You must be logged in to rate content!

6 minute(s) of a 461 minute read

5-23-2016

Fully disassembled the gearbox last night and started going through cleaning and blasting everything today. Looks like it's in good condition throughout, minus the broken collar on the selector pin. Planning on replacing a few common fault parts like bearings and potentially a cross pin diff (to future proof the box if I do eventually modify the engine too).

With the box locked in both 1st and 4th gear it meant I could remove gears without the shafts spinning freely. The bearing on the end of the mainshaft was a pain in the arse to remove as I didn't have a bearing puller at the time. Bought one now which helped on other ones. The nut behind this needs a 1-1/8 socket but as nowhere in Aberdeen seems to sell imperial stuff anymore (tried 5 different motor factors), I had to get a 29mm from Gibbs which did the job. Had to stand on the gearbox and use a bit of old exhaust pipe to apply enough torque to get it off though.  Here's the selector pin collar in all its sheared glory

Here's the selector pin collar in all its sheared glory

This should be symmetrical. Turns out this is a ridiculously rare failure and the part is now obsolete so I will have to source a decent used one instead of buying new.

All parts removed and disassembled awaiting cleaning

Cleaned the inside of the box with Autosmart Tardis which made light work of the years of oil, grease and debris that had collected inside it.

And I started to remove the casting marks from the box for a smoother final finish to help future cleaning and gives nicer finish when the Powdercoat is applied.

Hoping to have the engine removed sometime this week so I can get ancillaries off and stripped ready for coating as well to hopefully get a bulk buying discount.

7-5-2016

My overpriced and totally pointless titanium bolts arrived after a short delay due to broken tooling. They are ace.

Will give them a polish up before fitting

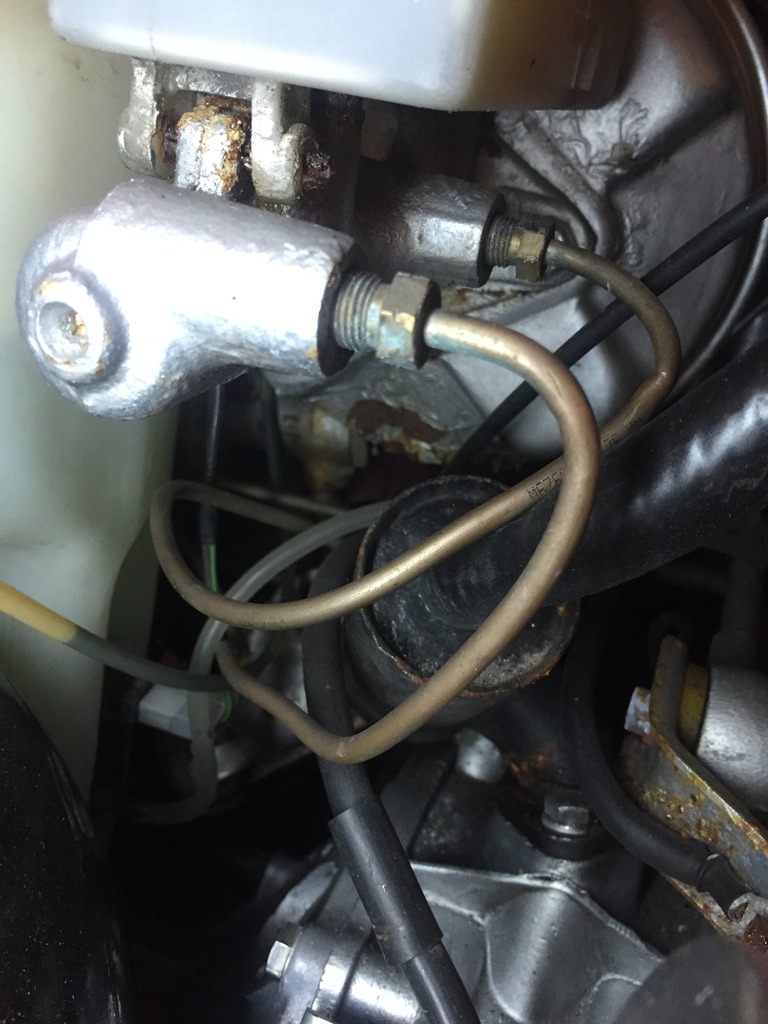

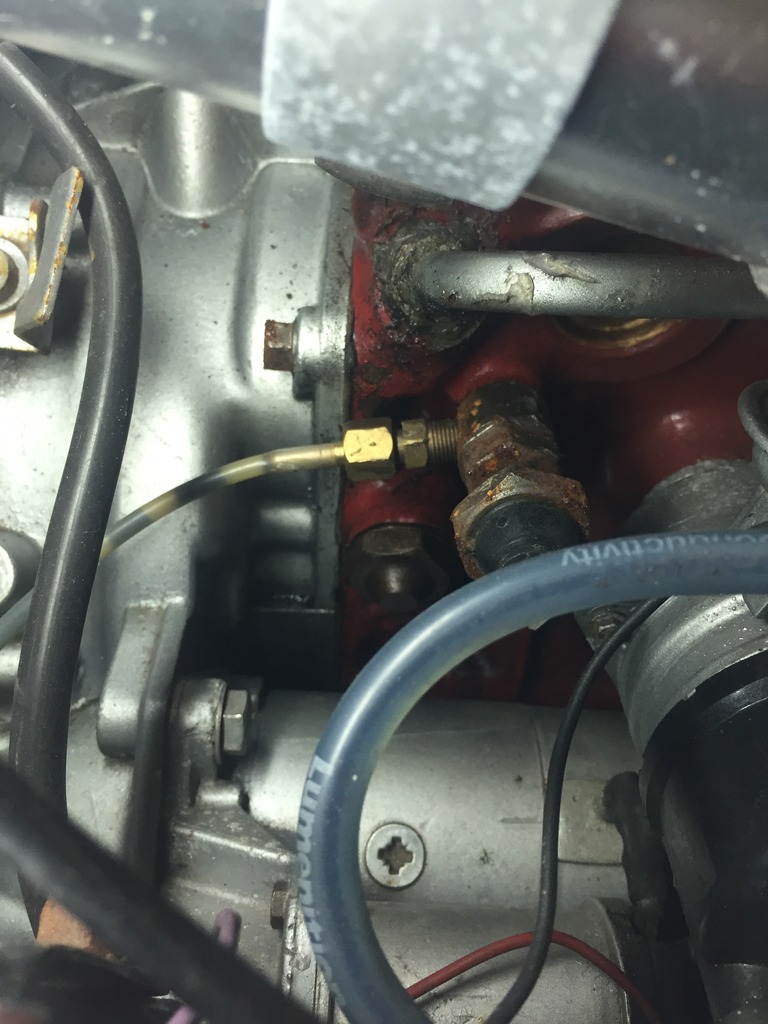

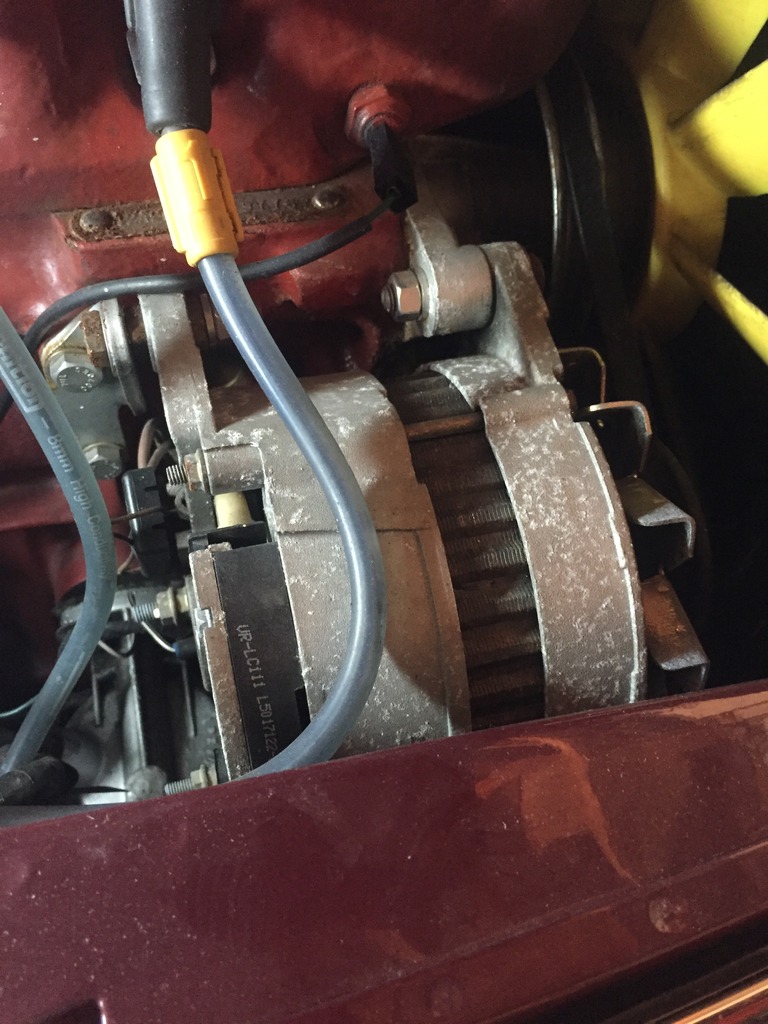

Got some time to get stuck into this last night again. Still smoothing casting marks from the gearbox casing but as that is boring to do I started to strip the bay ready to remove the engine.

Heres the current state of the enginebay.....what I would call a complete mess.

Also diagnosed my **** ride quality issue. Suspension cones have collapsed. Set of new ones are only £160 which isnt bad as they have lasted 7yrs.

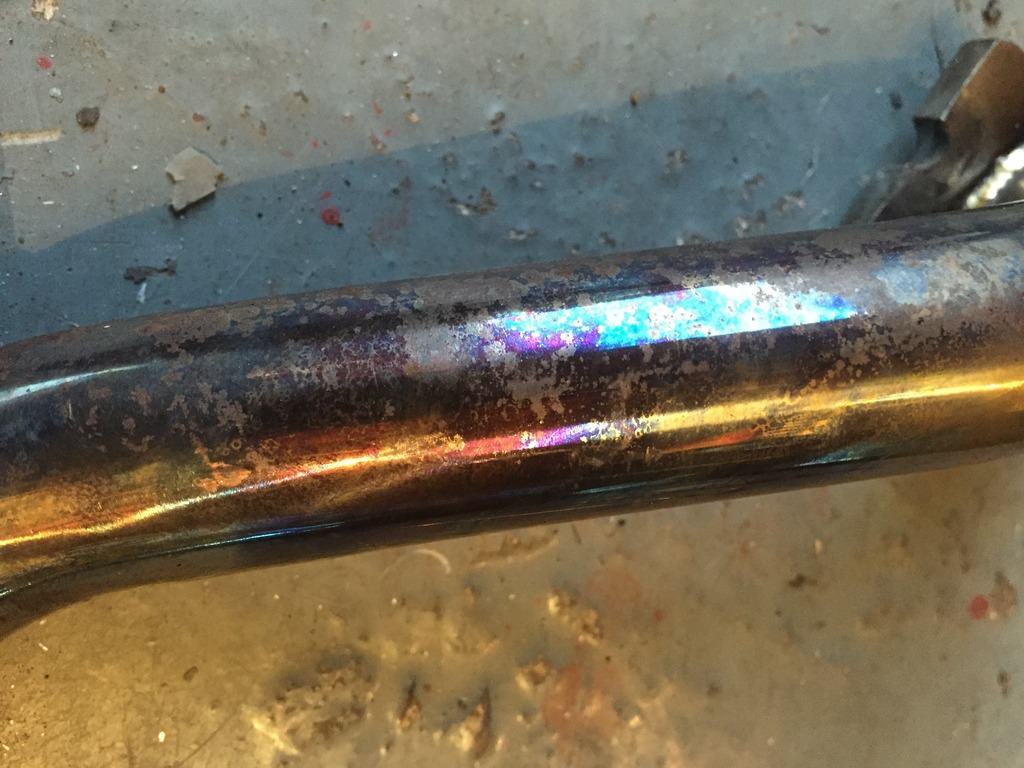

Obviously had to take the exhaust manifold off and its turned a lovely shade of rainbow with the heat. Polishes up bonny too.

All that remains is to drop the fluids, disconnect the driveshafts and its ready to rip out. That will mean I can get the other casings from the flywheel/clutch side, along with lots of other bits, powdercoated at the same time.

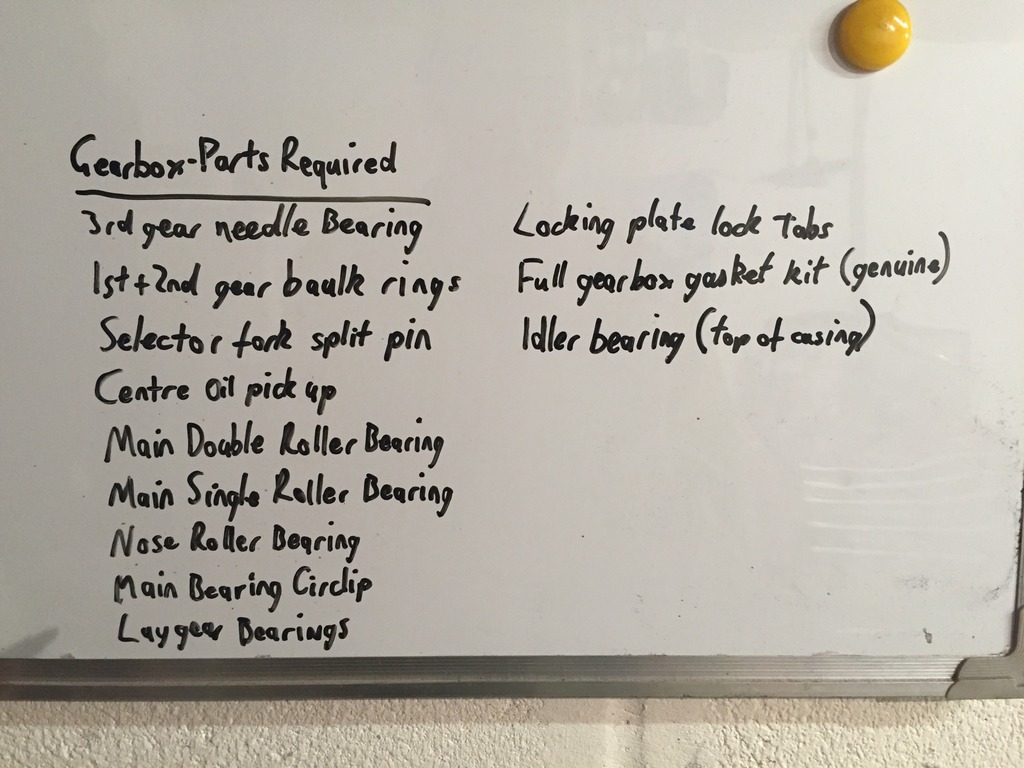

Got a list of gearbox parts I need so will try and get them ordered after payday.

Feels great to be working on the actual car again. Lots of ideas developing as I go so should be good fun

Comments

I LOVE Mini Coopers. Wow fantastic detail / photos here!

Posted by Diggymart on 1/22/19 @ 4:17:19 PM

Congrats BOTW what a beauty!

Posted by Diggymart on 2/6/19 @ 3:15:15 PM