You must be logged in to rate content!

21 minute read

M54 spark plug replacement on a 2002 BMW 525i E39

Compliments of bluebee @ www.bimmerfest.com

Disclaimer:

While all the photos are mine, many of the informative TIS & NGK attachments and diagrams will be recognized from a variety of sources in the Bimmerfest spark-plug archives.

Specifications:

- 2002 BMW 525i automatic, 95K miles

- Cylinder numbering is 1,2,3,4,5,6 from front to rear

- Firing order is 1-5-3-6-2-4

- Ignition coils are Bosch PN 12131703228, $85.84

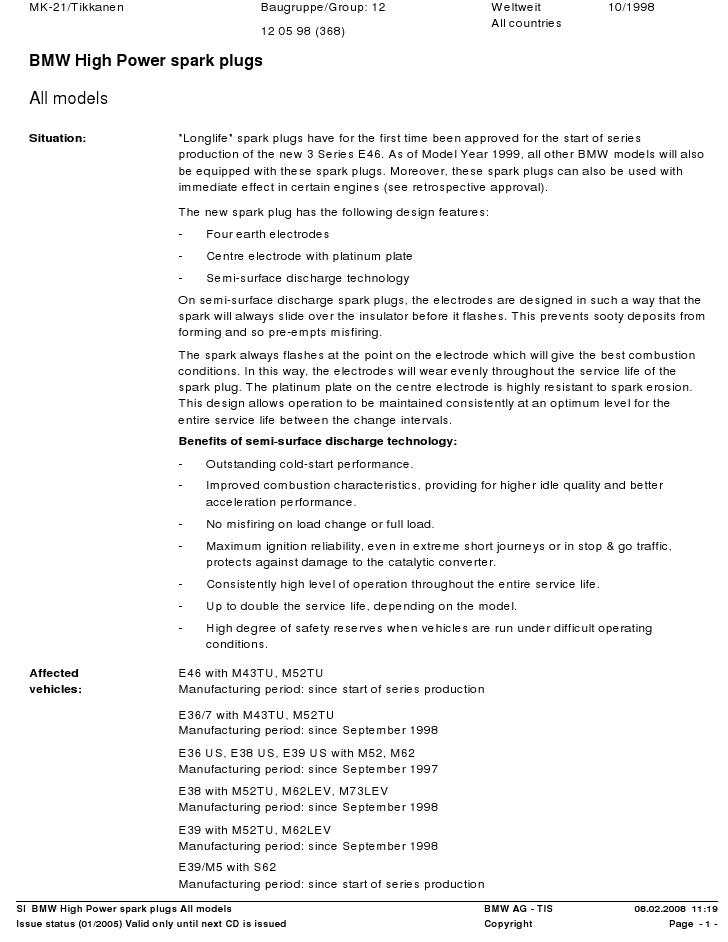

- Spark plugs are NGK BKR6EQUP (aka NGK 3199)

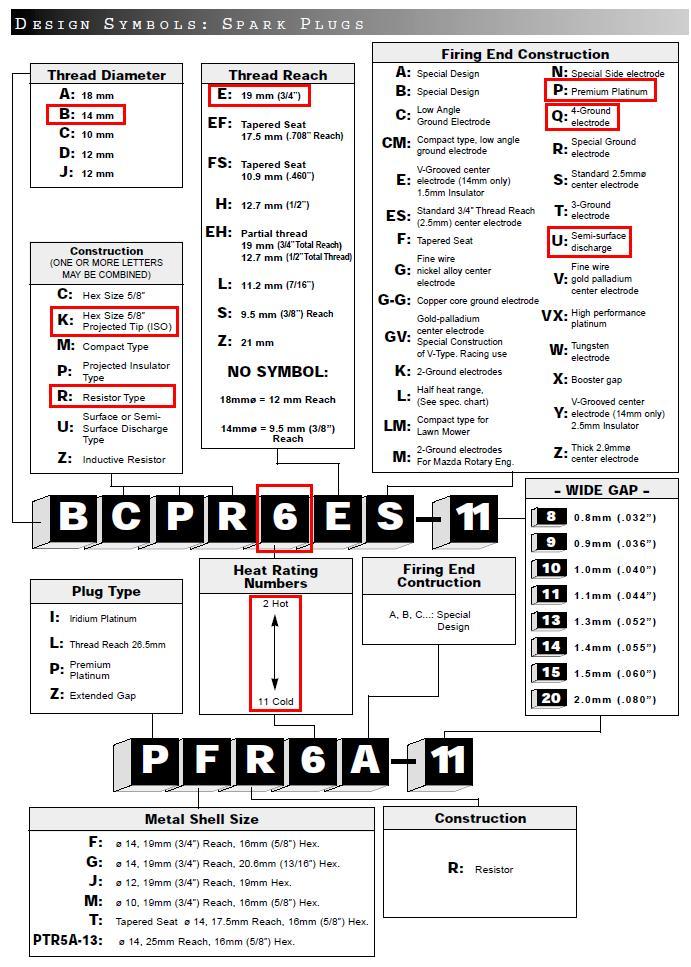

- B = thread diameter = 14mm

- K = hex size is 5/8", projected tip (ISO)

- R = resistor type

- 6 = heat range (where 2 is hot, and 11 is cold)

- E = thread reach is 19mm (3/4")

- Q = quad, i.e., 4-ground electrode (i.e., 4 prongs)

- U = firing-end construction is semi-surface discharge

- P = center material is "premium platinum"

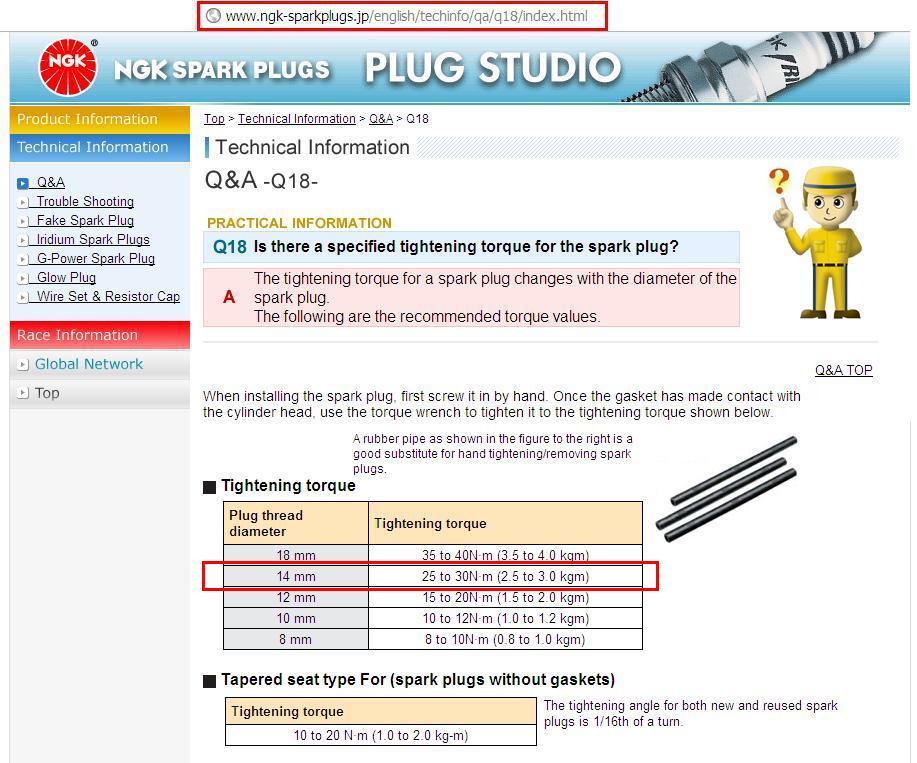

- Torque specifications

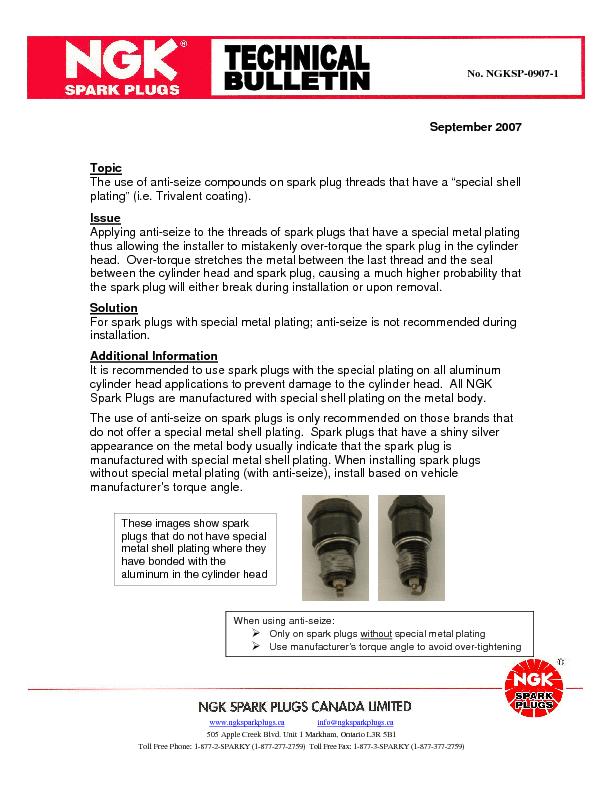

- NGK spark plugs should be dry (i.e., anti-seize is not recommended by NGK)

- Bentley

- 25 Nm (18 ft-lb)

- NGK

- 22 Lb-ft +- 2 Lb-ft

- 266 Lb-in +- 27 Lb-in

- 2.5 to 3.0 kgm

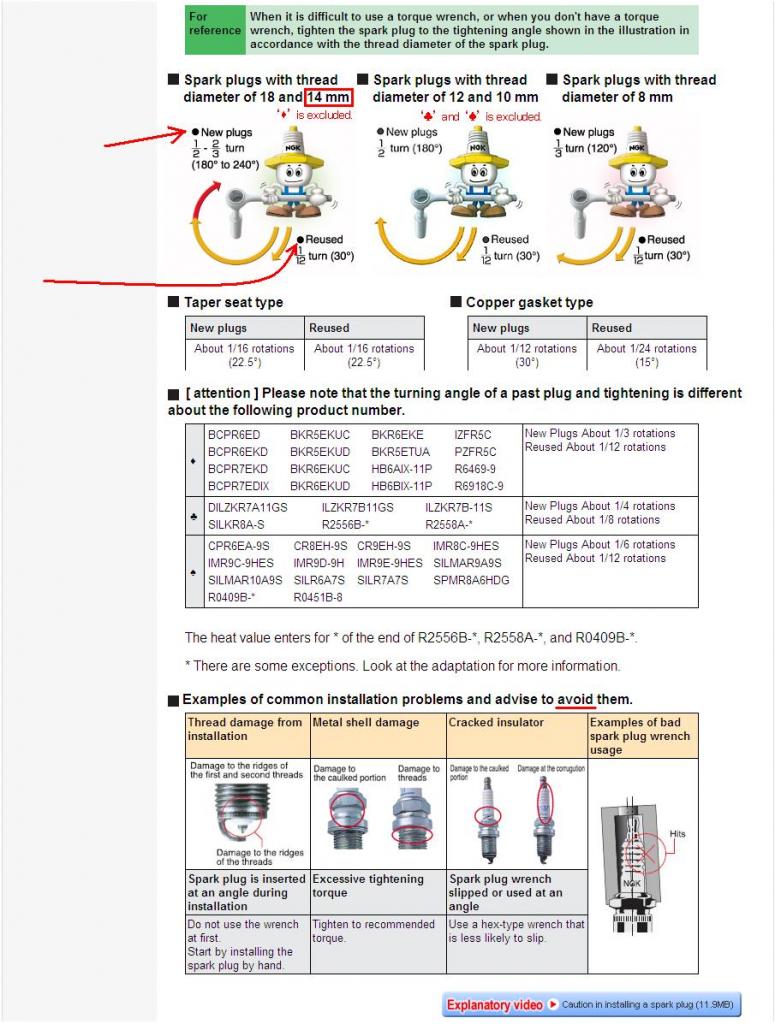

- Or, 1/2 to 2/3 of a turn after bottoming by hand (for new plugs)

- Bentley

- Coil bolts (M6X25-ZNNIV SI, PN: 07119905400)

- Torque = 10 Nm (7.5 ft-lb)

- Fuel supply plastic engine cover bolts (M6X12-Z1-ZNS PN: 07119900272)

- Torque = ?

- Cylinder head plastic engine cover nuts (AM6-8-ZNNIV SI2 PN: 07129904553)

- Torque = ?

- NGK spark plugs should be dry (i.e., anti-seize is not recommended by NGK)

Research:

- BMW spark plug application charts (1) (2)

- The best plug to use (1) (2)

- Deciphering key for spark plug codes(1)

- Visually reading plugs (1)

- The truth about torque (1) & gap (1) (2)

- DIYs for replacing spark plugs (1) (2) (3) (4) (5)

- Relevant pages from the 5-series BMW E39 Bentley manual:

- Page 010-15, spark plug socket is 5/8", deep well

- Page 020-9, Spark plug service interval, M54 engine, 100K miles

- Pages 020-20 to 020-22, Spark plug R&R procedure

- Page 113-17, torque specifications

- Spark plug to cylinder head 25 Nm (18 ft-lb)

- Ignition coils to cylinder head 10 Nm (7.5 ft-lb)

- Page 120-9 cylinder numbering & ignition firing order

- Page 120-11, ignition coil resistance specifications

- Page 110-11 to 110-16, removal of plastic engine covers

Parts & Tools & Supplies:

- Six (6) NGK BKR6EQUP (aka NGK 3199) spark plugs

- 10mm socket

- 5/8" spark plug socket (or 16mm deep socket)

- 1/8" flathead screwdriver

- 1/4" flathead screwdriver

- 6" socket extension bar

- 3" socket extension bar for 3/8" socket wrench

- 1.5" socket extension bar for 3/8" socket wrench

- Socket handle

- Universal joint for 3/8" socket wrench

- Dielectric grease (optional)

- Anti-seize paste (optional)

Idealized DIY Steps:

- Optionally remove the passenger side cabin air filter housing and hose

- Note I did not remove the cabin air filter nor the hose; the last spark plug would have been easier to remove & replace had I done so.

- Remove the oil filler cap temporarily.

- Using a 1/8th inch flathead screwdriver, pry off the two plastic passenger side cylinder head cover bolt caps and remove the two 10mm nuts with a 10mm socket wrench; pull the plastic cylinder head engine cover off by hand.

- Note you may need a u-joint socket bar extension to remove the passenger side nut due to the proximity of the passenger side engine air filter housing hose.

- Replace the oil filler cap so that debris does not enter the engine.

- Optionally, using a 1/8" flathead screwdriver, pry out the two driver side plastic fuel-injection system engine cover bolt caps and remove the two 10mm bolts using a 10mm socket; pull the plastic fuel-injection system engine cover off by hand.

- Note now is a good time to loosely replace the bolts removed so you don't lose them.

- Notice the long clip on the passenger side which holds the coil wires in place (it's optional to remove that clip to make coil removal slightly easier).

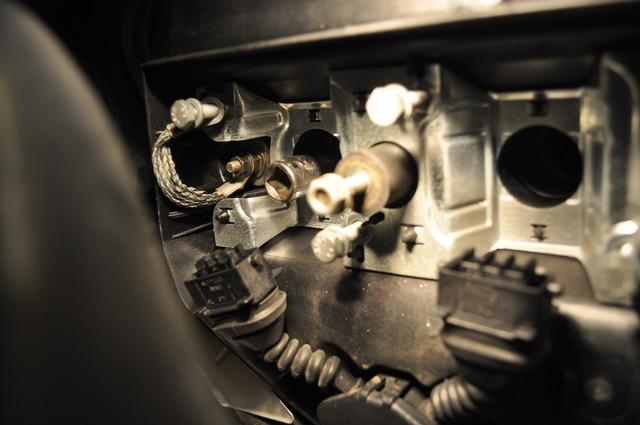

- Look around. Notice anything amiss or astray (e.g., different brand coils or mouse-chewed insulation like I had). Notice the two braided silvered ground straps, one at the #1 (fore) and the other at the #6 (aft) cylinder.

- Optionally, mark numbers 1 through 6 on the top of the coils with whiteout or other suitable marking.

- With a 10mm socket, remove the two bolts holding each coil in place.

- With a 1/4 inch flathead screwdriver, lift up on each coil's metal u-shaped harness connector clip and pull the harness connector toward the fender, away from the coil.

- By hand, wiggle each coil, and pull upward off the spark plug; the #6 coil will just barely make it out with the passenger side cabin air filter & hoses intact; but it will lift out.

- Optionally loosely replace the coil bolts so you do not lose them.

- Optionally test coil resistance as per the E39 Bentley page 120-11 (2002 edition)

- With a 5/8" standard spark plug socket & six-inch extension, remove each spark plug taking care to not apply any side forces while twisting it outward.

- Note a five-inch long deep socket just barely makes it to the top of the engine.

- Optionally number the plugs as you remove them (place a line in each of the six landings to label the six plugs).

- If you did not remove the passenger side cabin air filter & hose, then the 6th spark plug will require a short 3" extension bar & a normal 5/8ths inch spark plug socket. Some use a length of fuel system hose, and/or a universal joint.

- Note the old plugs were labeled NGK R5 BMW, while the new plugs are labeled NGK BKR6EQUP.

- Optionally, when replacing the plugs, some people apply a dab of anti-seize on the spark plug threads; however NGK advises against that because of the danger of over torquing.

- By hand, place the new plug in a rubber hose or in a rubber-seated spark-plug socket with extension bar sticking out (but no socket wrench yet), and turn the spark plug socket by hand in the counter-clockwise direction a few turns, and then clockwise, to avoid cross-threading.

- By hand, continue to turn the spark plug clockwise until you cannot turn it by hand any more. Then connect the torque wrench and torque to the figures listed above (1/2 to 2/3 turn or, about 180 to 240 degrees of rotation after you couldn't turn it by hand).

- Note the #6 plug may require a deep socket, and/or a 1.5" extension instead of a regular socket and a 3"inch to 6 inch extension if you did not remove the passenger side cabin air filter housing & hoses.

- By hand, replace the coils & tighten the two 10mm bolts on each coil with a torque wrench.

- By hand, lift up on the u-shaped metal clip on each coil and insert the wire harness connector into each coil; when seated, push down on the u-shaped metal clip to secure the harness connector to each coil.

- Optionally, apply dielectric grease to the female fitting of each coil harness connector.

- By hand, replace the driver side engine cover & 10mm bolts and plastic bolt caps if you had optionally removed it.

- By hand, temporarily remove the oil filter cap and replace the passenger side engine cover, tightening the nuts with a 10mm socket; replace the plastic bolt caps & the oil filler cap when done.

- Check your work area and start your engine to hear it purr!

Informal Pictorial DIY:

The only special item needed before you start is a box of the right spark plugs:

I pried up the fuel rail plastic cover bolt caps; but it turns out I could have left this cover on:

Interestingly, two of the four engine cover bolt caps were broken by someone else!

I removed the two 10mm bolts under the fuel rail cover caps with a socket wrench:

The 10mm bolt was hard to get out so I used bent-needle-nose pliers to grab the bolt head:

The fuel rail plastic cover bolts are short as can be seen below:

Since I elected not to remove the passenger side cabin air filter housing, I used a universal joint socket extension to access the last nut under the cabin air filter housing hose.

It should be noted that the fuel rail cover is held on by two bolts:

While the cylinder head plastic cover is held on by two nuts.

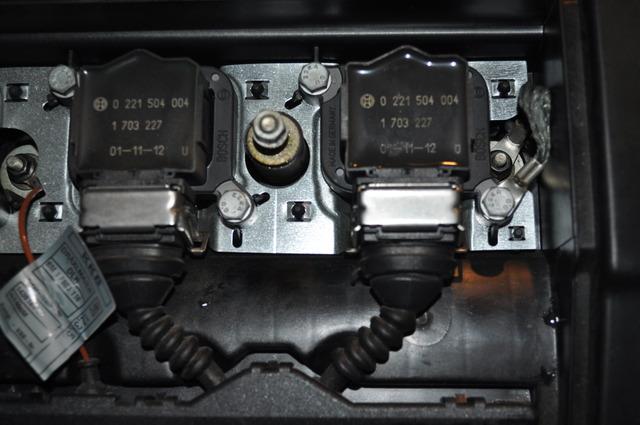

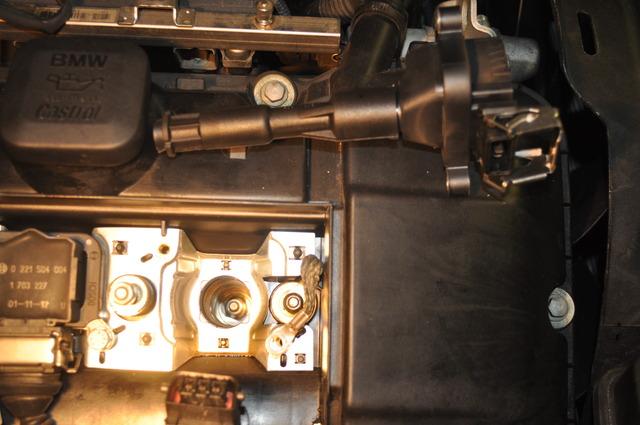

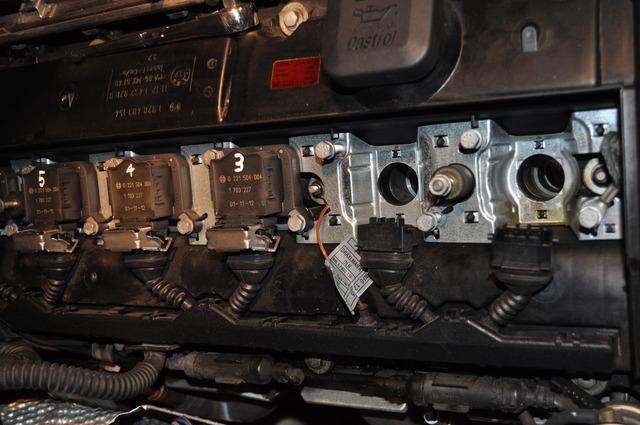

Here we have both plastic engine covers removed.

To keep things tidy, once I pulled the two covers off, I loosely replaced all bolts, nuts, & oil filler cap previously removed:

Optionally, once the coils are visible, you can run a quick coil operational test:

And, you should do a visual inspection of all undercover hoses and wires.

Here, for some strange reason, you see the foam insulation around a plastic wire tube badly eaten away:

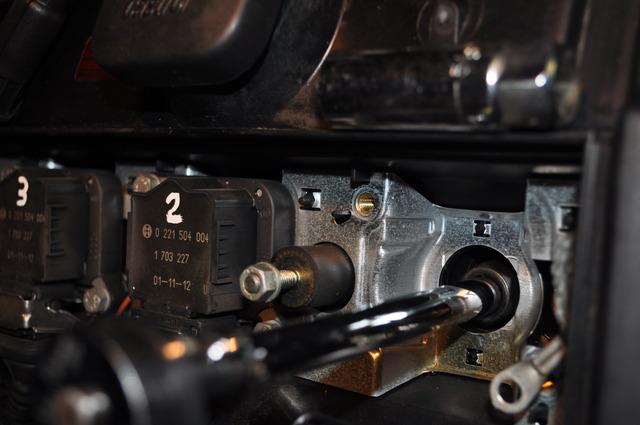

In your visual inspection, make note of the #1 and #6 braided coil ground strap locations:

And make note of the brown wire between coil #2 and #3 (which does not need to be removed):

Also note the plastic clips covering and holding down the coil wires.

Some spark plug R&R DIYs advocate removal of this coil wire cover clip:

But I left the cover clip in place as the coil can easily be wiggled free simply by disconnecting the harness connector and removing two bolts holding the coil down.

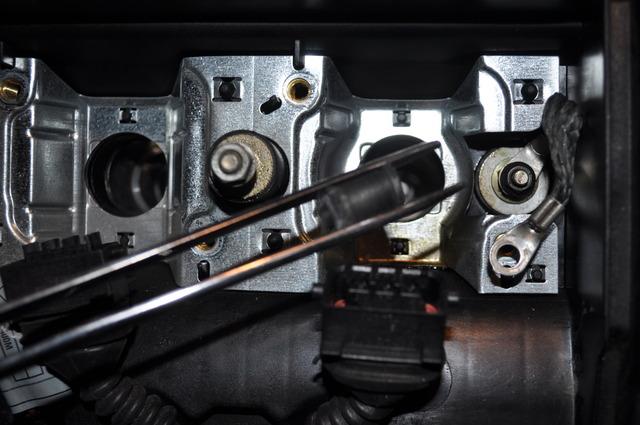

Remove the 10mm coil hold down bolts (there are two per coil), one by one:

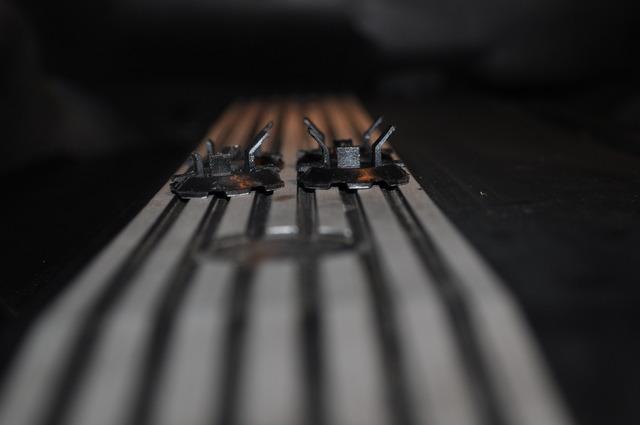

This is what the hold-down 10mm bolts look like:

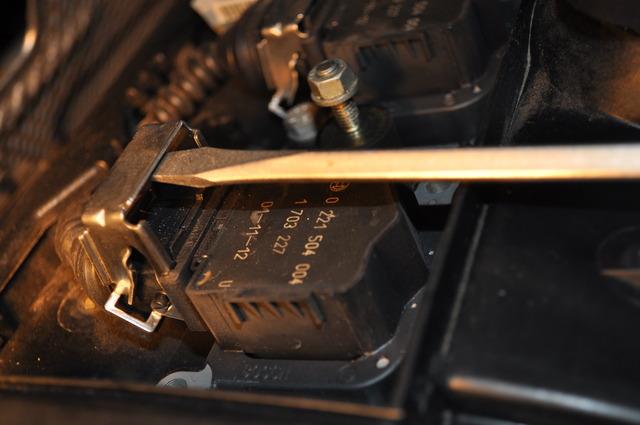

Pry up the spring clip holding the coil wire harness securely in place:

Lift the u-shaped spring clip until it is almost an inch up:

And then pull backward (toward the passenger fender) on the harness connector:

With your hands, then grasp the coil and wiggle it upward and off the spark plug:

At this point, I realized I should number the coils, so I numbered them with whiteout #1 to #6:

Once the coil was off the spark plug, it was a simple matter to remove the spark plug:

I marked the spark plug with a single line on a single hex landing & compared old & new:

I repeated that process starting from the front of the engine, working backward:

The last (#6) cylinder required shorter extensions, a u-joint, and a shorter spark plug socket:

Here is a shot of the labeling (one line per cylinder) of the first three spark plugs removed:

After unclipping and removing the 6 coils and 6 spark plugs, I loosely reattached all bolts, nuts, and clips:

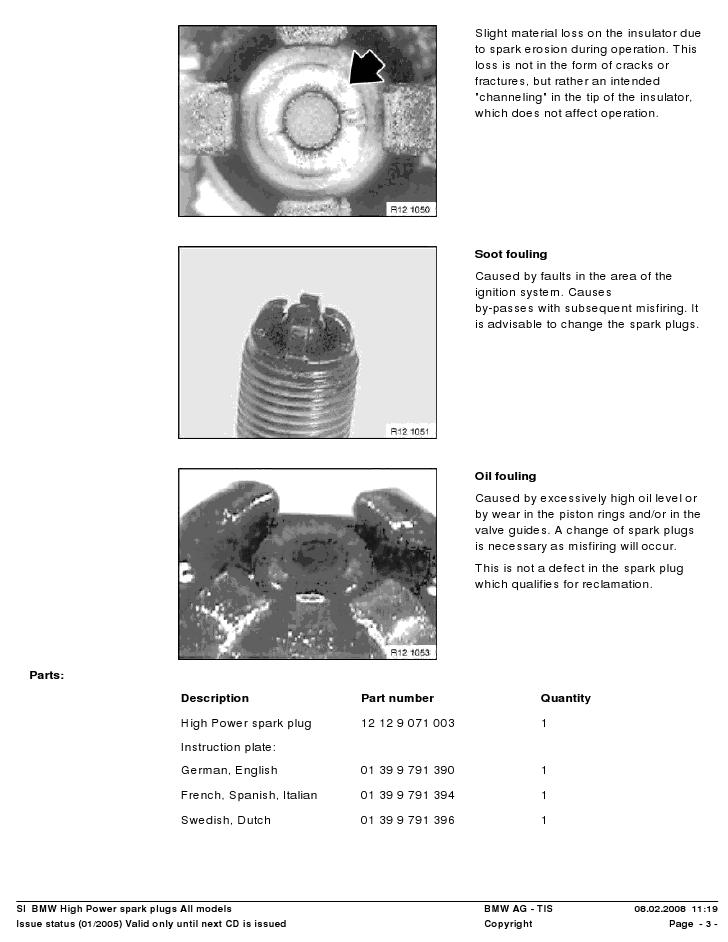

I then compared the six plugs visually, taking note of the threads explaining what to look for:

Once all the plugs were out, I measured the hex nut to be 5/8ths (a 16mm also worked) and the threads were clearly 14mm (With calipers, I measured .537" thread diameter at the tip & .542" at the base of the plug; these measurements, converted to metric, are 13.634 mm to 13.769 mm. Since 0.5512" is 14.0000 mm, the nearest standard "hole" size is 9/16" or 0.563" or 14.288 mm).

I replaced the spark plugs starting from the rear, which needed a hose to get it started:

As with removal, I employed various different sized attachments for the back-most plug:

My torque wrench was acting up (see broken oilpan bolt thread for details) so I used the 1/2-turn "torque angle" method of tightening the spark plugs after applying anti-seize to the threads.

I used a hose to start the spark plug, twisting counterclockwise before twisting clockwise, and tightening hand tight with the hose, and then with just the spark plug socket and extension bar.

Again, I worked my way down, this time from front to rear:

Again, the #6 cylinder required slightly different combinations of shorter elements:

Zipping it all back up, I lifted up all the clips, and reattached the coil wire harness connector, starting from #6 and working back to #1:

One of the cylinders wouldn't allow the coil to be reattached; this was solved when I realized the spark plug socket rubber boot was still on the #1 plug. I removed it with a very long pair of tweezers.

For the record, I took careful note of attaching the two ground straps (#1 & #6) properly:

And, for what it's worth, I used dielectric grease on all electrical connections:

Here's a shot of all the coils lined up, ready for me to snap down on the metal spring clip to lock the electrical connection into place.

At this point, I did a visual inspection and then started the car to run the water-shake test:

Then, I replaced both plastic engine covers, and the bolts and nuts holding them down:

And, finally, I performed the final visual inspection prior to closing the hood on another successful DIY.

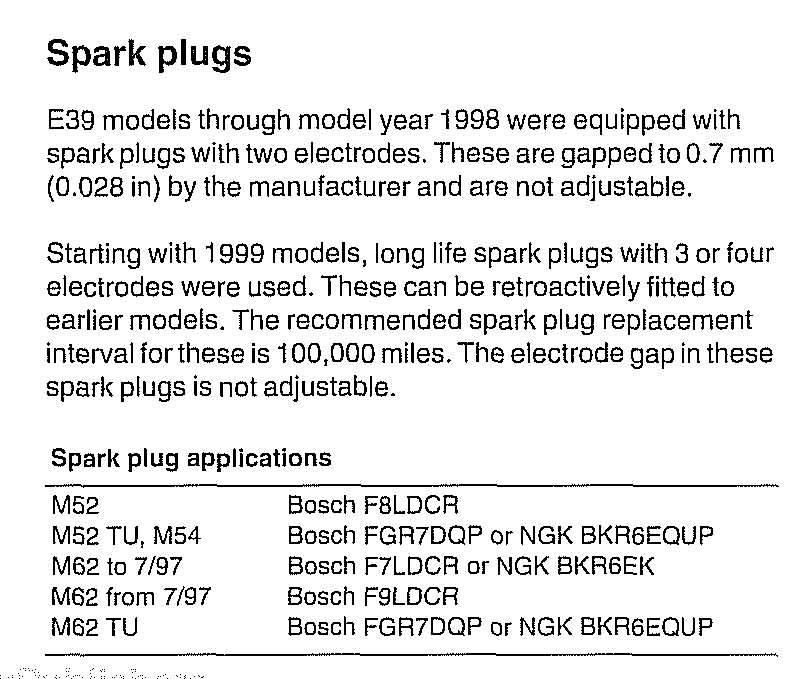

For reference, here is a snapshot of the E39 Bentley recommendations for the E39:

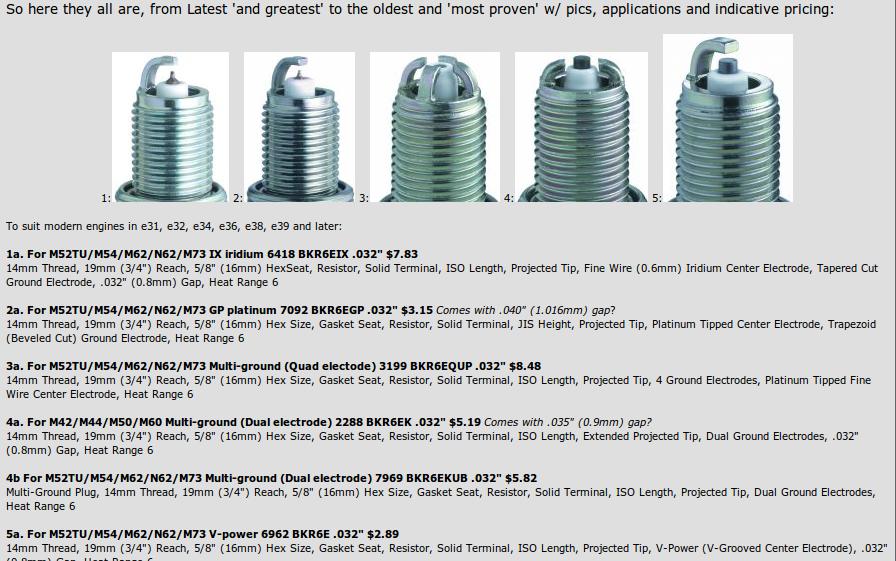

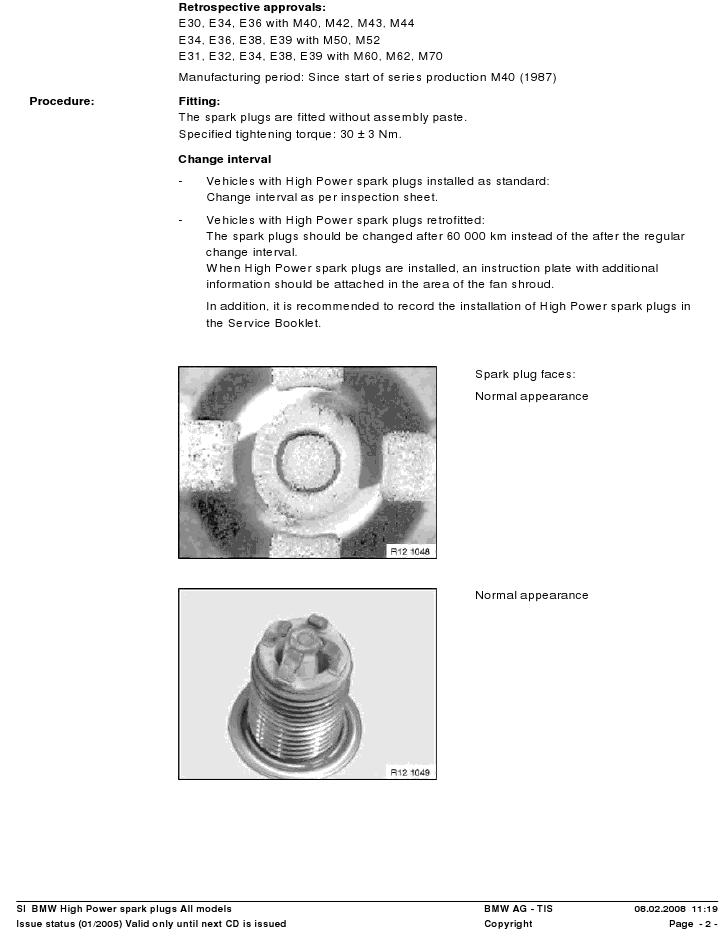

For reference, here is a quick look at the various spark plug types used in recent engines:

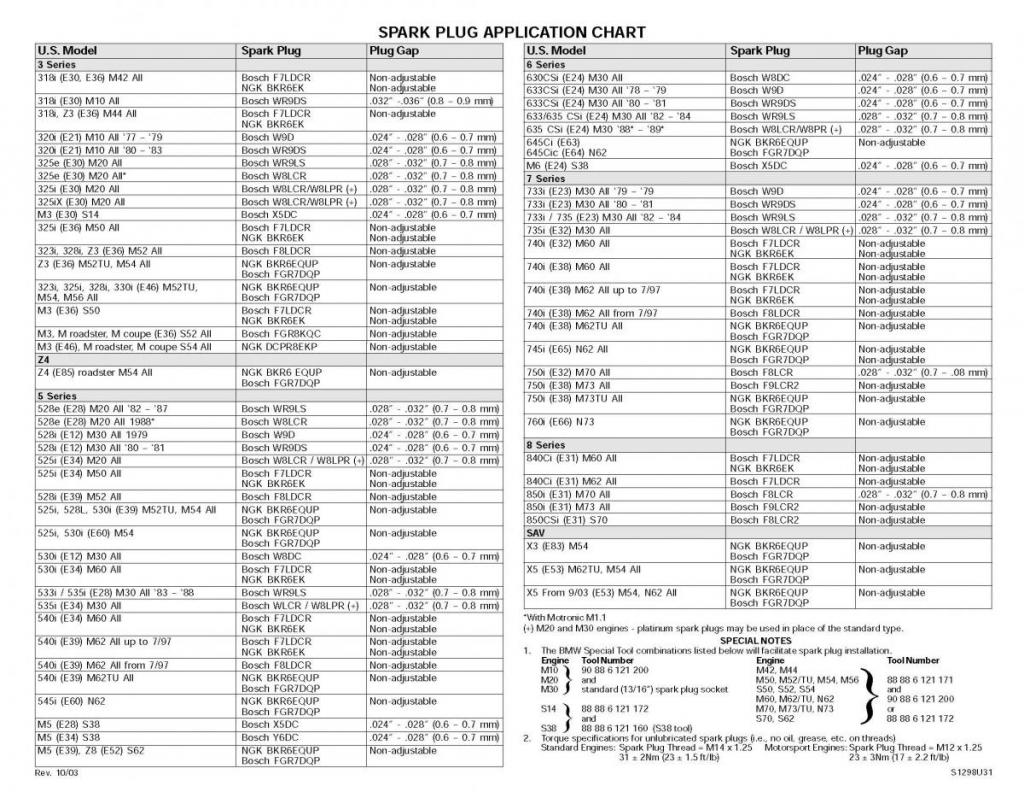

For reference, here is a spark plug application chart for a variety of modern BMWs:

And, for reference, here is a deciphering key for NGK spark plug markings:

For reference, here is an NGK brochure describing torque for the various thread-size plugs:

For reference, this diagram shows torque angles for the NGK spark plugs:

For reference, this NGK technical bulletin discusses the use of anti-seize (they don't recommend it):

And, for those who want to know more about the advanced plugs, here is a three-page TIS from BMW describing the features:

Truth be told, despite the fact I glossed over the topic in the DIY (saying only the politically correct words), I actually agonized for quite some time in my ever darker garage as the night wore on, over whether to use anti-seize or not on the plugs.

I even went back and researched and re-read all the literature i could find about the "special shell plating" (i.e. Trivalent coating) on the NGK BKR6EQUP plugs and 'what' it does for us.

The problem was, much like reading about religious dogma on motor oil, the more I read, the less I knew which way to go.

It's a good question:

- Anti-seize?

- Or not?

Here, for example, is a discussion I read over and over and over again:

- The Truth About Spark Plug Torque and Anti- Seize

It seemed that half the people said:

- Use anti-seize because it prevents broken plugs later, even if the plug has the special tri-valent coating ...

While the other half (and both BMW & NGK) said:

- Anti-seize is not needed (nor recommended) if the plug has a special coating; and it may cause you to have improper torque values if you do use it ...

As I pondered what to do, I came to the (perhaps misguided?) tentative conclusion that the warnings against using anti-seize (which were in plain sight) seemed to be "all about" torque.

Yet, the contrarian view (perhaps also as misguided?) was that you'll be sorry five years down the road when you bust a plug trying to replace it.

What sealed my decision (to run a test) was the fact that the plugs were VERY DIFFICULT for me to remove. They're OEM plugs (BMW branded, along with NGK). They were probably put there sans anti-seize paste.

They were really really really stuck in there. I had to use a LOT of force to remove them. And, when they creaked out those first few turns, it scared me that I was stripping threads because it felt like I was twisting the plug like a tap, cutting my own threads on my way "out" of the spark plug hole!

Those six tortuous removals instilled, in me, a foreboding sense of:

- Fear

- Uncertainty

- Doubt

This FUD caused me to ponder (for quite some time) what I should do.

It didn't help that my Harbor Freight torque wrench wasn't working right (which is why my oil pan bolt busted). So, I had already decided to rigorously follow the 1/2 turn "torque angle" approach on all six plugs (for lack of a better idea).

In the end (for better or for worse), as a ghoulish 'experiment', I actually used anti-seize on only HALF the plugs; leaving the other half pristine and bare to the ravages of the engine over time.

In five years, when it's time to remove the six plugs, only then will I know what the 'right' approach was!

Until then ... ???

In the picture below (sorry, bad garage night lighting), you see a thin coating of anti-seize on this particular spark plug before I screw it in.