You must be logged in to rate content!

3 minute(s) of a 217 minute read

9-9-2013

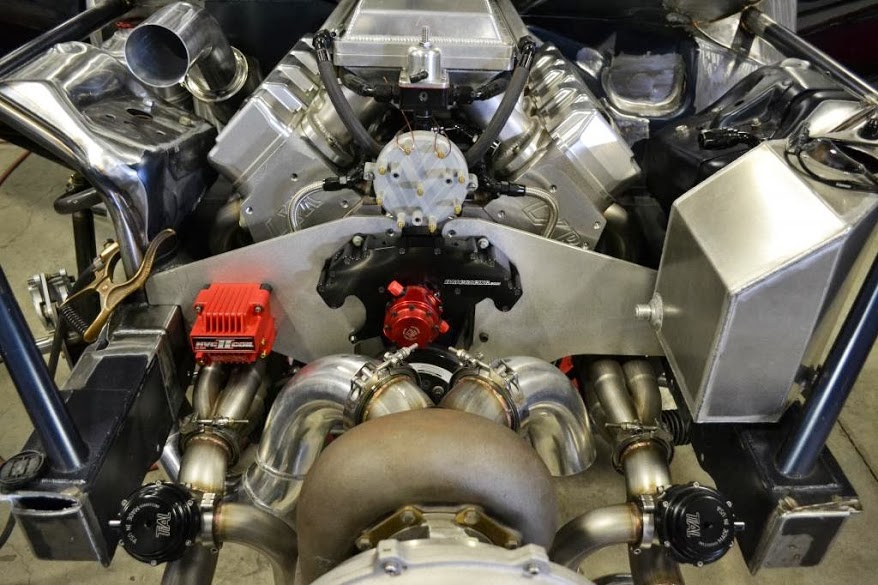

As promised here are some more photos of past progress. I last posted some pictures of the cold charge side of the turbo system and now I will post the hot side.

We chose aluminum to keep weight down. With all the tube that is being used stainless would have added up quite fast and that is the last thing we wanted. I said in some posts back about how I couldn't stand the way some of the bull horns look on cars and how most cars have the exhaust exit right out in front of the front tire and hanging in the breeze but I couldn't deal with that. Dennis said he thinks that he can come up with something that should make it much nicer and cleaner but yet still work. So I said go for it and he ended up frenching them into the fire wall so it would clear the front tire and hide as much as the pipe as he could. I think he did a great job and think that they turned out great. Here is the process.

From the homemade Y out of the Turbo the exhaust pipes start

The start of the passenger side of the car

Behind the spindle

Into the turn

Now out with the tips

Full view

Mounted up with the tabs and welded

Now onto the drivers side and fast forwarded through the whole process and we have a completed exhaust

And when you take a step back and look at this here is what you see

As you can see this is a perfect example why things take a lot longer then expected. This was not a just make some tailpipes and mount them. The amount of metal work that went into just doing this was crazy but it is clean as can be. It is stuff like this that I feel helps set it apart from the others. The guys at DMC are craftsmen and enjoy doing the stuff that makes it mean that much more to them. Once again thanks for looking and hopefully I can post a few more soon.