You must be logged in to rate content!

9 minute(s) of a 241 minute read

7-5-2016

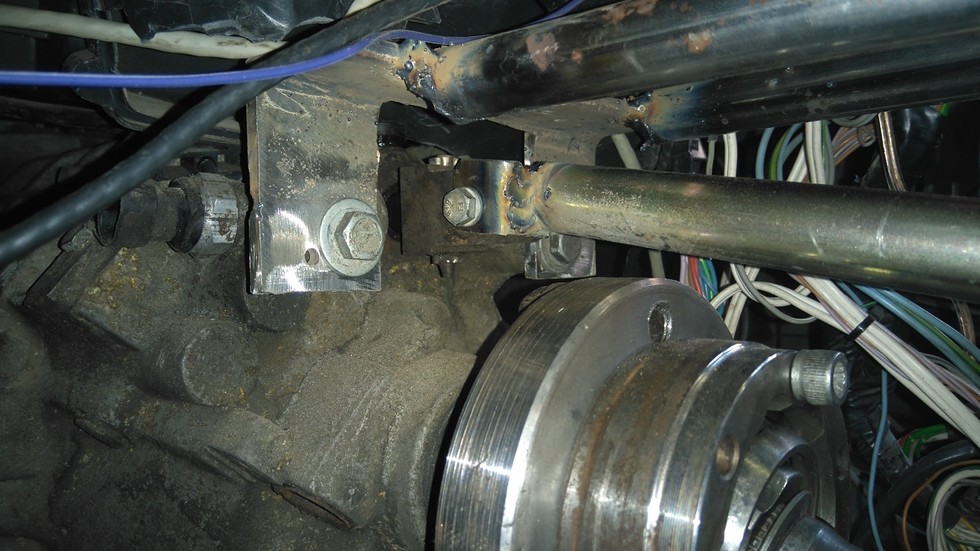

Today i span a full day over a lathe this couple of pieces may look easy or simple but they are crucial for this conversion, the first you've seen before, i just re drilled new set of bolt holes and taped them for the lobro joint, the original flange for the mi16x4 drive shaft is cast iron and known weak part, so i found a forged flange from some russian 4x4, and let me tell you is really hard, we used up a full pack of lathe tool titanium inserts,the other flange came from some vw and is also steel not cast iron, so it should be strong, next i need to weld them together and start test fitting it in place, it took me an entire day but i should be able to continue with the exhaust, shifter mechanism, tunnel sheet metal, more to come.

7-6-2016

Yesterday's machining took way longer and i had couple of jobs backup so today had to finish them, only progress is i bought couple pieces of exhaust pipe, i'm making it from 60mm OD that's the same bore as the manifold and i will split it at the back, i always wanted quad exhaust tips, i also bought this big piece of steel to make a new exhaust header flange, , to make a complete turbo header, i contacted couple of companies, that have plasma, laser cutting machines, but it seems that they have them to say that they have them, not to use them, it will be the hard way, i have to drill it and cut it by hand, for now i plan to mock-up the two flanges and to locate the turbo so i can connect the pipes letter, now i have the most access and later when i find an standalone ecu i can just unbolt the header and bolt the turbo manifold, i will use a ball and socket flange so i can change a small section of the exhaust and the ball will allow little movement, i like to avoid a flex joint, because they do not last, probably cheap bad quality.

7-9-2016

Quick little update, i've been busy, next part on the list is the driveline, the drive shaft needed the support bearing changed, and i do not see reason for it to come out, i clean it removed the old support, i was surprised, the splines tapered down to 22mm and that will be a weak spot, after that i prep it for a new coat of paint, i don't care too much for the look, more to protect it from rust, tomorrow i'll reassemble it and start the drive shaft mock-up.

7-11-2016

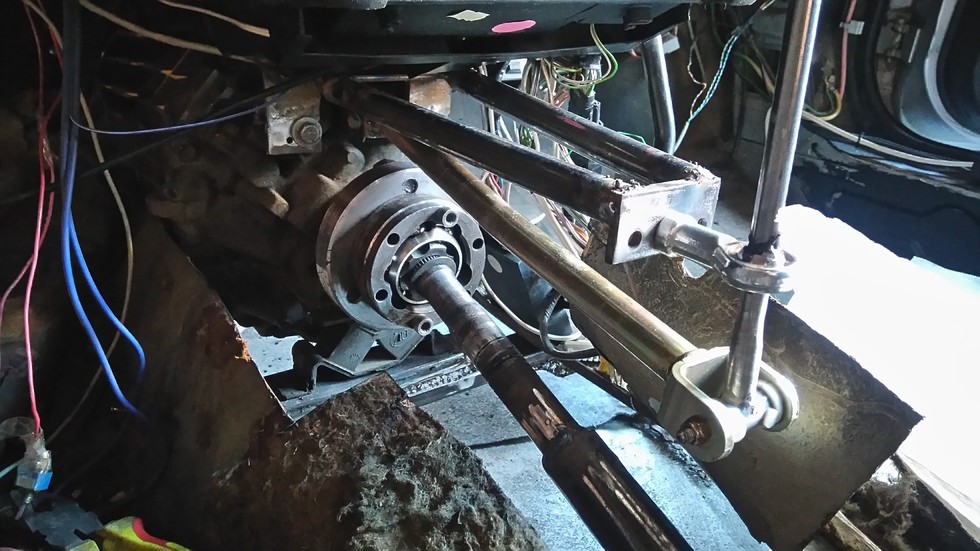

Today i finished refurbishing the drive shaft, press in a new bearing in the support, then press it together on the drive shaft and pressed the protective cover and seal, then i installed the driveshaft on the car and tighten the bolts, after that i had to retread the adapter holes and had cut back the shaft from the gearbox, after than i use a tape measure and the mesurment was 40,5sm or 405mm funny that, then i mark and cut both shafts, chamfered both ends, clamped them in angle iron, and welded them, after that i shorten the sleeve and drilled 10 holes and again welded it, after it cooled i installed it and i was enabled to turn the back tires with a ratchet on the crank pulley now is connected, not sure how it will stand up to abuse, when the shaft was cooling i did some work on the exhaust, i was looking for couple of bends but could not find in the size that i needed so i'm using old ones that i have, more to come

7-13-2016

Yesterday and today i've put in 26 hours working on the shifter mechanism and clutch master cylinder, started by measuring the original shifter, and placing it little closer to drivers seat where is more comfortable for me, after knowing where to place it i made couple of brackets for the gearbox, test fit them and they did not fit so i made a new one bigger for the mounting flange on the box, redrill the one for the mehanizam and made one more for the shifter to bolt to, the shifter handle itself, i made it couple of weeks ago and it fitted nicely, as the bottom part was from the 405 i use the rod to, i had to straighten it on a press because it had a band and that made the shifter stay crooked, when i strengthen it it was perfect, after that took couple of measurements cut couple of tubes and had to tack welded it in place, then took everything of the car and welded it solid after that reinstalled it found the right hardware and tighten everything up, if i lower the shifter lever down the shift throw becomes shorter, found this happy medium and left the lever long, leter when i get the center console in place i'll trim it. After that i started on the master cylinder for the clutch started by measuring everything and drilling a big hole for the cylinder to pass, i had to hummer the sheet metal little so the cylinder will mount straight, then i drill two more holes and bolted it i had to mount it with the input sideways so i can bolt the line to the slave cylinder, after that i drill a hole in the grommet for the abs loom and run a hose to the rezervoar i decided to put it next to the master cylinder to keep the firewall clean, the rezervoar fitted nicely, next went on the inside, drill two holes and shortened the rod and it attach with the original hardware and spring, hard work but i thing is worth it how it turn out, more to come.