You must be logged in to rate content!

3 minute(s) of a 891 minute read

6-22-2009

LSfan70s... this thread was supposed to be my post-build thread!!! I tried detailing as much of the already-completed (or so I thought) conversion in text, because I didn't even own a digital camera at the time to take pics during all the work...

If you read through the text, it should give you the jist of what I did, although of course this has turned into a ridiculous project now, as stuff normally goes. Don't hesitate to ask me any questions you my have!!

The MC is a "MBM" GM-application power master cylinder. It is cast aluminum, not titanium (I wish!!!) but it is still much lighter than the boat-anchor iron MC that came stock... http://www.mbmbrakeboosters.com/Mast...-1/8-Bore.html

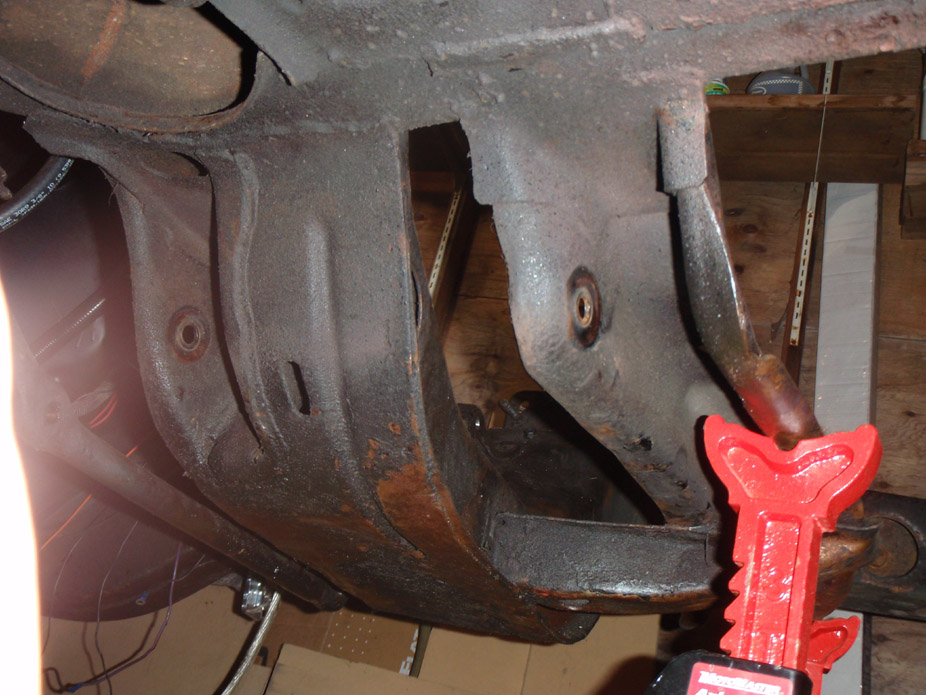

What happens when you're too lazy to move your car to get at the engine which you need to weight the front end when you don't have a spring compressor?? You have to use substitute weights! And by the way, separating ball joints sucks...

6-27-2009

So I guess upgrading to aftermarket control arms is a good idea, if not for the improved camber/caster gain then certainly for the Delrin bushings....

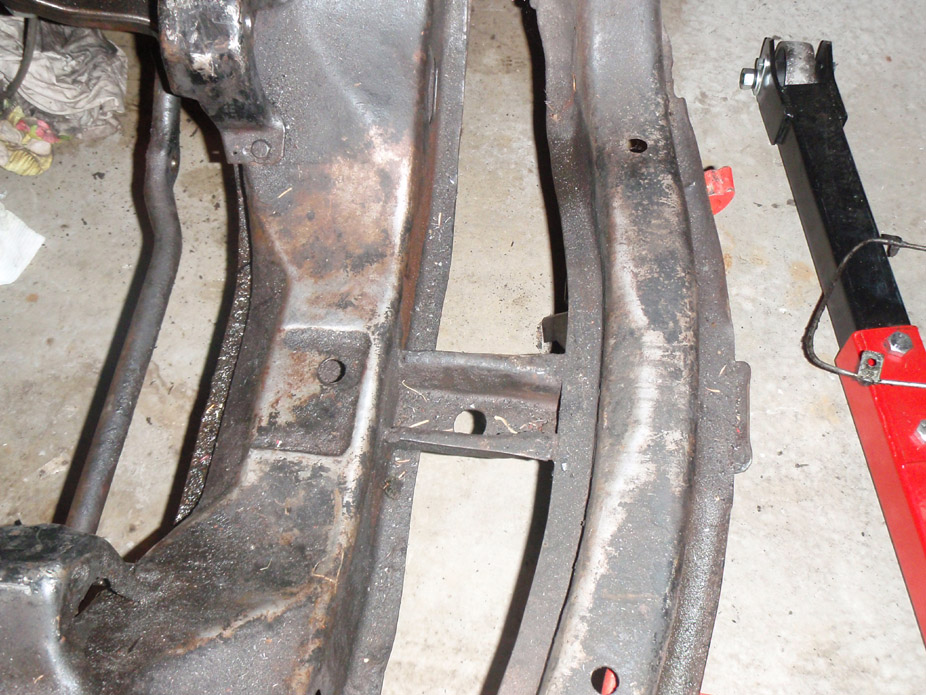

So as far as I can see, there appears to be minimal welds length-wise on my subframe, mainly just folded-over steel...

Only welds I can find are where the two cross-members are welded to the "frame rails", quality looking stuff I'll say...

SO, the question is, should I go through the trouble of welding up the weld-less seams on the frame rails?

I was also thinking about maybe boxing in the bottom of the front cross-member...

And maybe box the connecting piece between the front & back crossmembers, maybe even weld in two more pieces, one on each side of the center connector...

Now I can't afford/don't want to buy an aftermarket subframe. I think the stock one should be able to do just fine, but I want to make it as stiff as possible. This will be a daily driver eventually, but I plan on flogging the crap out of it on the road track as well.

What are the opinions on said welding mods to the subframe? Straight up not worth it? From my engineering experience/schooling, a little bit of metal here and there connecting stuff and boxing C-channels, etc can go a long way in making stuff more rigid, and I would think the fab work/weight of extra metal could be worth it. What do you all think??

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM