You must be logged in to rate content!

3 minute(s) of a 636 minute read

5-21-2020

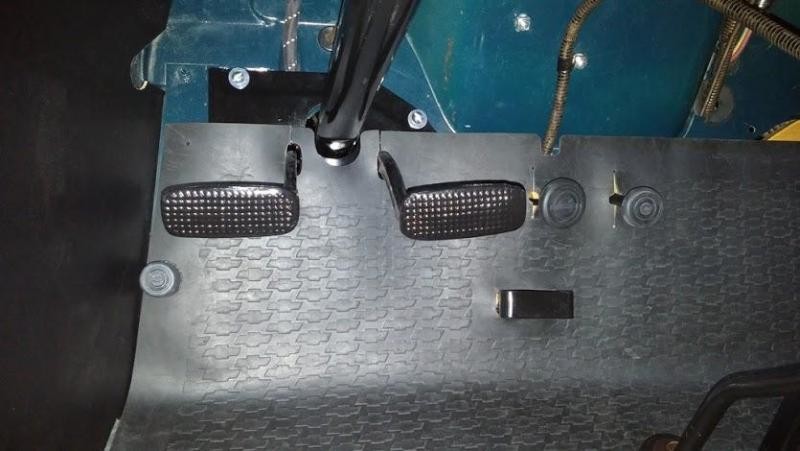

yeah another issue, getting them to work together ![]() a few shots of the rubber mat around the pedals in my 1929

a few shots of the rubber mat around the pedals in my 1929

5-27-2020

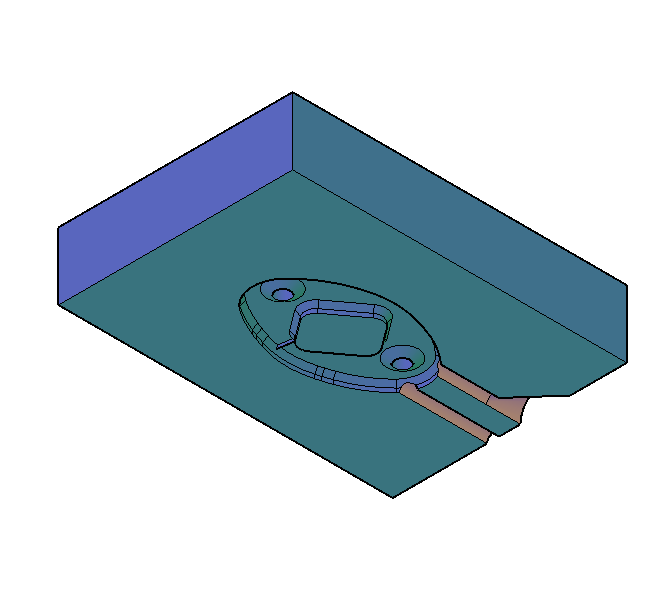

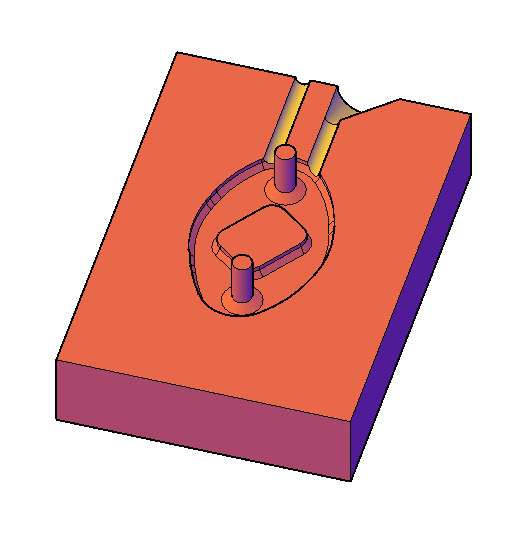

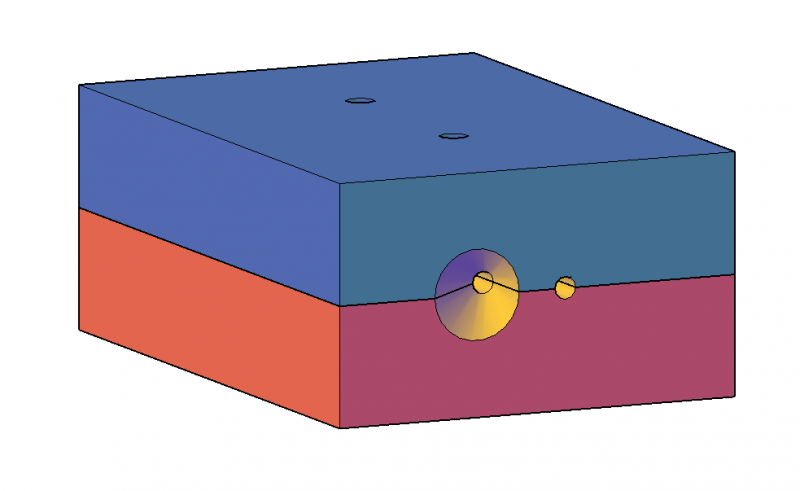

ok, started design of the mold for these seals...

going to be a standard 2 part mold, parting line will be right down the middle if laying flat. bottom half will have extended pins, which are the holes, and line up with the top half which will not have pins, but have through holes for the pins to go in and line up the part. not sure if i should add a third or fourth line pin outside the mold are for alignment. going to pour with the item standing up vertically, and use a 3/16" vent hole next to a 3/16" pour hole with a 3/4" lead in funnel. this should allow me to get material in all areas, vent our any air, and not leave any voids. the metal inset will sit on the pins dead center (float). metal should fit snug on the pins. going to pour using a polyurethane 60. so should be soft but sturdy, supposed to be pretty viscous to pour easily !! we shall find out.

any thoughts or comments let me know.

thinking i may move the vent to dead center, or the fill to dead center ?? i know it will need to be trimmed when removed, but that is ok. its rubber ![]()

also have quotes out for rubber, and for cutting the insets.

looking at doing 6 sets up front, for testing, that would be 12 of everything.

hoping i can get 12 rubber pours out of the rubber batch.

looking at a cost of approx: $25 per seal, or $50 per set for materials only no labor charges. Geesh....

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM