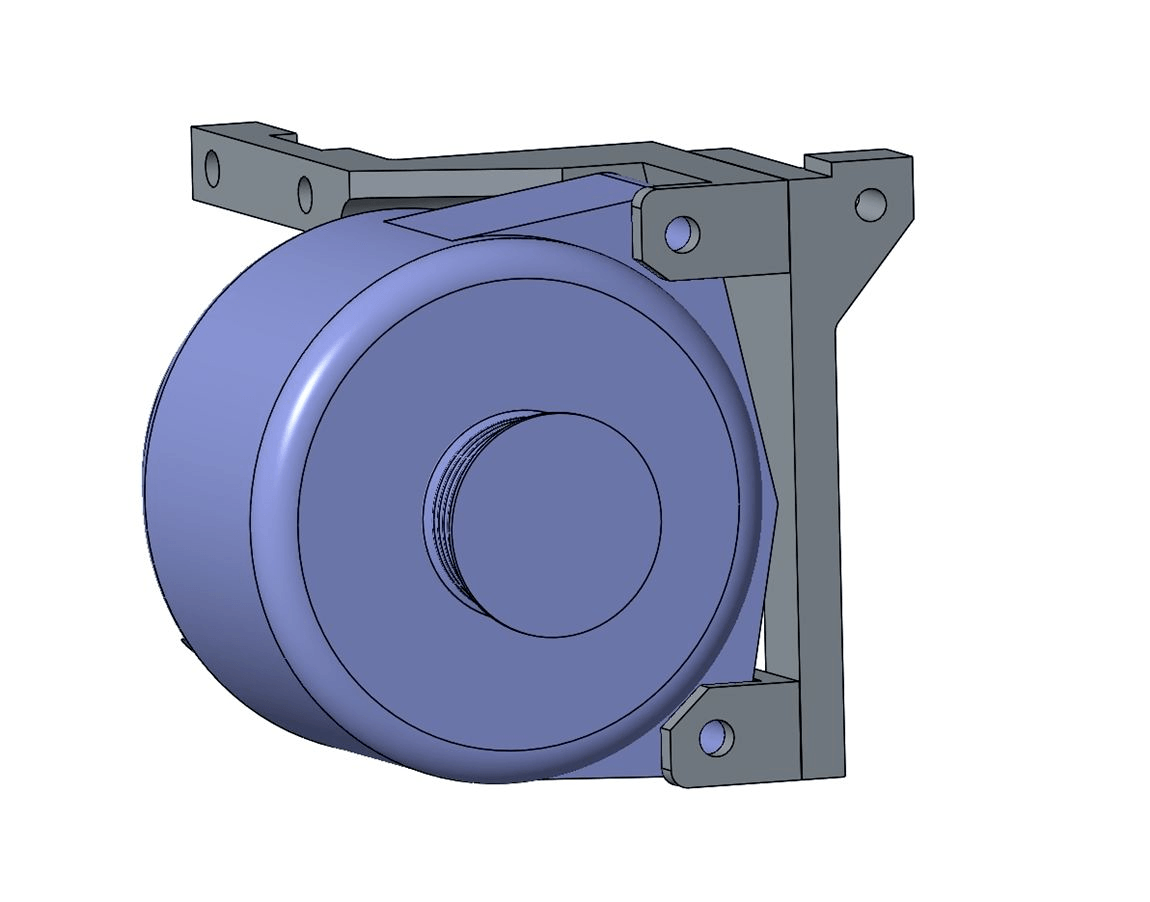

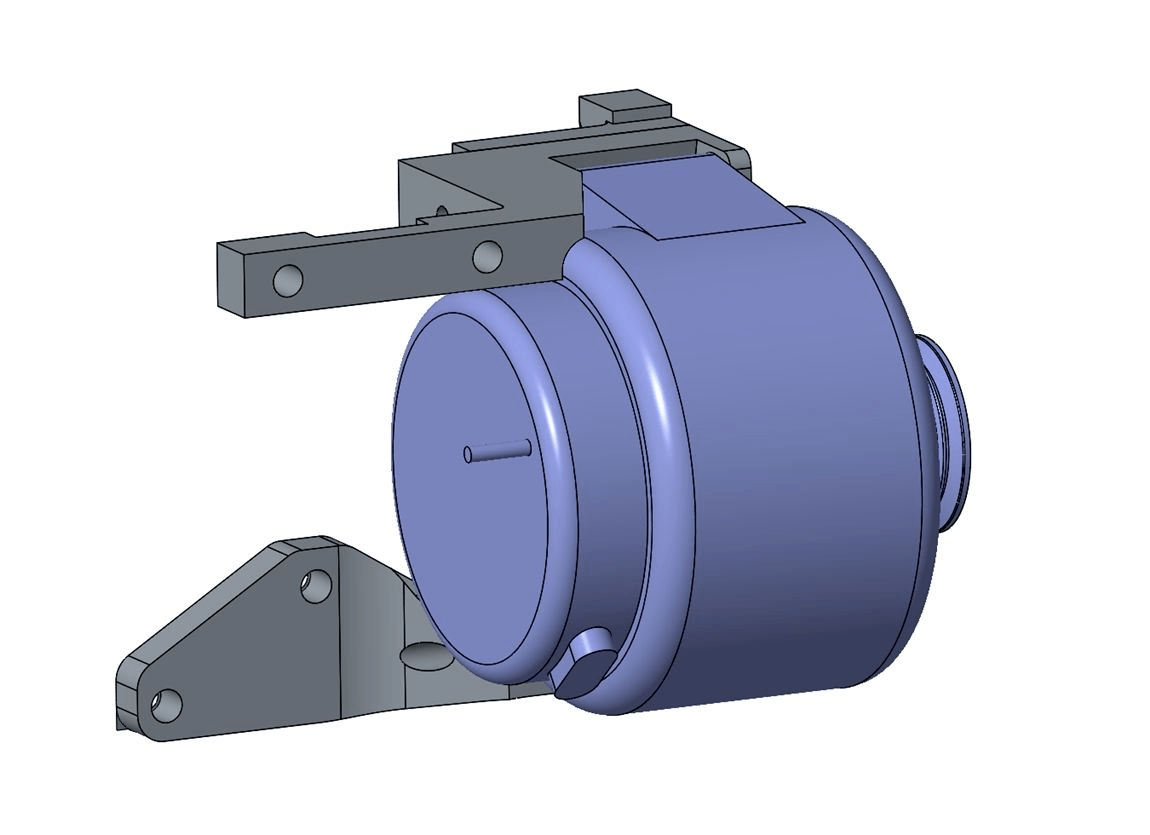

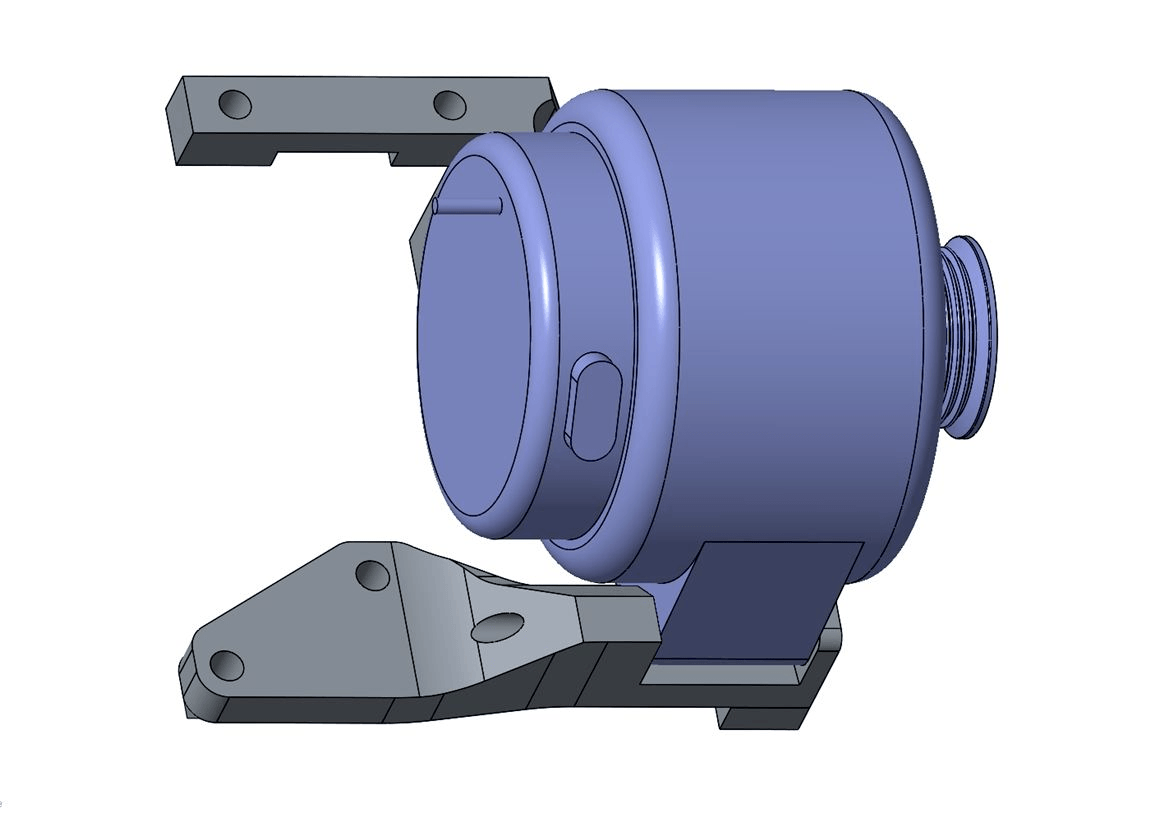

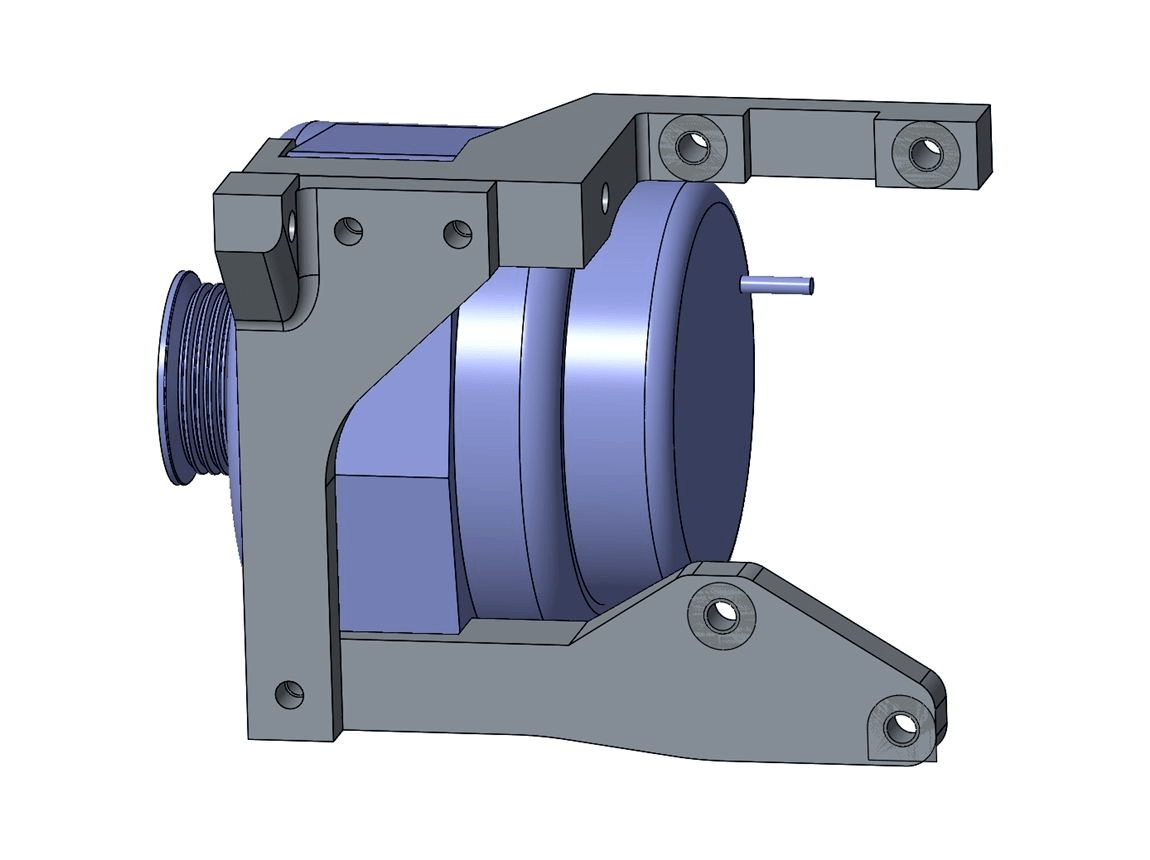

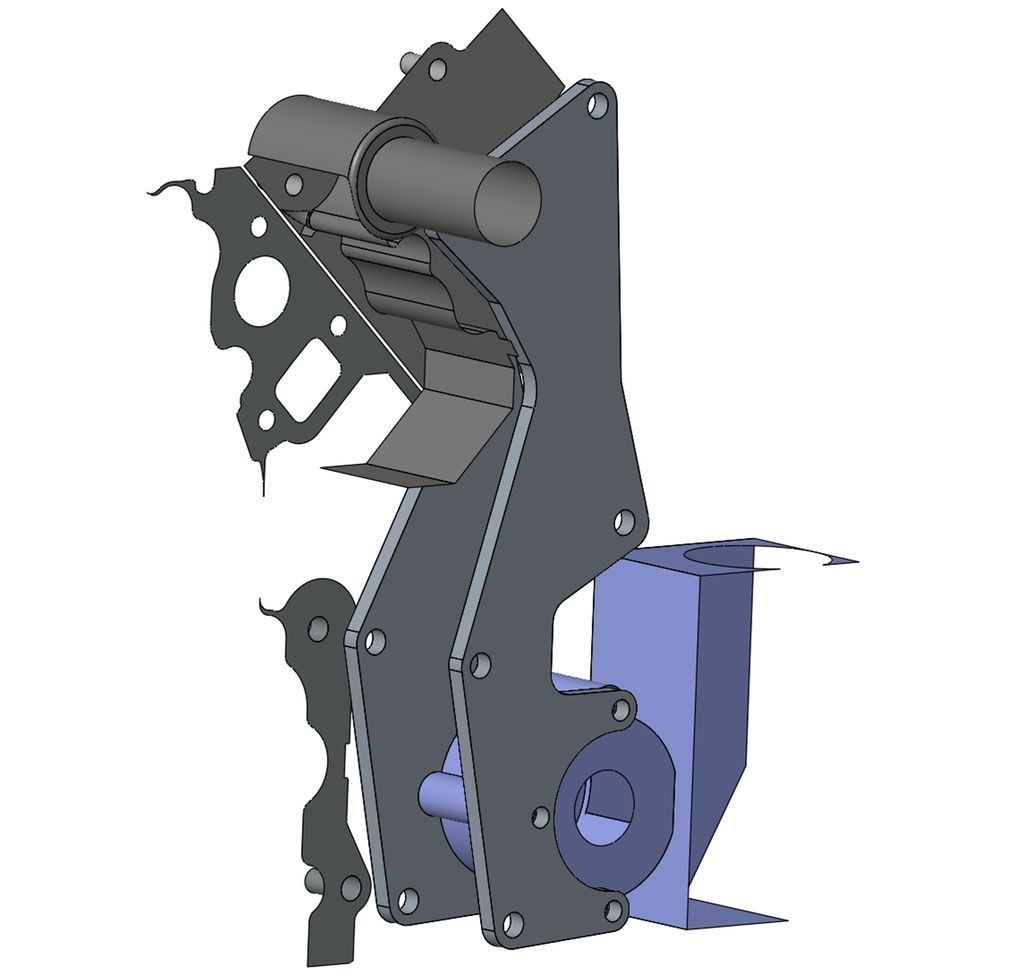

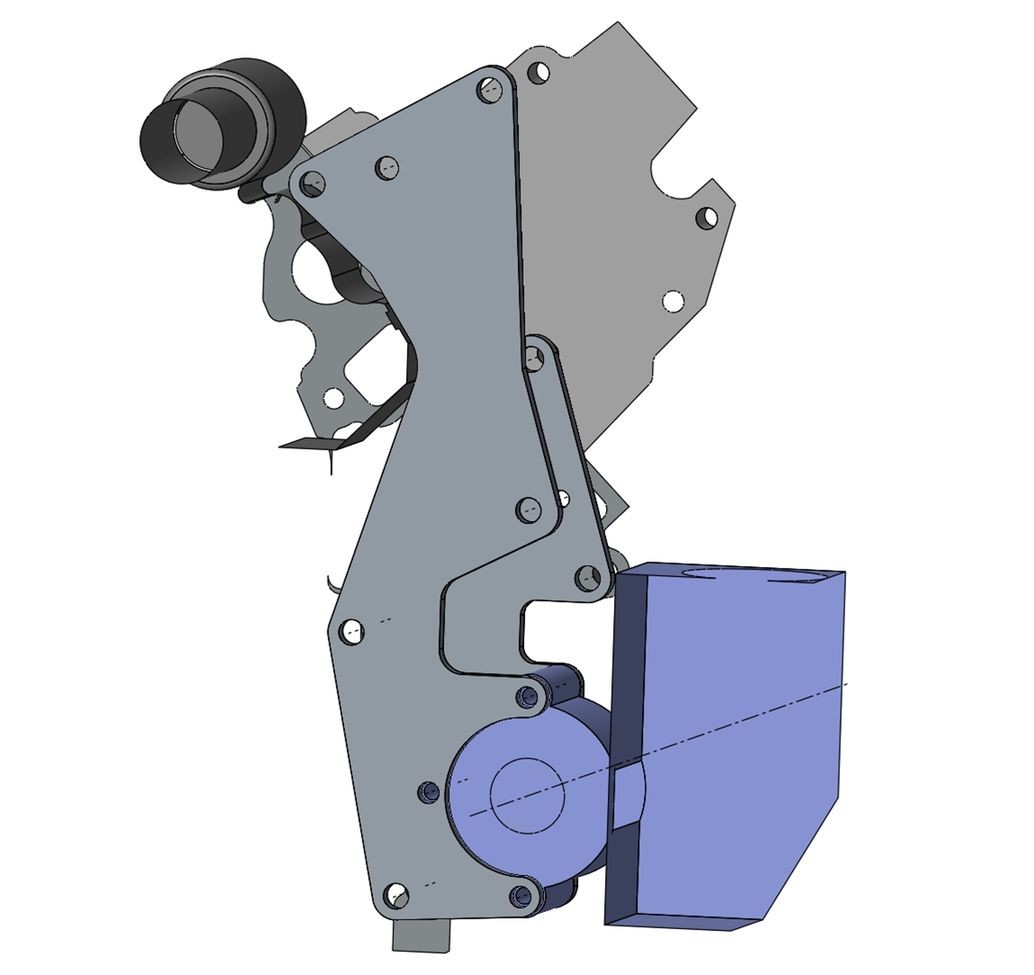

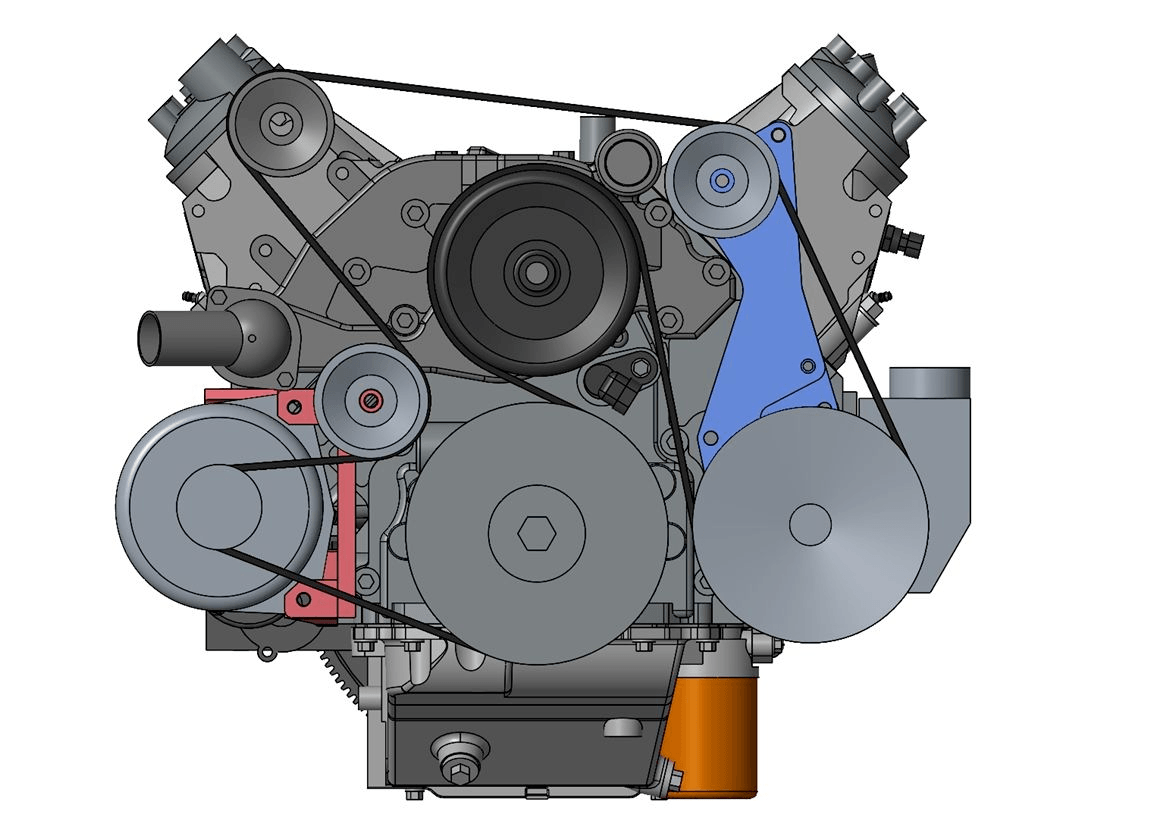

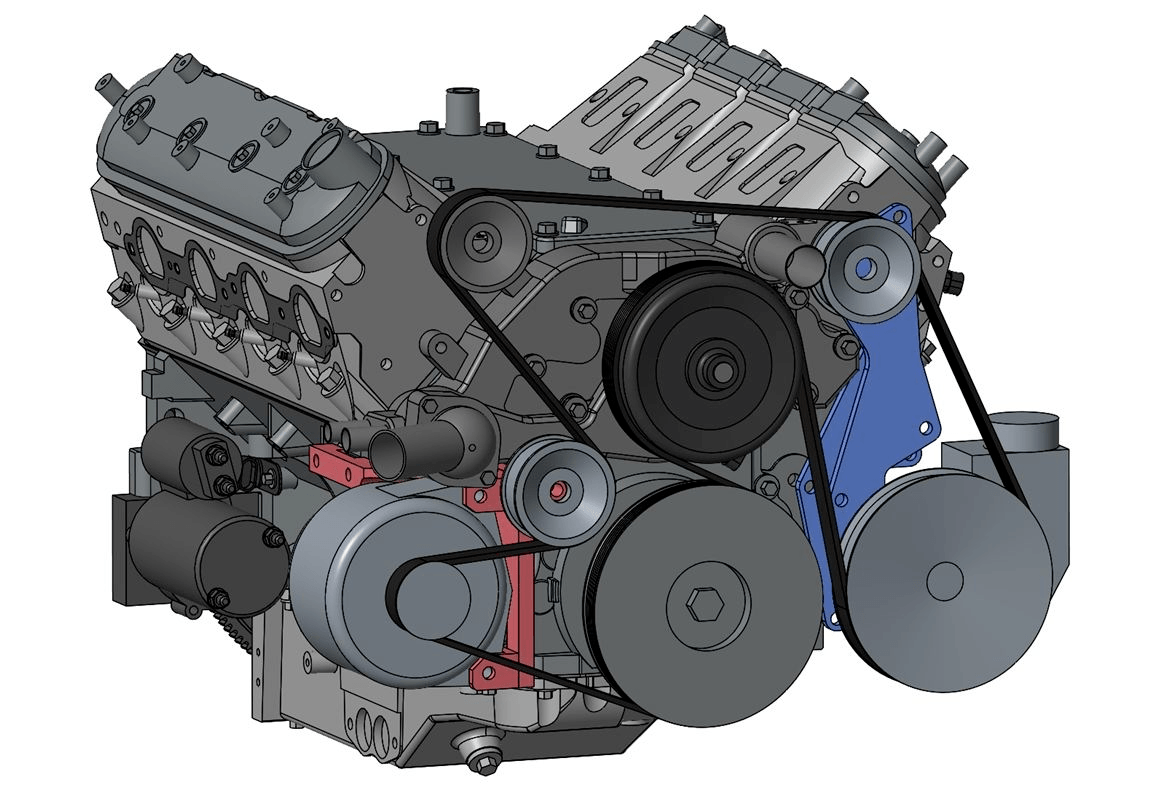

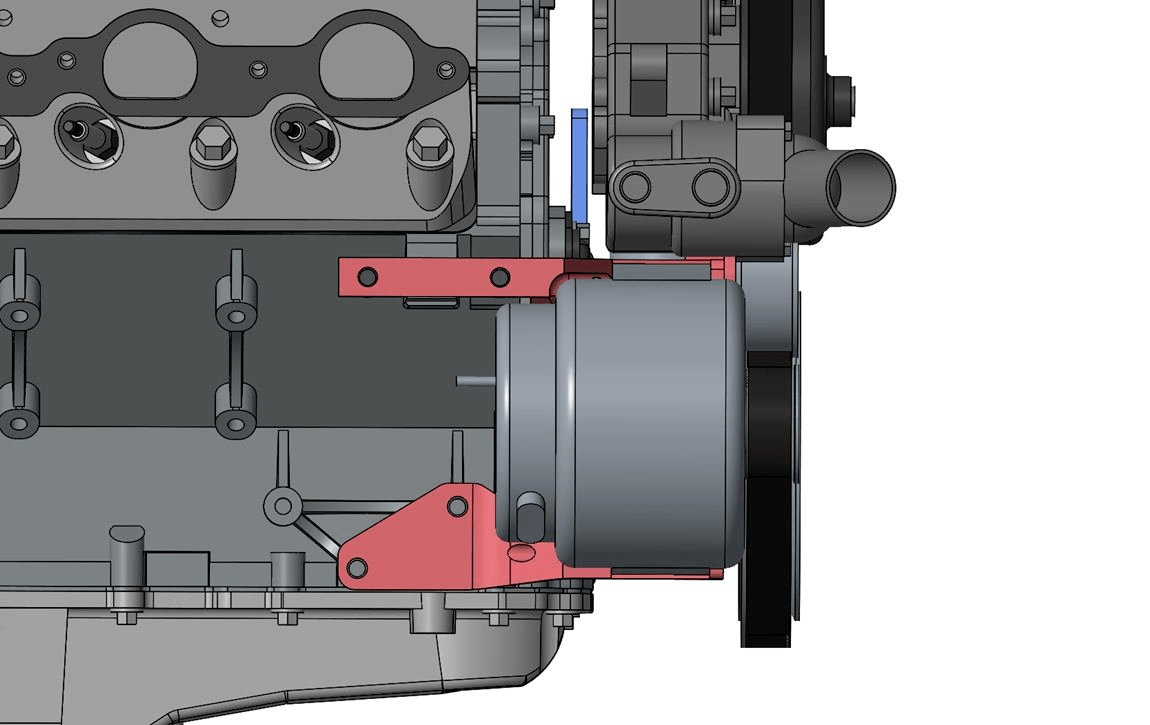

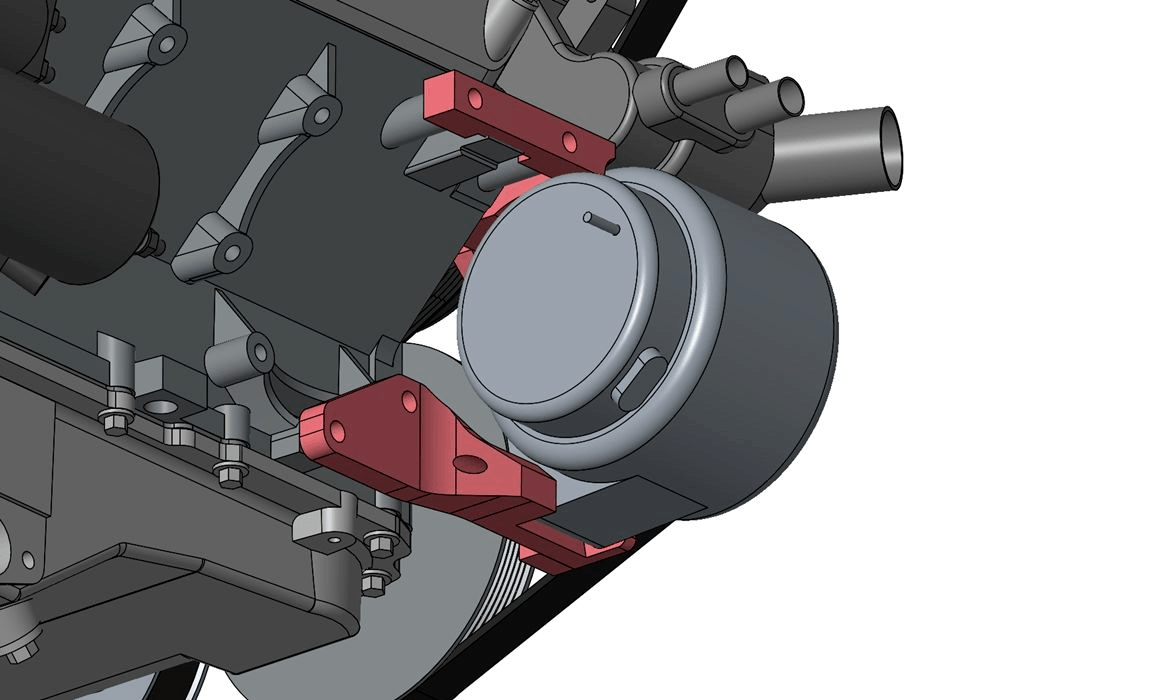

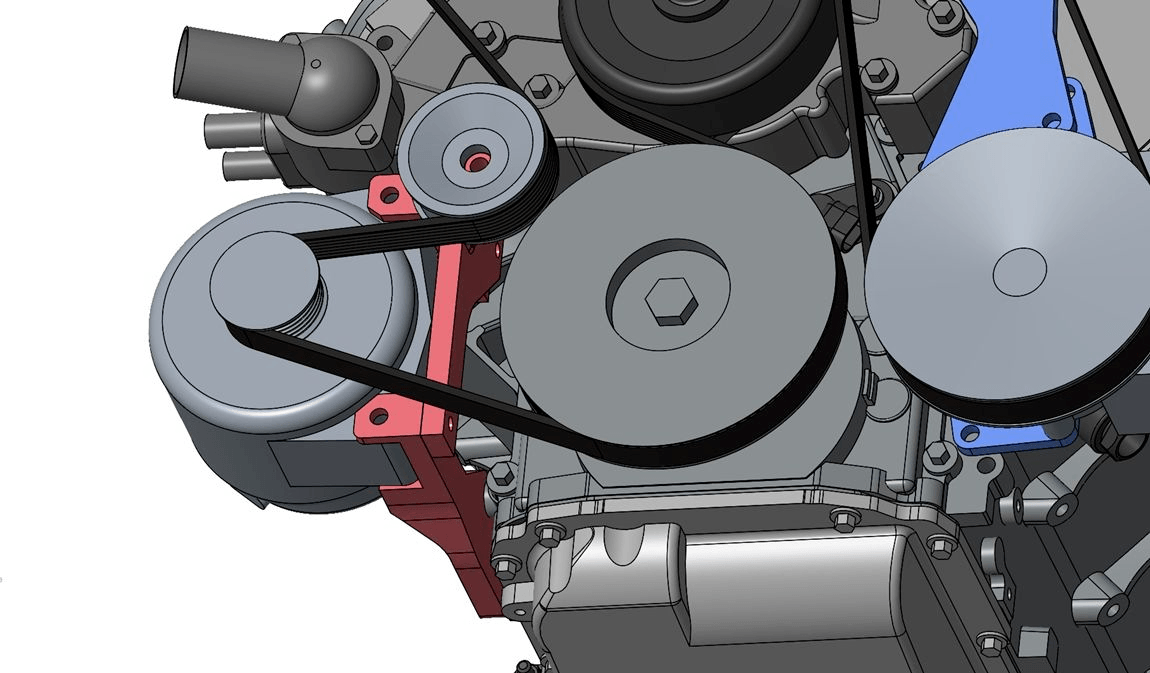

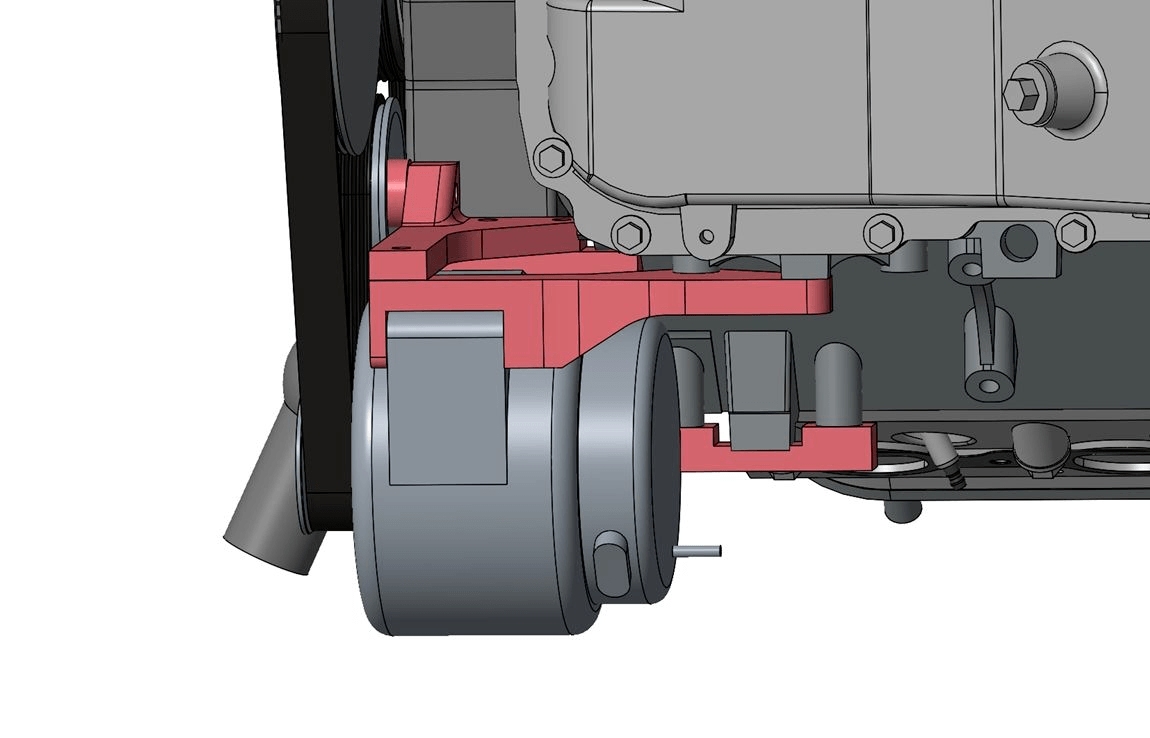

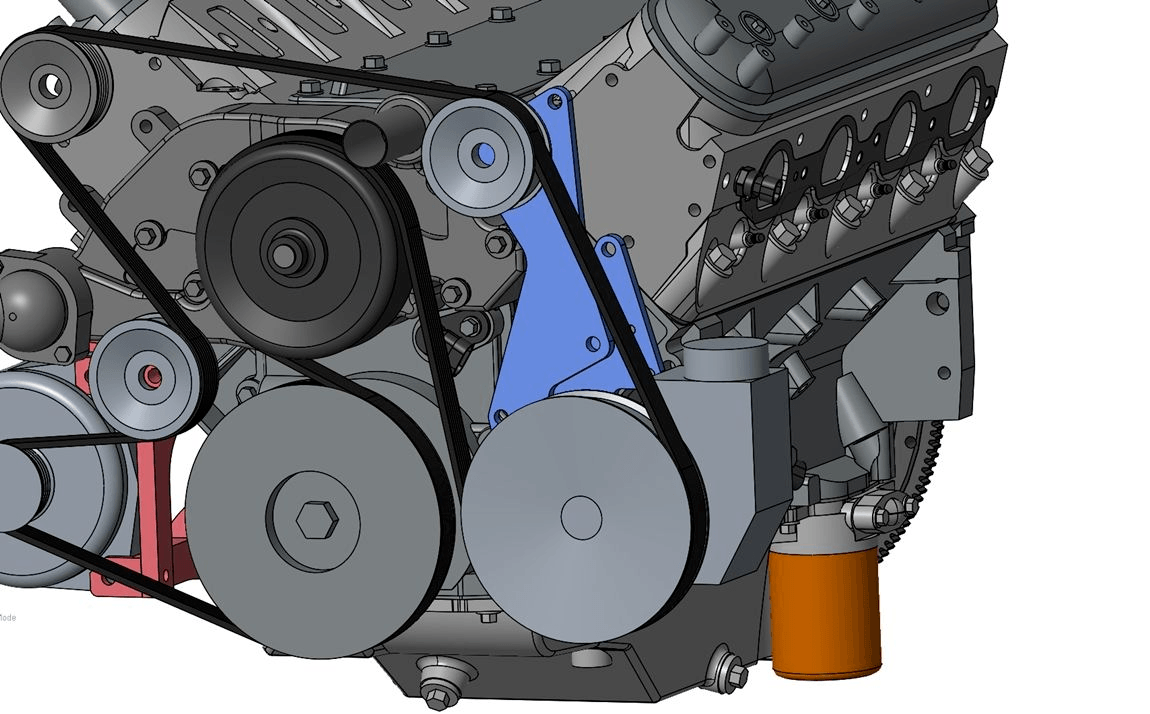

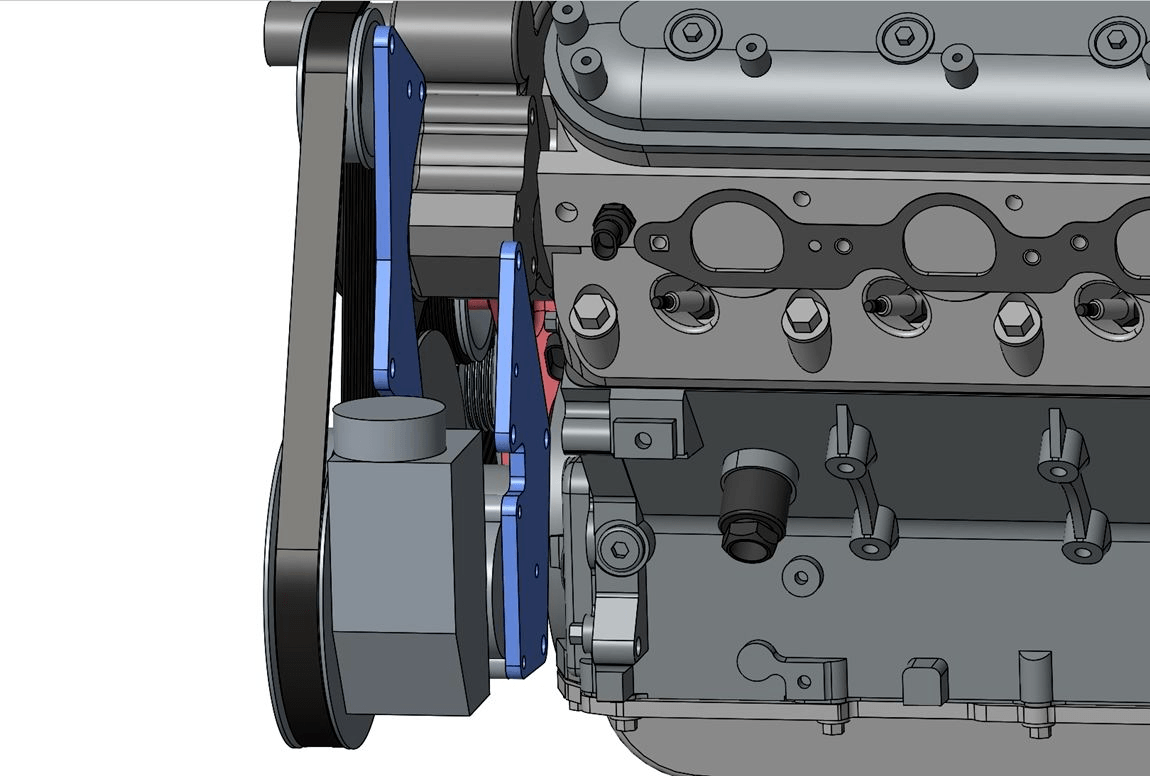

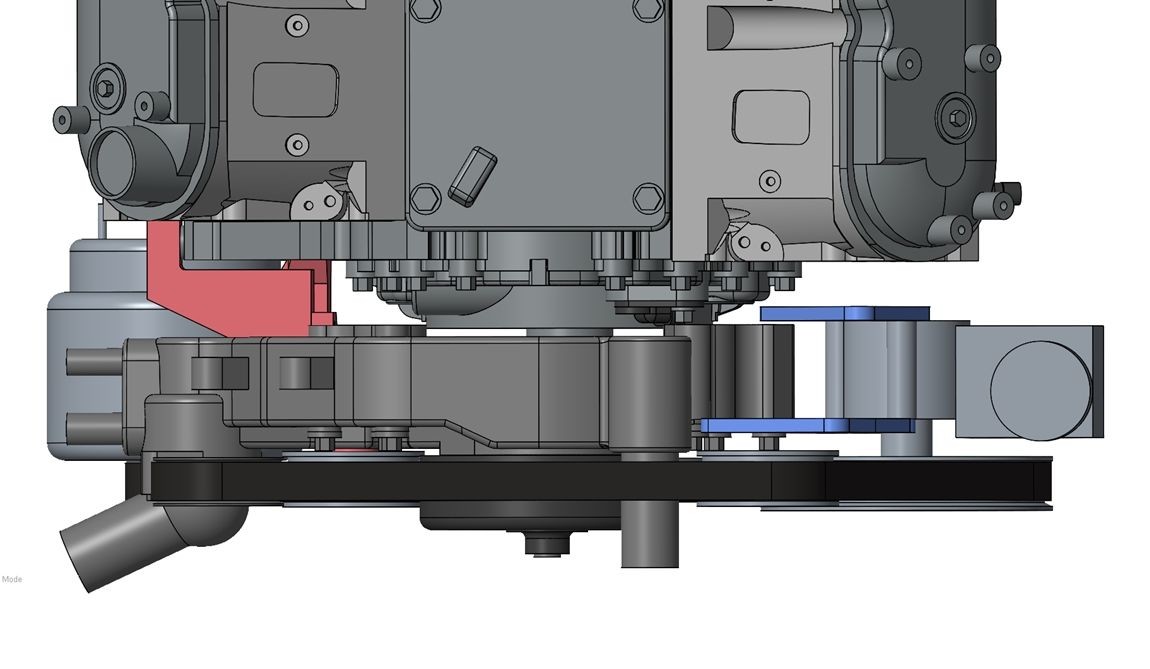

I've made it about as far as I can fabrication-wise without having the actual turbos here, which I'll be ordering probably next week. So I tackled the accessory drive setup. I went thru a couple iterations and am liking this setup.. sure is handy having a 3D model of an LS3 longblock. The alternatorbracket is a 3 piece design which I think I'll CNC at work. Top and bottom alternator bolt pieces are pretty rigid and double shear on the alternatormounting, with a vertical 3rd piece to link the two together as well as locate/mount a redirect pulley.

I'll make a new power steering pump bracket to lower the pump 2" lower to get it further away form downpipe and wastegate pipe heat, and to eliminate the old alternator mounting stuff. The last design of two plates with simple turned spacers was easy to make and worked well and seemed very rigid once mounted.

The likely belt routing that I'll try out, for low everything...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM