You must be logged in to rate content!

9 minute(s) of a 461 minute read

10-3-2011

Well its been a long time coming but Ive finally got a rust free Mini!  Thats the inner and outer passenger sill done along with the passenger side tubbed arch. So next is the front end which, if not done/started already, will be done Friday morning when im next out. Or at least started on anyway.....

Thats the inner and outer passenger sill done along with the passenger side tubbed arch. So next is the front end which, if not done/started already, will be done Friday morning when im next out. Or at least started on anyway.....

The much needed pics!

Phil worked on after I left the other day to get the metal into place for the tub.

Leaving an ample lip for me to trim down this morning

And then the remaining bits that needed repaired were patched up. Doesnt look too pretty here but they are yet to be dressed up and the floor/arches are getting stone chipped and painted black anyway and the wheels/arches will easily cover it all. Function over form for once!

Trig gained a friend in the form of an Austin A35. Pretty solid looking thing but in for some welding work on the front arch.

And sill on. Hadrian panel but does the job....just.....fit was ok thankfully but did need a bit of tweaking to get right.

Progress progress! Roll on Friday morning

10-7-2011

Was at Uni this morning and got a text from my dad saying my bootlid had arrived.....what bootlid you ask? Well this one to be exact......

As you can see in this photo the filler they used on the lock holes has sunk. So that needs dug oot, welded and properly filled! Theres a couple ripples in the finish but again it will all be sorted out.

eBay bargain find! Full metal skinned lid with a little ripple where the top lock was before. Easy to sort and will save £££s in labour with Phil! Affa happy! Its already got an internal release mechanism on it but just need to source a mount/part that will go inside the boot itself and get a cable system into the car. It appears to be a bonnet/boot pin from another car of make unknown so may need changed altogether. Mounting plate is welded on though so it will be easy to sort out hopefully! Holes for hinges will be removed and hinges sourced for internal ones. This things going smoooooooove!

And here is the back showing the mechanism...

Its fitted with Torx bolts so all I know is that its off a modern car. No idea which one but going to go find a replacement asap.

It still has the original recess so that bits kinda hollow and it shows how the lids been made. Plan is to get it painted and make up 3 panels to the shape of the cut outs on the inside. Get them slightly smaller than the recesses and get these parts then carbon fibre wrapped (in real carbon not the sh1tty vinyl....) Nice touch and hides the truth!

So I know have 4 bootlids in total......so anyone in need of a genuine bootlid? Got 2 for sale at £20 a pop. PM me if you need!

Also got a call from Phil around lunchtime. The front end is now welded on  Not bad for a mornings work! No pics of the front welded but its done and will get some tomorrow

Not bad for a mornings work! No pics of the front welded but its done and will get some tomorrow

Out tomorrow morning to work on it again. Bring on the sanding and filler!

Another mornings work done. Now the panels are on its a case of paint prep. Scotch Brited the intricate details and will take the Mirka sander over it for the big bits. This included working under the arches which was dam uncomfortable but it means the stone chip will have a good key to stick to.

And I got to work on the bay getting rid of the rust and old stone chip/sealer crap with the MBX. Satisfying job!

and the panels done too....

And I forgot to add this to yesterdays update but my parents tidied the garage ready for the cars return.

So Ive now got three areas. Cleaning/prep/paint, assembly, and final assembly

Main bench is all cleared to resto small parts and we have an old pasting table for putting all back together again and the rest of the garage is free for the car to return to.

Also as I will be working on the car over winter its going to be cold in the garage. So we took some old carpet tiles (retro!) from the loft and put them down. Something soft for the car to go onto, to kneal on and also easy to replace when they get damaged/spilt on! Brilliant idea!

More progress monday afternoon all being well

10-10-2011

Well Ive been doing uni work/been at uni all day so thought I would wind down by working on some parts in the garage. Loads of suspension and steering parts to recondition so I set to work.

Started with a radius arm. Clarted in muck and covered in surface rust too.

Took apart most of it and gave it a once over with a wire brush

Then put loads of Deox Gel onto it and left it for about an hour whilest I worked on some of the smaller things.

The hub came up really clean after the same treatment.

Then once I had aggitated and then washed off and degreased the radius arm I put on a couple coats of brush on smooth black hammerite.

Came up a treat and just needs a few more coats!

Also got the steering rack done, just need to leave the track rod ends soaking in WD40 as they are well and truly seized.

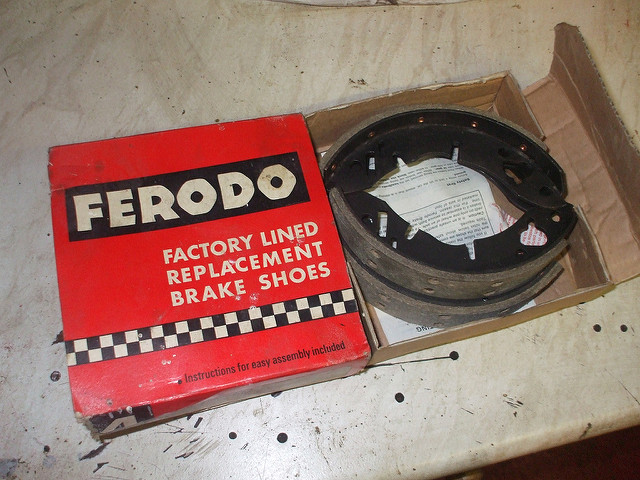

Also dug out an old cupboard and found a set of brand new Ferodo drums brake shoes. Result!

So more progress down. Running out of parts to redo quickly which is good! Just need subframes blasted and I can get them all reassembled again!

Comments

I LOVE Mini Coopers. Wow fantastic detail / photos here!

Posted by Diggymart on 1/22/19 @ 4:17:19 PM

Congrats BOTW what a beauty!

Posted by Diggymart on 2/6/19 @ 3:15:15 PM