You must be logged in to rate content!

6 minute(s) of a 65 minute read

10-14-2008

Alignment settings, have to adjust the toe in and maybe the camber. When we test drive it my first reaction was that the road noise was reduced, its runs more silence on the road now.

Now we have tried 2 option of changing the bolt pattern (not test driven the re-drilled hub yet). We can see what option that we can get the best result from. If this 2 option doesn't work well there always other solution, we are researching on another solution for changing the bolt pattern.

Next step for the Project Car 2 is getting other injectors and another fuel pressure regulator. But we let the project car 2 rest for now and working with the engine for project car 1.

I have contacted a dealer near us that fabricate custom exhaust manifolds, and I asked them if they could fabricate a collector for us and the could and for a real good price. After we have order the collector we gonna start fabricate the manifold. I hope, the engine gonna be finished this winter, but can promise anything

Thanks. I think I have pictures that you wanted, if not I take some more pictures this coming weekend.

10-19-2008

Requested pictures

Hope this pictures will do, you can see the spacers between the spokes. There is about 5mm of the spacers that is visible between the spokes. This differ what kind of rim you use, or you can paint the spacer black to make them more invisible

We gonna leave them like this cause there is so tiny bit of the spacer that are visible, maybe paint them black.

10-21-2008

The only way to test the strength of them is to test drive them really hard, but we haven't get the opportunity to test drive the car on a track or similar. But for now we are note concern about the strength and the company we bought them from told he have build bult-on spacers for V8 cars that are used for racing.

The bolt-on spaces are indeed well construct and feels very solid, I think it takes alot of HP and hard drivning to destroy them

But I will let you know if we have some problems with them.

If you guys have missed the movie I made I post it again (its also located in Resources > Pictures & Videos)

Edit 1: deadlink

Edit 2: Updated link to test run clip (36Mb).

Edit 3: Video uploaded to Youtube

12-24-2008

Mini Update

After rebuilding the exhaust system on Project car 2 we wasn't satisfied with the end exhaust muffler so we bought a new one. When installing it we also rebuild a part of the exhaust system at the end. The exhaust system is 2.5'' in diameter but on the end when the exhaust pipe goes over the rear axles we mounted the stock exhaust pipe, cause the 2.5'' was caused vibration on the chassis. But its only over the rear axle we have the stock exhaust pipe and don't think it will affect the exhaust flow to much.

The rear muffler is: Black Series NOOZE Black Muffler.

Merry Christmas and a happy new year!

12-31-2008

Collector from Customparts service

Yesterday we recived the collector from Customparts service, the result is fantastic. This is a local shop near where I live, my friend picked the collector from them cause I was at work. I told my friend to ask Customparts service if they could fabricate a custom exhaust manifold for the Peugeot 505 and they could and the price was reasonable (315EUR excluding collector). I have to e-mail them for more information.

So maybe we will order a custom exhaust manifold if the budget allow it. It would be very time saving and better to get a exhaust manifold fabricated by the professionals.

* Price for the collector 53EUR

* T25 Flange

* Dimenson of the pipes 42,4mm (good for 800hp according to Customparts service)

Happy new year!

1-18-2009

Parts

Pipes for the custom made exhaust manifold and I bought a late Christmas gift to my father a BOV, more expensive BOV and prehaps better than we got now on the Project Car 2.

3-22-2009

My friend offer some web space on his server. Due limited space on the server the video clip have been more

compressed and the quality have been reduced. But is better than nothing

3-26-2009

Exhaust manifold

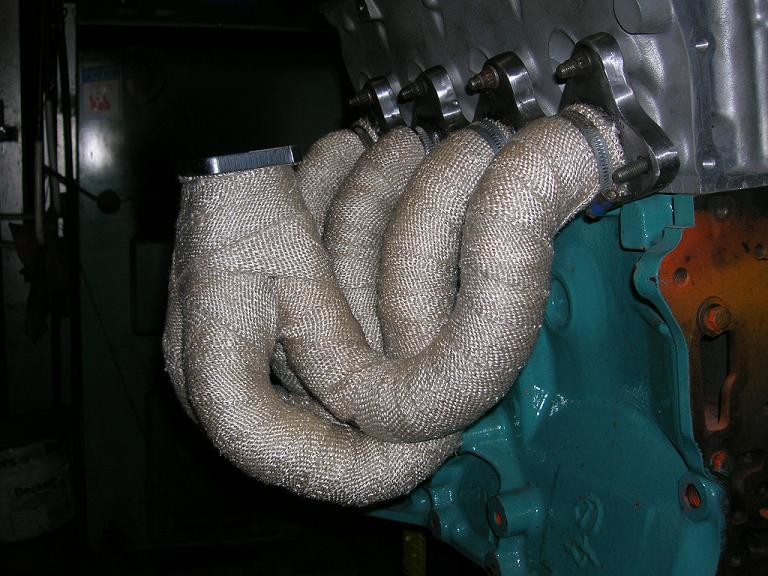

One milestone on the engine build is reached, the custom made exhaust manifold.

The exhaust manifold have a collector that cp-service have build with

a T25 flange and the runners are 42.4mm in diameter. Rest of the exhaust manifold are build and welded by us. We have wrapped the exhaust manifold with exhaust bandage. As a side note we have to custom made a engine mount on the exhaust side (OEM will not fit with the new manifold).

Next step in the engine build is the bottom end; grind and balance the crankshaft. But before we to that we have to find a reenforced clutch, the option we have is to purchase a Sachs or Specc clutch kit.