You must be logged in to rate content!

18 minute(s) of a 620 minute read

2-14-2012

Hey guys, everything's ok. I've been catching up on odds and ends.

I got to put the Willys to work last night. We got about 5 or 6 inches of snow yesterday. On my way home my neighbor slid off the road and got stuck. Hooked up the Willys, yes, using the hooks that I covered when I showed making the bumper mounts. He liked the convience of the hooks ready for service. Minutes later, he was unstuck and I was heading home, the old truck,62 years old and still yanking vehicles out of the ditch, how cool.

He liked the convience of the hooks ready for service. Minutes later, he was unstuck and I was heading home, the old truck,62 years old and still yanking vehicles out of the ditch, how cool.

Had another neighbor who brought me a plastic side vent cover off a Bobcat. The cover is close to the track and a branch got stck between the track and the vent cover. He asked if rather than going to Bobcat for a new one, if I could make one. I still need to drill a couple holes and paint, here it is with a slight change. He already has seen it and I got a thumps up.

For reasons just as the snow we just got, I don't want to get deeper into the Willys, so it will sit ready for service for a while yet.

Now the Willys sits where the '57 Chevy was and the '57 Chevy sits where the Willys was. They both look good sitting in the shop.

Although the '57 has a fair amount of body filler, most is just a skin coat to smooth the metal. The nice thing about this Chevy is the body is nearly rust free, this is great! The truck spent most of it's life on a farm in Texas so it had it's share of small dents a dings. I perfer this rather than rust holes and rotted sections to replace. Once the weather turns warm I'll get the base primer on the truck and it should look good.

Til then I want to get the 396 fitted in place. I'm happy with the motor location, I got that settled about a year ago. Now I'm dealing with all the front pulleys. I want to keep the pulleys as close to the block as I can, there's not alot of space between the engine and the radiator. I am using a dual electric fan, the idea being... with one fan blade, the electric motor is in the center, right where the water pump hub is. By using 2 electric fan blades, the center is more open for the water pump hub to have plenty of space.

Next up is exhaust headers. No problem on the passenger side. The drivers side needs the header moved out from the engine about 3/16". It's a long story but the outlet is too close to the oil filter. Soooo, I made 1/8" stainless steel spacers. These along with one more gasket will give me the spacing I need. Here are the spacers.

oldtime_ironman, the engine you describe in your last post sounds very close to mine. I did have it bored to a 402, and I do have the oval port heads. I worked the intake ports just before the valve seats to help the flow before they were assembled. I also have the high rise intake and HEI ignition. I used a comp cams 282 camshaft, should have a nice sound at idle which will require a stall speed converter, but I'm looking for the aggressive sound. I can't wait to hear it run.

For the rest of you, buying me a lifetime membership, wow. I suppose I have no idea of who or how many have kept up with this thread. I'm hoping it's been entertaining as well as a good learning. I've down or up loaded a few pics of the '57 issues, including rotating the back of the very commom GM alternator. Guaranteed if you're gonna do a build, this is the first choice alternator and to know something about it will help.

2-15-2012

I mentioned the usage of the Gm/Delco alternator. I doesn't much matter what your building, this is the design that will come into the equation sooner or later.

Go to Jegs or Summit racing and you'll find this alternator as a 100 amp output availability with only one wire attached to it. There is no need for an external regulator since it is also inclosed inside the alternator.

It has a couple different chioces for the pulley. There are single groove and double groove, both with different diameters.

There is one thing that does occasionally need changing and that is the location of the wire hookup.

There are 4 different locations available but the case has to be split to rotate the back to achieve the 4 locations. As with anything you disassemble the first time, the fear of what might spring apart as you disassemble becomes forefront.

The reason for the rotation is there may be a time that the wire outlets run directly into a valve cover, a bracket, or just to be able to hide the wiring for a nice clean look when done.

Also, there may some who are reading this knowing you can rotate the back by removing the case bolts and very causiously rotating the back without disturbing the brushes. Yes, in the right situation you can, but there'd be no learning.

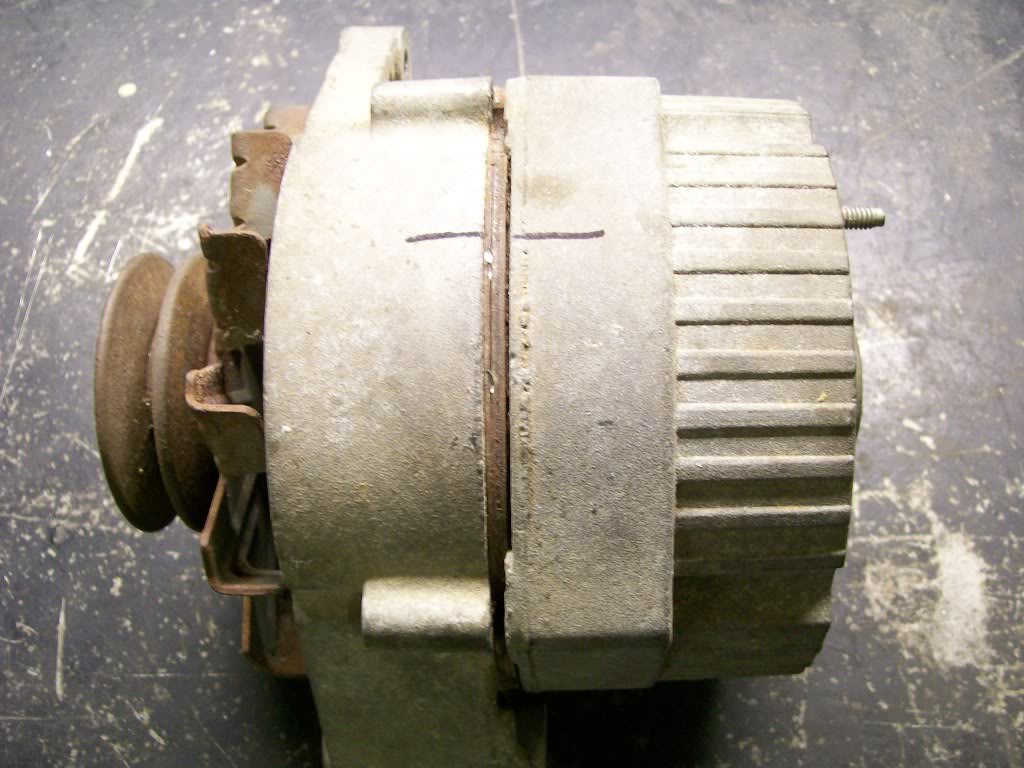

For the mock-up of this '57 Chevy I'm using an old alternator from my inventory, no sense using new parts for mock-up.

When I mount this alternator the extra bolt hole in very back is right against the valve cover, and I want the wiring to face a different direction.

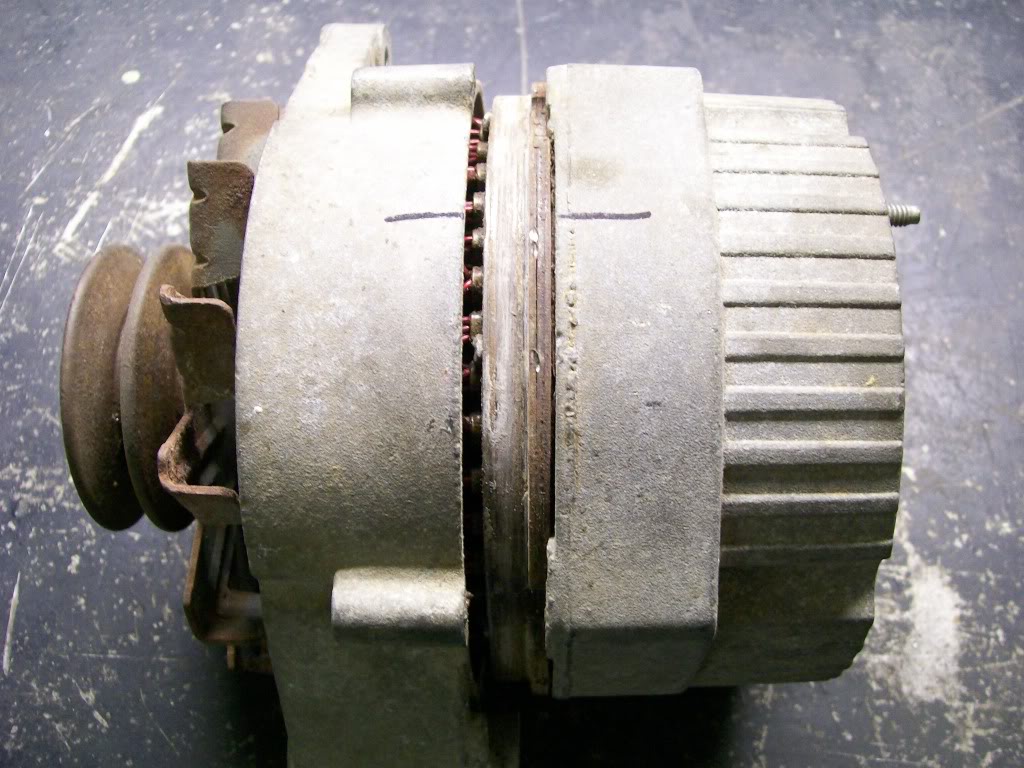

In this second picture the back has been rotated to where I need it to be. One arrow is pointing to the bolt hole that was up against the valve cover.

The second arrow pointing towards the center of the alternator, if you look closely, you'll see a heavy piece of wire sticking out. When you split the case, yes, there is a set of spring loaded brushes that pop out of their holder. It is designed that you can compress the springs and brushes back into their holder. Once compressed, slide a piece of wire through a couple holes, then assemble the alternator. Once reassembled, pull this wire out and the brushes snap back into place.

I hope to get some internal pics in the next day or two.

Happy learning.....

2-16-2012

Your concern is exactly what my concern is. I went back and forth deciding whether to use aluminum or stainless, I decided on stainless for it's facial strength.

What I mean is.... if there is shrinkage, then there will be vibration. If there is vibration, I figure the aluminum will be more sensative to having material rubbed away making the situation worse.

I tried to make the spacers in a way that they will have as much surface contact to spread the pressure around evenly.

Yup, this is one of those situations where you're down to your last resort, make your best judgement call and move forward.

I'll be the first to admit I hate breakdowns and failures. But I'll also be the first to admit, if I didn't take a chance, or step out of the box once in a while, I'd never advance in my fabrications.

But I'll also be the first to admit, if I didn't take a chance, or step out of the box once in a while, I'd never advance in my fabrications.

Just be prepared to learn from a failure, it's easier to get back on the horse and move forward.

Let's crack this alternator open. Since there are 4 positions available during reassembly it is best to mark the two halves to either get it back as it was if you're rebuilding it, or a reference if you're rotating the back to a different position. Then remove the 4 bolts that hold the 2 halves together.

Between the 2 halves you see a darker colored center section, I have to go back to my school days but I believe it's called the stator, the stationary set of windings. When you split the 2 halves this darker center has to go with the back half. Ok, yes, the back can be rotated by removing the bolts and very, very carefully twisting the 2 halves, keeping the center section with the back half. Only problem.. if the alternator is old, due to corrosion the center section won't co-operate with the twist. So disassemble is the best way in this situation.

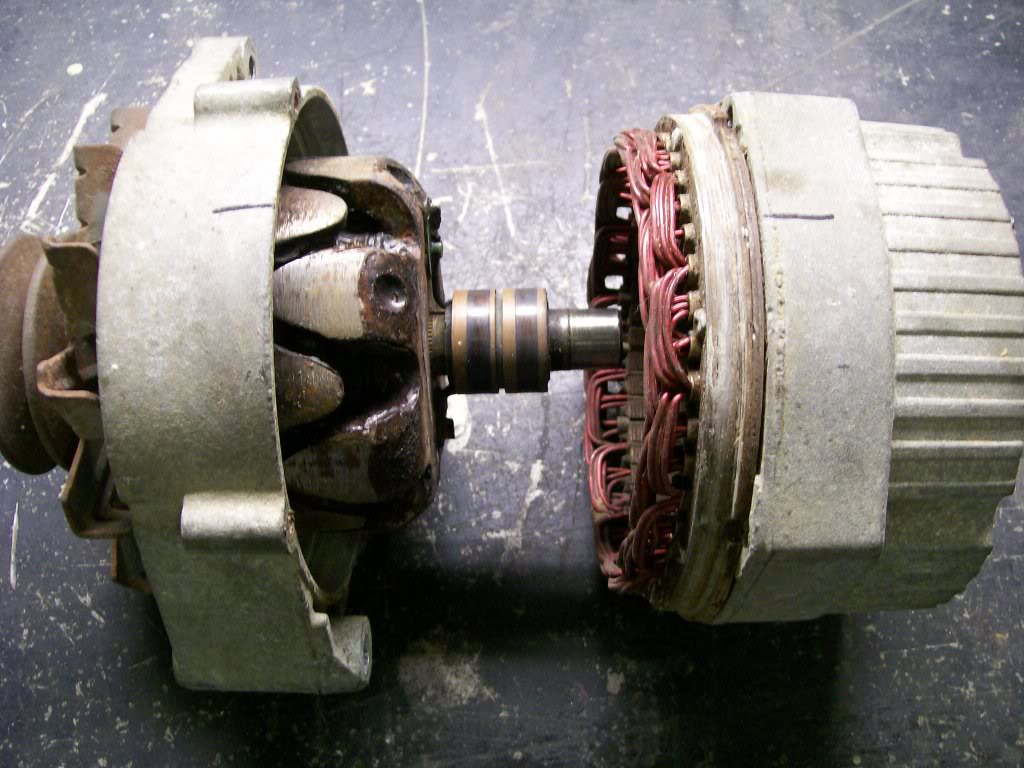

Being this far apart you can see the 2 halves, deeper inside you can see the 2 copper rings that the brushes ride against. It is these brushes that we can't see yet, that will pop out of their holder, these brushes and the springs are the only issue when do this rotation. I'll show resettting the brushes next

time.

2-17-2012

Now that the case is split open and the brushes have popped out of their holder, the brushes have to be put back into their holder before the case halves are put back together again.

Before reassembly I recommend getting some brake cleaner or electric motor cleaner and at least cheaning the brushes. Why?? Looking at the last picture of splitting the case where the two copper rings are located, just after those is the main shaft that goes into the rear bearing. When the brushes leave the copper rings during disassembly they slide across this rear shaft, chances are, the brushes may have gotten grease on them.

Ok, a look at the brushes that are out of the holder.

Down inside there is the voltage regulator, it is located below the brush holder. Later I will show a way to check the regulator with a small screwdriver.

Sorry for the fuzzy picture. You'll notice the plastic holder has a hole in it. This it the hole that a heavy piece of wire will go through. After cleaning the brushes, fit the top brush with it's spring into the holder. Depress the brush and spring far enough so you can slide the wire through the hole and in front of the first brush. Now repeat the process for the second brush, sliding the wire infront of the second brush and through the hole in the other end of the holder. Make sure the wire is long enough to extend far enough to go through the hole in the back of the alternator case. Be sure to leave only about a 1/4" wire yet on the top side of the brush holder. If too much wire is on the top side, it will make contact with the spinning part of the alternator when reassembled. I'd have to check but I believe the spinning part is called the armature.

Fuzzy picture, but it will show the end result of the brushes back in place.

With the brushes inplace, put the case sections back together, make sure the alignment is where you want the wire connections to be, now install the four bolts.

Now turn to the back of the alternator, you'll see the piece of wire you put there holding the brushes. Slowly pull it out of the alternator, you'll notice one brush, then the second brush snap back in place. And your done.

2-19-2012

Earlier I mentioned an easy way to test the voltage regulator that is inside this alternator. I also mentioned all you would need is a small screwdriver.

The designers of this alternator did a great job of creating a way to test this alternator. I once again am sorry for the miserable picture.

Ok, the vehicle is running, and you have a way to get to the back of the alternator with a small screwdriver. Look closely at the miserable picture I have provided. You'll see an arrow to the right pointing to a half moon hole. Just inside the half moon hole is a metal tab. The idea is when the vehicle is running you put the screwdriver into the half moon hole just enough to touch the screwdriver to the metal tab then at the same time touch the side of the screwdriver to the aluminum case.

It is designed that when you ground this tab while it's running, it will put the alternator into full charge. Since the alternator will draw close to 4 horse power when at full charge you will immediatly know if it is charging or not.

2-20-2012

hallsofstone, I figure most haven't had to deal with alternator stuff.....yet. but someday, or perhaps in the past, someone turned away from a project due to lack of knowledge. Your knowledge will carry your confidence.

but someday, or perhaps in the past, someone turned away from a project due to lack of knowledge. Your knowledge will carry your confidence.

Thanks for checking in.

While working on this '57 I'm not doing any major body modifications. One modification that was done before I ever started on it was the removal of hood and fender emblems. To be honest, sure, it smooths the look, but I still like the look of the old style truck too.

Soooo, I am looking at the original side fender emblems. They were long and oval and had the writing of "Chevrolet 3100" or "Apache 3100". Neither of these did anything for me, so I gonna step out of the box and try my hand at making my own.

I stuck with the same basic size and I wanted to put the size of the 396 engine in there also.

Once again I started with a paper tracing to get a feel of the size on the fender. Once I liked that I cut the main pieces.

I then cut the base plate that it'll all attach to and I thought the opening that the 396 aren't in needed something so I cut a filler piece for it also.

Once all the pieces are assembled, here is the look. I figure I'll drill holes in the backing plate that I'll be able to spot weld the pieces in place from the back side. I'd like to send them off for chrome plating, then I'd like to have the low spots painted to match the color of the truck perhaps.

2-21-2012

I think nickel does look good, I've seen it used. My only problem is I'd have a mixed batch of chrome and nickel. If I get around to the Willys paintwork it would look good there, but I have the same issue, I've collected some brand new chrome emblems already.

If I get around to the Willys paintwork it would look good there, but I have the same issue, I've collected some brand new chrome emblems already.

On the '57, I'm still focused on getting the engine bay odds and ends taken care of. One thing I've learned over the years is if at all possible, get the odds and ends taken care of, then disassemble and bag, tag and box everything. Assembly after the paint work is so rewarding without scratching the paint.

As I mentioned a little while back, I had to add a spacer to the header to get the clearance by the oil filter. The spacer looks like it solved my problem.

Only problem is.... now I have a gasket, spacer, gasket, then header flange. Also the header flange is 3/8 thick, I like the thickness, but before they ceramic coated it, they didn't grind smooth the edge so you can see the cut along the visable edge.

One other issue with the big block chevy is there is about 1 1/2" space between the bottom edge of the valve cover to the header flange. This space usually gets pretty hot and discolors the paint, or burns it off.

I also have an issue with after market spark plug wire holder/separators, they just seem to generic to me.

With one shot I hope to take care of all these issues.

This picture is the first design layout. It is a paper print of a polished stainless steel cover that will support the plug wires perfectly for each cylinder and cover the gasket, spacer, gasket look on the driverside and, cover the area that the paint looks bad after a while.

This paper cutout is to ensure I have all the valve cover holes and the plug wire grips in the right places before the stainless cut.

I trimmed down from the paper cutout on the computer and made the cut with 1/16" stainless. Rather dull at the moment, and the rust spot is just a stain from something else resting on the plate of stainless.

Here it is once I drilled the mounting holes, and no polishing yet. To me it looks a little large, it just covers too much space, but, This surface is going to have the plug wires running down the length of it. Once the plug wires are properly attached, it doesn't look so large and overwelming.

Comments

Great before & after!

Posted by Diggymart on 1/11/20 @ 4:10:28 PM

Gotta love the Willys! Good job...great build!

Posted by Diggymart on 12/10/18 @ 8:34:21 PM

Ultimate classic truck right there

Posted by CCmyVW on 12/26/20 @ 4:17:42 PM