You must be logged in to rate content!

6 minute(s) of a 620 minute read

3-1-2012

Thanks for checking guys, I forgot about the upper shock mounting tabs, they were a pain to get to match since I was working on a up hill, horizontal and vertical fit. They took a while, but it was worth it.

The crossmember, the torchmate did great on the sides of the crossmember, but I can't describe the patience of shaping the tops and bottoms. I was extemely set on not using any heat to shape those. By using the heat, sooner or later I'd use a hammer to pound things to fit, it just wasn't gonna happen, I didn't want and hammer marks when done.

Now the frame sections. When I started this thread, I figured everyone assumed it would be some overlapping patches to repair the bad spots. I recall the responce once I posted the finished welding and grinding. I knew with the responces there would be new interest in welding.

It's been 8 months now we've been going at it, and it's been an absolute pleasure.

Quick review so far. Hopefully these things I post next have stuck with everybody so far.

Squarebore and spreadbore carbs. By the way, when I showed the spreadbore, it was of a Quadrajet carb. Holley also makes spreadbore carbs.

Vacuum operated secondary carbs. They open by the demand of the engine. They can be adapted by the springs to meet the needs of different engines and applications.

If we force the secondaries open on a vacuum operated carb we get a hesitation. The secondaries do not have an accelerator pump for the immediate opening of the secondaries.

Port vacuum and manifold vacuum. The port vacuum is above the throttle plates, there is virtually no vacuum at idle since there isn't much air flow yet. Once you open the throttle plates, the air flow create a vacuum. To operate the secondaries, this is the perfect situation. The vacuum canister gets it supply by bolting to the side of the carb. But look closely, you'll usually find a hose nipple sticking out the front or side of a carb that is located about midway up the carb. This is usaually a port vacuum hook up.

Manifold vacuum, great vacuum at idle. The engine is running, the cylinders are sucking air but the throttle plates are almost fully closed. These hose nipples are usually right at the base plate of the carb.

We have distributor advance, transmission vacuum modualtors, brake boosters, emission control, even shaker hood shops, ect. All these work off the vacuum. There are parts inside and outside of carbs that deal with vacuum also, understanding these parts and their operation will be a great benefit someday if you build a hot rod or do any modifications.

The accelerator pump has come up a few times, it's time to go there.

First thing I have to say about the Holley accelerator pump system, even for those who have messed with Holleys, there is a boat load of settings you may not be familiar with. And nobody likes a hesitation, an inproperly set accelerator pump is usaually the problem. Oh boy, where to start......

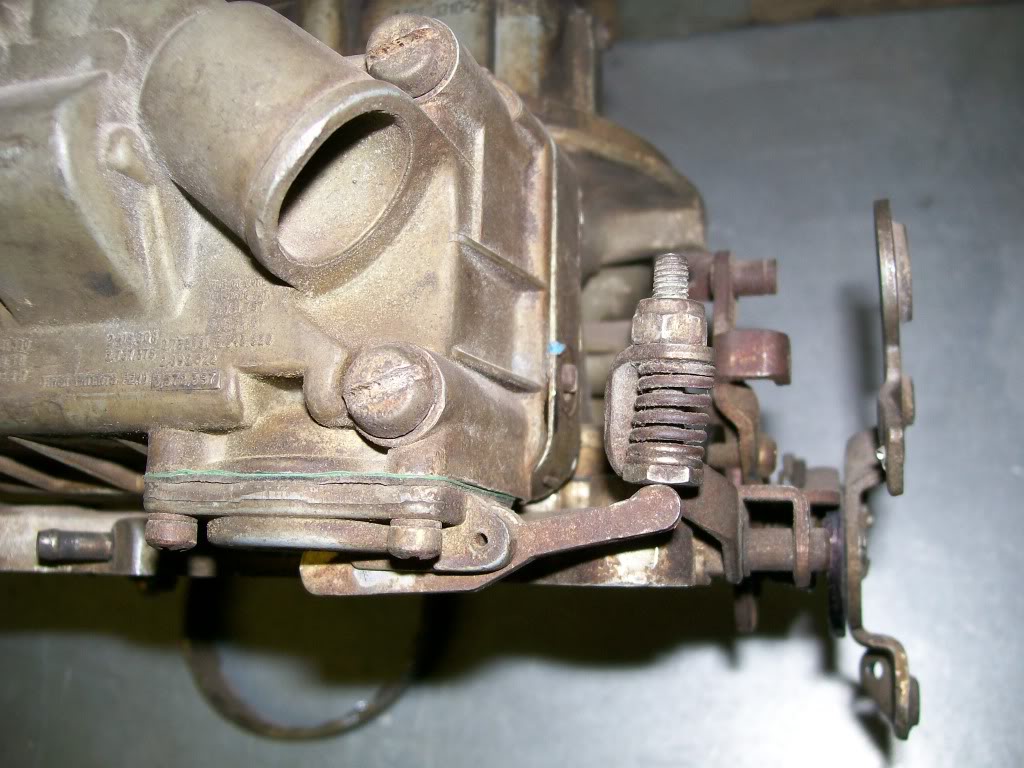

First let's look close up at the carb at idle, no pushing of the acceleratorpump yet. In the picture below, there are at least 3 changes or settings possible, yes, this might take a while.

I won't write much here so the pics stay close together. This is the carb in full open position. Notice the changes from above.

Ok, first, the throttle shaft rotated. You can see the arm that touches the throttle shaft has raised, which in turn. due to a pivot point, is gonna push downward on the lever that is at a 90 degree angle to it. Then the lever at the 90 degree angle has it's pivot, which in turn ends up pushing upwards into a rubber diaphram that has a pool of gasoline ready to be pushed into the carb.

Going back the the lever touching the throttle shaft. Obviously we have an eccentric, something than is now round but has a high spot built into it. Once rotated, it rose upward and pushed the lever upwards.

This is the first place for adjustment, most don't even know about this adjustment. There is a plastic piece that is held in place by a screw. Go back to previous pics, in post number "852" you'll see the screw and how the first lever is being pushed upward by the plastic cam. You'll also see a hole marked "2". You will have multiple choices to change these plastic "cams" and at the same time, use different holes also. Oh my head hurts just thinking of the possibilities.

Once again, Holley has a kit. You'll notice different cuts on these cams. They all change how much, and at what rate the fuel will be shot into the intake. You'll also notice the 2 holes in most of them, these add to the variables when setting up your carb. Depending on which hole in the cam, and which of the two holes you use on the throttle shaft, wow, the adjustablility is endless.

Comments

Great before & after!

Posted by Diggymart on 1/11/20 @ 4:10:28 PM

Gotta love the Willys! Good job...great build!

Posted by Diggymart on 12/10/18 @ 8:34:21 PM

Ultimate classic truck right there

Posted by CCmyVW on 12/26/20 @ 4:17:42 PM