You must be logged in to rate content!

3 minute(s) of a 184 minute read

4-15-2012

4-15-2012

I am able to adjust the exhaust up and down maybe 1/2-3/4" each way so if I end up being too close the to driveshaft I can lower it down a bit. Added some more tack welds to the exhaust and took it off the car before I weld it all the way.

More wiring done....

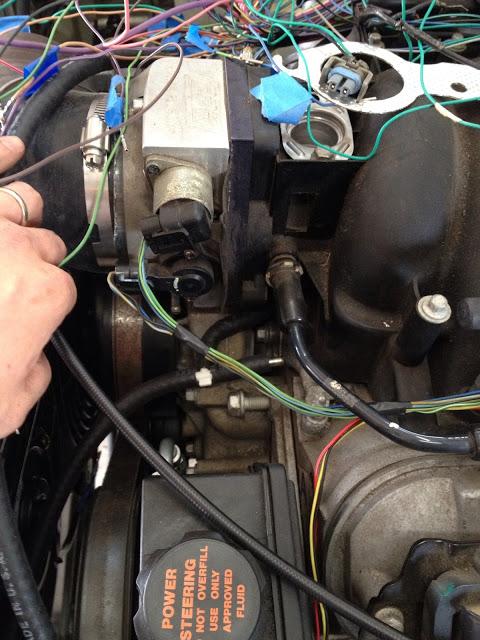

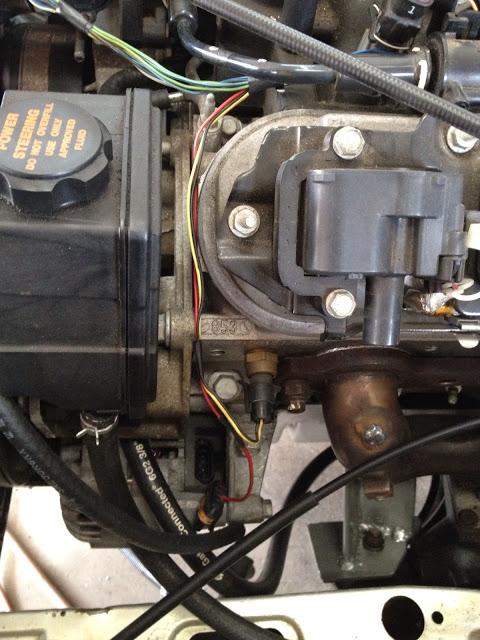

Wiring coming off the TPS and IAC

Alternator and PCM coolant sensor

Wiring routed along from the injectors, coil, evap valve. Tapped anytime a wire comes in or out of the bundle.

Goes along the back of the engine...you can just see the wires coming up from the trans (O2 sensors, VSS, reverse lockout). Then it picks up, oil dummy light, cam sensor, maf, knock sensors.

From the passenger side...You can also see the crank sensor, coolant gauge, and starter wiring coming up into the bundle.

Passenger side bundle....it's getting bigger. Picks up the other injectors and coil wires.

Here you can see the wires started to be plugged back into the PCM in its new location. Some of the wires are too short and some are too long. The short ones will have to be lengthened of course but I am debating shortening the ones that are too long.... Some are up to 12" too long and I could sorta fold them back on themselves in the bundle or I can shorten them..... Any suggestions which way is best?

All connections of wires have been soldered and then covered in dual walled heat shrink. Inside has a adhesive that melts and bonds to the wire to provide moisture protection.

The rest of the AC parts will be here tomorrow so then I can finish the AC pressure sensor wiring as well as the MAF/IAC wiring.

If anyone else is doing a similar swap and needs harness work let me know. I really enjoy this step.

I was hoping it would be running next weekend but I am guessing it is the following. One of the problems I have is when I start to see the end of a project I almost don't want it to end...it's like a really good movie.

Nice build!

Posted by Diggymart on 1/2/20 @ 7:47:19 PM