You must be logged in to rate content!

4 minute(s) of a 128 minute read

8-31-2011

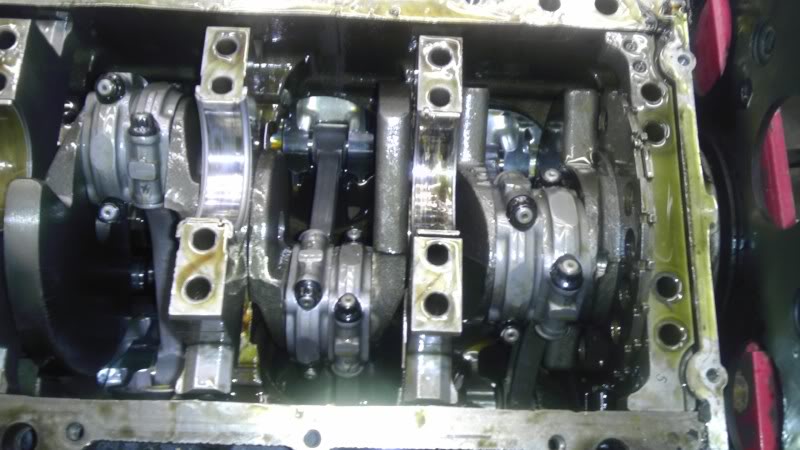

Well I'm glad I decided to pull some main caps. #2 is wasted as seen below between 1 and 3 which are in good shape.

#4 was even worse pictured below to the right of #3.

Stock crank with stock bearings, I'm not sure. I've decided to take it to Mike @ TEC and let him figure it out. Could be line bore from the last time. Could be flexing the stock crank. Could be wrong tolerances. I just don't want to have to pull it again for a WHILE.

Well, it looks like the heads were the culprit behind the cooling issues and pressure in the cooling system. I thought that it was a blown headgasket originally but when I took the heads off, the gasket looked good.

I brought the heads to my engine builder Monday and dropped them off (2 days before I brought the rest of the longblock). He was supposed to have the bottom end tore down today but he didn't get a chance to get to it yet. He will be doing it Tuesday for sure.

Anyway's, back to the heads. When I dropped them off, he showed me a spot where it didn't look like they had good seal on the gasket. Today I found out that he had to take .015 off them in order to get them flat which to me is a good thing as it makes me feel good about that problem being identified and resolved.

I got the bolt in oil pan baffle from Improvedracing.com today. Nice piece and should help a good bit under hard acceleration at keeping oil around the pickup.

It'll be a little while before I get to test it's functionality as my headgasket replacement turned into a full on rebuild.

9-8-2011

Well the autopsy is complete and the results are in. Crank was bent .005. When he went to do the linebore, he saw that #4 main cap was damaged. He believes that when I bent the crank the last time around, it tweaked the #4 main cap which led to the current problem this time around. He replaced the main cap and put a fresh line bore on the block. All is good now with the block. Cylinder bores were perfect.

I'm done ******* around with stock cranks. Just having him order me a stock stroke Eagle forged crank, fresh balance, new bearings and slap it back together. I do remember reading something somewhere about Eagle cranks having some issues lately. I had a 4" stroke Eagle crack on me years ago. Anyone familiar with any issues on the Eagle before he gets it ordered tomorrow?

I believe that the 120's should get me to 1000 rwhp. I have not made that yet. Not sure how additional injectors are setup with the Holley. I haven't played with any of that yet but I shouldn't need to.

As far as boost levels, I went the fastest at 22 psi (8.98 @ 153). 17 psi got me a 9.33 @ 144ish. Please keep in mind that I have not been down the track with the Holley ECU and all of the great logging features. My first 8 sec pass came with a stock 98 PCM that would only log to 15 psi so I was just fudging the tune. Then I didn't with the AEM and that at least showed me the actual KPA values but the logger in that software is junk so data acquisition was not the best. Once I get her all back together, I should have some new, good data. Unfortunately, it wont be apples to apples. I now have a powerglide in the car with a fully functional tbrake and travel limiters that should allow me to run some solid 1.2 60's as well as perform better out the back door. I will also have a larger T6 1.00 A/R exhaust housing on her and have much more solid fuel control thanks to the Holley ECU. Hopefully I'll be ready just in time for the good air. My only concern at this point will be that the track is starting to crack down on tech and I wont be able to make very frequent passes.