You must be logged in to rate content!

6 minute(s) of a 891 minute read

10-3-2018

This past weekend I completed the tailpipes and got the car on the ground in preparation of a maiden voyage!

I drove it forward out of the garage under its own power (yay!) BUT I couldn't get it into reverse gear no matter how hard I tried.

I started troubleshooting by trying to put it in reverse with the car off, rocking the car forward/back with my foot out the door... no luck. I was able to get it into what felt like the reverse gate since I could feel the noticeable increase in force required at the stick as I was manually overriding the coil spring in the reverse lockout assembly.

With this, I thought.. well maybe there's something screwy with the lockout solenoid, so I jacked the car up, loosened the solenoid off and pulled it out of the transmission about 1/4".. that should've been enough to move the stick over well into the reverse gate with minimal force on the lockout solenoid coil spring... nope no reverse gear.

I then thought that the McLeod short throw aftermarket shifter might be limiting things, so I pulled it out and put it on the bench to measure its angular range... 18deg to the left and 23deg to the right... I thought surely that would be enough throw to engage the reverse gate fully. Threw the McLeod shifter back on and no matter how I adjusted the baseplate... wouldn't engage reverse... ****.

As a last ditch effort I borrowed back the stock T56 shifter form the buddy I sold the old trans setup to, and installed it... success! Apparently both the Mcloed shifter and the solenoid were limiting the reverse gate throw.

It appears that if the lockout solenoid is energized and its pin is out of the way, the coil spring plunger assembly in the lockout housing DOES actually move out of the way enough to allow reverse to be accessed on a retrofitted Magnum... but if no electronics are hooked up and the lockout pin is in place, just manually overpowering the coil spring will NOT allow enough plunger travel to go deep enough into the reverse gate in order to shift it into reverse. Between the regular T56 and the Magnum there must be slightly different selector travel on the shifter rod, or maybe tighter/better tolerances on the Magnum, that disallowed me to overpower the spring and get all the way into the reverse gate, where I was able to do that on the old T56. I'm guessing just about everyone that has paid extra for a 4th gen retrofitted Magnum aren't affected by this because they're throwing the trans into an f-body and hooking up the wiring to the lockout solenoid, and the solenoid correctly working allows full functionality.

Anyways, I made a pair of internal spacers inside the lockout housing that shuttles the coil spring plunger assembly outboard enough to allow the full plunger travel I need in order to move fully into the reverse gate.

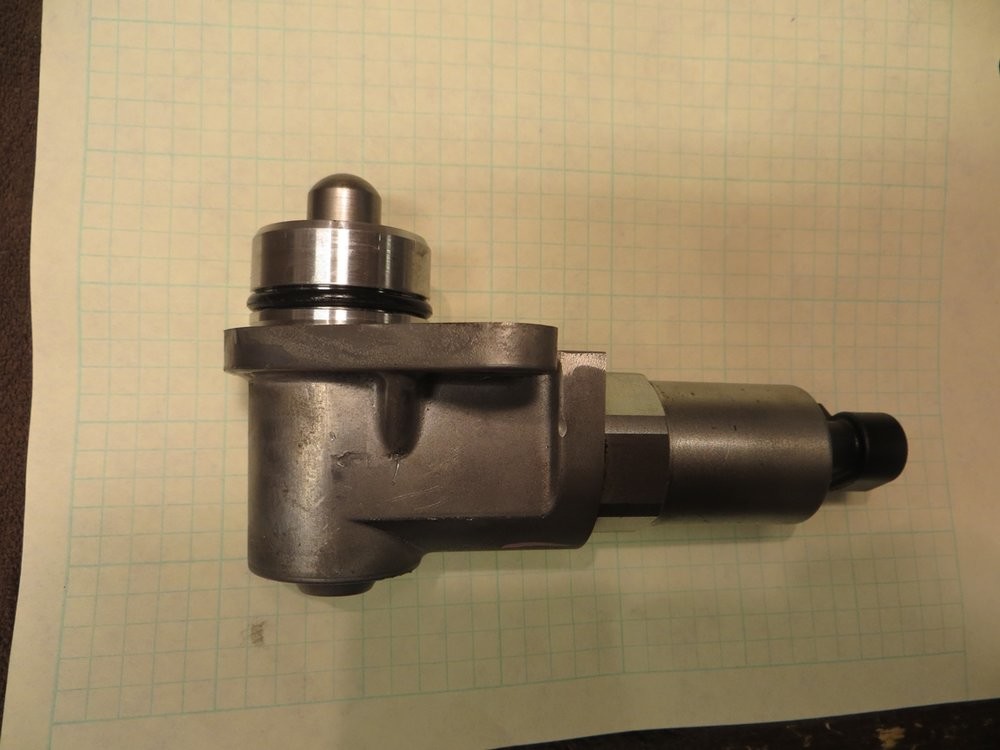

Here is the assembly as removed, with the plunger bottomed out. This situation below is with the solenoid pin in place (no energized or removed) capturing the bottom seat for the plunger coil spring, and the coil spring is in full coil bind. The plunger is sticking out about 1/8", which is about the amount of extra travel I need in order to move fully into the reverse gate...

This shows the solenoid pin in the non-energized state, just hanging out as a ledge to capture the bottom of the plunger coil spring assembly..

Here is the view that the solenoid has of the bottom of the coil spring plunger assembly, you can see the steel spring retainer plate that the pin would support...

Pretending the solenoid is energized, allowing the spring plunger assembly to shuttle by freely, this is what the coil spring assembly looks like...

This shows the plunger being flush with the housing if the solenoid is energized like in the above pic...

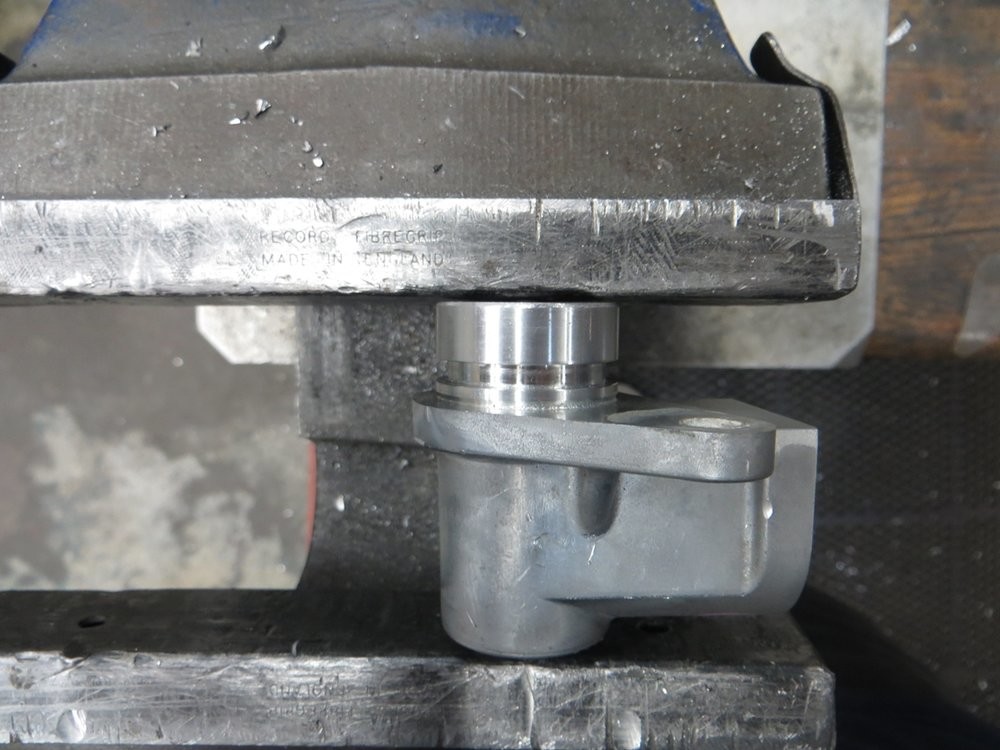

So I made a bottom spacer to lower the resting position of the coil spring plunger assembly, including a chamfer to move the solenoid pin out of the way during assembly...

This height spacer blocks the solenoid pin out of the way so it's no longer the deciding factor of where the coil assembly sits in the lockout housing...

This shows the coil spring assembly bottomed out at full coil bind with the new spacer I machined, gaining the 1/8" of extra travel I needed...

Shuttling the coil spring assembly further into the housing meant that there was slack to take up between the plunger in its resting position and the internal snap ring that keeps everything together....

Just made a steel spacer to take up the slack between the plunger and the internal snap ring...

And full reassembled, waiting to go back in the car and get test driven!...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM