You must be logged in to rate content!

3 minute(s) of a 891 minute read

8-3-2018

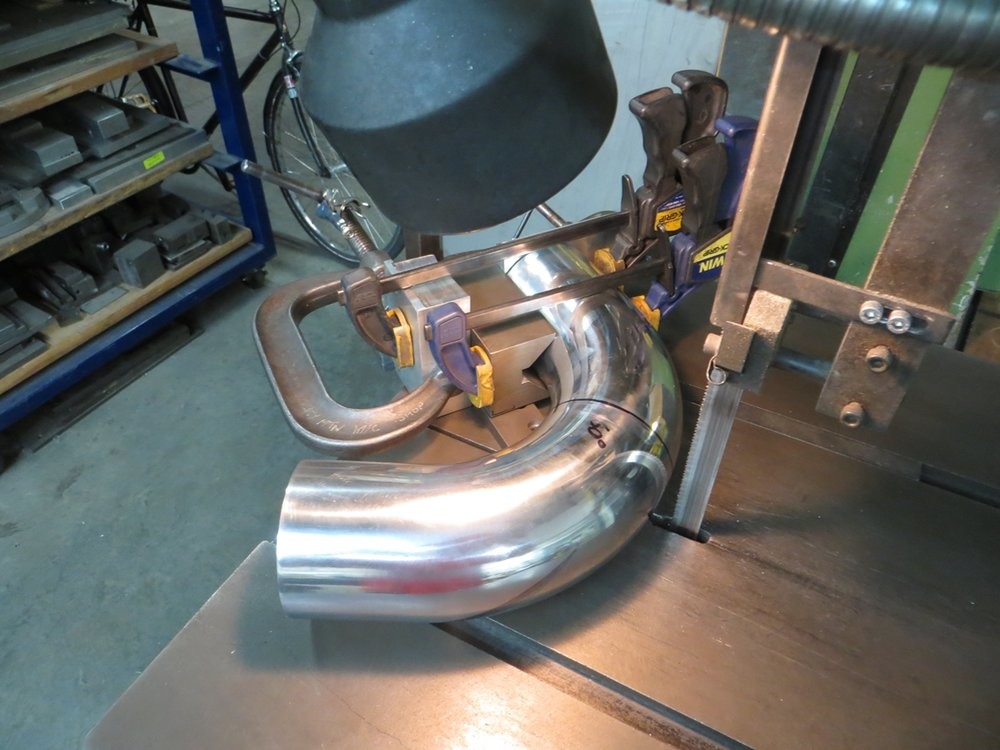

Received the 120 degree 3.5" mandrel bend I was waiting on to make further progress on the intercooler top tank. From the 3D assembly I mocked up, it looked like I only needed 55* bends and not 60*, so cutting it was a bit more complicated than just hacking the bend into two pieces...

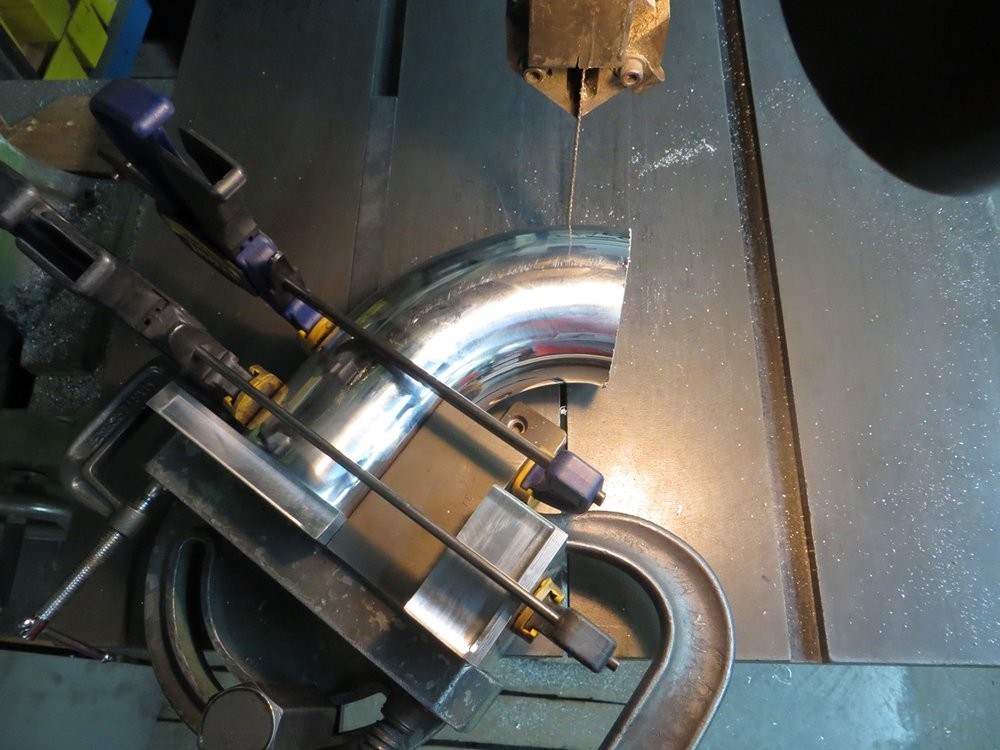

After one side was cut to 55*, then I trimmed the remaining 10* off the other side...

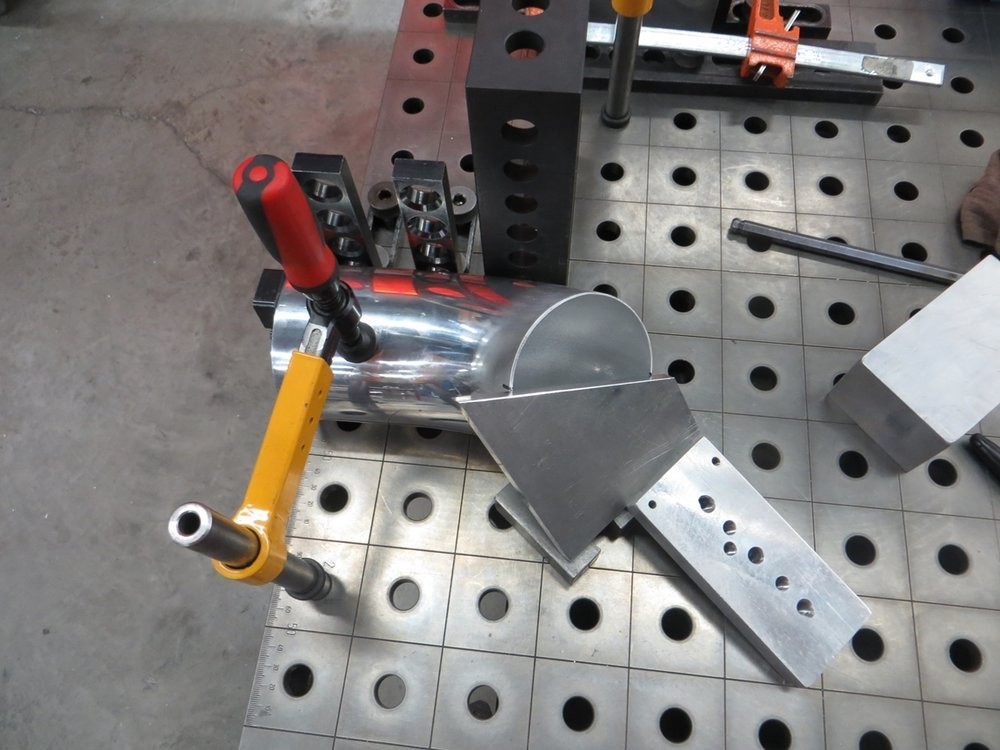

Used the same leaning-anglecut-piece method as before to orient the bend, to scribe the trim lines...

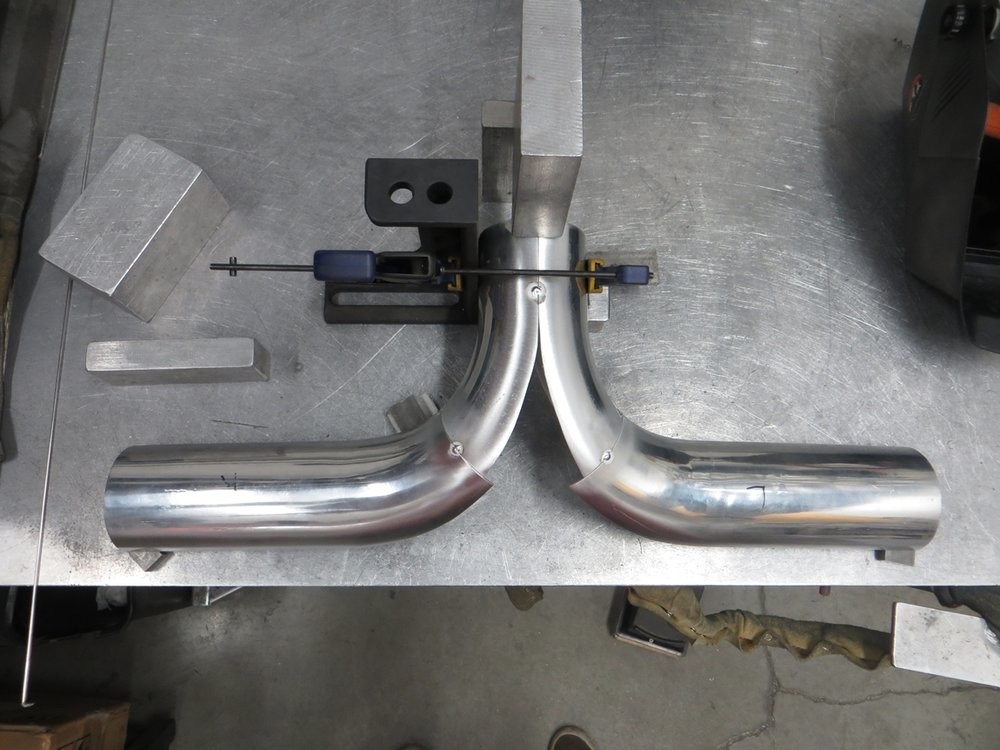

Skipping some of the boring stuff, I trimmed the sides and tack welded the two halves together...

And then joined the upper merge subassembly to the two core-side pieces. I aligned the bottom pieces to be perpindicular to the top piece, and made the top piece horizontal... clearly my eyeballed trim lines were a bit off, but all good.. still extra material to trim to final profile before I add the fill in plate pieces. I'm SUPER stoked on how flowy this end tank piece is looking....

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM