You must be logged in to rate content!

3 minute(s) of a 162 minute read

2-13-2007

nar, did a lazy photoshop tho, with a pic of a car from bingly - this was just to give an idea of scale, nothing special....

Also, whilst i can't work on my actual mini, i've started work on my CAD project for one of my uni modules, which is a 3D model of my mini in alias. I was thinking about showing progress of it alongside my real project... not go much to show for it ATM tho, just made a 10x6 GB alloy and a bit of the side of the car....i'll post something when it looks recognizable

oooow yea

2-14-2007

How coooooool would that be if i could do an endo  lol

lol

I think you underestimate the strength of the kevlar front - they're damn strong - it the carbon bonnet bit thats a bit more fragile.

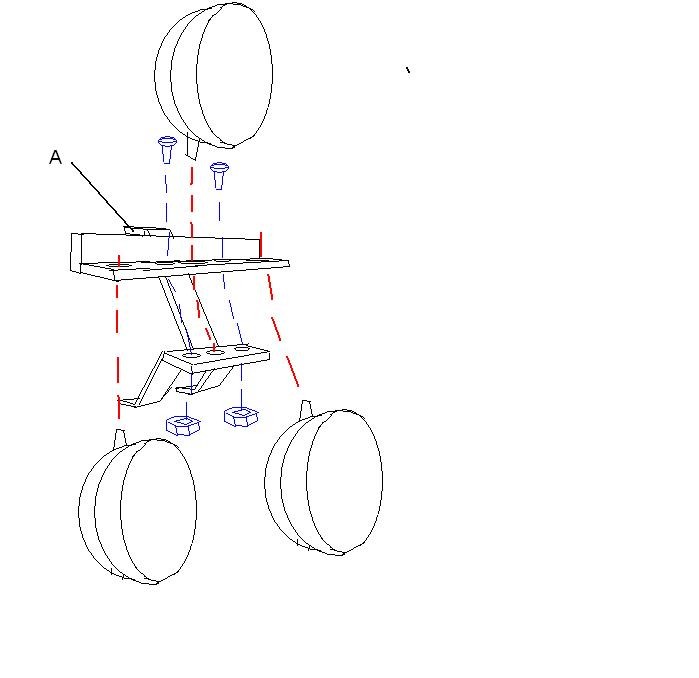

ere you go, to give you an idea of of how they will be made.....

Braket A will be made from a wide strip of steel, then i will cut a pair of slits into it and bend it with a hammer and blowtorch  It will look very similar two a 2 up 2 down bracket - except with two bottom legs. Then the bit of angle it just there to space out the two bottom ones apart, the angle will stop any flexing. Does that make sence?? The idea is to make it without welding, simply because i can't.

It will look very similar two a 2 up 2 down bracket - except with two bottom legs. Then the bit of angle it just there to space out the two bottom ones apart, the angle will stop any flexing. Does that make sence?? The idea is to make it without welding, simply because i can't.

The braket will attatch to the ridge behind the bumper lip, and on what would normally be the slam panel on standard bonnets, easy peasy

Love Mini Coupes! My best friend has one.

Posted by Diggymart on 4/12/19 @ 1:35:23 PM