You must be logged in to rate content!

10 minute(s) of a 241 minute read

8-4-2016

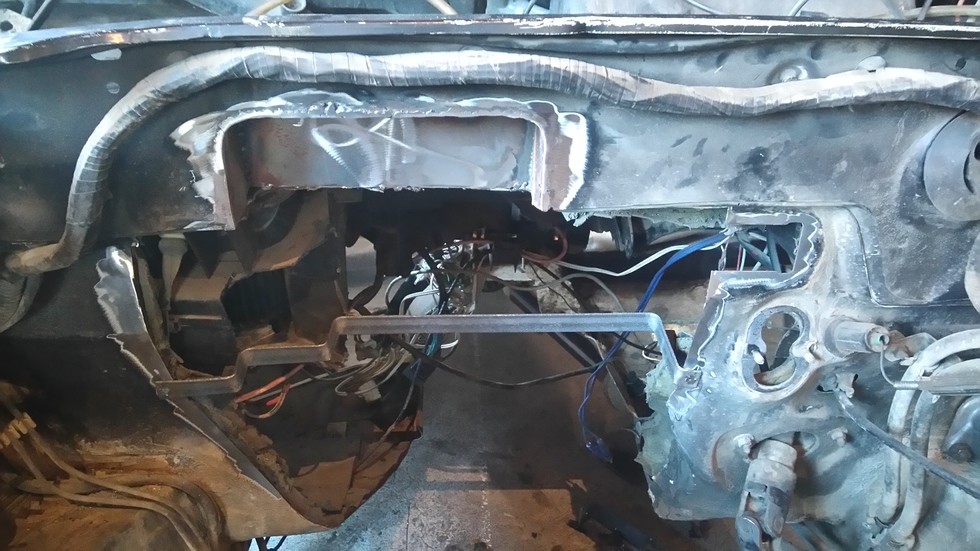

Today i was finally able to work on the mi16 again, started by cutting even more metal out of the firewall, floor and subframe, my thoughts are if i have to change the engine or box i will have more room, therefore bigger tunnel, at first was going to making the tunnel round, but that means having to roll a big piece of 1.2mm steel, which is hard, then decide to make it square, started by making the dividing support, made it from 20x20x2 angle iron, which was quite expensive for what it was, place it in place, and started making the new firewall, used paper to make a template, transferred it to steel, cut it and use the press and bending jig to make the big bends, and bend the little edges by hand, and punch weld thru holes and started trimming it in place, now is roughly welded in i also made a little piece for where the A/C lines use to come out, there's more welding to be done, i had to stop, more to come

8-7-2016

You've heard when it rains it pours, well we had an enormous freak storm, it hit about 20 km from me, and is not over, we will have one more tonight and tomorrow, you can search:Macedonia storm 07 08 2016. Once things come back in normal i'll be back to work on the mi16.

8-9-2016

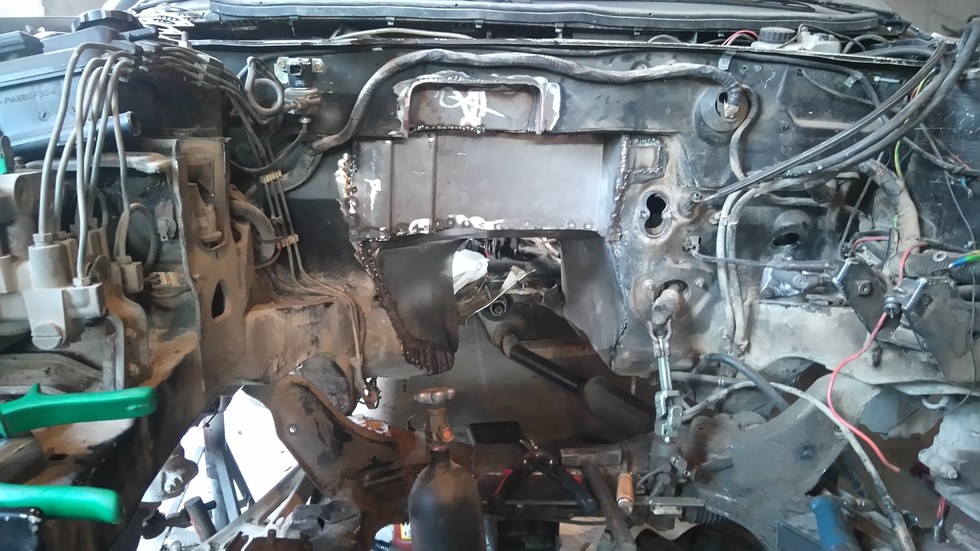

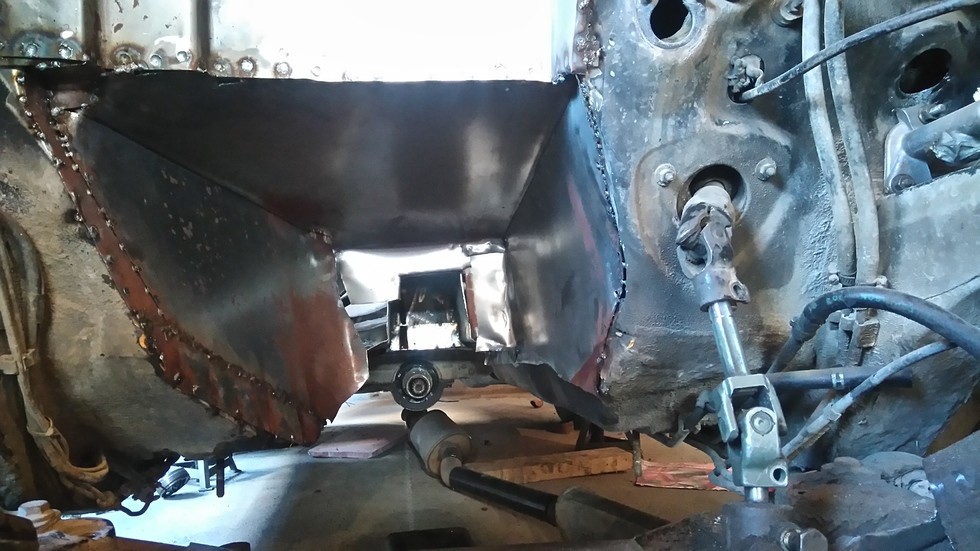

Things are settling down, the freak storm took 21 lives, i decided to work on the tunnel, started by bending all the edges, to be able to weld the tunnel, to the body, then i made a paper template, then cut it in steel and bent it, then i used couple of jack's to spread it in place and weld it in place, i caught the insolation on fire, almost burn the car down, got couple burn blister no my hands from putting it out, at the end used a CO2 bottle to extinguish it, no big deal, now i need to make one more piece and be done with the sheet metal.

8-13-2016

Today i continued working on the trans tunnel, started by cutting more metal out to make it square, starts with tin snips, to avoid sparks and starting another fire, then use hammer and dolly to bend the edges and punch holes for welding, then i made the metal piece, had to make it that shape because i want to install the original center console, and started to weld it in place, it fits nicely, i need to finish welding it, may not be the most beautiful but should do the job, more to come.

8-31-2016

Everyday jobs have keep me away from working on the mi16, also other home jobs made the garage a mess, so today i finally found some free time to clean the garage so i can resume work and get it finished. You can see there was no place to work or move around, the rear axles are for a another project that i need to finish before the winter begins, it includes peugeot xud9 engine, but i'm not sure if is it appropriate for this forum, in the meanwhile i've been sourcing more parts for this build like a bigger intercooler couple of fans, and other miscellaneous parts that i was missing, now that the garage is clean i can continue work on this project, more to come

9-1-2016

Today i put a solid day of welding on the car, started with the exhaust header, then turn on the engine mounts, i'm particularly proud of the gearbox mount, then moved to repair the rusted piece in the passenger wheel well, first cut and clean all the rust then made a paper template, then made it in steel, and then weld it, then started welding on the new passenger side subframe, then i weld the sway bar mount this took some time because all the sides had holes so i had to plate them, then i cut the front frame straight and plated it with 2mm steel same thickness as the frame, last thing i did is dropped the steering rack not to damage it, more to come.

9-8-2016

Today is independence day in my country so i had some time to spend in the garage, i put in about 8 hours of welding, first i finished the tunnel, i need to test fit the engine before i protect the new tunnel, then i started on the drivers side subframe, there was a lot of welding there, as a final job i decided that i should remove the extra steering shaft joint, to connect them i got out my spare steering shaft cut it to extend the one on the car, more to come

9-16-2016

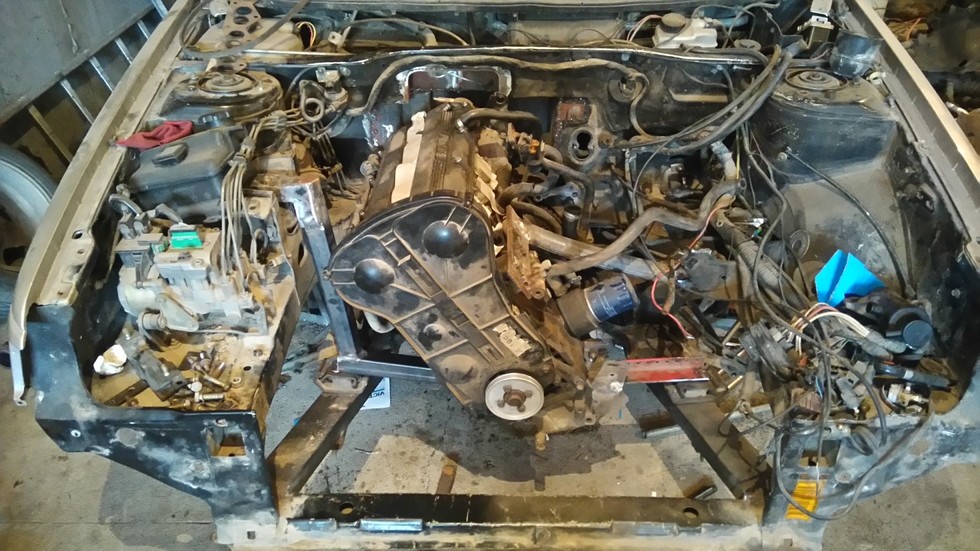

Today i reinstall the engine in the engine bay, to check for clearance, it wasn't the smooth install, it fall from the engine crane when i bolted the gearbox mount, so when it drop it rip the mount, so i will order a new one, it clears everything and it has more than enough space all the way around, i'm thinking about installing one more engine roll stop on the passenger side, when the engine torques it won't move too much

9-18-2016

I've mentioned in a previous post that i've got a bigger intercooler for this build, i've been so busy i haven't even looked at it, to day i offer it to the car and is little too big, way to wide to run it behind the grill, and the shape of the mi16 bumper, the air grabber is low on the bumper, so i need to position it there, i would like to position the pipes in the upper position, because lines up perfectly in pipe diameter and location to the turbo, but hit the mainframe if i flip it it will fit with a little cutting, but i don't like the 50mm side to go to the intake, i'm wondering if i can make new aluminium tank for one side and weld it without destroying it from the heat.