You must be logged in to rate content!

25 minute(s) of a 636 minute read

6-23-2016

Started up on the Stand...

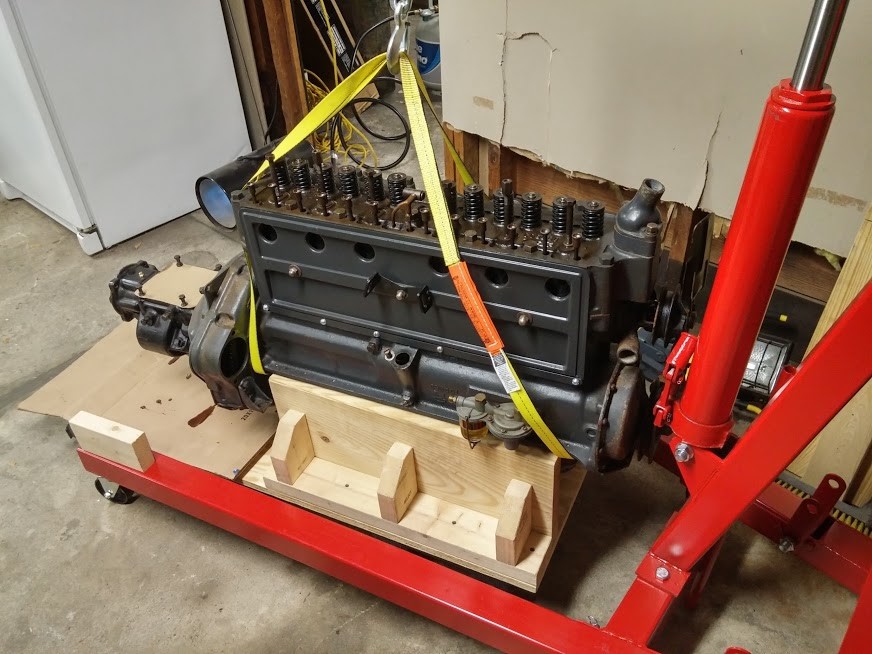

Where I am right Now:

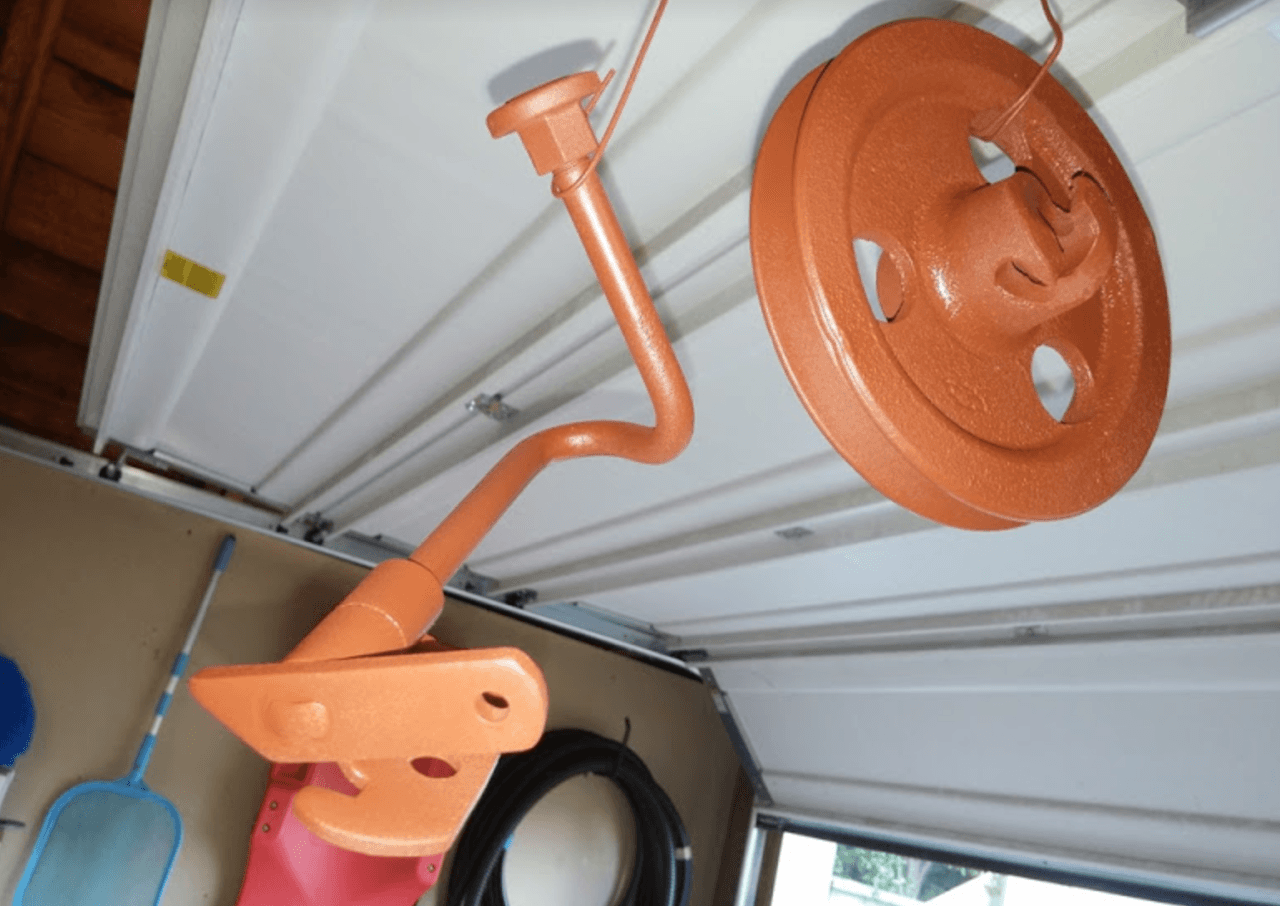

Engine Stand Side Rails Coming Together

Ok, got the bulk of it built last night...

Ready to drop the engine on it...

Will build the Transmission Support when I get the Driveline out and set on here. To make it sure it is right.

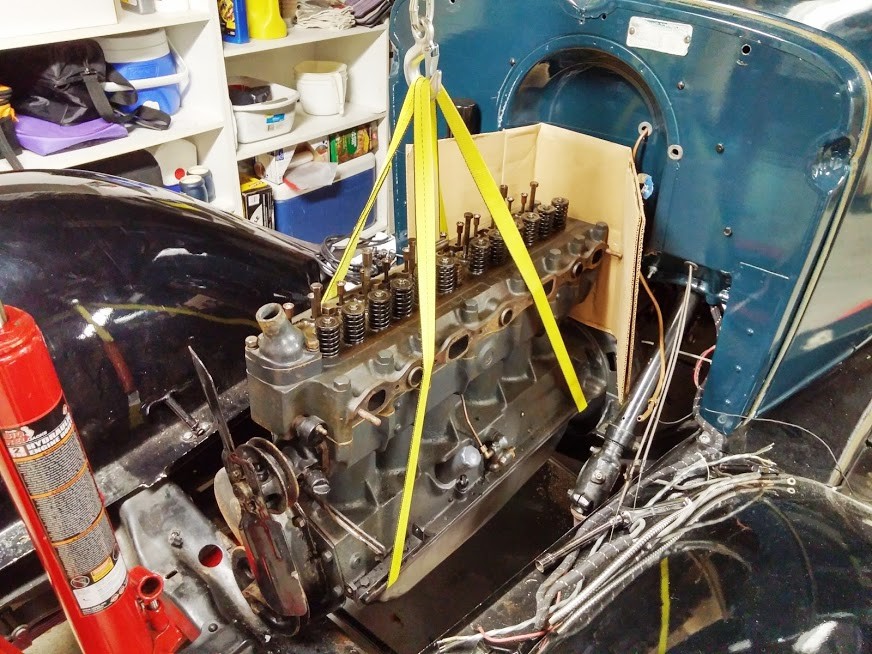

Well spent some time prepping to remove the drive train in my 1929. Already removed the Manifold assembly and the Carburetor.

First Removed the hood & Radiator. Then started to remove the surrounds. Removed both side Engine Splash Pans (What a Pain to remove the hardware) Also had to drop & remove the Exhaust to remove the drivers side pan. Also removed front bumper & apron, mainly to gain better access to the front. Also removed Starter & cable. Disconnected wires to generator and temp sensor.

Hoping to get some time to remove the oil pressure line & fuel line. Think that removes all connections to the engine. Need to cut out my blank off plate so i can remove the transmission top cover. then will need to Disconnect speedo cable, unbolt transmission from cross shaft, and then unbolt the rear cover of the u-joint housing.

Final step will be to unbolt the drive train from the frame. cardboard up the firewall for protection. and get ready to pull it out !!

A Lot of work but first time doing this so taking my time and trying to be safe and precarious !!

Thought I would share some pictures...

All I have to do is remove the distributor and the drivetrain is ready to come out ( I Hope )

1929 Drivetrain Ready to Come Out Driver

1929 Drivetrain Ready to Come Out Passenger

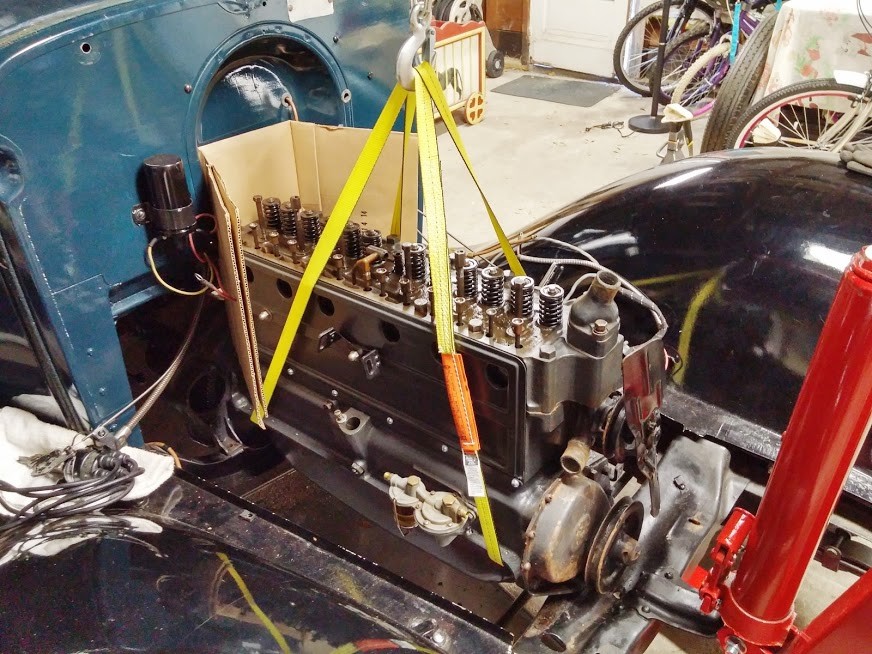

Ok, got it all strapped up and ready to pull...

Did an initial lift to see how the engine would raise... adjusted the straps to get the rear to lift first and more level.

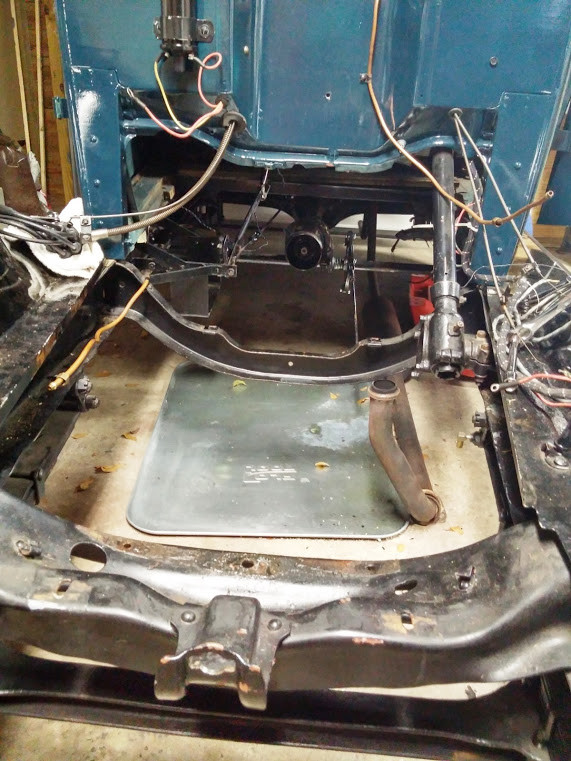

Got the Driveline pulled out !!

Slow and steady !!

Now will build the Transmission Support for the stand, and get ready to do some work...

Well got back out to the garage for the first time in MONTHS...

made me some transmission guide pins so that i can pull the transmission from the engine.

Transmission Guide Pins

Got the drivetrain pulled, and went to remove the fan blade and noticed that ONE of the bolts holding it in was not securely tightened. When i went to remove it it just snapped off !! the other one came out easily.

Also noticed that the pulley had 4 tapped holes. Are four tapped holes in the pulley correct for a 1929 Pulley, considering it has a 2 blade fan ??

I was thinking of just swapping and bolting in the other two holes in the pulley but Looking closer it looks like one of the other tapped holes also has a broke off bolt !!

Know to remove the pulley you have to remove pump and press it off. any thoughts ?>? seems only solution is to remove pump press off pulley and drill and tap out broken bolts...

I did debate on upgrading to the Maintenance Free Water Pump a while back so will revisit that aspect as well. Also saw that you can get a Replacement Pulley for about $30 plus shipping from The Filling Station.

Going to play with the Pulley and see IF i can drill it out and tap it. Fun part will be keeping the Pulley From turning.

Yeah, thinking of it makes sense. Dry Seal, Dry Shaft = Friction

Once it gets in service and working, should spin happily !!

here are some shots of the Pump I picked up Water Pump TFS

Went out and pulled the pulley off, thanks to my neighbor and his collection of pullers. Was a pretty easy job with the right tool, used a 4" 3 jaw puller.

Then removed all the hardware holding the cover on, then gently with a small putty knife worked my way around the edges to break the seal of the RTV... WHAT A PAIN !! Head on Shot

Spent some time cleaning up the cover & the face of the block

Cover Underside

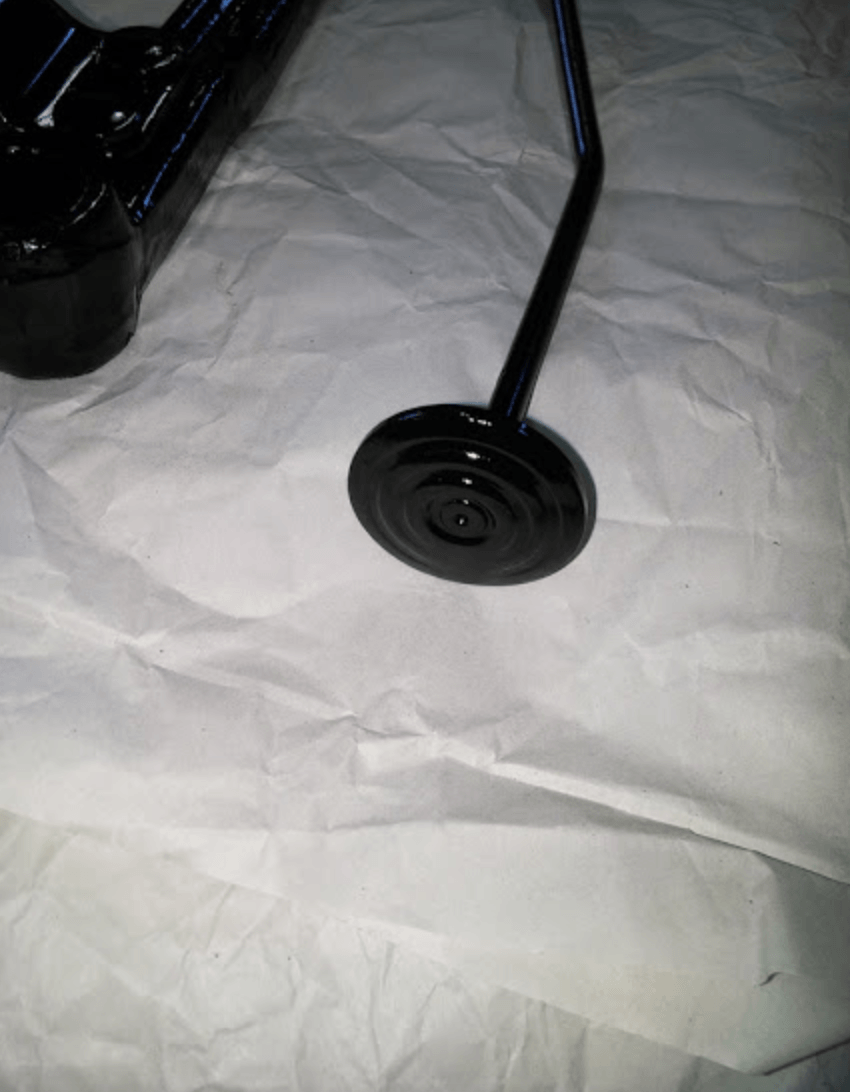

Anyone Identify this, looks like a seal of the sorts. It spins around

Seal ?!

Also is this the oiler ? Oiler Pict 1?

This is a close up of the Timing Gear, Looks like it is pretty new, so figuring it was replaced on the engine overhaul.

Timing Gear Close Up 1

OK, finally back into the car again, nice weather and some time...

Trying to figure out how to mount/ install the thrower

Thrower, Crankshaft Oil.............835603

Here is how it was mounted/ installed when i removed the cover:

Flinger

is this correct, it has a keyway slot in it. does not seem right.

how does it spin ? i know the cover goes on then the pulley

seems like it would just sit there while the shaft spins since there is no drive or anything to make it spin.

Is there a way to know what the original interior color for my 1929 4 Door Sedan was ?? is that part of the Job No or Body No?

Job No: 8850

Body No: N 7762

Cowl Tag

I know this helps with proper exterior color(s)

looking at what color scheme to do the interior. have seen both the tan interior palette & the green for my body paint scheme. the tan looks REALLY nice, and the Green is well, way too much green. nothing like green on green on green with a side of green. wish there was a grey I think that might actually look pretty nice !!

I have the Swatches and price sheet from Hampton Coach now LeBaron Bonney. great people to deal with and talk to.

To have more fun, I have an early 1929

Based on LB/HC Options are:

...Tan A-803

...Blue 13-LM

...Green 4-LM

Looking at handles for my 1929 4 Door that Ted is working on. Doing my research on Proper Window handles for the Rear Quarter Windows.

Here is what I have in the car now:

Quarter Window handles in Car NOW

These were in the car when I got it, and show their age, pitted, cracked, crumbling. Classic T- Style handle.

So when looking for new one, I checked out The Filling Stations website, and found they listed these for the 1929 Quarter Windows. Part No GR-485 TFS Quarter Window Handles

These are Shortened Window handles, same ones used on the Windshield. Talking to the guys there they say THESE are the CORRECT ones for the 1929, when I asked about mine having the T handles, they said someone must have swapped them out years ago. But the GR-485 is CORRECT for the 1929.

Now when I talk with Gary or Lonny they say the T handles are correct.

Can you guys assist me with the Correct ones so i can get them ordered.

Now could ONE use the Shortened Windshield Handle and it work ??

seems the sourcing for the handles is SLIM PICKING, mainly the T-Style and the Locking Exterior Handles.

I know TFS and those places list them, BUT none in stock and NOT sure IF they will get anymore in as they are looking for new sources.

as most of you know my car, 1929 Chevrolet 4 Door, is up In Mass with Ted [Chistech]. he is doing some structural work as well as the roof and interior. While it is away i was to be reworking the Drivetrain. Pull the engine & Transmission, strip down, clean up paint, put on rebuilt Rocker Arm Assemblies, new push rods, caps, etc...

Well i finally got around to working on it, yeah been about 6 months.

Started blasting some parts, priming and then painting.

Round one was the pedals:

Pedal 01

Doing 2 coats of primer, then 2 top coats of Gloss Black

Puzzle ?!? Wait a minute, I am no good At puzzles... Hopefully the Pictures I took will help put Humpty Dumpty back together ?!?

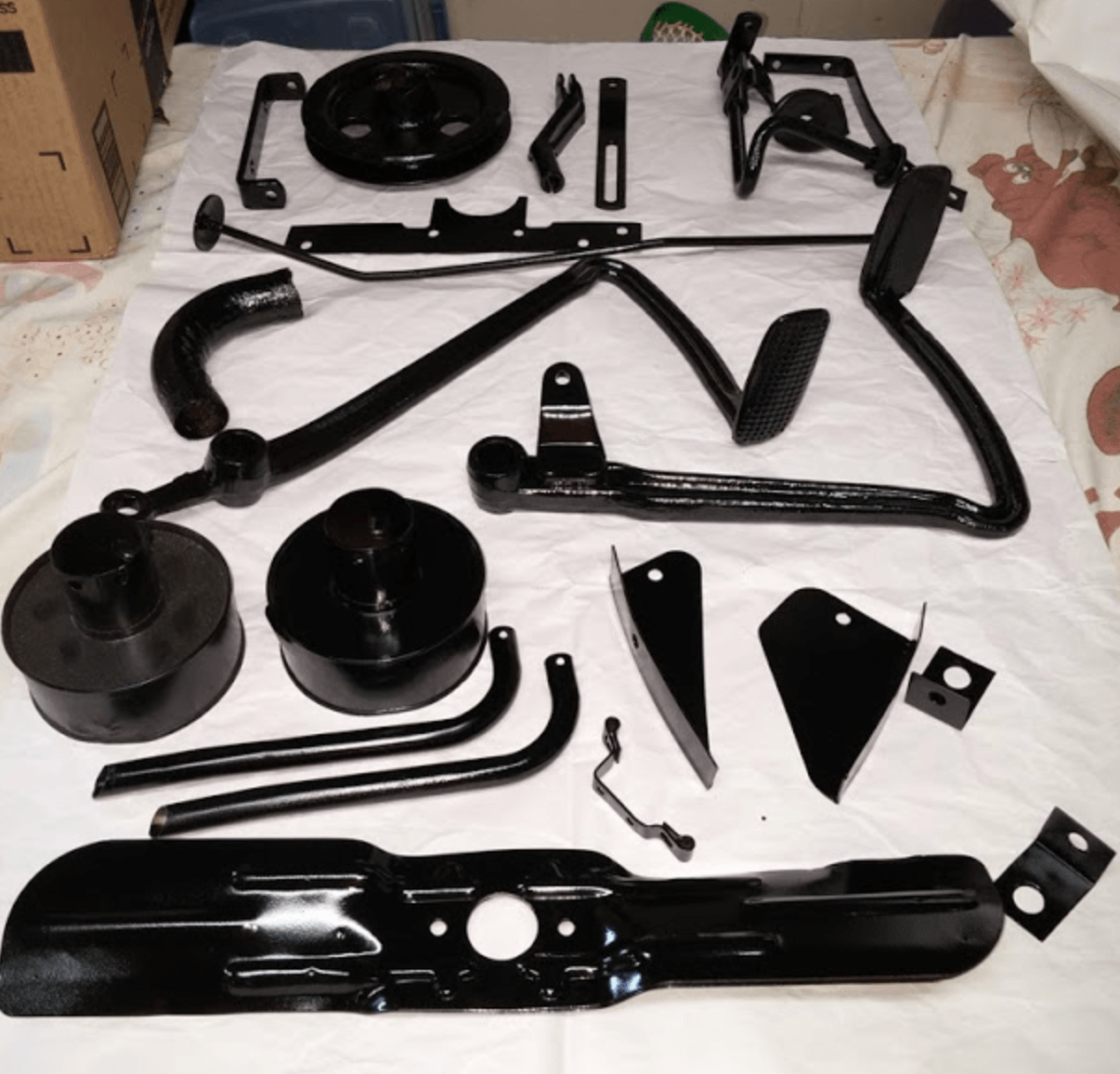

Here are some Pictures of Parts 1 Painted Up:

Parts 1 Painted 01

Batch 2 was blasted yesterday at work, until machine burst a line and I got a shower in Glass Beads...

Blasted a few more parts today...

machine was fixed and cleaned, and now works like a champ, took me 20 minutes to blast and clean all these parts to bare metal !!

1929 2 Blade Fan

I did my best to straighten it out and such BEFORE Blasting, so When i Paint it should be OK

Fan Blade

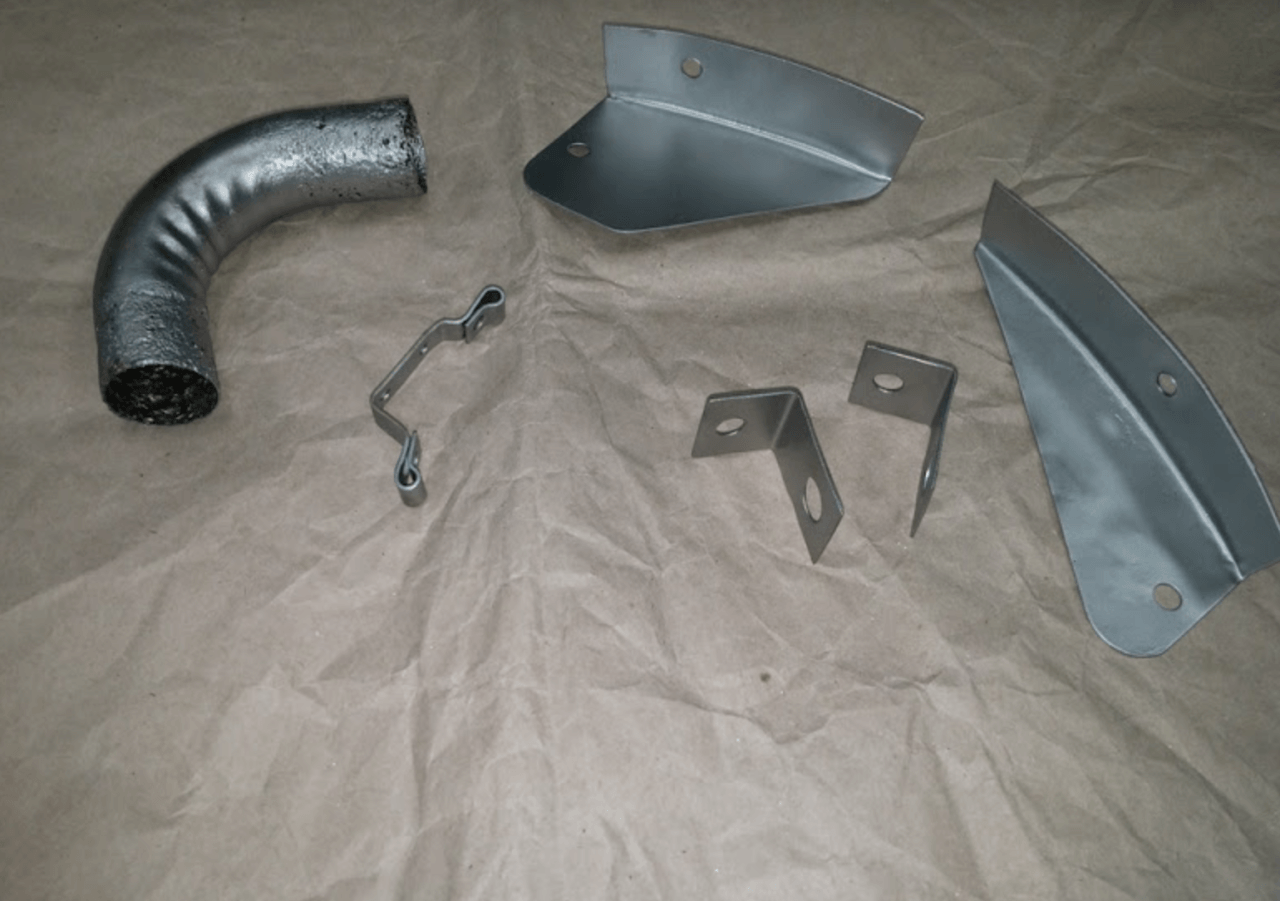

Misc Brackets for: Splash Pan, Carburetor, & Radiator Elbow

Misc Parts 01

1929 Air Cleaner

1929 Air Cleaner 01

Tonight will be prime and paint... Assuming all are Gloss Black

well got all those part painted up and looking nice:

Fan Blade

Fan Blade 01

Other Parts

Misc Brackets

1929 Air Cleaner

Air Cleaner

All Ready

Collection

Now on to the larger parts...

Manifolds

Starter

Generator

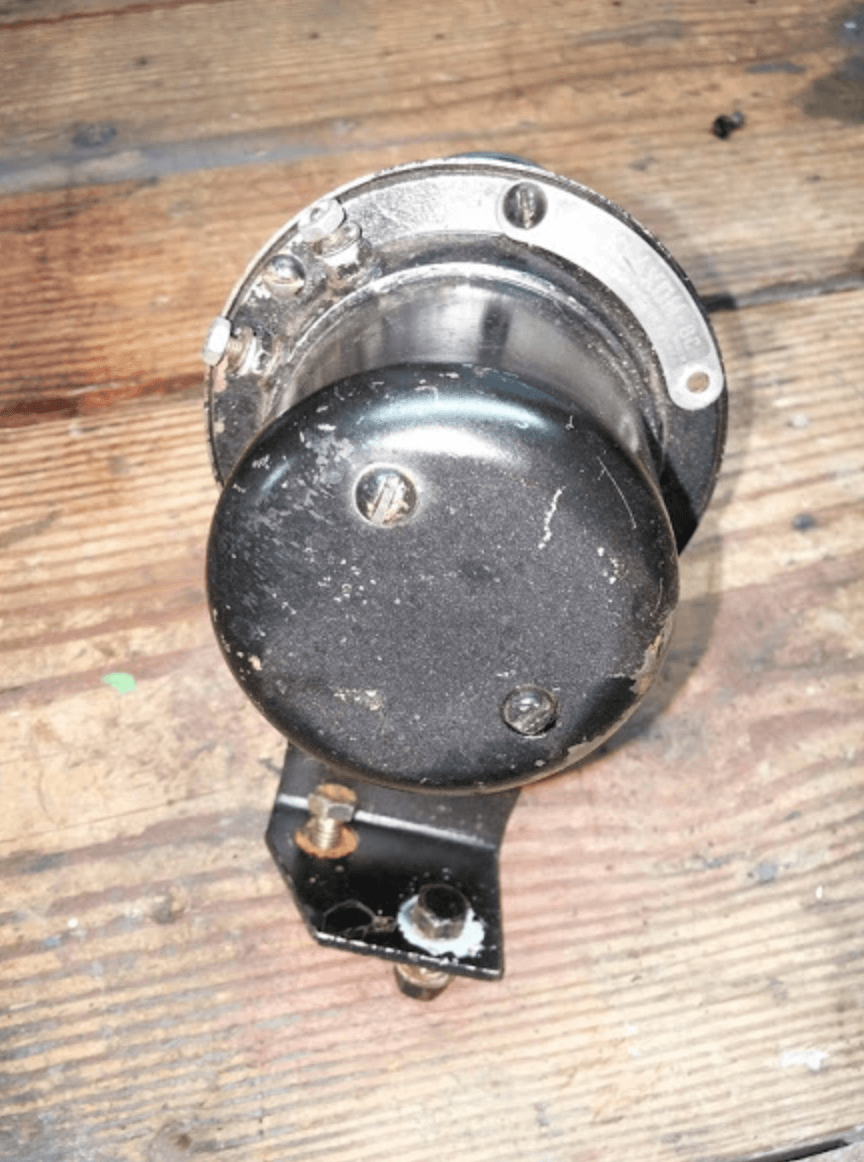

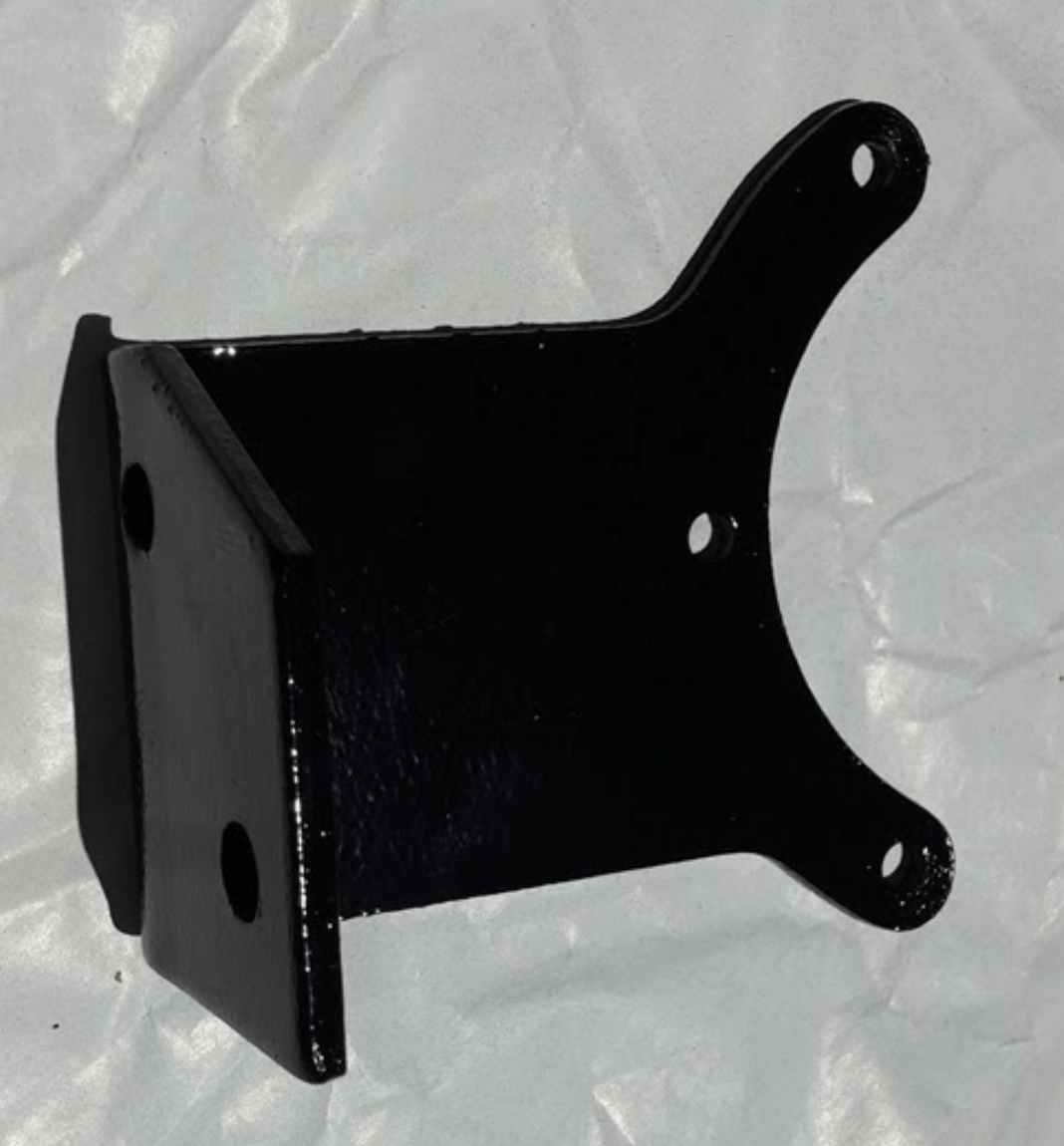

Horn & Bracket

Splash Pans

Apron

Last will be

Engine

Transmission

OK, since i am blasting and paint parts I have completed most of the small general components for the engine. I am moving on to larger assemblies/ components. Horn, Generator, Starter, etc...

Horn is topic of this Discussion:

I have a Klaxon 8C and was wondering about best way to go about rebuilding/ painting it. it works great no issues, but missing paint and such.

Should I:

1- Just rough sand the surface and cone, then apply a few fresh top coats of gloss black paint ??

2- tear it down, strip it to bear metal, prime, paint, cure, reassemble ? and if so anything i should be weary of or know before tearing it apart and breaking it down. looks to be pretty simple in build and components.

Well got home today and started to analyze the horn, there is some rust on the inside of the horn and at the base...

so part it will come, clean, blasted, primed, painted

clean up the guts, oil the bearings, assembly and test

hopefully it well look good and sound good !!

Well here are some pictures of the Horn as it sits:

now to start tearing it down

Gasket Question:

there are 3 gaskets in the horn

1- Two of the same shape, size, & material: one on each side of the diaphragm. One was destroyed on removal, the other one came out in one piece. this is great so that i can replicate and make 2 new ones. what MATERIAL should they be made out of ?? they look like a paper material. I was thinking of using Fel-Pro Karropak but how thick ?? 1/16 or 1/32 or 1/64 ??

2- Gasket between the Mounting Plate with the Electronics & Motorand the rear cap. This one came out whole, but was rolled, looks to be rubber like, black in color. can i use a thin rubber material to make the gasket or what material would be best here.

ok, so on to the parts:

Pieces ready for Blasting/ Clean Up

Collection

Pieces all Cleaned Up

All Clean 01

Now to Prime & Paint

Well took some time and painted it all Gloss Black

Now to cure, then get new hardware and assembly it all back together

Test and see IF it will still work

Decided to go with some karropak via Fel-Pro at 1/64" thick. this should suffice for the paper gaskets. At least give it a try.

So Yesterday I decided to blast, prime and paint my Crankcase Front End Cover on my 1929.

Removed From Engine:

Crankcase Front Cover 01

Seems like most of the paint was removed via dripping coolant from the water pump.

I bead blasted the cover, and cleaned it up for prime n paint

Cleaned Up:

Crankcase Cover Cleaned Up 01

I then Primed two coats, then Painted 2 Coats...

Primed Up:

Cover Primed

Painted Up:

Cover Painted Up 01

NO I did NOT Prime and Paint the backside of the Cover, since it will see oil and such, and did NOT want to chance paint peeling/ flaking off in the cover and getting into the Oil or Gears.

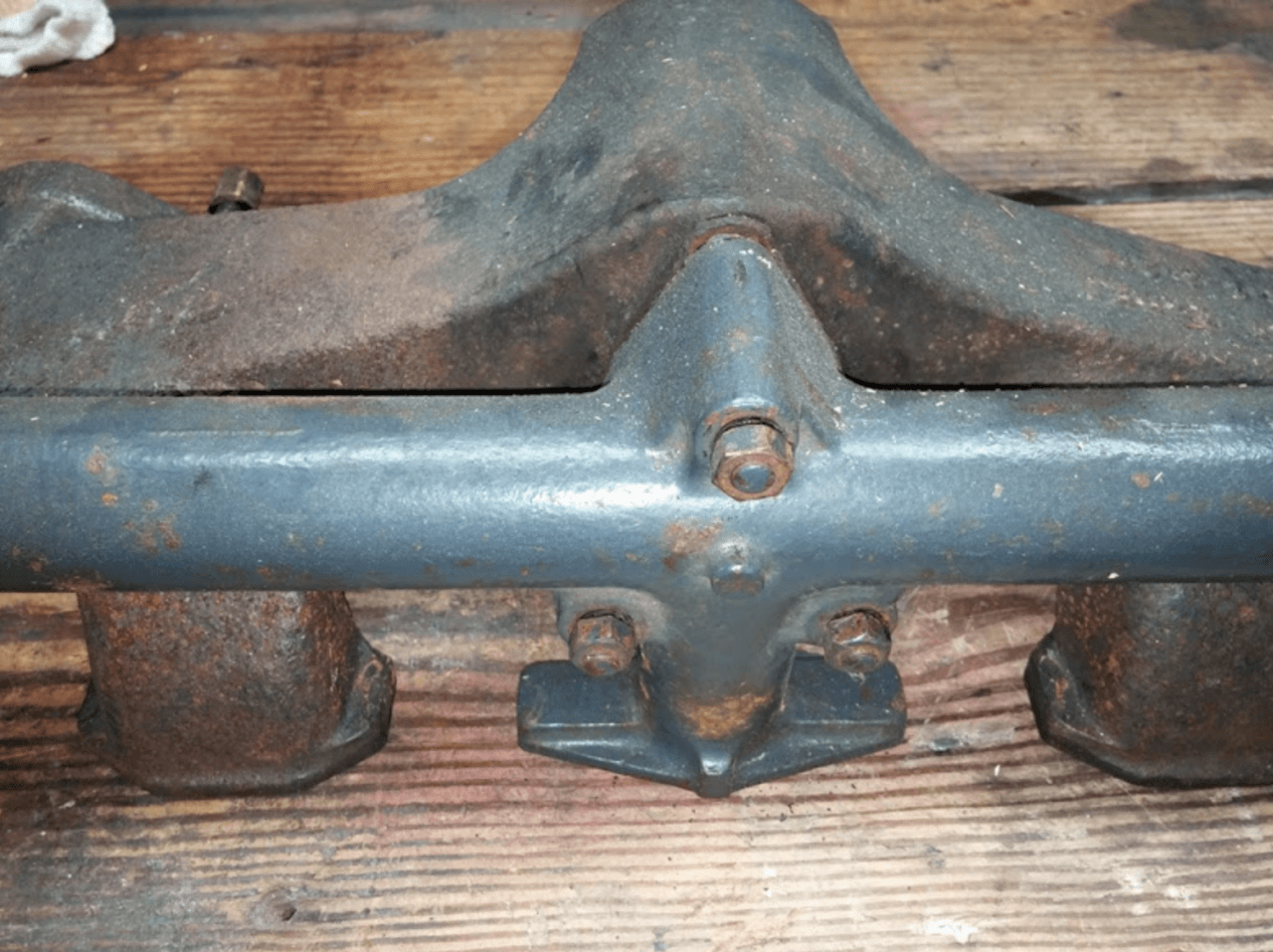

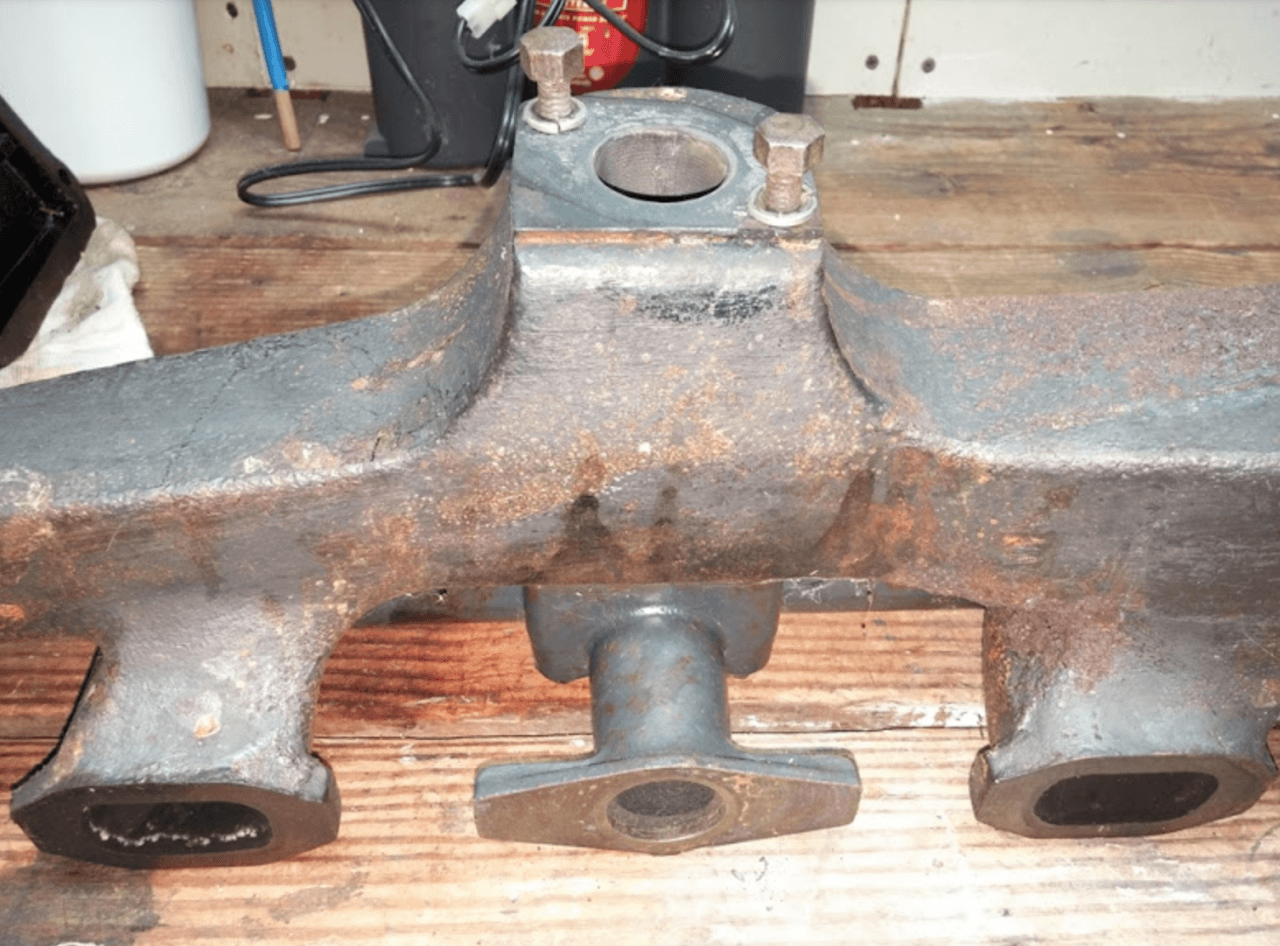

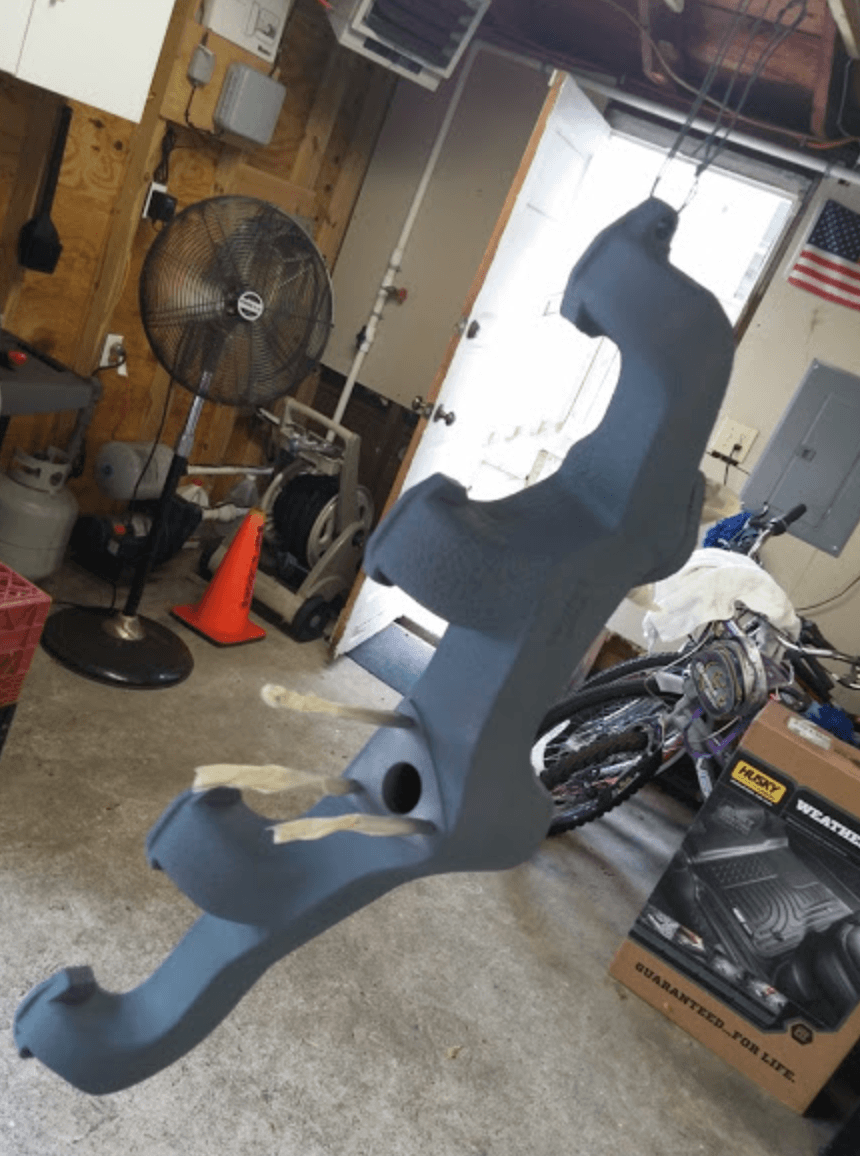

As you know I have been tearing down my engine, painting pieces and parts. I am now ready to start work on the Manifold Assemblies. I laid it out on the bench for disassembly and pictures. this way I have some before and after.

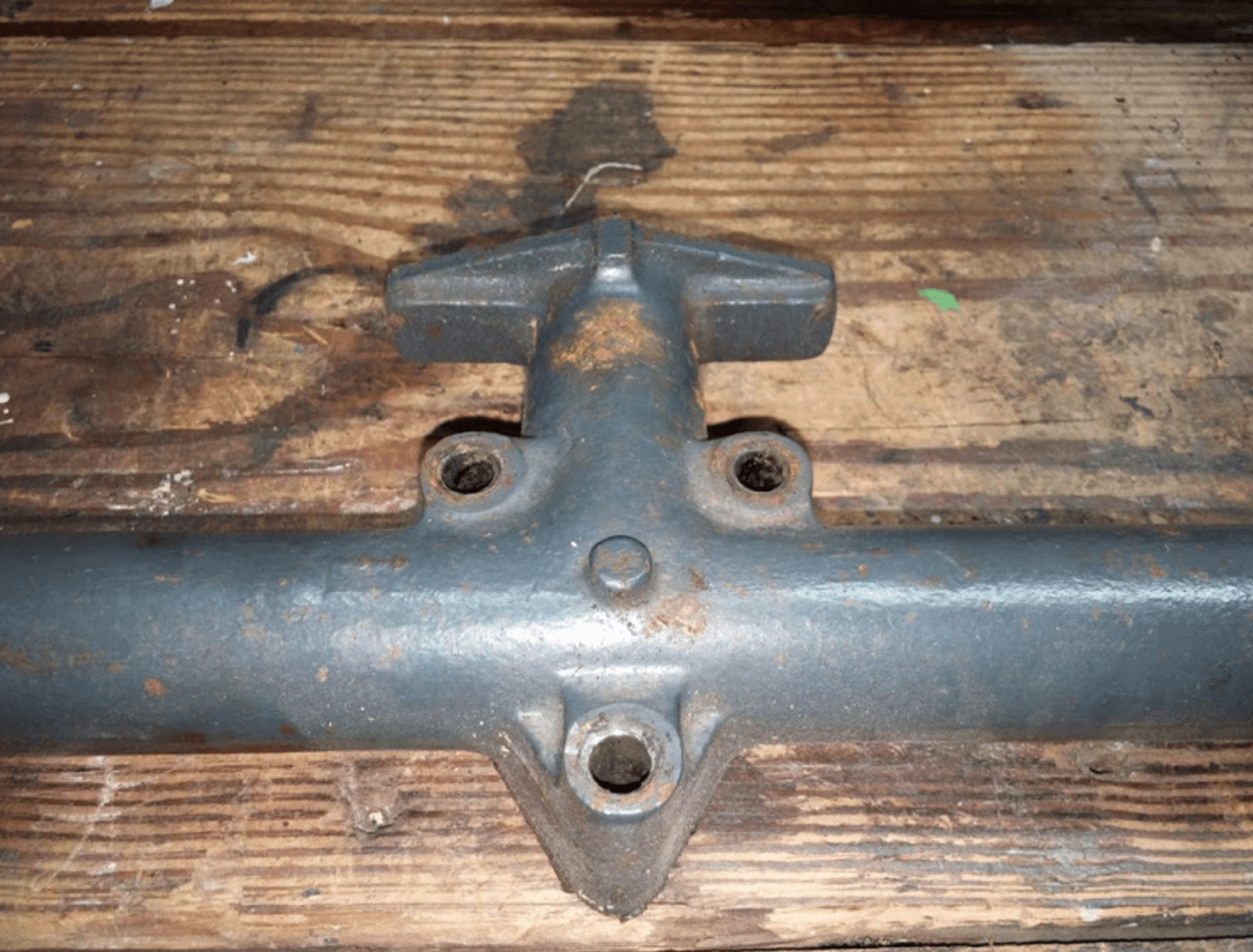

Manifold Assembly

Manifold Assembly 01

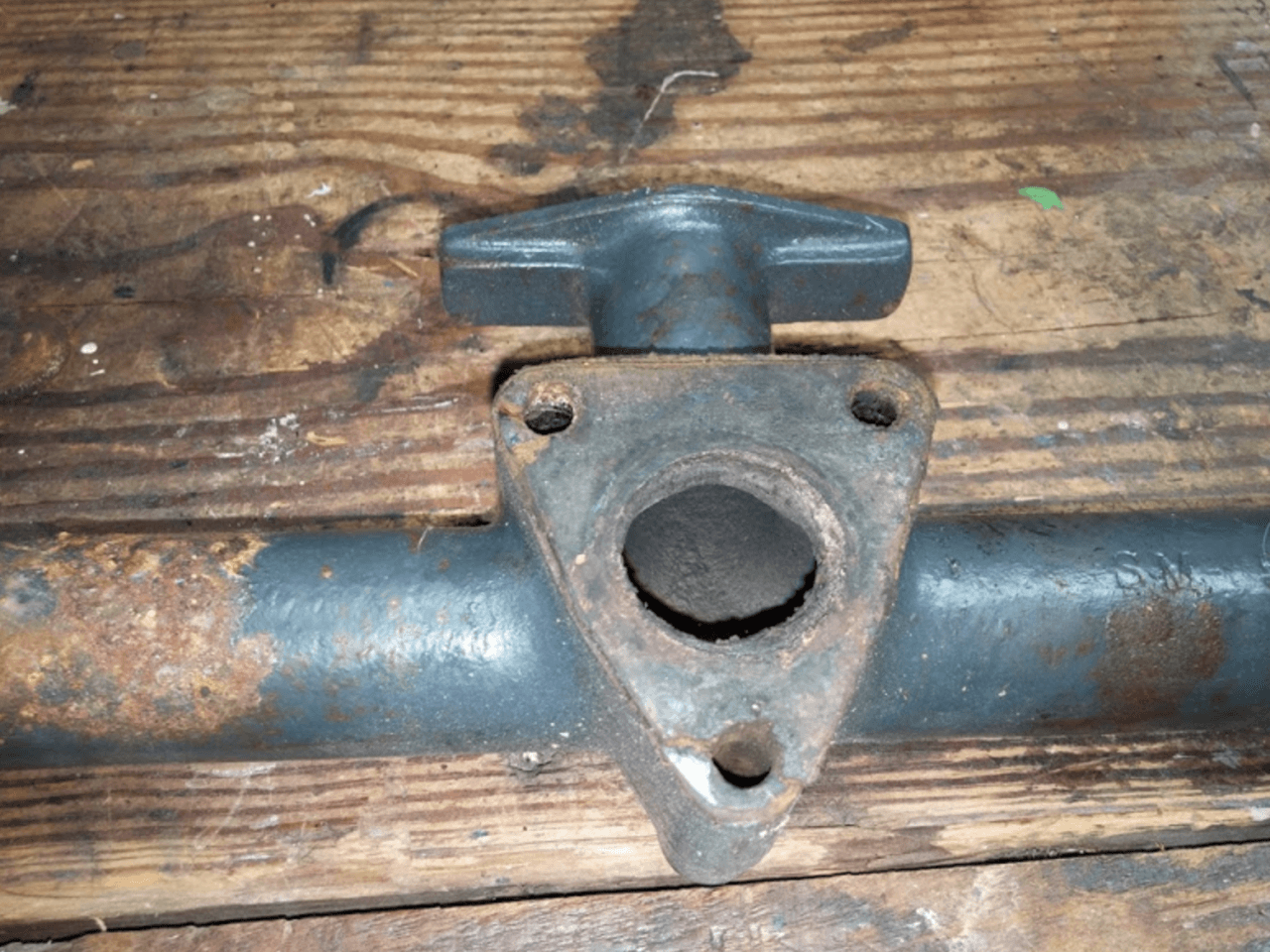

Intake Manifold

Intake Manifold 01

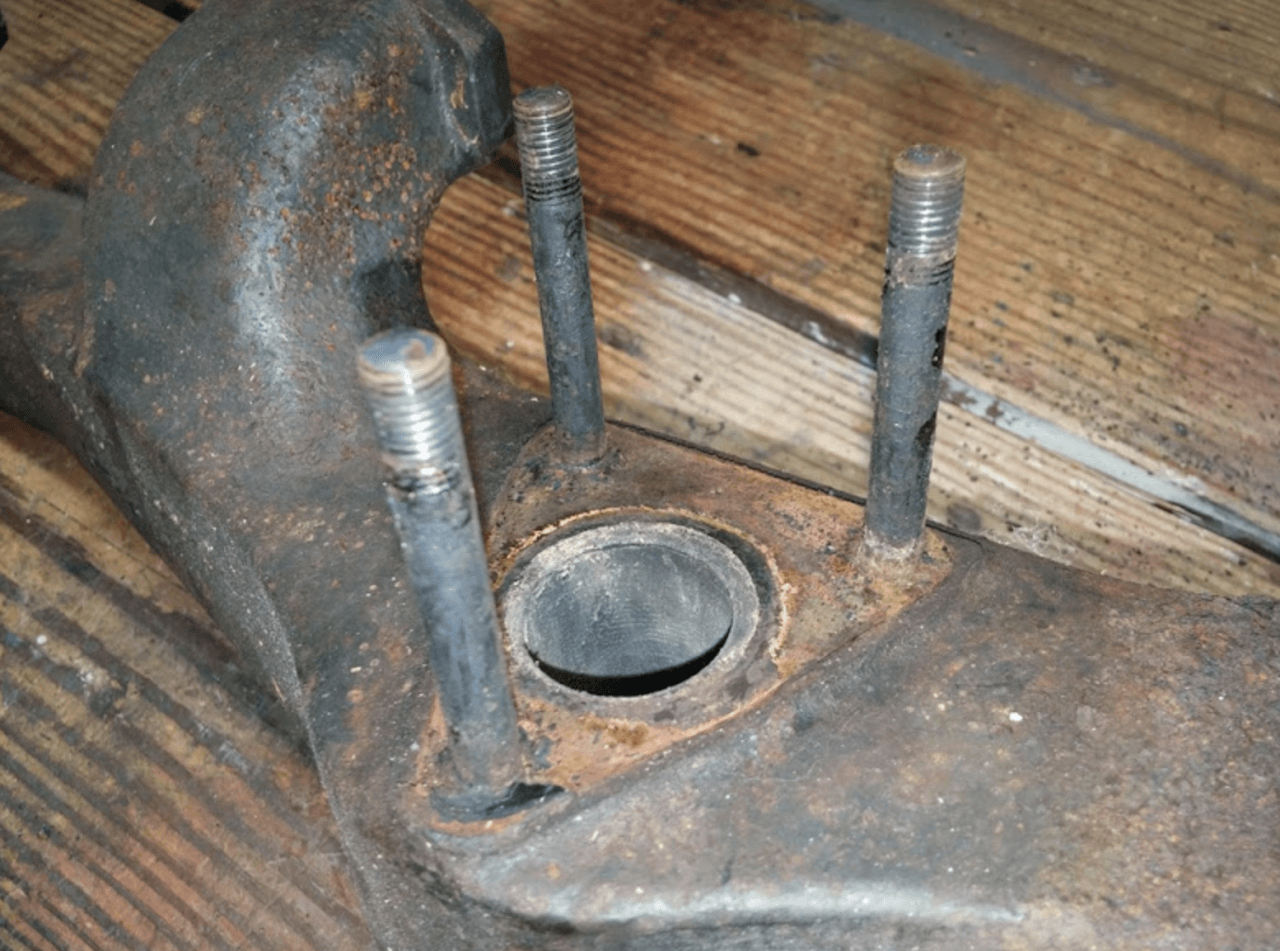

Exhaust Manifold

Exhaust Manifold 01

Prime & Paint Question for Intake Manifold

I am going to blast it to bare metal, Should I Prime and Paint or Just Paint ??

Going to Paint it using TFS Engine Paint that i have for doing the engine as well.

on the Exhaust Manifold I am using KBS Coatings Xtreme Temperature Primer and Paint Will blast it, prime it twice, paint it twice then cure it !! interested to see how it comes out.

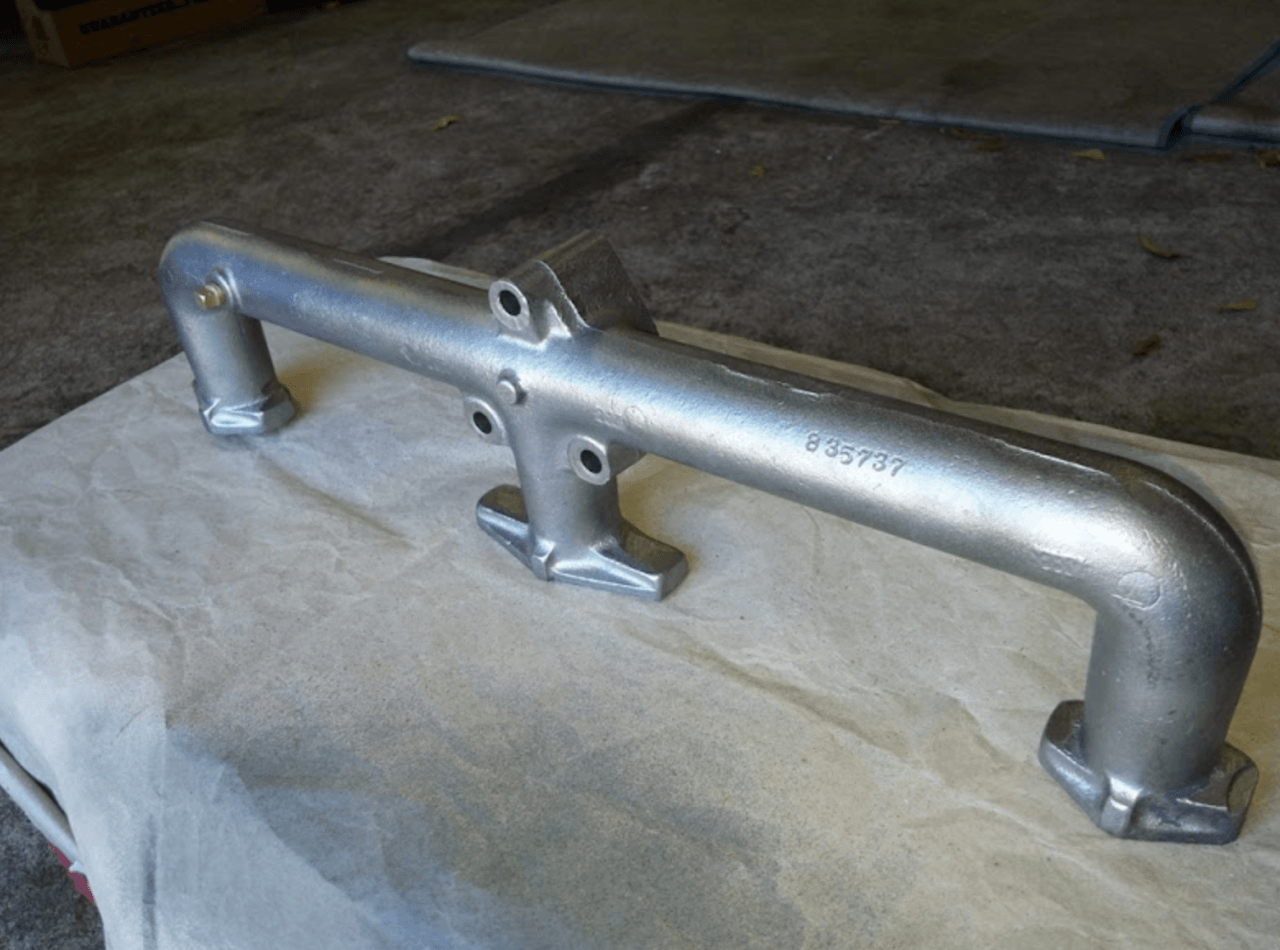

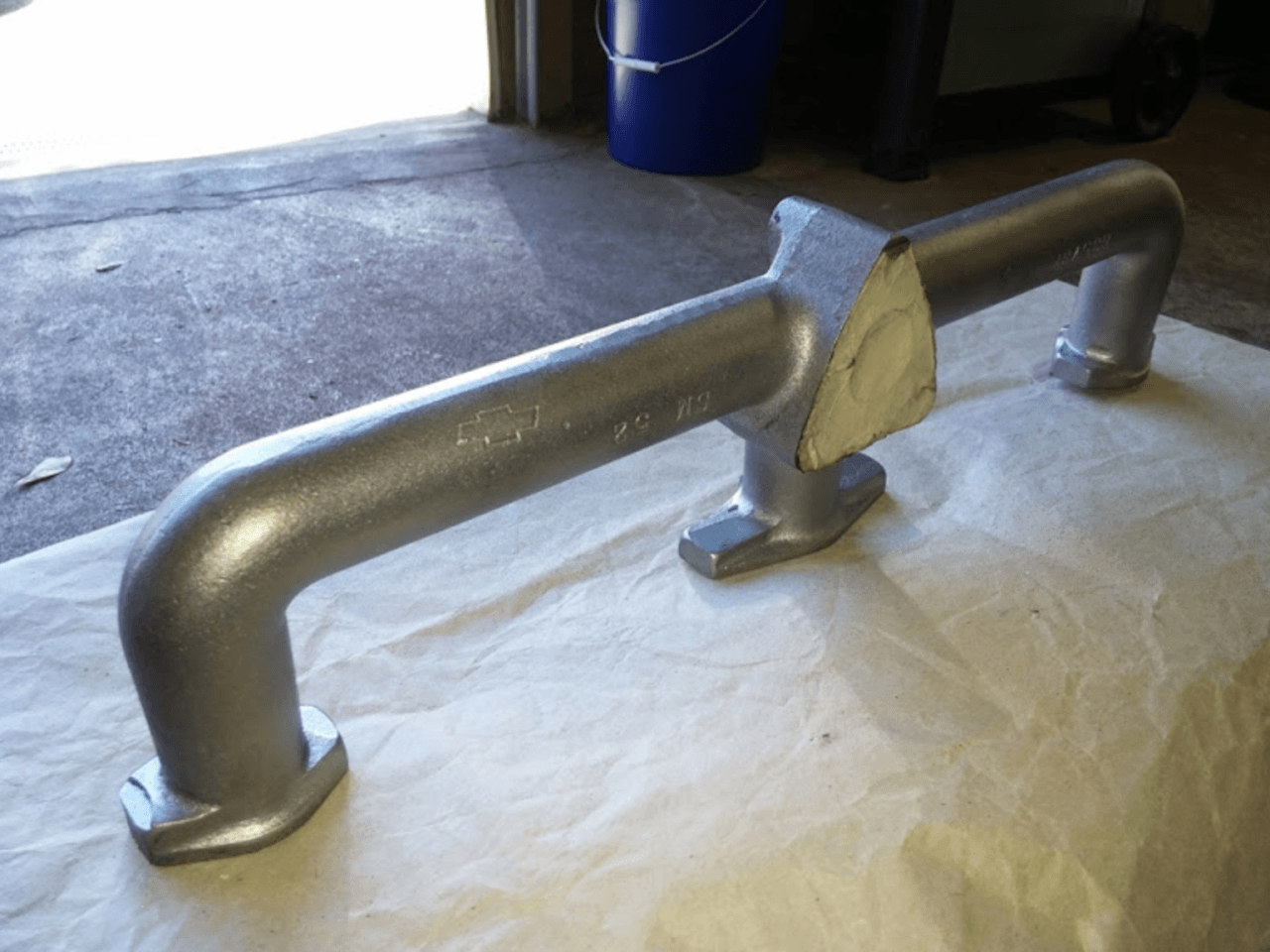

Alright got the Intake Manifold Blasted, wow, looks like new:

Anyone know what the the "SM 25" stamped on the Manifold Means ??

Alright got the Intake Manifold Painted all Up

Looks GREAT:

The Part Number 835737 is stamped on there twice, then the Chevrolet Bowtie, and SM 25.

Better Painted Pict in the Daylight

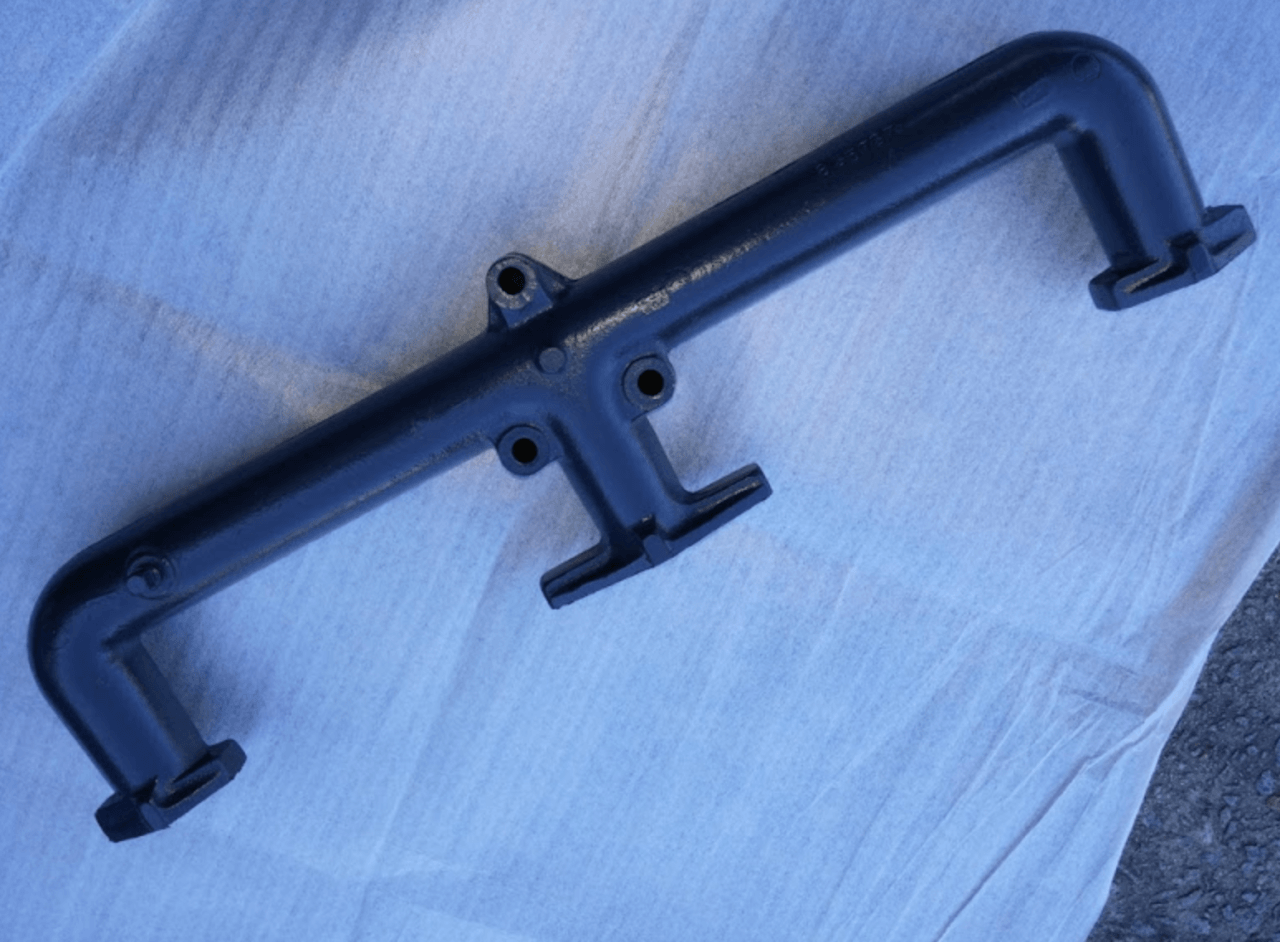

Blasted up the Exhaust Manifold today...

Looking a LOT better than before (see above pictures)

Now to prime and paint !!

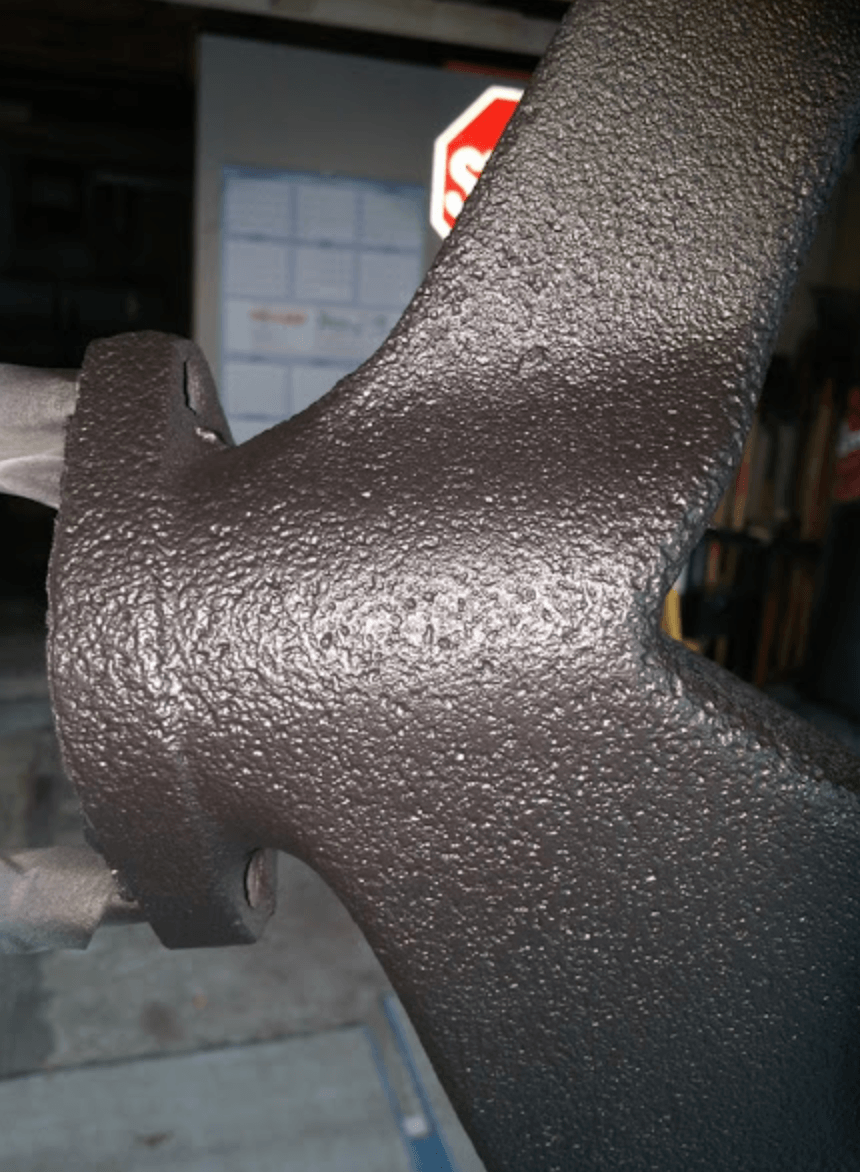

Got my Exhaust Manifold All Primed up.

I am using the KBS Coatings Xtreme Temperature Zinc Primer, goes on smooth and clean. Following Directions from KBS, I applied 2 light coats of the Primer.

Exhaust All Primed Up:

Exhaust Manifold Primed 01

Have to say with the Primer on it looks REALLY NICE and CLEAN !!

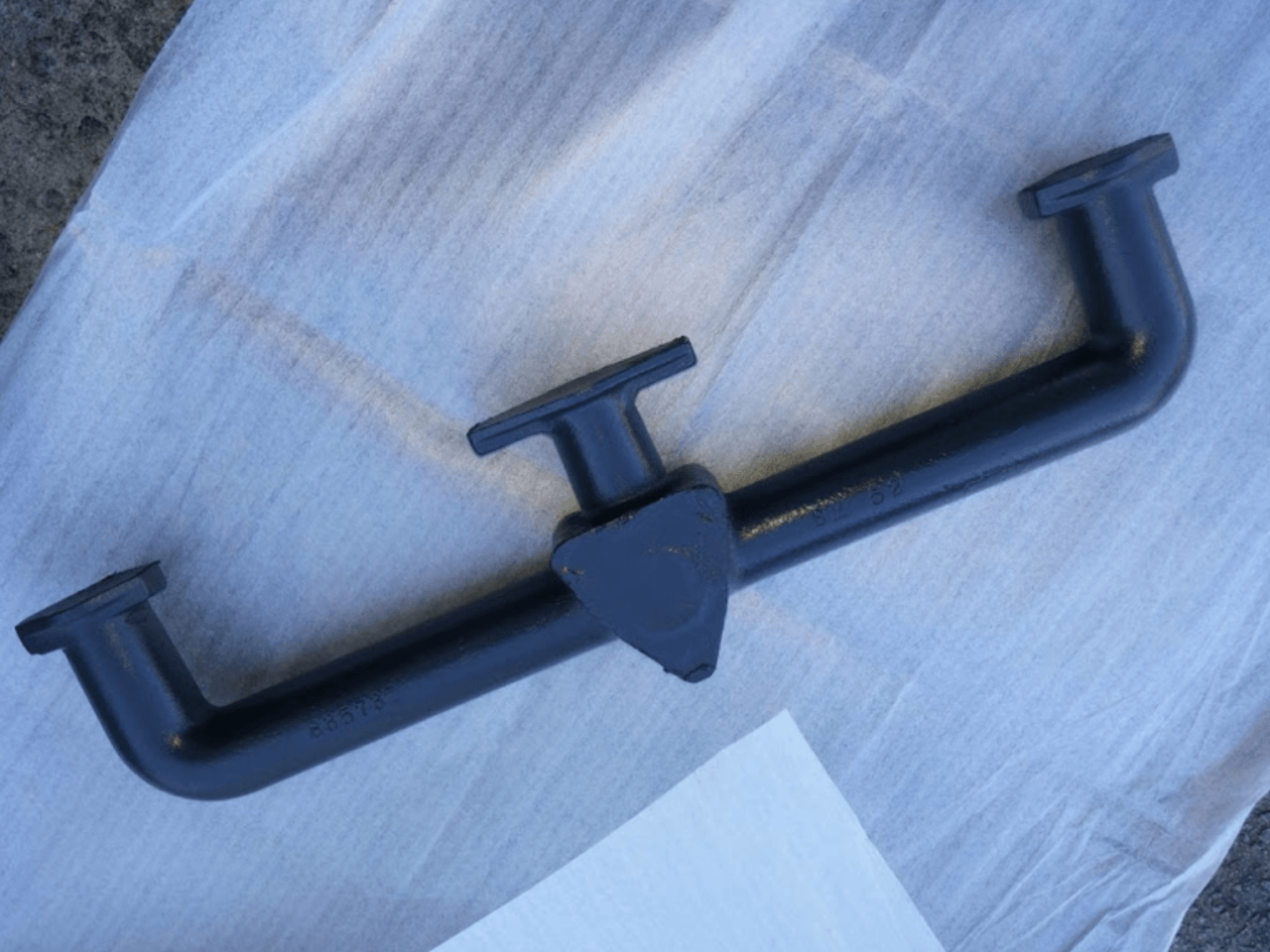

Next was Top Coat, this is the KBS Coatings Xtreme Temperature Paint, I decided to go with Jet Black, I know, I know it is NOT correct, but I like how SHARP it looks and the contrast against the Chevrolet Grey Engine color, plus will go nicely with all the BLACK Accessories on the Engine. YES, they make a Cast Iron Gray As well that many of you may like to make it look like RAW Metal. KBS Xtreme Temperature Coating Colors

Exhaust All Painted Up:

Exhaust Manifold Painted 01

I like the way it looks, have to say I am pretty impressed with the outcome so far.

Now let it dry for 8 hours then will heat cure per instructions to FULLY CURE the product. Supposed to withstand temps up to 1200 F once it is fully cured. Will see how it works and how long it will last.

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM