You must be logged in to rate content!

7 minute(s) of a 891 minute read

10-23-2017

Hey Clint.. great questions, I appreciate the fact checking as I've wondered the same questions for the last couple years until I finally decided after much thought that changing up my setup was the only viable solution, let me try to explain:

1) first and foremost is cooling, for a couple reasons:

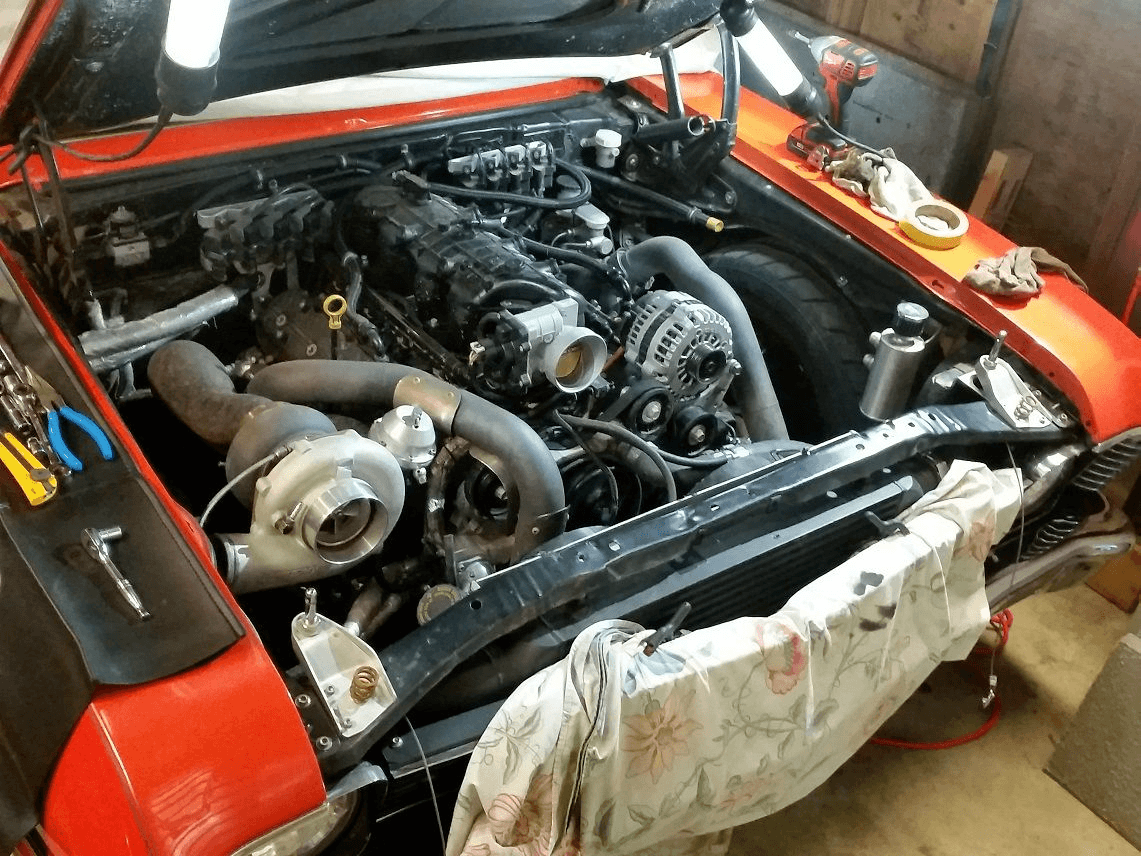

- current turbo hotside pipes wrap around in front of the waterpump and have limited my radiator thickness.. I physically can't put in a thicker rad and fan stack without removing the grill and pushing the intercooler forwad above the bumper, or removing the hotside crossover piping

- to reduce underhood pressure as much as possible and make the radiator the most efficient, I need inner fenders.. with my low ride height I simply cannot fit an inner fender in the passenger side with the 275 tire at full left steering lock

2) power/response:

- I'm at the physical limit of turbo that I can fit under the hood in the current location.. remember I don't have subframe bushings to my hood is now that 3/4" lower to the engine.. the max turbo size would be a Precision 78/75 but that's only a small step up from current

- for the single setup I tried to keep the hot piping similar lengths side to side, but there is still ~3ft of passenger side piping and probably 4+ft of driver side piping, at 2.5" OD pipe it's oversized and slowing exhaust velocity down, and likely what is introducing lag from what I've read

- I want to go from a horizontal flow intercooler to a vertical flow to spread the airflow path wider and shorter for less pressure drop..

- I need to remake the exhaust anyways, so I might as well start that project as dual 3.5" pipes from two turbine housings instead of a single 4" pipe from one turbo and possibly redo later

The upsides I can see from going single to twins:

- frees up several inches of room between the rad and the waterpump, allowing a thicker but also taller rad core that fits an upsized dual fan setup, to help pull air thru the thicker core

- significantly shorter turbo hotside (from ~4ft @ 2.375" ID per side to hopefully <1ft @ 2.25" ID)

- better airflow overall (for if I decide to go bigger cubes now or later on) by having dual 2.5" compressor outlets to single 3.5" feeding the throttlebody

- turbos moved forward allows more room for inner fenders, which are essential for lowering the underhood pressure and making the pressure drop across the rad larger

- I've always liked the idea of twins, even since before Mark started his project (I'll naturally be a tad larger than his 6265 Precisions, just because)

- Lastly.. why not? If I've done a single turbo setup to pretty good success (self admittedly, for a first ever attempt that I fabricated in my early 20's) there's only one direction to naturally progress to!

11-5-2017

Well it finally happened, started tearing apart the car!

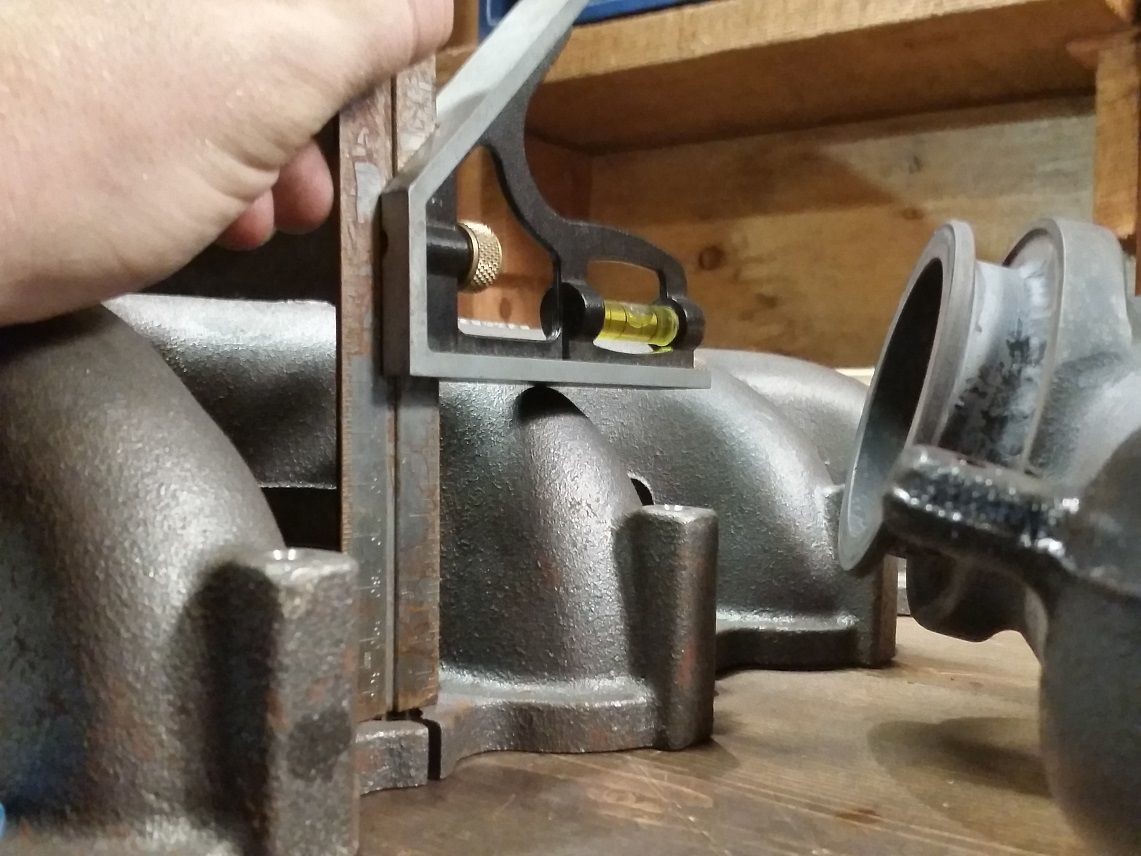

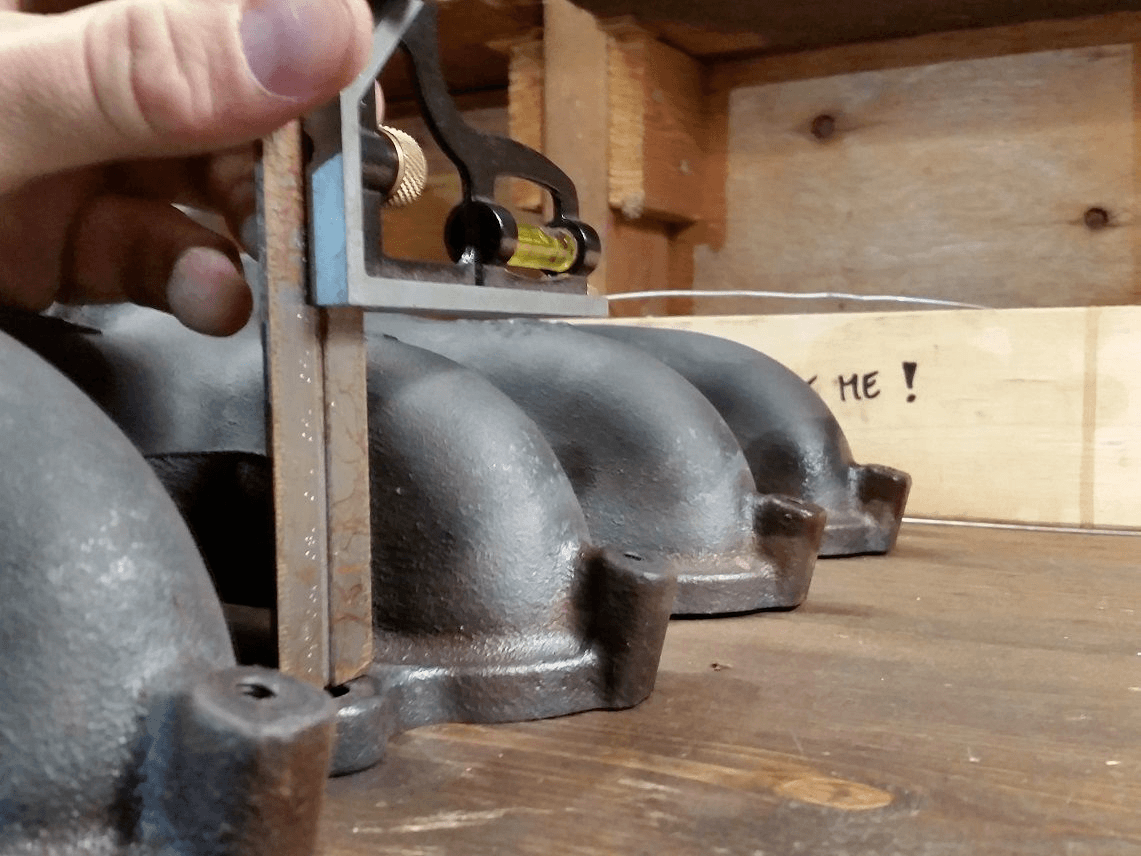

Here's an interesting comparison between LSA CTS-V (left) and LS3 Corvette(right) driver side manifolds..

I like that the CTS-V manifold angles the flange tighter and more perpendicular to the head, tucking it in closer to the edge, however the bends are a bit more gradual leaving the head so the manifolds runners are ~3/8" more outboard that the LS3. I'm beginning to see that it's going to be quite tight on the driver side, snaking the downpipe between the manifold, steering box, subframe, motormount, and UCA cross-shaft, hopefully this extra bulk on the CTV-S manifold doesn't hinder anything.

CTS-V manifold height off the head, in line with the mounting hole..

And same location on LS3 Vette manifold showing the the extra clearance..

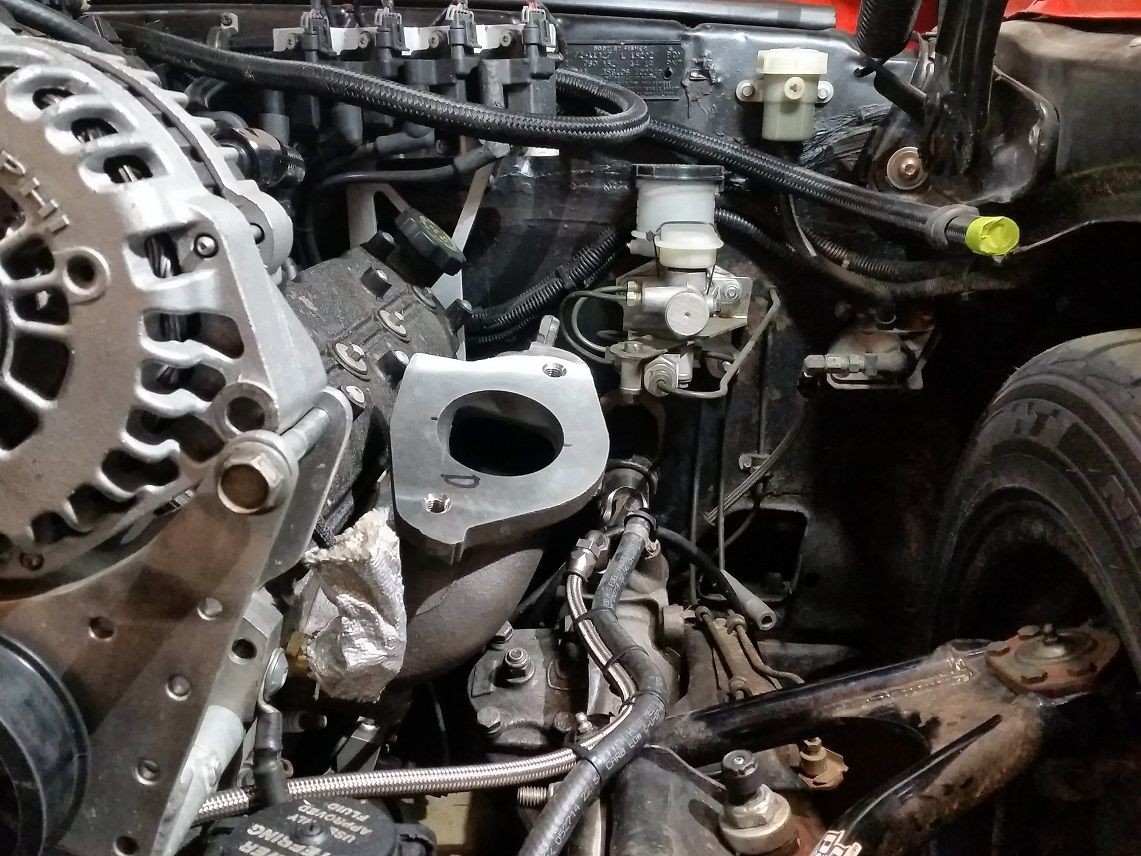

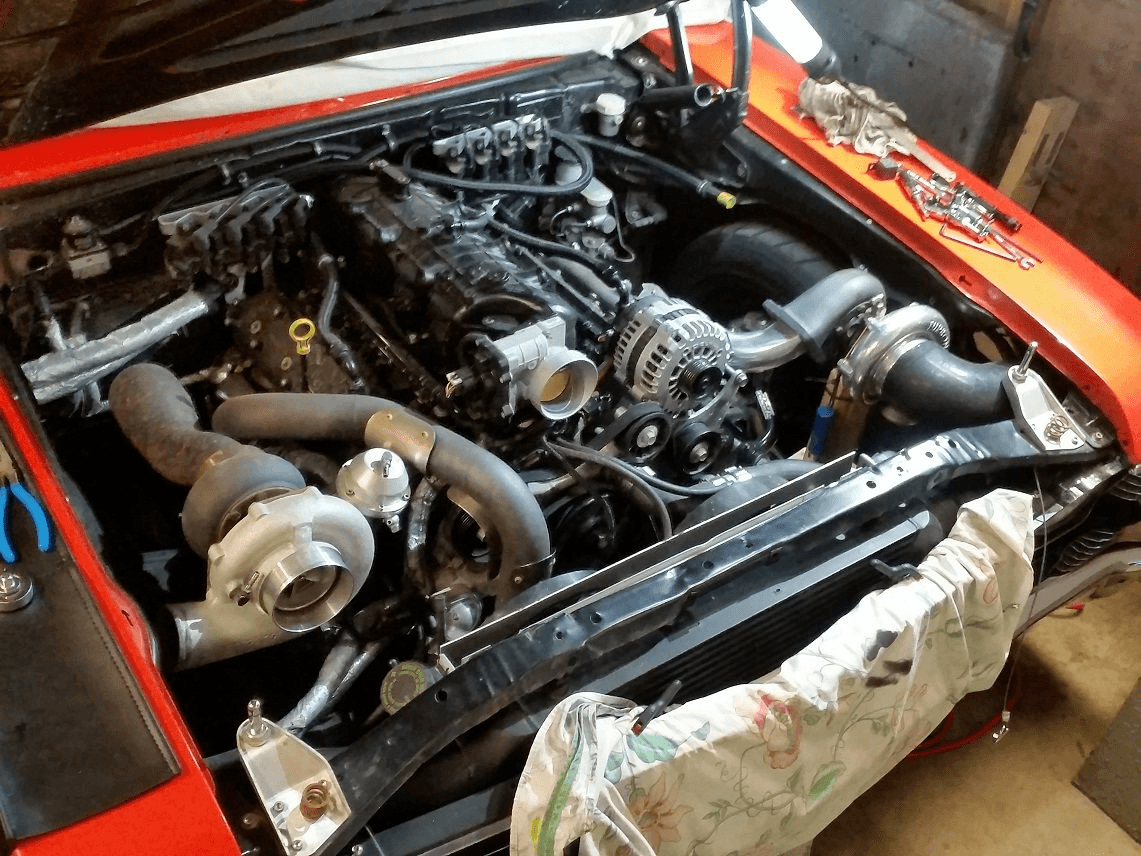

Here you can see how how tight the manifold is to the head. I'm going to try moving the alternator inboard closer to the throttlebody, to move it away from heat. I was also thinking I may try to relocate the alternator to the lower passenger side (like an AC compressor) and notch the subframe. But that would make the belt routing pretty screwy.. I'll evaluate that fitment when I have the engine bay more apart.

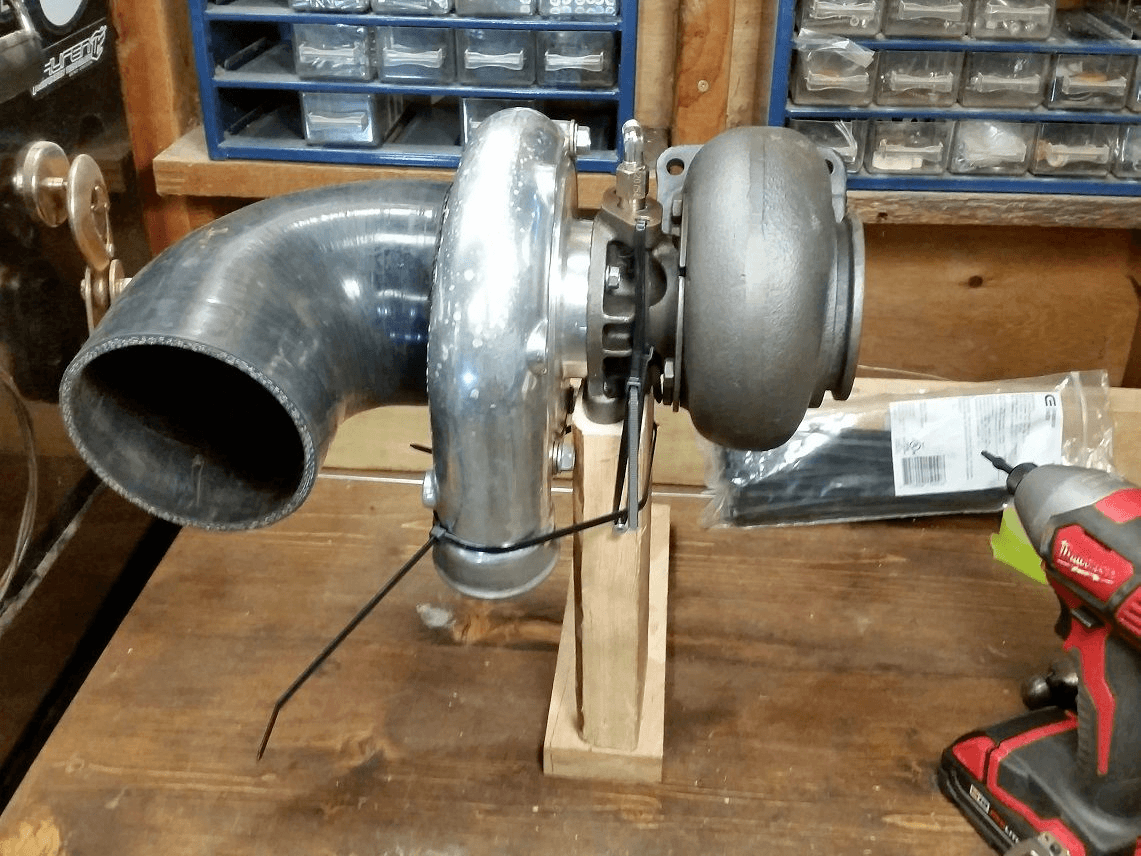

Next I made a super-precision turbo stand for my old blown-up TC-76... definitely Roadkill-approved. It has a T4 housing, but the housing is tiny, so I'm using it as a rough approximation.

Check out how short the hotside piping will be! Wastegate likely be put in a direct path right off the only bend. Was using a cheap-n-easy 2.5" aluminum bend to mock up the sizing, before I order SS321 material...

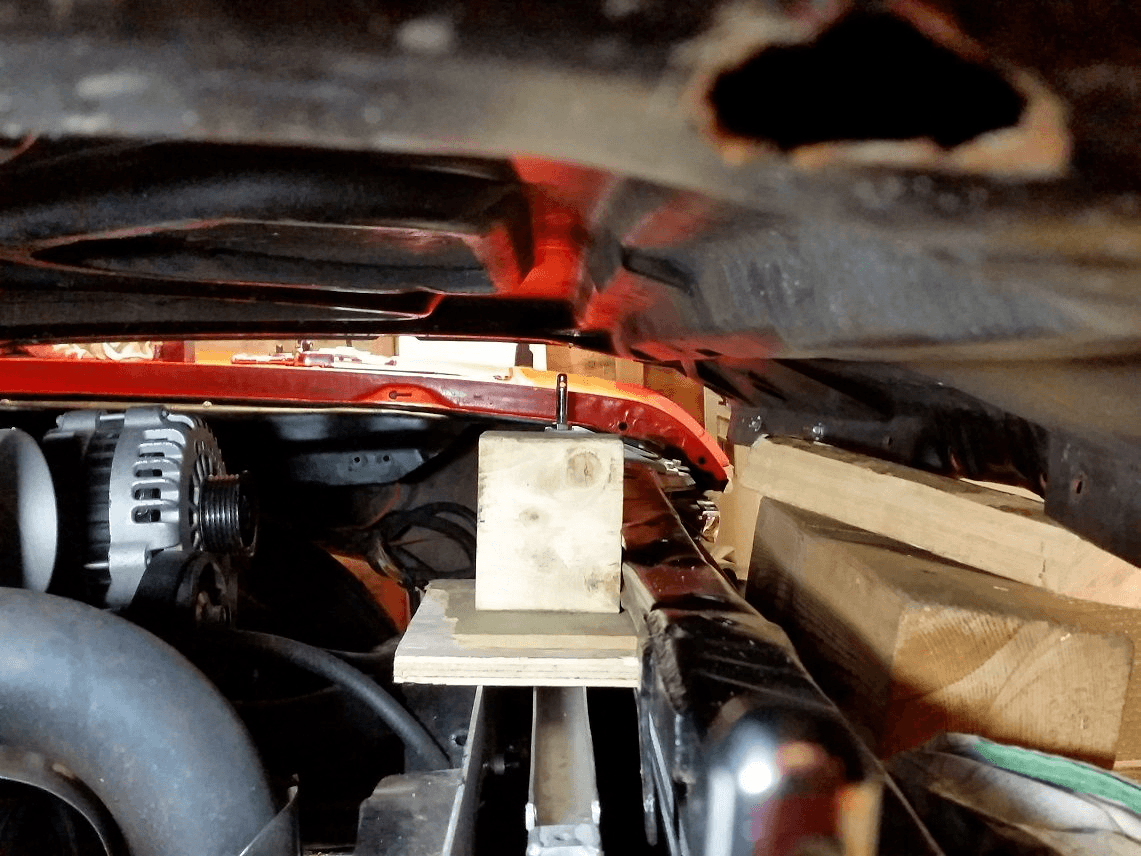

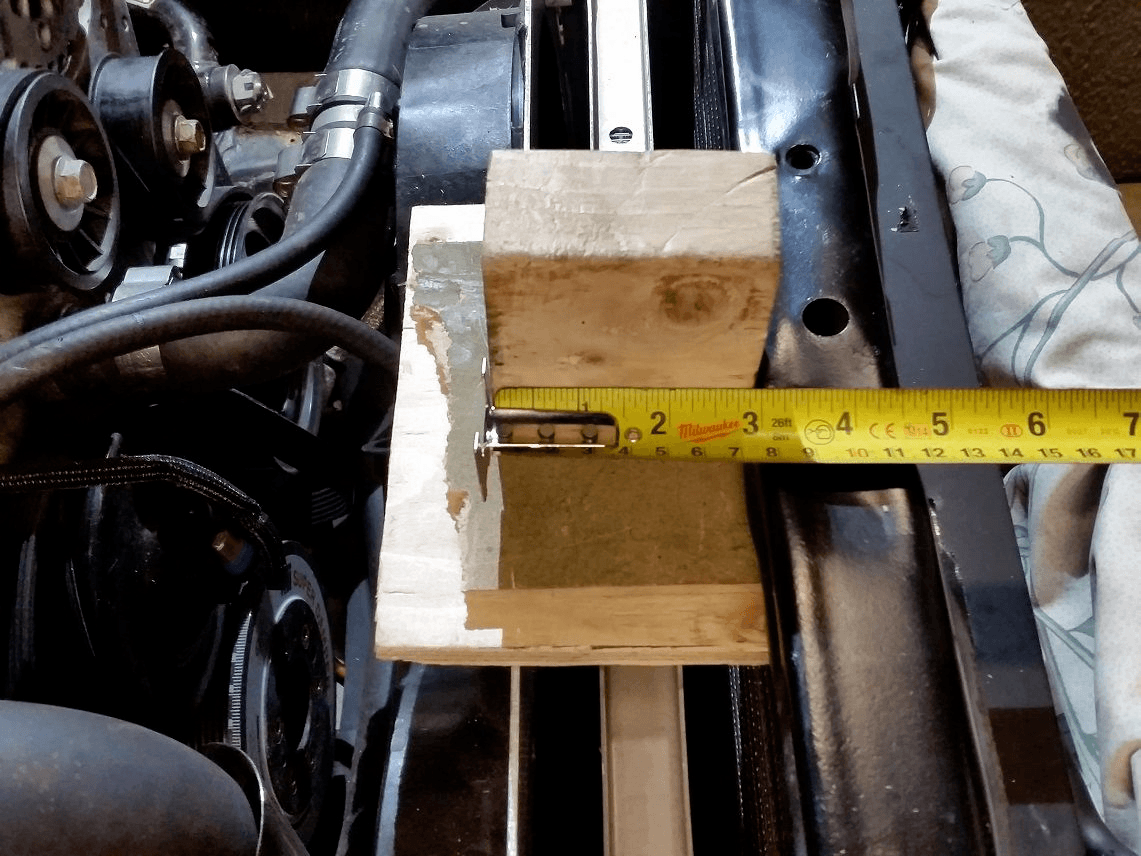

And something I've been curious about for a while.. exactly how much more vertical room is there to grow the size of the radiator... well there's a lot! Used wood to mock up a 3" core, slammed forward to the rad support, and measured at the center as well as the ends of the rad. You can see this placement relative to the hood bracing. Looks like I have an extra 4.25" height on top of the current 16.5" high rad, so total height before it'll hit the underhood bracing is 20.75". And that's with no subframe bushings, so for anyone else it could be as much as 21.5" high. So I'll start thinking about using a 19-19.5" high by 28" wide core radiator, and totally seal the entire rad support to the hood underside with a "dam" on top of the rad support and then a rubber seal on top of that, maybe something similar to a universal door seal.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM