You must be logged in to rate content!

4 minute(s) of a 891 minute read

7-20-2018

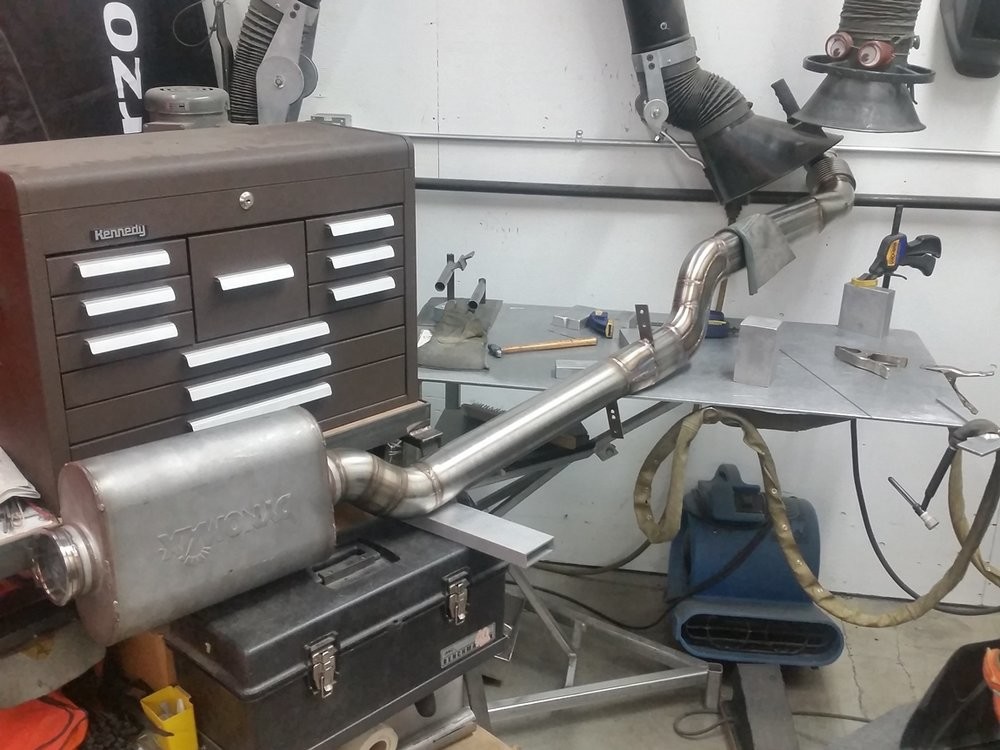

Got around to wrapping up the dual exhaust welding this week. Spent 6hrs one evening... 1 hour making the fill-in plates for the homemade round-to-oval transitions, then 5 hours of welding... it was so hot and awkward working around these gigantic pipes, but it's all done and ready to install for good!

Smaller plate on the bottom side of the pipe...

Ghetto but effective metalworking tools...

Larger fill plate on top side of the pipe...

Fit pretty well... didn't have the mental energy in me to make them fit absolutely gapless and perfect like you see on Instagram...

So big and awkward...

Lots of standing and hunching over to get at a lot of the welds....

Here's the slightly longer pipe, the passenger side....

This next pic just goes to shows the expansion and shrinkage from welding that a lot of people don't take into account. In the picture, the left side of the pipe is the top side, and the first side I fully welded up. It WAS completely flat and flush when I tacked it together during mockup. I knew that warping and shrinkage would happen so I tried to be smart about it... there was no way I was going to keep jumping from front to back and top side to backside in an attempt to even out the heat introduced into the pipe, so instead I methodically started at the front and worked my way to the back, only welding the side facing up. I welded to the center plane of the piping then moved on. I then let the whole pipe cool down (worked on the other side's exhaust pipe). Once cool and fully contracted, I then flipped the pipe over and did the same process of starting at the front and working my way back.. hoping to introduce the same amount of heat and thus re-bend the piping back.... to being straight. And it worked! Anyways, the below pic is just showing the pipe after having one side completely welded, and the resulting warping from shrinkage....

Both pipes ended up straightening back out once cool (luckily) and now all that shitty welding work is done and behind me!

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM