You must be logged in to rate content!

3 minute(s) of a 636 minute read

6-2-2020

spent the weekend tinkering with concepts and trial and error, then ran out of filament for 3d printer, so ordered a new spool that arrive monday afternoon. the first picture are the iterations i have gone through testing and playing around, learned that printing the pins in i kept messing them up or breaking them off, so plan B. Other picts are the latest design, going to try and use external pins that i can push in and pull out the mold (Thanks Ted) also need to put some chamfers on the pins for guidance, and also makes it easier to pull the mold apart. notice the chamfer edges where the two molds meet, this allows me to insert a blade/putty knife in to separate them.

also talked with a few shops and found a place that is working on laser cutting my metal insets out !! said 3-5 days and i should have them, so will post pictures once i get them. excited that everything is coming together. once i get the mold to a happy place (waiting on the stainless steel rod to arrive so i can make pins and test fit.) then i can order a batch of urethane rubber. that will be the last thing then i can start molding a set, plan to make 1 set a at time, requiring 2 molds, one for each seal.

few iterations i went through this weekend

latest iteration, fits nicely together, just need to chamfer the alignment pins

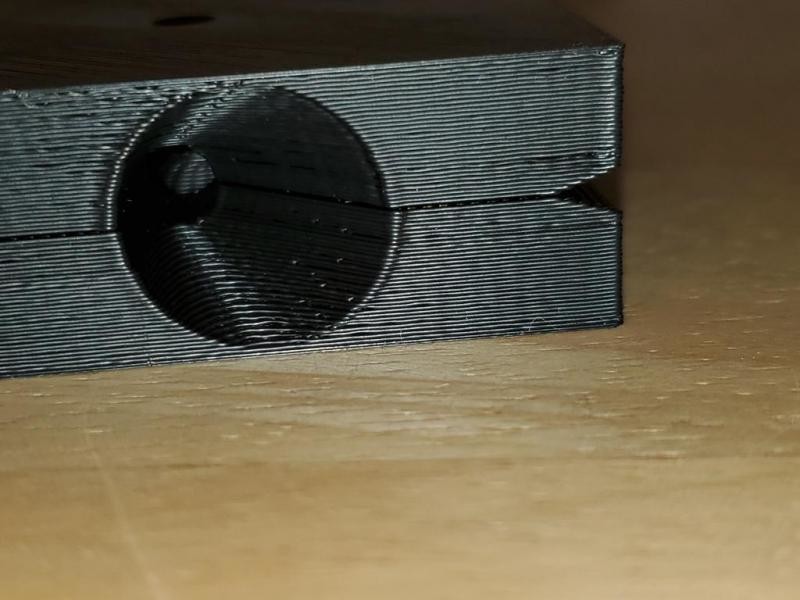

clearly see the through holes for the hole pins

clear view of the leading chamfer for ease of separation

pour in funnel, this is the top, pour in and let urethane rise, pushing out air

other side view can see alignment pins in the 3 large holes

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM