You must be logged in to rate content!

10 minute(s) of a 241 minute read

6-27-2016

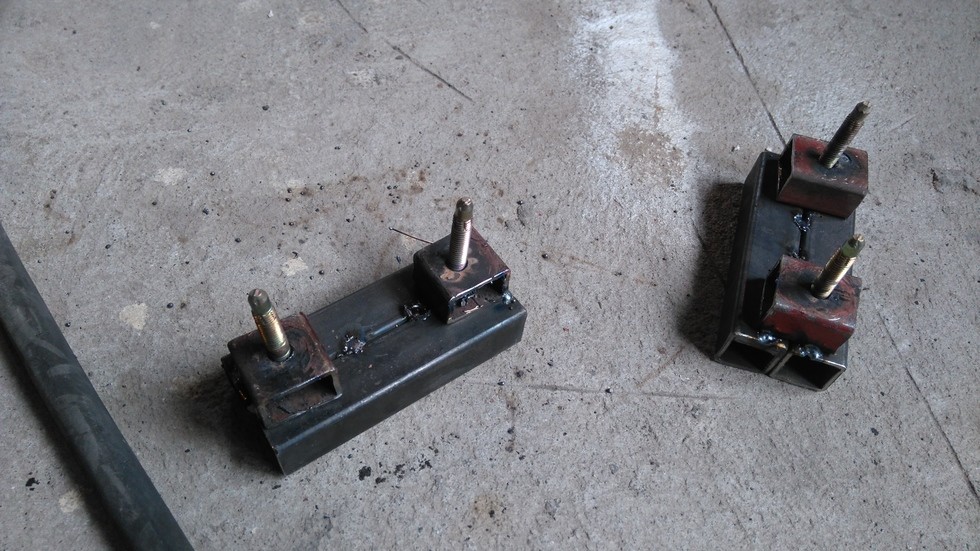

Last couple of days i've been organizing the garage, to be able to found all the sway bars that i have, i had 14 of them, couple are too long hitting the tires, started with the original one there was no space to install it towards the cabin, because it hits the steering rack, flip it towards the front and the tire hits it, then after couple more those in the picture where they came closest to fitting, the thickest was going to lay way to low, the one on the floor seams to be the right it is thinner at 20 mm, but the ends are longer and should apply more force, and the front end should be lighter as the box is in the middle, and by the looks i will have to run one more front crossmember to be able to bolt the sway bars on. Not too much progress but now the garage is clean i should be able to work more effectively, more to come.

6-28-2016

Today i went to the car breakers with a tape measure and a measurement to find a sway bar that will fit my set up, this time i strategies, scrap steel to those people is like gold, and trying to buy heavy part they charge too much, so i loaded a scrap engine block, with the intention to lower their prices if they say i can get that much for scrap, i will say hire you go, and it turned out better than i thought, they said how about straight swap, in weight so i got them for free and cleaned my garage, so i went searching in the yard searching for the right one, and the closest was form B5 vw platform, got two front bars and one rear, one was from a passat estate and was 27mm the other was from a audi S4 and it was 31mm, they are identical except the thickness, it was a hot day and lying underneath the cars dropping the entire front subframe was hard work. Thet took me awhile but when i got back i could not leave it just sitting, i test fitted it, and it fit like it was made for it no need to run a diagonal cross member to attach it. Then the work started with the bar i got there links but they point the wrong way, the rears are too long got the 405 links, thay are shorter but way longer then i need, so i shorten them, cut them chamfer the end i aligned them and welded them, then connected the sway bar at both ends and lifted it in place, i needed a small spacer to clear the oil pan, little closer to the oil drain but it should be fine, and it will protect the oil pan from bumps, next i had to drill the bolt holes bigger the 405 had thicker bolts, so i made the spacers and brackets from some tubing, didn't weld them fully because i was tired, after that i disassemble the mi16 driveshafts i need the outer part to hold the wheel bearings together, i remove the inner core and ball bearings from the passenger side and protect it with a piece of rubber. As a last test i needed to check if the tires will hit the bar at full lock, i needed to do a quick aliment of the wheels, but both lock nuts wear size, one let go with heat, the other one was solid, had to cut it and split it, run a die to clean the threads and installed a new nut, and the tires clear the sway bar, it was a long day, more to come.

6-29-2016

Today i've been busy with everyday work, did not work on the car but made a plan. Jobs need doing are making a shifter mechanism, but i can't make it before i connect the gearbox do the drive shaft to avoid it, some way to make the speedo work, 405 is mechanical with a cable, the gearbox i'm using doesn't have provisions for cable, it is going to be hard to make it function, making a exhaust, probably will make a header for the turbocharger, and install the intercooler, intercooler piping, cooling system. Next thing is the sheet metal on the firewall and gearbox tunnel, finish welding a subframe make steering rack mounts and a protective garde for the rack, finish mounting the accessories, modify the intake manifold, probably detail the engine bay, more to come.

6-30-2016

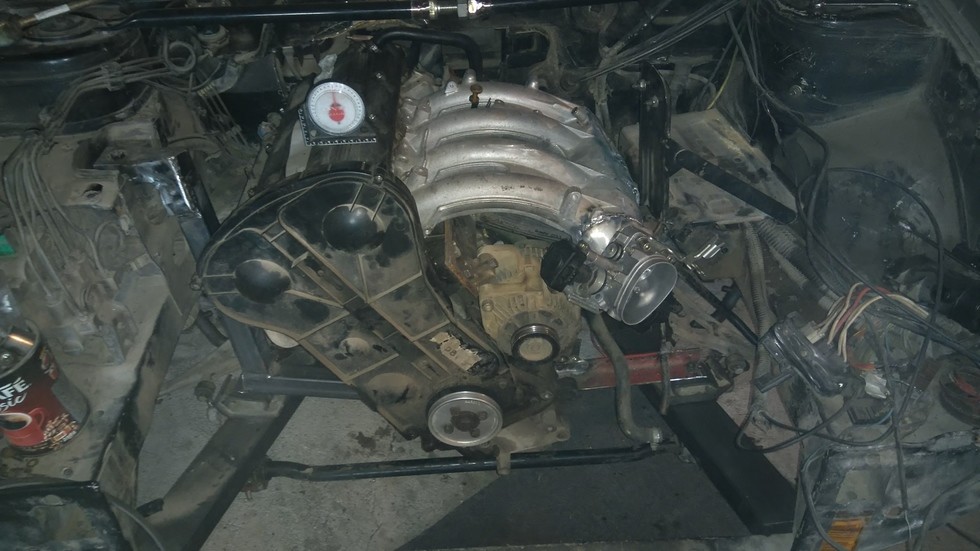

Today i modify the intake manifold i needed it to face the other way, and i wanted to get rid of the core plugs, end two fell off on their one, wanted to make it tapered with a rounded end, so i used a aluminium fire extinguisher for the round part, the middle part did not come out as is should, and is hitting the battery holder, i will cut it out and weld a new part, i welded the throttle body sideways to clear the alternator, this is a big part of the conversion and is not completed, but much better then before, this took a full day a lot of welding, more to come.

7-2-2016

Unfortunately during a thunderstorm we had a big power surge and it blown all the light bulbs and their holders, it was like a thunderstorm inside the garage, during the day i'm busy, most of the work on this project i do in at night, now without light and couple of blown fuses i need to repair the garage first before i work on the car, during the day i removed the box for the relays and fuses next to the timing mount, i had to bent the brake lines little, it should fit and it will be highest point in the cooling system, the expansion tank is from a peugeot 605 and it has two air vents, they will make purging air from the system easy, i like to keep all parts PSA corporation, more to come.

7-4-2016

Today i put a full day of work in the garage, most of the time i spend fixing the electrical for the garage, organizing parts searching for a mounting brackets for the power steering pump. I also mounted the pulley to the pump properly, had to re drill the holes bigger, and then file them out, to fit the holes on the pump flange, you can see all the brackets i found but none fits, reason because the progress is slow is i'm waiting for a flange to be machined for the driveline, getting frustrated with the mounts for the power steering pump i moved to the exhaust, first remove the manifold and cut the ears were the bolts attach, install it in the car, way to tight to the frame, cut it back just behind the flange, this means i need to weld the two halves together, more i looked at it more i found little cracks plan to weld them later, in the last couple of pictures you can see how much carbon can a exhaust pipe get on the inside, both pipes are out of exactly the same make and model of car one owned by older men the other by a young, can you guess which is which, in the carboned one you can see the swirl from the turbocharger.