You must be logged in to rate content!

5 minute(s) of a 636 minute read

7-30-2019

well first things first... i got a package in from FedEx today, and it was from Uvira. Opened it up to find MY 1929 Reflectors, well the set i just sent him last week. they look great !! i validated they are mine, and when i get time i will open them up and start my headlamp assembly.

task for the night was to try a few suggestion i received to get the brake shafts moving freely when tightened down. Noting that with all the hardware installed loosely, just enough to hold the assembly up in the frame, the shafts turned freely very little resistance at all.

first made sure the bushings were moving and rotating, just in case a bracket was crooked or off. made a small tool out of aluminum, basically a 1" wide flat piece maybe about 1/16" or so thick and rolled the 1" wide part over a socket and beat it with a mallet to make it lay flat against the bushing face. then used the mallet to tap the flat end of the aluminum bar to see if the bushings move, they all moved pretty easily when not under any stress or tension while installed. this had no effect on the spinning of the shafts. once i tightened the front bolt on the drivers side i could NOT turn the front shaft by hand and the rear shaft was a lot harder to turn.

second tightened everything down and then used my mallet to see if tapping the brackets would assist in easing things up, maybe brackets were not straight, etc... no such luck. tried both sides, few options, no go.

third thought about shims as mentioned above. with hardware loose, i pressed the drivers side bracket up against the frame and then used my feeler gauge to see if there was any gap between the bracket and the frame rail and if so how much. on the drivers side the back bolt hole was flush, no clearance, the front had about a .045" gap. so i got out my collection of 5/16 washers and measured them all. had a good range from .040" up to .075" thick. tried a .040" worked good, so tried a .050" and worked great. tried a .060" and back to binding again. so no shim in rear and a .050" shim on the front for the drivers side. did the same for the passenger, and ended up only needing .025" shim. so put in a .065" in the front and a .040" in the rear. and then tightened everything down. and wow they all move freely, not 100% like on the bench but about 90% !!! i can easily and freely turn either shaft with one hand by just grabbing the shaft and turning it.

installed the springs to do a return test and wow the snap back into position quickly and nicely. i will redo the complete brake setting procedure and then see what happens, that is on the agenda for tomorrow. then i can reinstall the exhaust system and secure that once again.

drivers side with springs installed

passengers side

center support

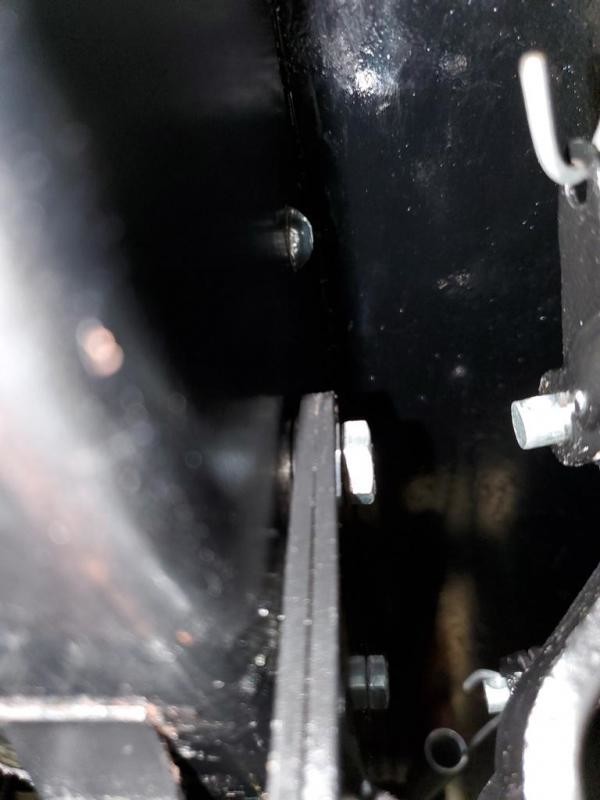

look closely you can see the .040" washer between bracket on right and frame rail on left.

oh yeah just in case... the springs on the shafts near the center support work great !!

if i push or pull the shaft to the left or right, they easily pull the shaft back to the center point set. they did NOT do that before. so that is another huge plus.

i THINK i have the cross shafts ready to go... i THINK and HOPE

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM