You must be logged in to rate content!

12 minute(s) of a 241 minute read

9-19-2016

Today i put in couple of hours work on the mi16 one of the jobs left was to make a hole for the shifter and test fit it, started by installing the center console to find the center for the shifter, the console was hitting the back of the tunnel so i cut notch it and made a plate so close it, for now i just tack welded in place, then i started on the shifter hole, started with a hole saw but it was too small and wouldn't go thru, then i drilled the pilot hole to 32mm biggest notch on my step drill to use as guide, then marked it and drilled many small holes, then removed the mid and use a file and hammer and dolly to finish it, now it fits the saxo rubber gaiter, this should seal good, the next 3 hours pass to fast to photograph, i had to redo the entire shifter mechanism, because it was hitting the tunnel, i still have an hour work to finish the mechanism, and weld the end piece, more to come

10-1-2016

Update time, progress on the project is slow, had to prep the yard and house for winter, so my spare time is going there, don't worry i should be back working on it in couple of days, i have to protect the bear metal and then pressure wash the entire floor pan so i can undercoat it, thats has to happen quickly because winter is coming, more to come.

10-2-2016

Lately i've more busy than ever, but i'm using every spare minute i can, after seeing that i can't use the factory manifold for the turbo, i decided to make the turbo manifold from scratch, couple of mounts ago i made a flange for the turbocharger, next is the flange for the exhaust ports on the engine, i spend an hour marking this piece of metal, and then i center punch all the holes, then pilot drill them and after that i drill them with the final size for the bolts, this will allow me to bolt i to the head so i can make a jig for the turbo manifold, i don't plan to built it now but i should make the jig now when the engine bay is dirty and not detail.

10-5-2016

Today i had some time to spend on this project so decided to make one more engine roll stop, i don't want engine vibration but also don't want the engine to move too much, the drivers side is supported on two places, on passenger side both mounts bolt to the engine with 3 bolts, and when the engine torques it will go to the right, so this is the design i come up with, started with 3 pieces of flat stock to make the flange to the engine, then i started on the other flange thet bolts the engine mount to the frame, for it i used two bigger pieces and weld a bolt in the back to make it easy to install and remove, then i mock it in place and fully welded it, in the background u can see where i started poisoning the turbo, stuff like this do take some time, more to come.

10-8-2016

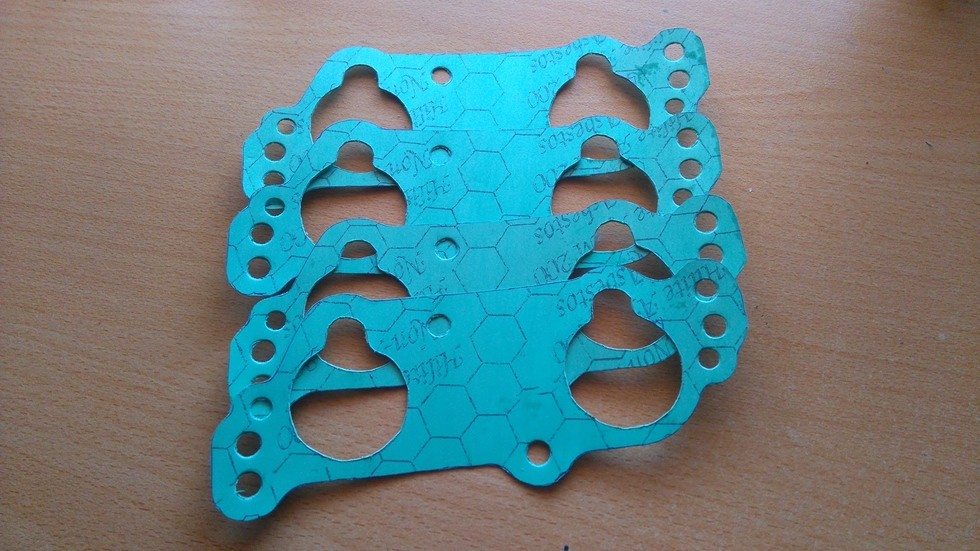

Today i begin working on the inlet manifold, last time a friend of mine welded for me, i didn't like the way it came out, so decided to redo it, started by opening the throttle body flange, for the bigger throttle body, then i cut out the ugly pice and formed a new piece, then started cutting back the welds and removed the black paint, did not finish it, had to stop, also made new intake gaskets from AFM 200, more to come.

10-9-2016

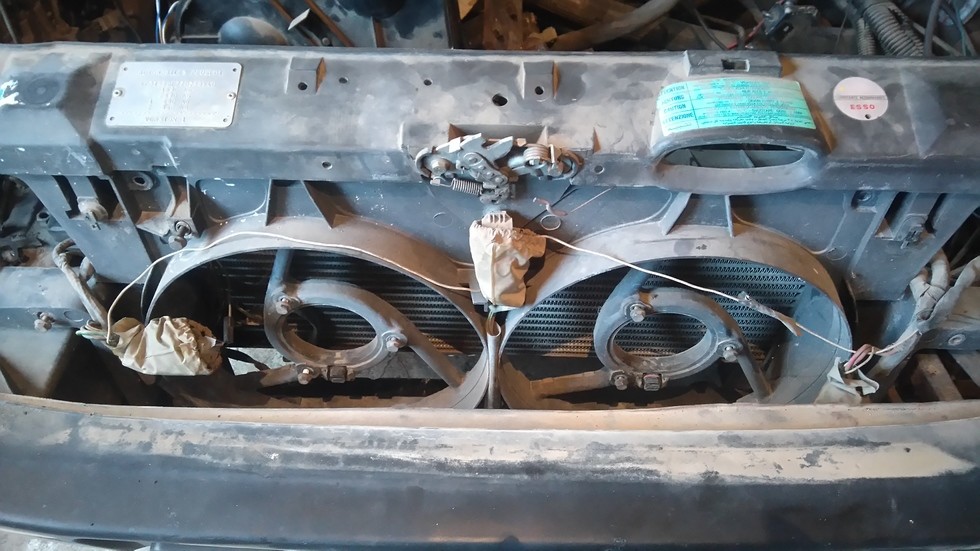

Today i decided to mock up the intercooler and radiator, first i mounted the rad support and front bumper, first i check in front of the support but is way too wide, it intrudes on the headlights, then i mounted it behind the support it fits nicely, it has enough space for the cooling radiator too, i need to make mounts for both and extend the shroud to funnel air flow, i also check the hood clearance, it seems to be very close to the outside screen of the hood, not sure if is inner structure there, if it hits i have to make some sort of hood scoop, i had those fans from a 305 if i wasn't able to use the factory ones, but this way is better, more to come.

10-11-2016

Today i started where i left yesterday, marked where i need to clarens the radiator support then removed and stored it and the bumper, then started on mocking up the turbo, because of the 30 degrees tilt of the engine there is absolutely no space, had to place it further back than i liked, and the flanges touch, so decided to tack welded together, after that i removed the turbo and the flanges, that was the last thing i needed to mock up, so i started removing the engine and box, started by removing the shifter, then supported the engine and started unbolting the engine mounts, then i unbolted the front brake calipers just moved them over and removed the knuckles and shocks, on order to be enabled to drill the rod end tapers from the lower side, the plan going forward is to make more permanent steering rack mounts and better steering shaft, the weathers been cold last couple of days, and my health is acting up, so i may wait for a day or two to become better, all the work i need to do now is upside down on the cold garage floor, more to come

10-14-2016

Today the weather was warm, so i've put in a 12 hour work on this project, most of the work was done from underneath, ground down all the welds, trim the edges that were protruding, hummer them flash and welded them,after the mount the steering rack and made stronger mounts for the rack, then made a new direct steering shaft, had to make a new hole for it to pass because the rack is so lower in the frame, actually made two holes the first was a miss, then i redrill the tapered holes for the steering rod ends, then i pressure wash the knuckles and shocks and spray them with anti rust solution to kill the rust, use the same solution on the new tunnel and you can see how it kills the rust in couple of minutes, i'll leave it overnight to neutralise the rust.

This was one of the hardest days working on this project, i've got red eyes couple of dozens burns from the welder, but i'm happy how it turned out, if i have time tomorrow i'll seam seal every seam and spray black primer on the new steel, more to come.

10-15-2016

Working long hours is not uncommon for me my personal record is 8 days hard work without sleep, i have a question have you had power steering fluid boiling problems, i'm at that stage do i keep the stock siple tube power stering cooler or i upgrade, i have had the fluid boil on this car twice it seems to happen when driving high rpm city turn to turn driving, for coolers i have those two, the bigger one i plan to run for the oil, the smaller should be more efficient than the stock tube type, what is your experience?

The original P/S cooler is underneath the driver's feet, i'm not that concerned for space there is enough space to go 4 coolers back to front because the engine is moved so far back, today i seam sealed all the welds, i used an entire package of seam sealer, more to come.

10-16-2016

Today i spend couple of hours in the garage preparing and painting the new metal now is all protected, i also painted the knuckles and shocks, more to protect them form rust, the plan now is to get the knuckles and shocks installed, car back on the wheels, and push it out and pressure wash the engine bay and floor pan, to be able to undercoat the new metal and thin spots on the floor pan, and then decide is the engine bay bad enough to be painted, i'm not sure but it seems peugeot painted the wheel wells same color as the paintwork may do them as well, should be fun cleaning all the old grease and grime, more to come.